Composite plate processing equipment based on cabin light weight and electromagnetic shielding

A technology for electromagnetic shielding and plate processing, which is applied in metal processing equipment, magnetic field/electric field shielding, turning equipment, etc., and can solve problems such as unfavorable fast turning of plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

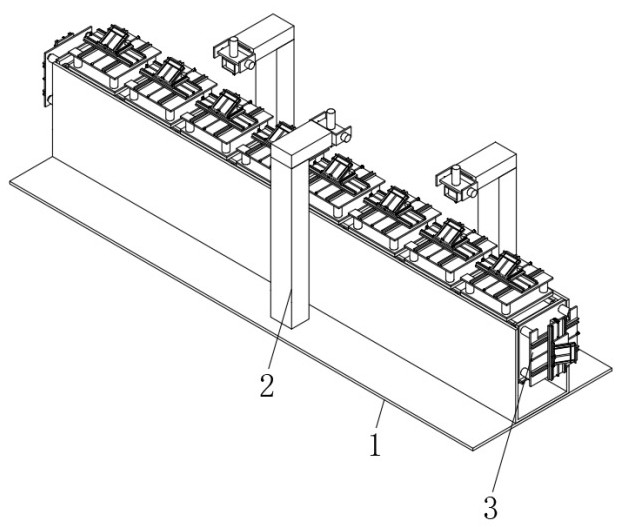

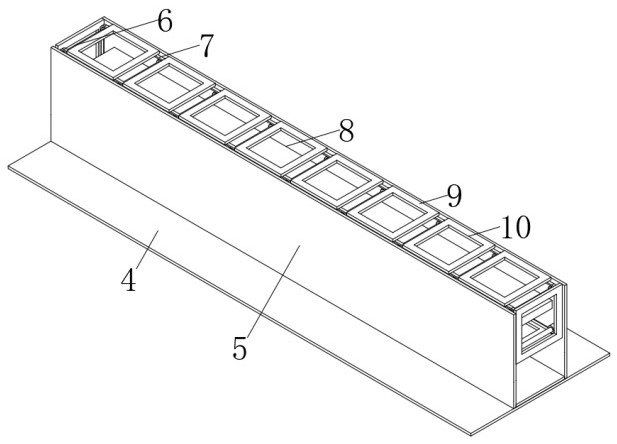

[0039] Please refer to Figures 1 to 10, the present invention proposes a technical solution, based on a composite type of cabin lightweight and electromagnetic shielding

[0041] The plate clamping assembly 3, the plate clamping assembly 3 is used to clamp the composite plate and drive it to move.

Embodiment 2

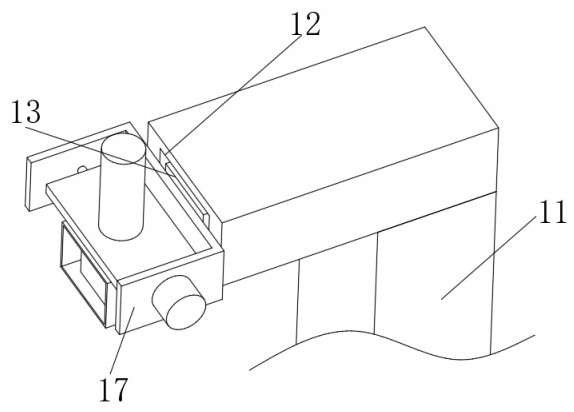

[0046] Please refer to FIGS. 1 to 10, on the basis of the first embodiment, the present invention provides a technical solution: the plate clamping assembly 3

[0048] The clamping displacement structure-25 includes a base plate 28, and the top of the base plate 28 is fixedly mounted with two sliding seats-30, and the sliding seat-1

[0055] After the clamping tool 27 is completed to clamp the plate, because the clamping tool 27 is fixed on the inclined plate 44,

[0059] The wireless charging assembly 8 is installed inside the U-shaped frame 5, and the plate clamping assembly 3 is actively charged when moving around

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com