Electromagnetic fuel pump nozzle drive control method and its device

A control device, fuel pump technology, applied in the direction of fuel injection device, fuel injection control, electrical control, etc., can solve problems such as inability to correct or even give opposite predictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

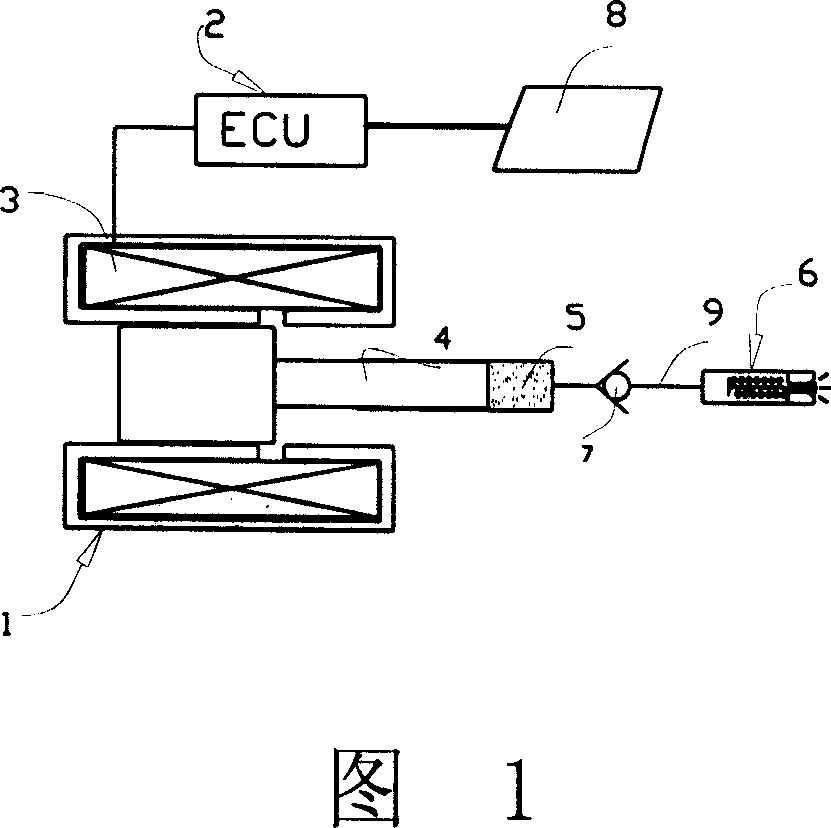

[0073] Figure 1 is a schematic diagram of the nozzle structure of an electromagnetic fuel pump. Its working process is: after the fuel enters the pressure delivery chamber 5, under the action of the plunger 4, it passes through the oil outlet valve 7 to the nozzle 6. When the fuel reaches a predetermined pressure, for example 15 bar, sprayed by nozzle 6. The movement of the plunger 4 comes from the electromagnetic force generated after the solenoid device 3 is energized, and the solenoid device 3 is driven by the PWM pulse voltage sent by the ECU unit 2 . The duty ratio of the PWM pulse voltage determines the fuel injection quantity Qi, and under the condition that other conditions remain unchanged, the fuel injection flow Qi is proportional to the driving pulse width T1. The demand of the engine for the fuel injection flow rate is mainly determined by the operating data 8 of the engine, which includes the engine speed, thermal load, and environmental conditions. This electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com