Chip contact assembly and consumable container

A technology for contacting components and consumable containers, applied in instruments, electrical recordings, optics, etc., can solve problems such as poor contact between chips and electrical connections, and achieve good electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

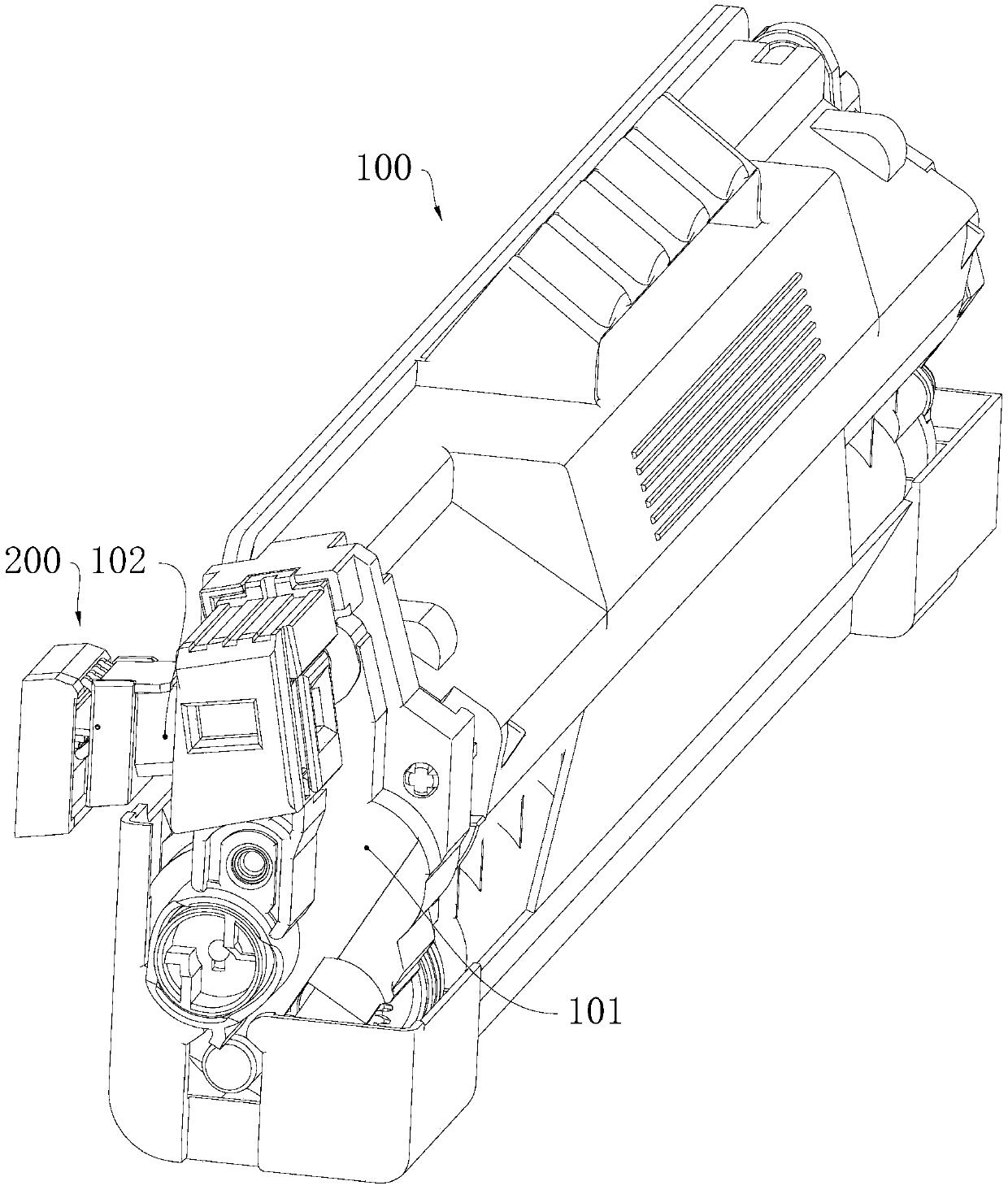

[0026] The consumable container, such as the ink cartridge or the developer cartridge 100, can be used in a printer or a copier. In this embodiment, the application of the chip contact assembly and the consumable container to a laser printer is taken as an example.

[0027] The laser printer has a body 200 and a developer cartridge 100, the developer cartridge 100 is mounted on the body 200, and the direction in which the developer cartridge 100 is inserted into the body 200 is set as a first direction a.

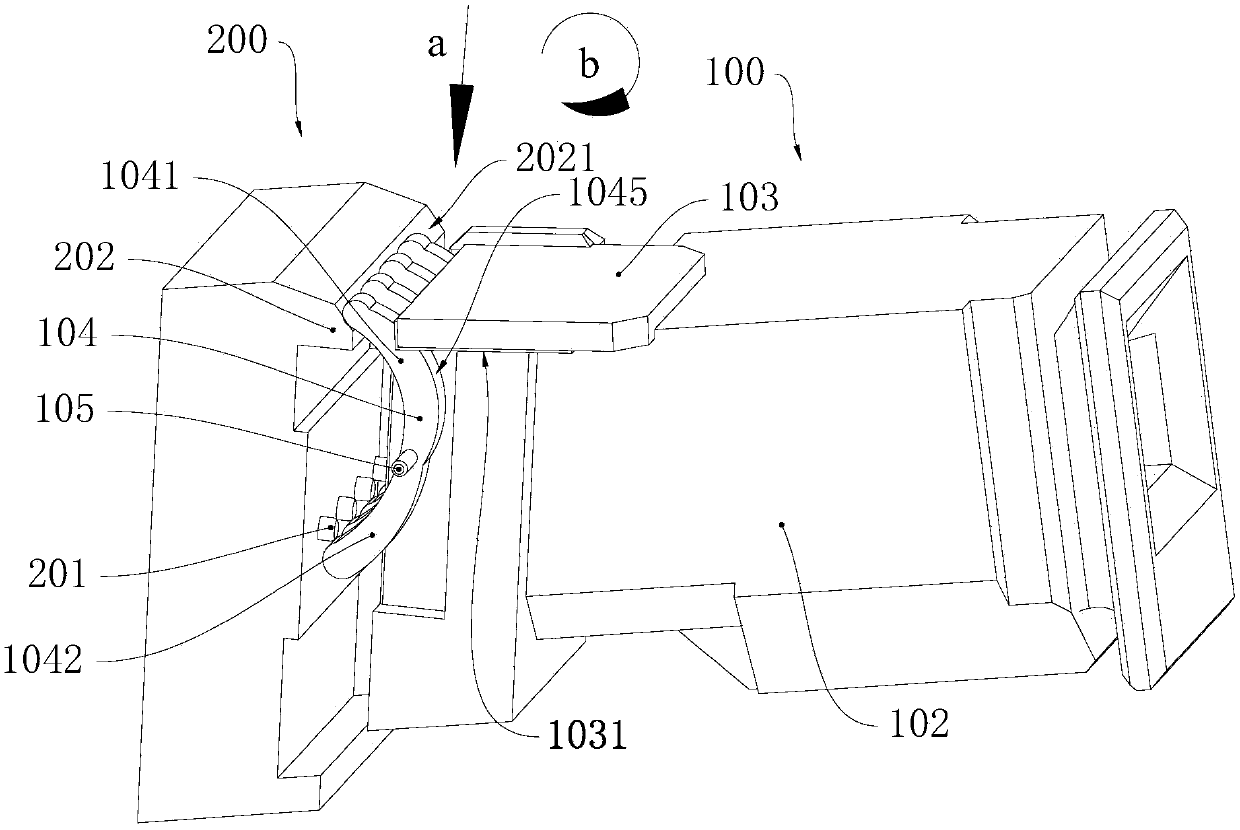

[0028] Please refer to Figure 1 to Figure 2 , the body 200 is provided with an abutment portion 202 and an electrical connection portion 201, along the first direction a, the abutment portion 202 is located behind the electrical connection portion 201, and the abutment portion 202 is provided with a guide surface 2021, along the first direction a , The guide surface 2021 is inclined toward the developing cartridge 100 side.

[0029] The developing cartridge 100 includes a...

Embodiment 2

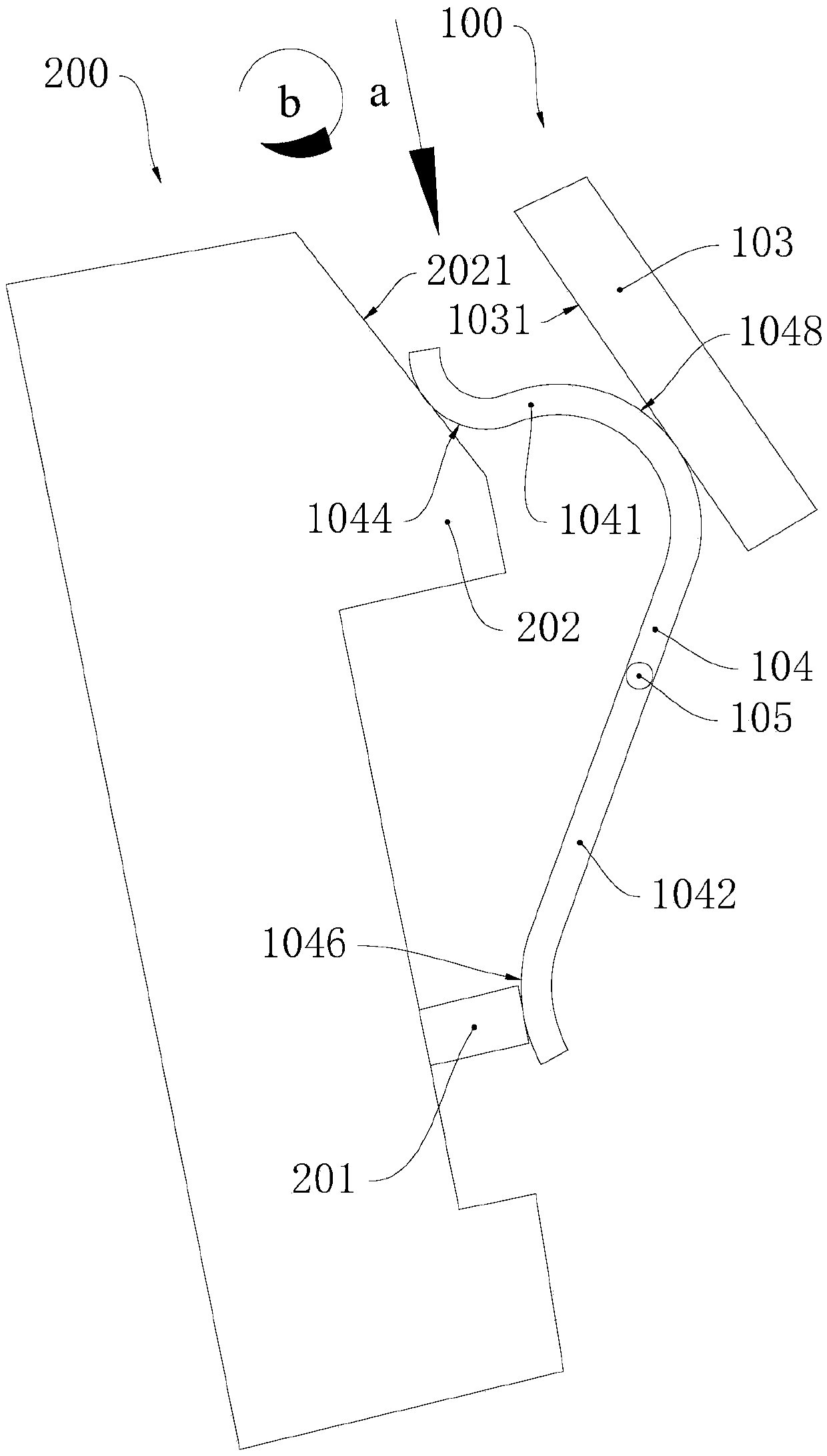

[0041] Please refer to image 3 , the connecting contact pin 104 is made into three curved waves, the wavy connecting contact pin 104 has a convex arc surface 1044, a convex arc surface 1048 and a convex arc surface 1046, and the guiding surface of the convex arc surface 1044 and the contact part 202 2021 abuts, the convex arc surface 1048 abuts against the electrical contact surface 1031 of the chip 103 , and the convex arc surface 1046 abuts against the electrical connection portion 201 .

[0042] Other parts of the second embodiment of the chip contact assembly and the consumable container are the same as the first embodiment of the chip contact assembly and the consumable container.

Embodiment 3

[0044] Please refer to Figure 4 , the connection contact pin 104 may also have a third leg 1043, the first leg 1041 of the connection contact pin 104 abuts against the electrical contact surface 1031 of the chip 103, the second leg 1042 of the connection contact pin 104 abuts against the electrical connection portion 201, The third leg 1043 connecting the contact pin 104 abuts against the abutting portion 202 on the printer body 200 .

[0045] In the case of setting the third leg 1043, the first leg 1041 and the chip 103 can always be kept inside the chip seat 102, and the third leg 1043 protrudes out of the chip seat 102, and is inserted into the developing cartridge 100 along the first direction a into the machine body In the process of 200, the third leg 1043 abuts against the abutment portion 202, under the abutment of the abutment portion 202, the connecting contact pin 104 rotates until the first leg 1041 abuts against the electrical contact surface 1031 of the chip 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com