A vertical installation and inspection device and installation and inspection method for an optical system

An optical system, vertical technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problem of uneven shaft hole matching gap, affecting the optical axis consistency and mirror surface shape of the optical system, and imaging defects of optical products. , to achieve the effects of multi-dimensional adjustment, favorable optical axis consistency, simple and feasible device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

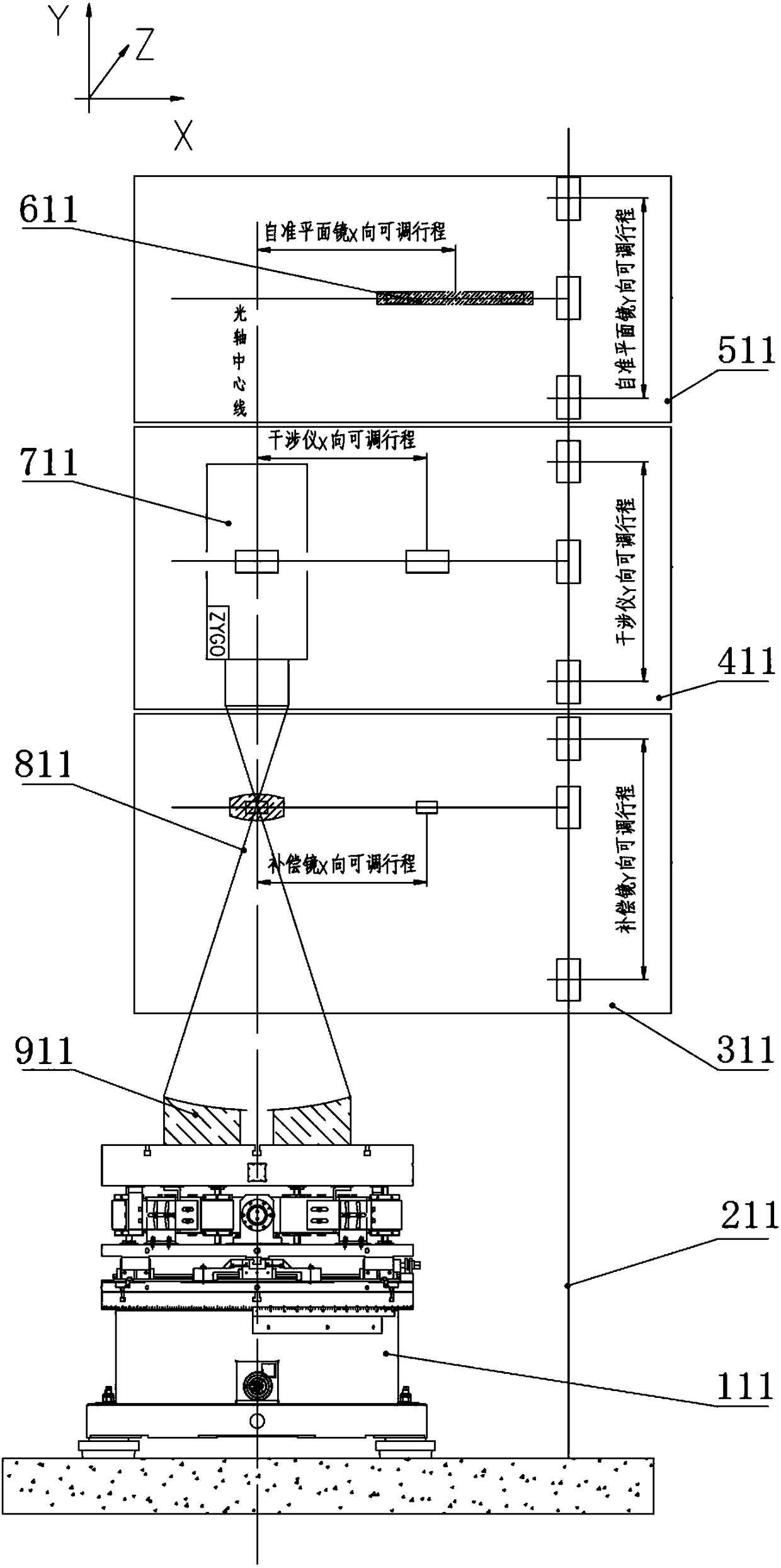

[0047] Such as image 3 As shown, the present invention includes an adjustment turntable 111, the adjustment turntable is used to place the parts to be inspected; three adjustment brackets are sequentially arranged on the adjustment turntable from bottom to top; the three adjustment brackets are installed on a fixed mounting frame 211, respectively It is the compensation mirror adjustment bracket 311, the interferometer adjustment bracket 411 and the self-collimating plane mirror adjustment bracket; the fixed mounting frame is a truss structure with high strength and rigidity welded by section steel;

[0048] The three adjustment brackets all include vertical guide rails and horizontal guide rails. The vertical guide rails are fixedly connected to the fixed mounting frame, and the horizontal guide rails can slide up and down along the vertical guide rails;

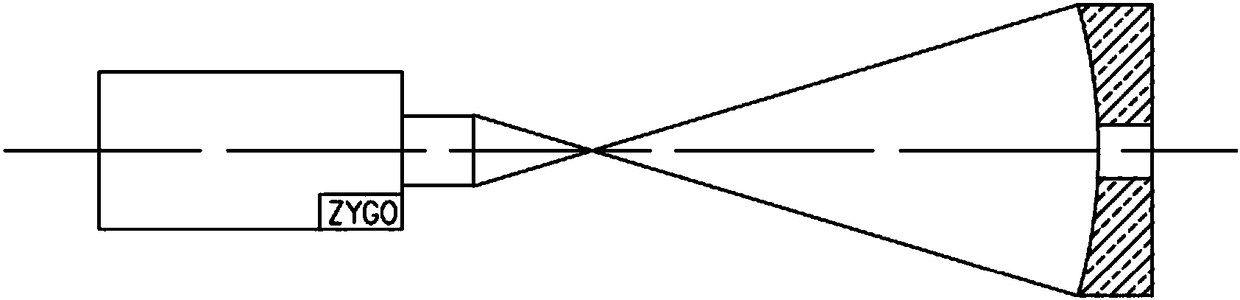

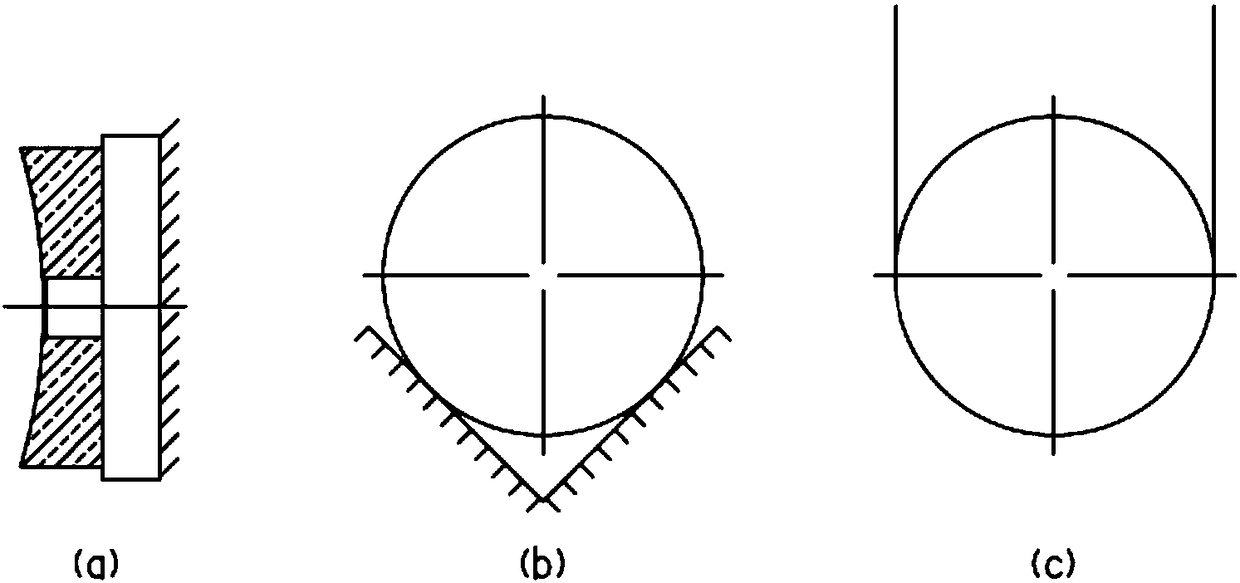

[0049] The compensation mirror adjustment bracket also includes a compensation mirror 811; the compensation mirror is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com