Pre-tightening force adjusting device and method of tension guiding mechanism

A technology of guiding mechanism and installation and adjustment method, which is applied in mechanical pressure/force control, motor vehicle, transportation and packaging, etc., can solve the problems of increased operation difficulty, poor position accuracy, low efficiency, etc., to avoid free rotation and improve installation. The effect of adjusting efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

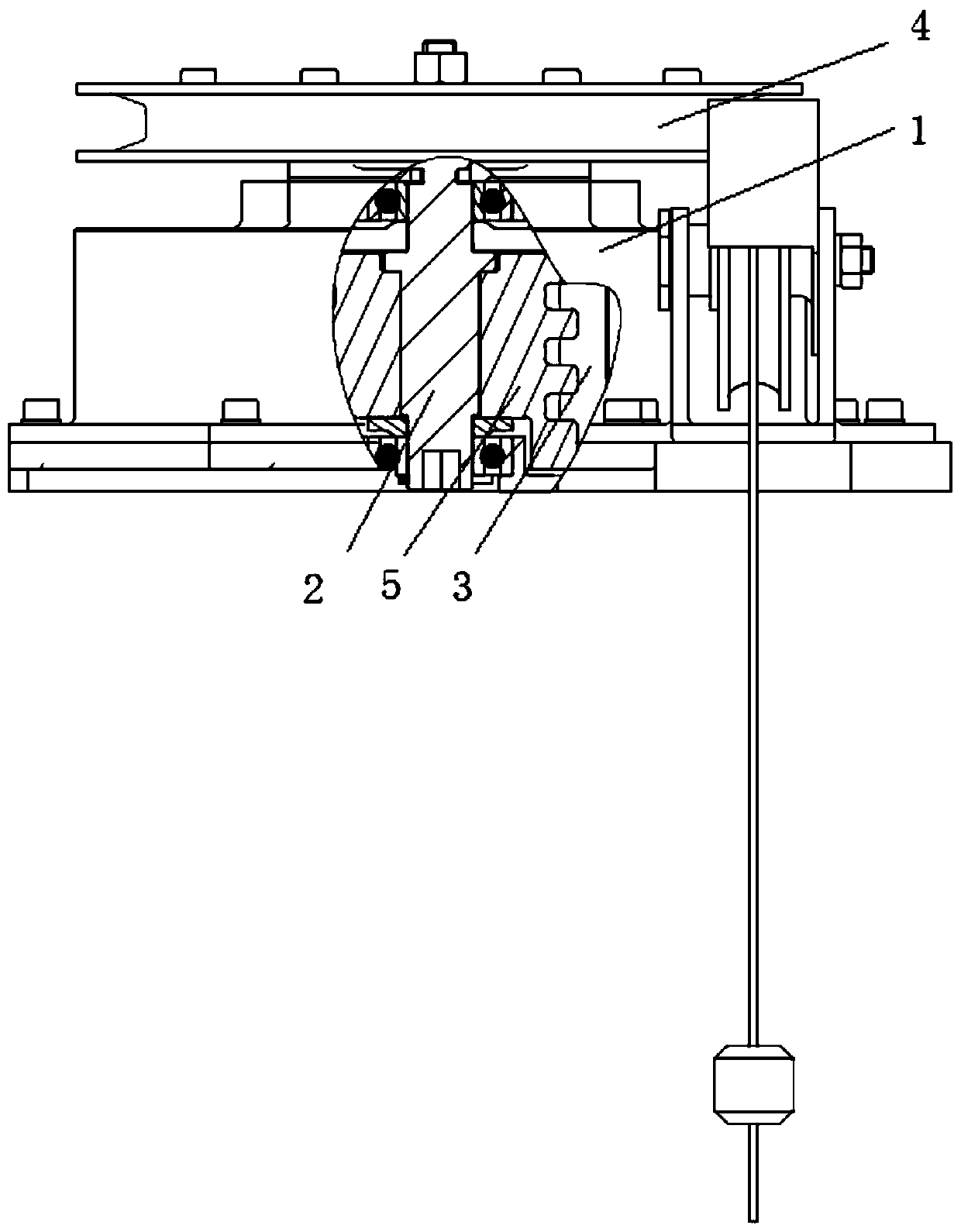

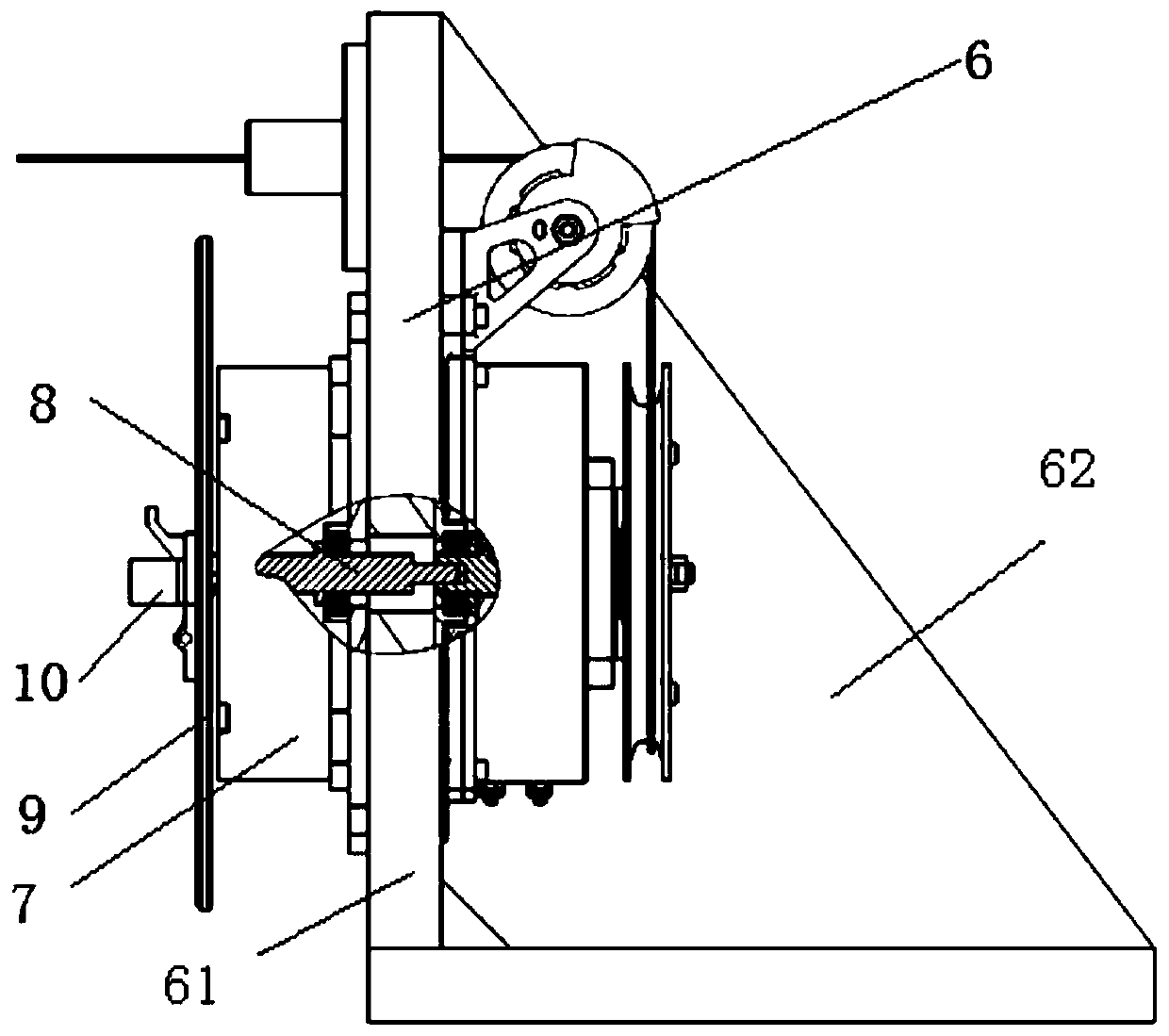

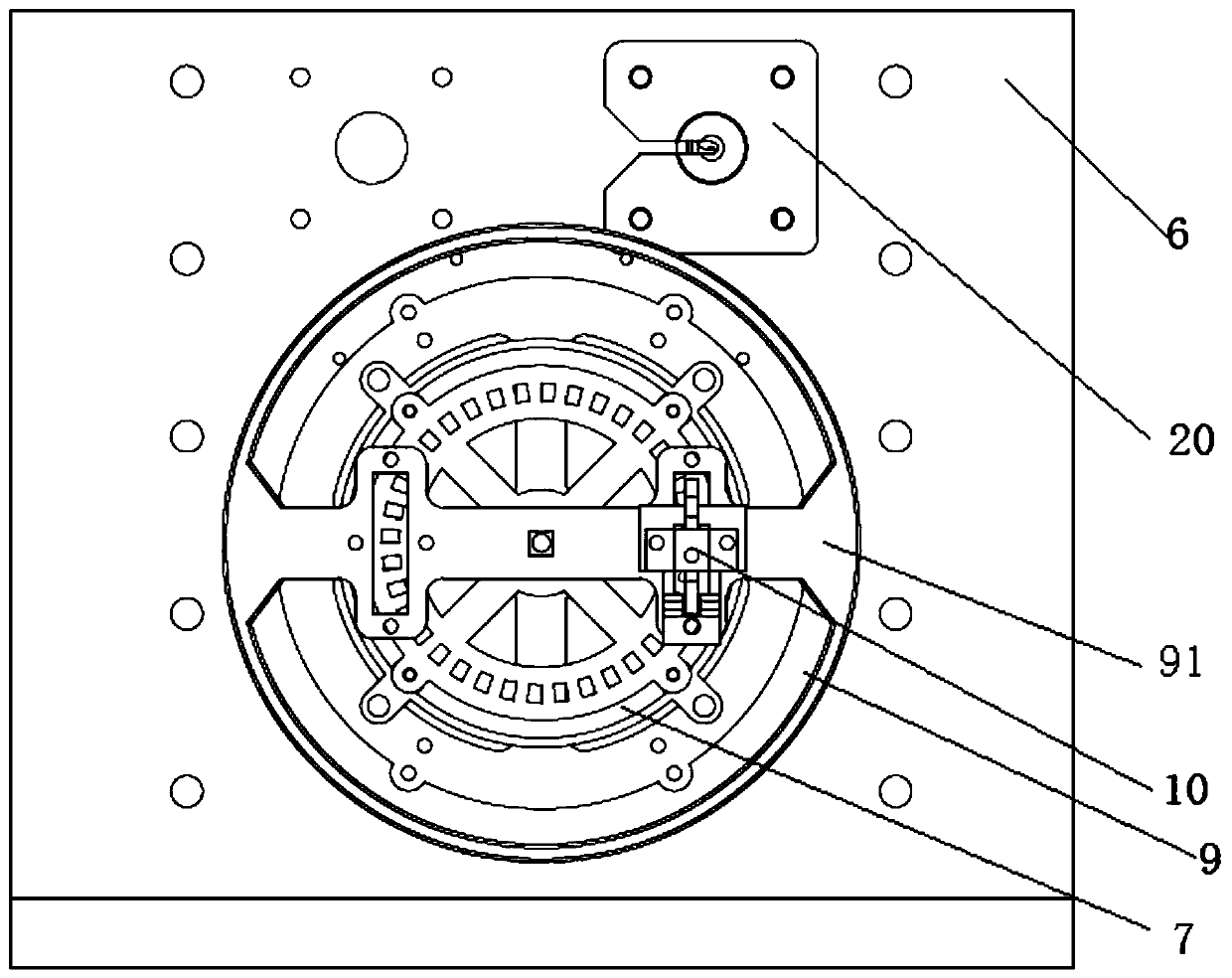

[0043] see figure 1 with 2 , the embodiment of the present invention provides a tension guide mechanism pre-tightening adjustment device, such as figure 1 As shown, the tension guide mechanism includes a housing 1, a first rotating shaft 2, a scroll spring 3 and a reel assembly 4, the first rotating shaft 2 is passed through the housing 1 and connected to the housing The body 1 is rotationally connected, the reel assembly 4 is located outside the housing 1, and is fixedly connected to the upper end of the first rotating shaft 2, the reel assembly 4 includes a hub and a wheel set on the hub A roulette, a rope is wound on the roulette, the rope 5 is preferably a steel wire rope, the scroll spring 3 is located in the housing 1, one end is connected to the first rotating shaft 2 through the inner end fixing mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com