Dust prevention structure for dental handpiece

A technology of dust-proof structure and dental handpiece, which is applied in dentistry, dental drilling, medical science, etc., can solve the problems of increasing the wear and tear of front bearing 501), wear, and unusable handpieces, so as to weaken the axial negative pressure return. Suction phenomenon, strengthen dustproof effect, prolong life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

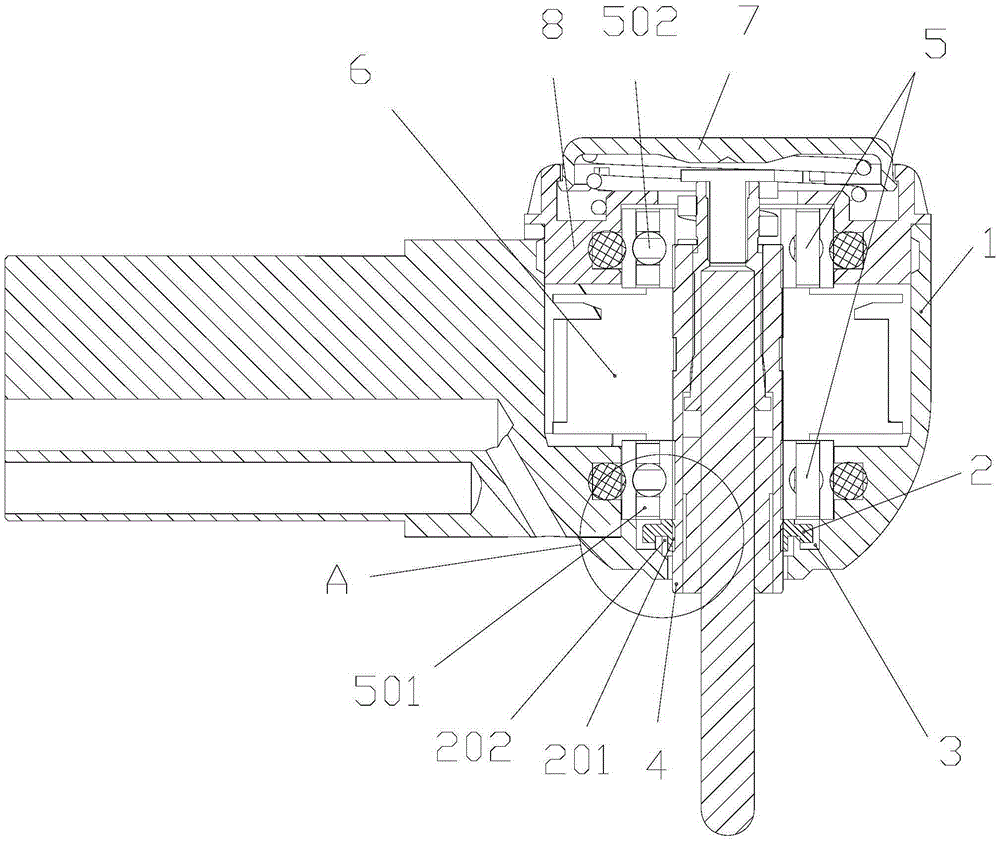

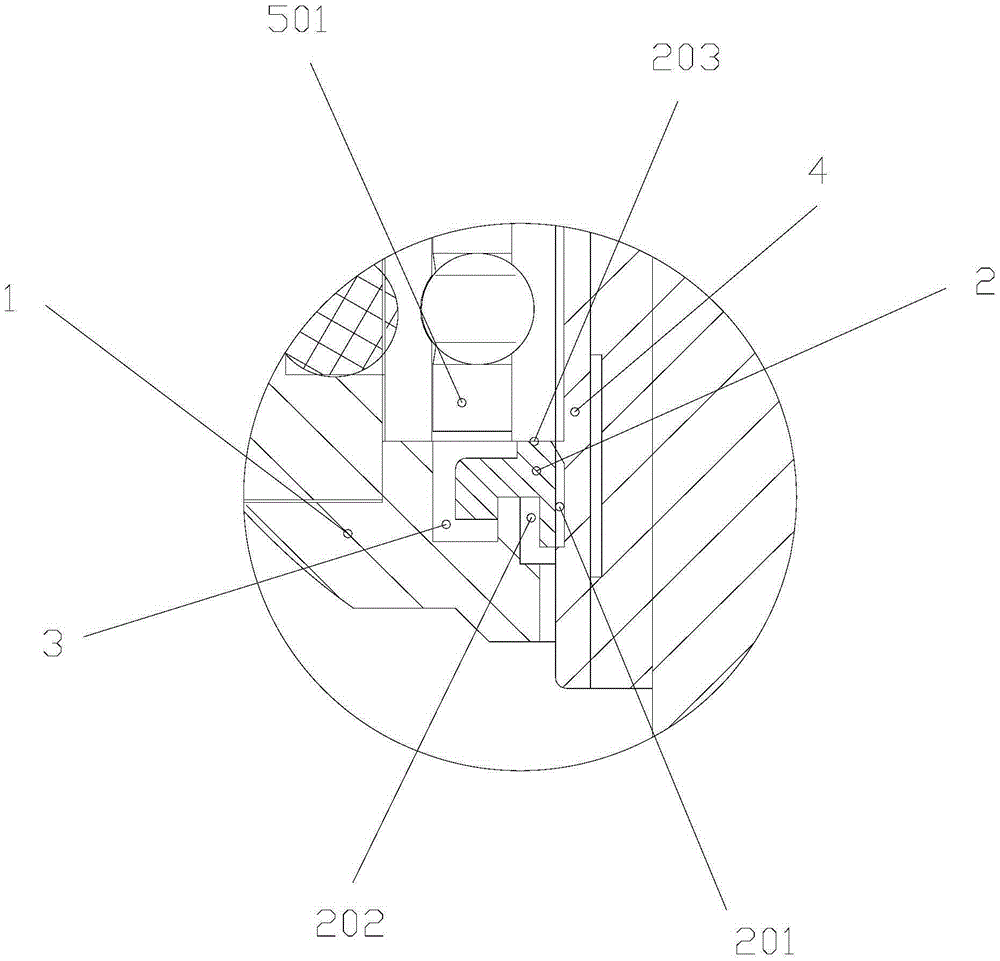

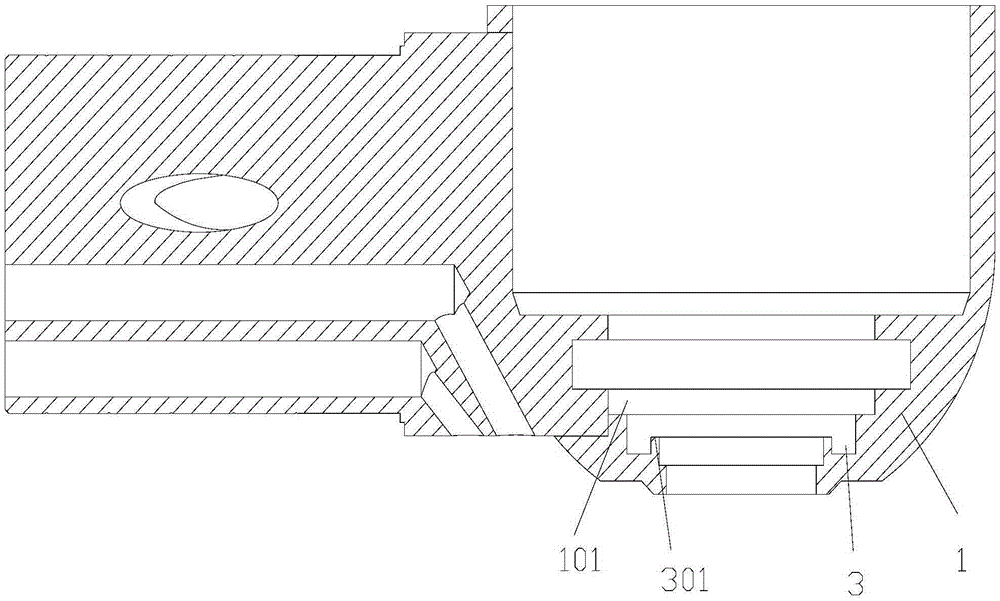

[0019] Attached below Figure 1-4 An embodiment of the present invention is described.

[0020] Dust-proof structure for dental handpieces (such as figure 1 As shown), the dental handpiece is composed of a handle and a machine head. The machine head has a machine head shell 1. The upper end of the machine head shell 1 is sealed and fixedly connected with the lower part of the bearing seat 8. The upper part of the bearing seat 8 is provided with a gland 7. The machine head shell 1. There is a movement inside. The movement mainly includes a movement turbine 6 and a movement shaft 4 driven by the movement turbine 6. The front end of the movement shaft 4 is supported in the nose shell 1 through a front bearing 501. The rear end of the main shaft 4 of the movement is supported in the bearing housing 8 through the rear end bearing 502. The front end bearing 501 is the most easily worn part in the mobile phone. In order to avoid wear and tear, a groove I3 is formed in the head shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com