Train brake pad

A technology for brake pads and trains, which is applied in the direction of brake types, brake parts, friction linings, etc., can solve the problems of easy eccentric wear, large difference in thickness between the inner and outer rings of friction blocks, and easy cracks, etc., and achieve the friction coefficient Stable, reduce the probability of injury, and solve the effect of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

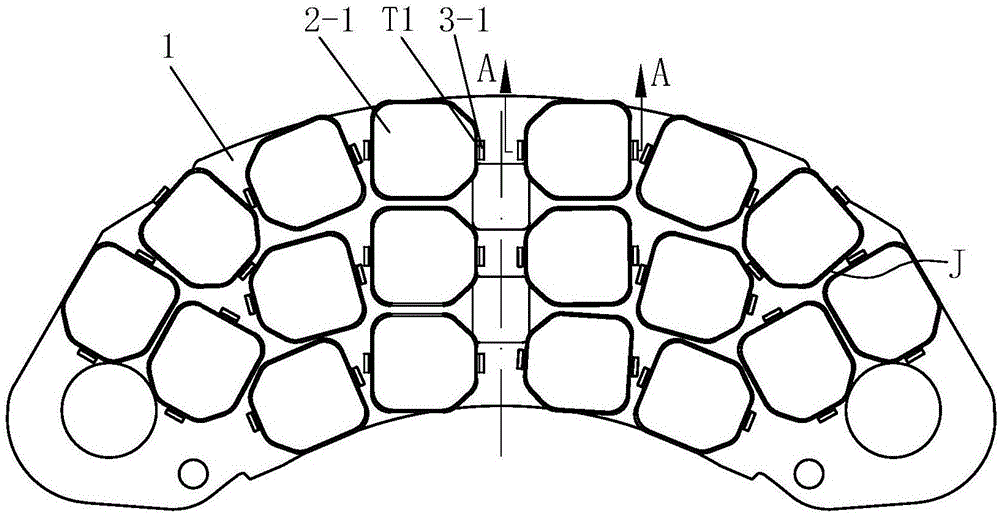

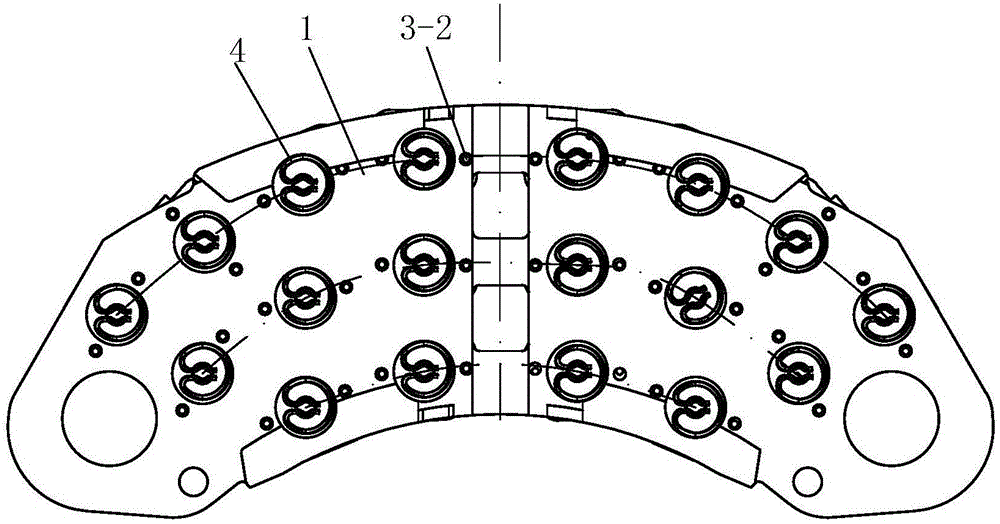

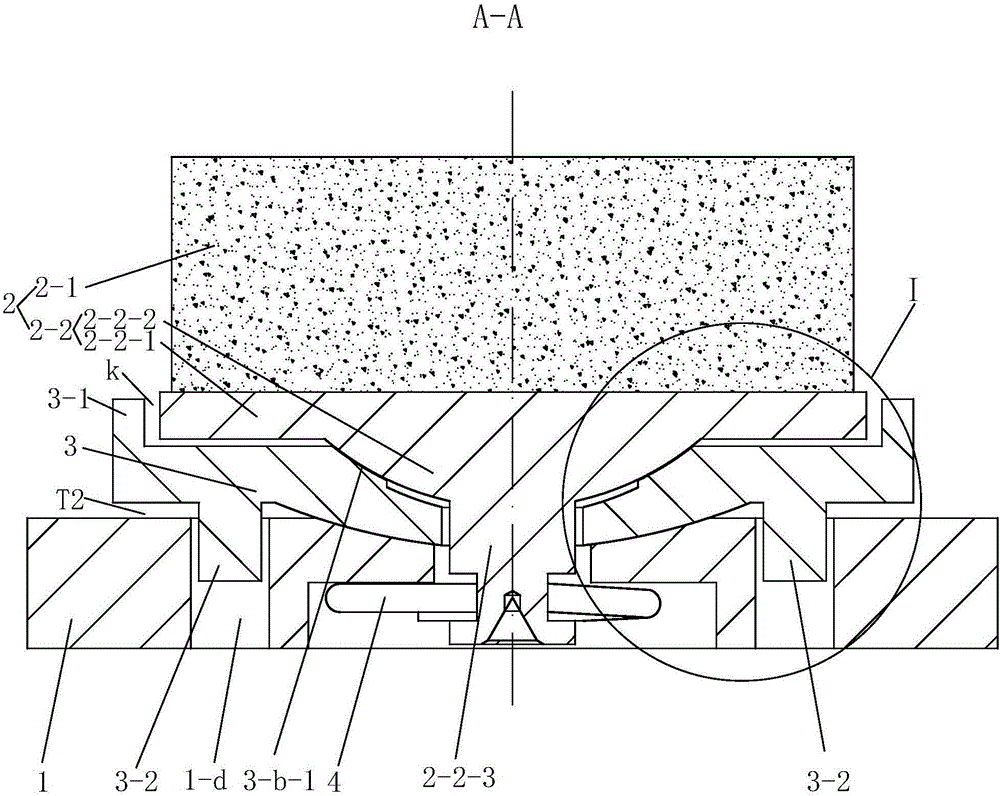

[0026] See Figures 1 to 10 , the present embodiment has a back plate 1, the back plate 1 is waist-shaped, and 18 friction blocks 2 are arranged on the back plate 1, and the number of friction blocks 2 is set according to the specifications of the brake pads. Correspondingly, 18 installation holes 1-a are provided on the backplane 1, and positioning holes 1-d are provided on both sides of each installation hole 1-b. The distribution of the friction blocks 2 on the back plate 1 is left-right symmetrical, and the friction blocks 2 are arranged in three arc lines, and the friction blocks 2 on the three arc lines are 4, 6, and 8 respectively.

[0027] The friction block 2 includes a friction body 2-1 and a support body 2-2. The friction body 2-1 is a hexagon with large and small ends. The shape of the hexagon is composed of a rectangle E and an isosceles trapezoid F. One end of the isosceles trapezoid F is a trumpet-shaped small end. The friction body 2-1 has six The straight si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com