Preparation process of molybdenum oxide composite pressed balls and drying device of molybdenum oxide composite pressed balls

A drying device, molybdenum oxide technology, applied in drying gas arrangement, dryer for static materials, molybdenum oxide/molybdenum hydroxide and other directions, can solve the problems of inconvenient adjustment, glass damage, inconvenient observation, etc. The effect of easy spacing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

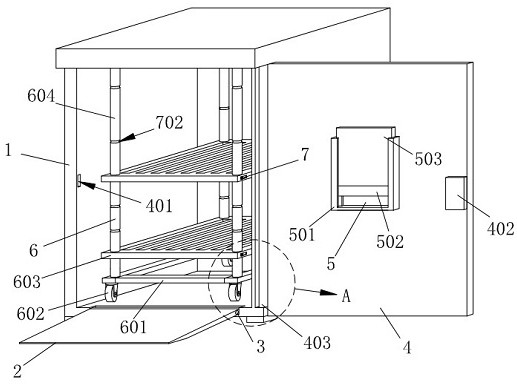

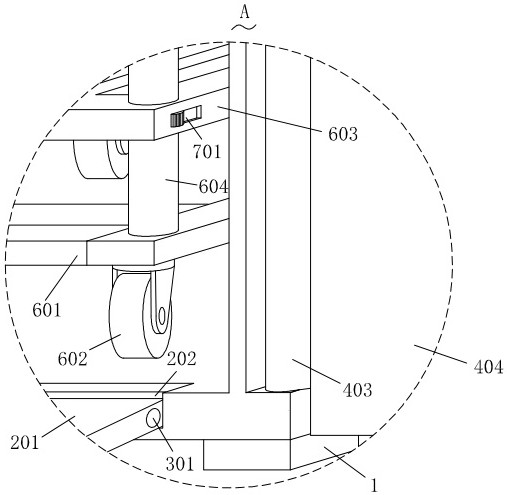

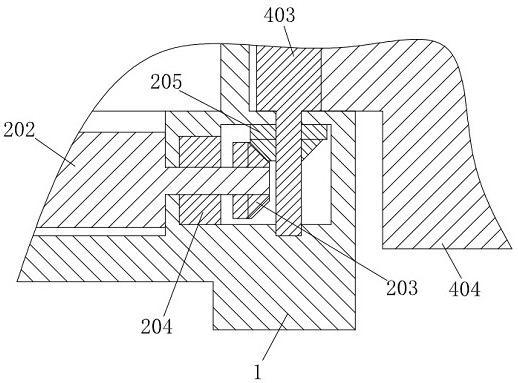

[0031] Such as Figure 1-Figure 8As shown, a drying device for the production of molybdenum oxide composite briquettes according to the present invention includes a main body 1 of a blast drying oven, which is connected with a device for placing molybdenum oxide composite briquettes. Placement structure 6, said placement structure 6 is connected with a position-limiting structure 7 for positioning, said blast drying box main body 1 is connected with a bearing structure 2 for assisting the movement of placement structure 6, said bearing structure 2 is A disassembly structure 3 for disassembly is connected, and a protective structure 4 for protection is connected to the main body 1 of the blast drying box. The observation structure 5; the protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com