Device for testing dynamic stiffness and constant pressure of high-speed electric spindle

A high-speed motorized spindle, dynamic stiffness technology, used in measuring devices, using stable tension/pressure to test the strength of materials, testing of mechanical parts, etc. The performance is difficult to predict, and the loading cannot be constant, etc., to achieve the effect of convenient data acquisition, real-time measurement, and stable dynamic loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

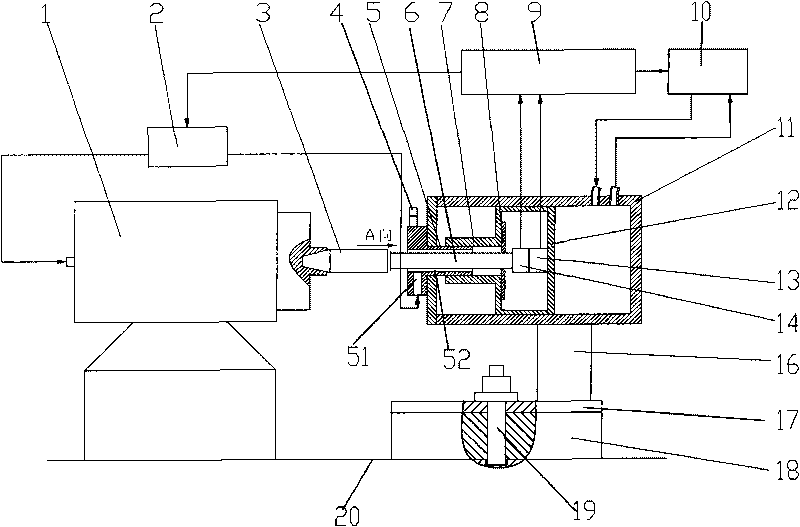

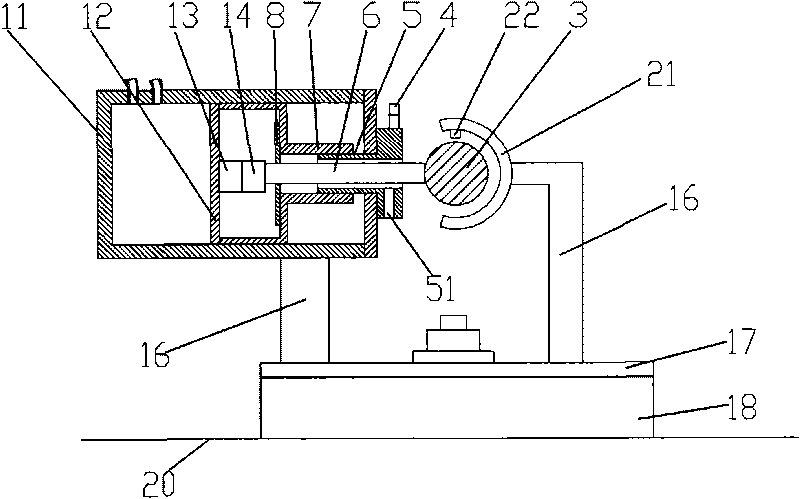

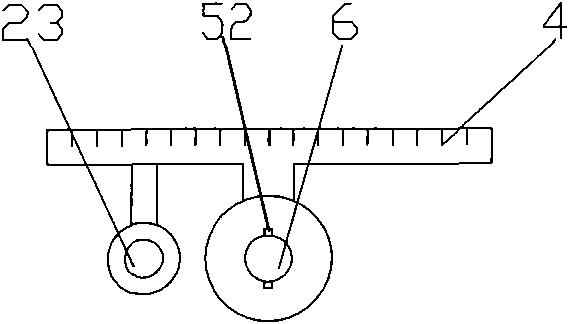

[0021] figure 1 It is a schematic diagram of the axial detection structure of the electric spindle of the present invention, image 3 for figure 1 View along direction A, Figure 4 It is a schematic diagram of the connection mode between the bracket 1 and the mounting plate, as shown in the figure: the high-speed electric spindle dynamic stiffness constant pressure testing device of the present embodiment includes a base 18, a loading system, a lubrication cooling system and an automatic control unit 9;

[0022] The loading system includes a hydraulic cylinder assembly, a hydraulic cylinder oil circuit system 10, and a loading rod 6. The hydraulic cylinder assembly includes a cylinder body 11 and a piston 12. One end of the loading rod 6 penetrates the piston axially in an axially slidable manner. 12, and a pressure sensor 14 is set between the end face and the piston 12, as shown in the figure: the piston has an open end structure, the loading rod penetrates into the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com