Quenching method for integral cast steel supporting roll

A backup roller and cast steel technology, which is applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems that cannot be overcome, and achieve the effects of overcoming defects, reducing total heating energy consumption, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

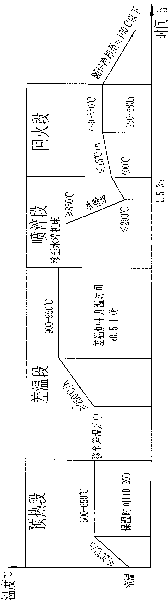

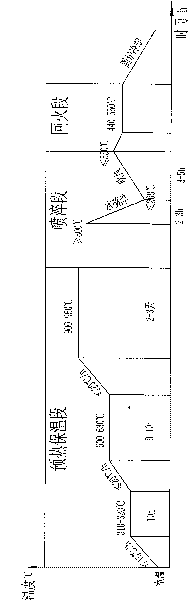

[0016] Embodiment: Take the quenching process of an integral cast steel support roll with a diameter of D=1.5 meters as an example. according to figure 1 There are roughly 4 process sections shown. Preheating section: firstly put the integral cast steel support roll in quenched and tempered state after casting into the trolley-type resistance furnace for preheating, heat it to 630°C at a heating rate of 12°C / h, and keep it for 20 hours; then move to the differential temperature Continue heating in the furnace, rotate at a speed of 8rpm, and rapidly heat at a heating rate of 280°C / h to the quenching temperature of 910°C on the surface, stop heating, and keep warm in the furnace for 36 hours until the heat penetration thickness is greater than the required hardened layer Depth, the total energy consumption of heating and heat preservation is about 35,000 kWh, and it takes 56 hours. After the heat preservation is completed, move it into the water quenching machine, rotate it a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com