Four-degrees-of-freedom magnetic suspension flywheel

A degree of freedom and magnetic levitation technology, applied in the direction of magnetic attraction or thrust holding devices, bearings, electrical components, etc., can solve the problems of increased volume, mechanical wear of mechanical bearings, large zero-crossing friction torque, etc., to overcome the axial The effect of large length, small rotation power consumption, and small fluctuation of magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

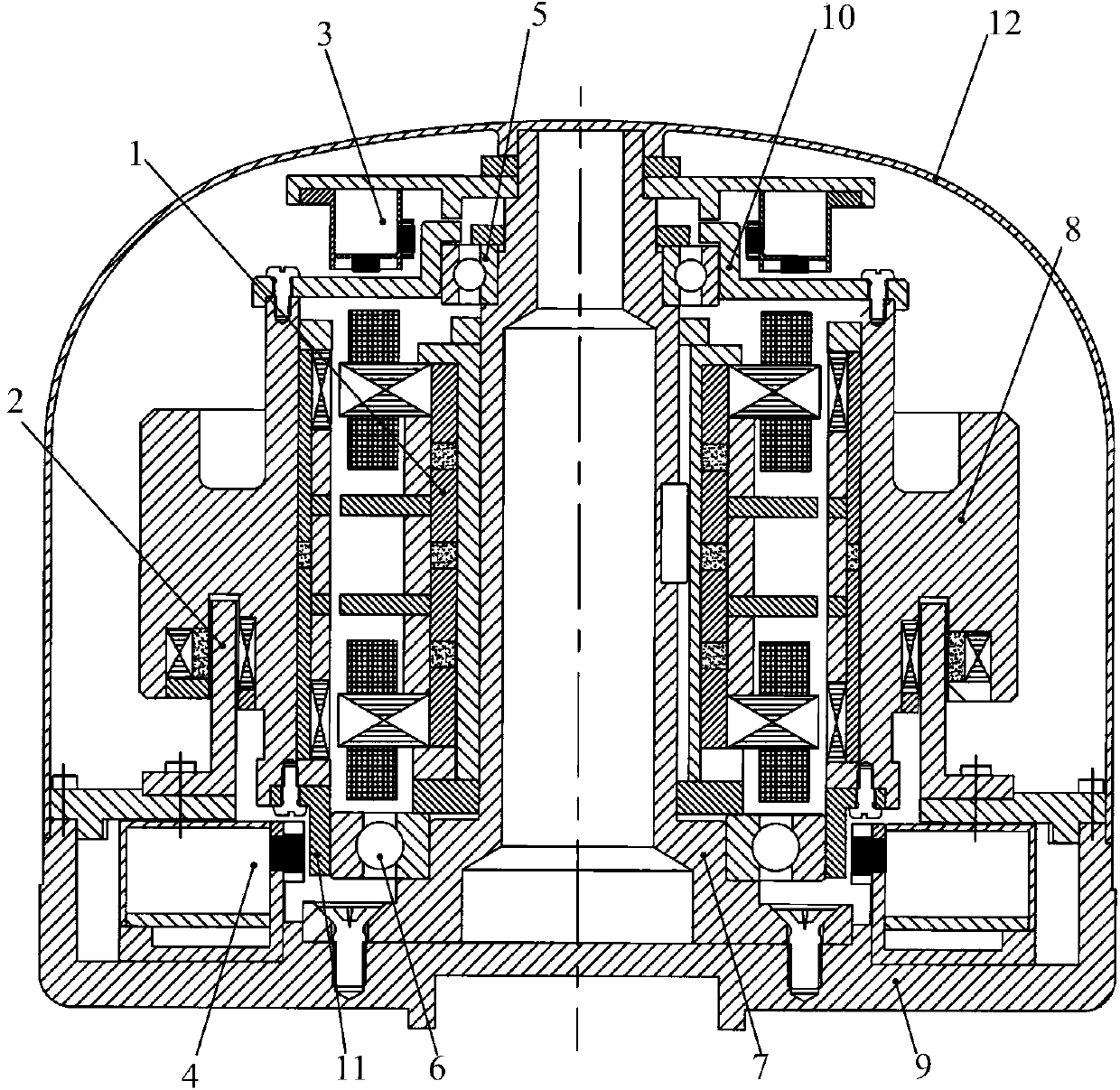

[0020] Such as figure 1As shown, a four-degree-of-freedom magnetic levitation flywheel consists of a four-degree-of-freedom magnetic bearing (1), a high-speed motor (2), a radial-axis integrated sensor (3), a radial sensor (4), an upper protective bearing (5), The lower protective bearing (6), the mandrel (7), the wheel body (8), the base (9), the upper sensor detection ring (10), the lower sensor detection ring (11) and the housing (12), of which four free The four-degree-of-freedom magnetic bearing (1) is located in the middle of the flywheel, and its stator part is installed in the middle of the mandrel (7). The upper end of the four-degree-of-freedom magnetic bearing (1) stator is an upper protective bearing (5), and the upper protective bearing (5) is also Fixed on the mandrel (7), the radial outer side of the upper protection bearing (5) is the upper sensor detection ring (10), and a radial protection gap and Axial protection gap, the radial outside of the upper sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com