Non-contact throttle position sensor

A throttle position, non-contact technology, which is applied in the direction of transmission of sensing components, instruments, measuring devices, etc. using electric/magnetic devices, can solve problems such as output signal lag, brush or ceramic substrate wear, sensor failure, etc. Achieve the effect of improving output accuracy, improving service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

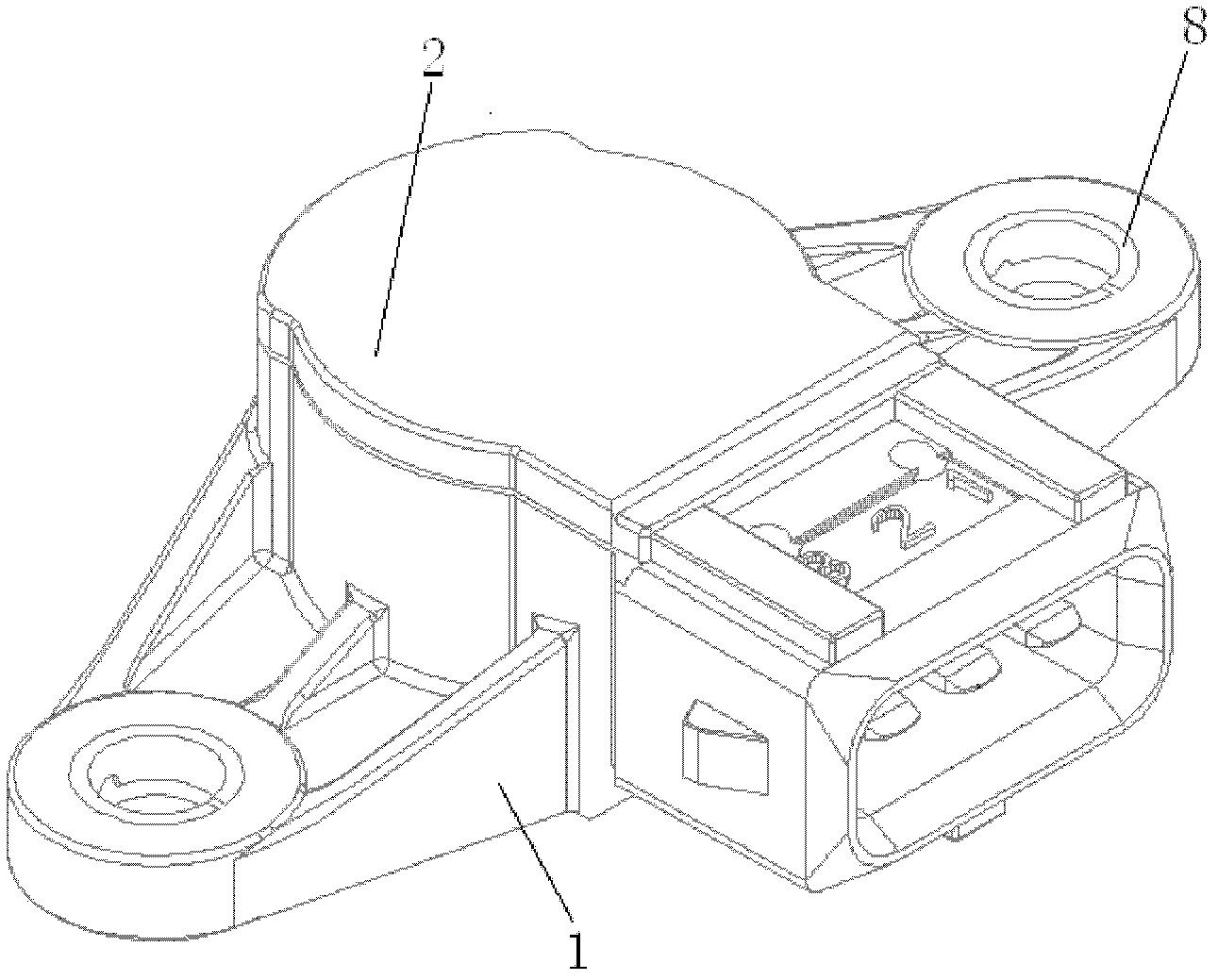

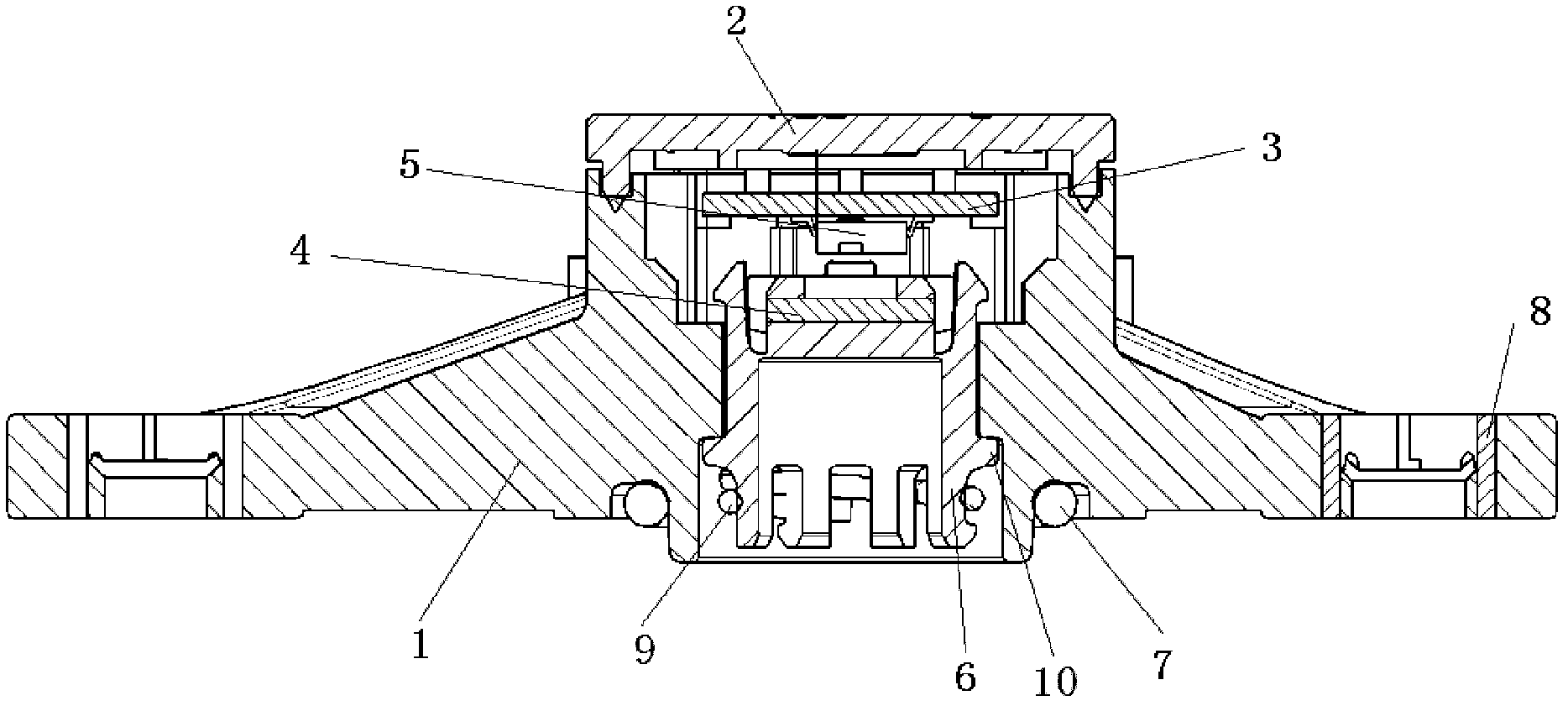

[0018] The non-contact throttle position sensor of the present invention, as figure 1 It is mounted on the throttle body as shown. The sensor includes a housing 1, a cover plate 2, a circuit board 3, a Hall element 5, a magnetic element and a rotor 6, wherein the circuit board 3, the Hall element 5, the magnetic element and the rotor 6 are located in the housing 1, such as image 3 shown. The rotor 6 is closely connected with the throttle shaft, the magnetic element is fixedly installed on the rotor 6, the circuit board 3 is installed on the housing 1, and is fixedly connected with the Hall element 5, and the Hall element 5 and There is a gap between the magnetic elements. The magnetic element is a magnet 4 .

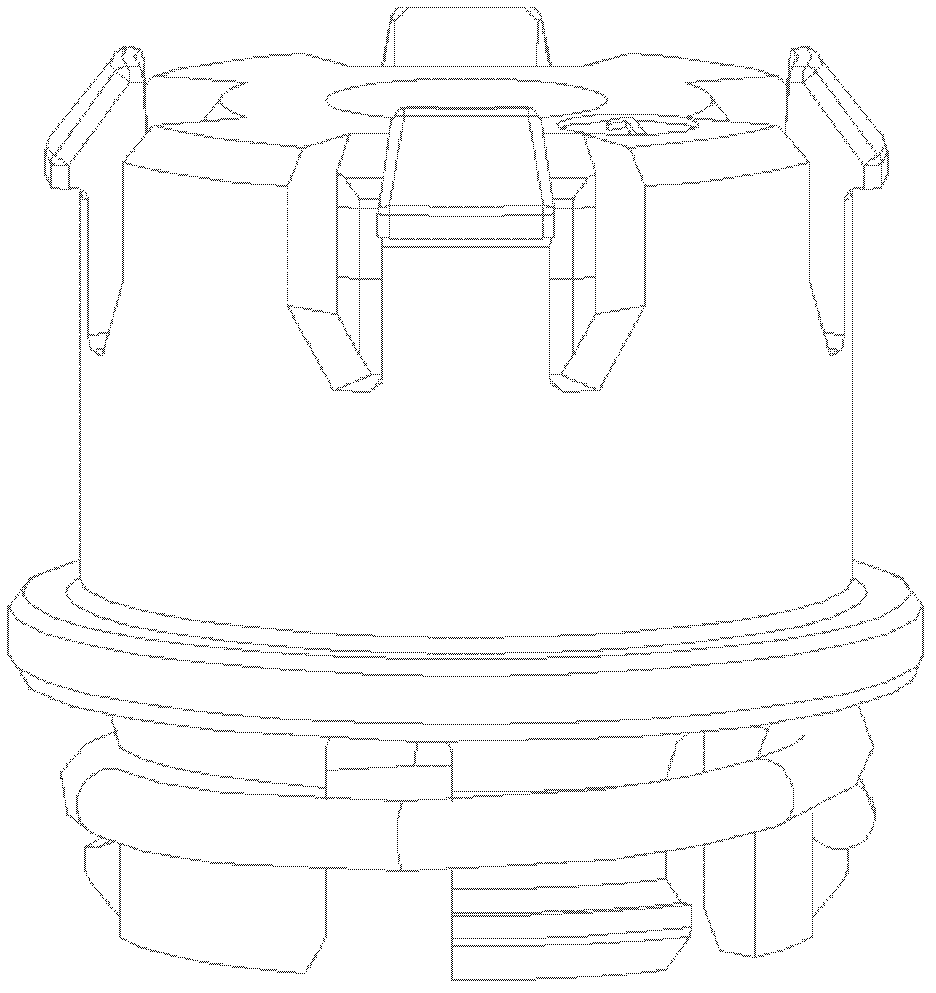

[0019] Such as figure 2 with image 3 As shown, the lower end of the rotor 6 is tightly connected to the throttle shaft through the circlip 9, so that the cooperation between the rotor 6 and the throttle shaft is tighter, thereby reducing the hysteresis error meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com