Cell-less composite type artificial skin and preparation thereof

A kind of artificial skin and composite technology, applied in coating, medical science, prosthesis, etc., can solve the problems of unfavorable wound epidermal cell crawling and wound sealing, difficult to observe wound infection, complicated production process, etc., to promote Effects of treatment and healing, prevention of recurrence, and promotion of healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

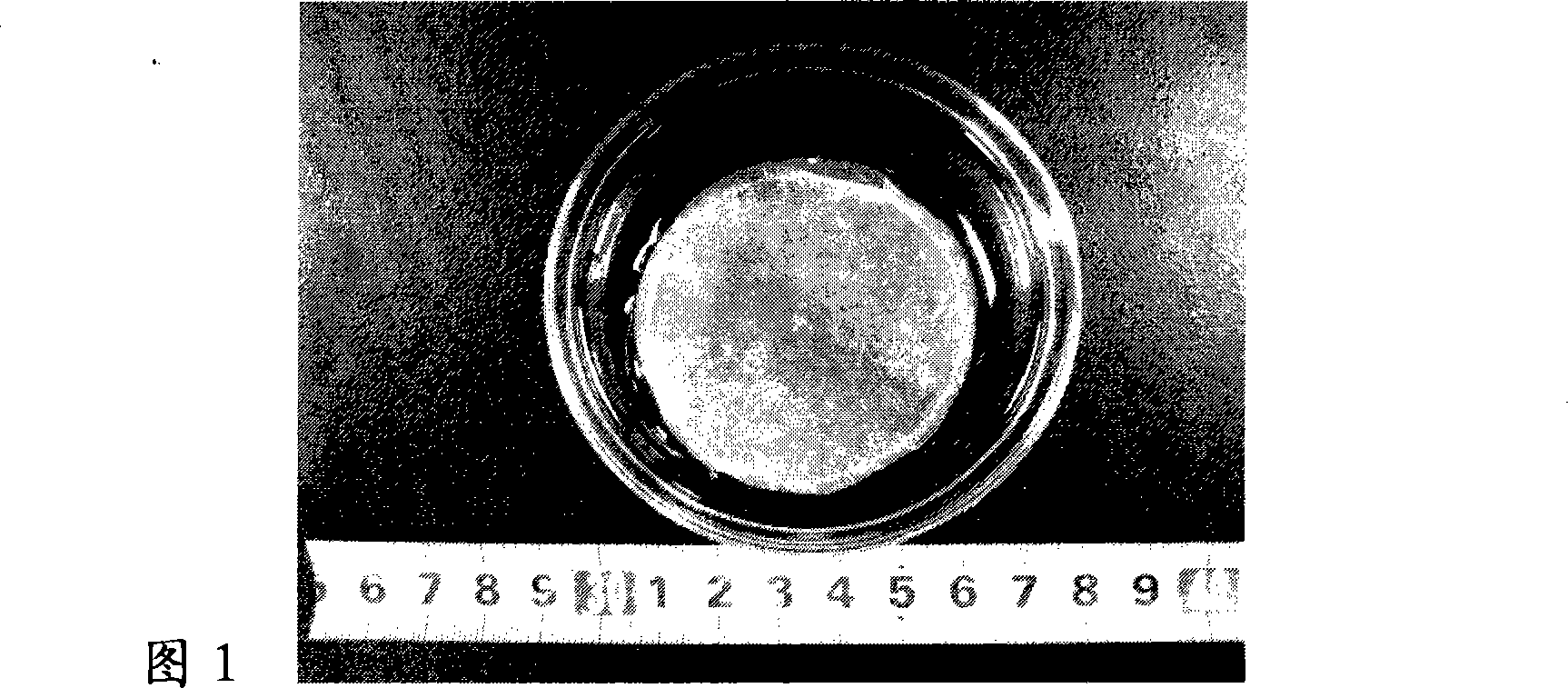

[0022] Step 1. The preparation of the dermal layer material refers to the Chinese patent (CNZL No.: 200510096463.3) "Preparation method of tissue engineered extracellular matrix" to obtain a loose and porous acellular dermal matrix material, which is a circle with a diameter of 3 cm and a thickness of 0.5 mm .

[0023] Step 2. Loading of growth factors: under sterile conditions, human recombinant EGF (rhEGF, Sigma company) was prepared into EGF aqueous solution, and 2 mg of freeze-dried gelatin microspheres (provided by the Biomacromolecular Materials Laboratory of Western Polytechnic University) were added to the EGF solution. , 4 ° C to fully soak the EGF solution into the freeze-dried gelatin microspheres.

[0024] Step 3. Preparation of epidermis material: select biological protein glue to be prepared into a gel solution, under aseptic conditions, add 2 mg of gelatin microspheres containing EGF to the gel solution of 10 ml and stir evenly, so that the final concentration o...

Embodiment 2

[0027] Step 1. The dermis layer material is prepared from a mixture of collagen, chitosan and chondroitin sulfate to form a recombined dermal matrix, which is a loose and porous extracellular matrix material with a diameter of 5 cm and a thickness of 5 mm.

[0028] Step 2, drug loading: prepare penicillin into penicillin aqueous solution under aseptic conditions, add 2 mg of freeze-dried medical protein colloid particles to the penicillin solution, and fully soak the penicillin solution into the freeze-dried particles at 4°C.

[0029]Step 3. Preparation of epidermis material: under sterile conditions, add penicillin-containing microparticles into 10 ml of polylactic acid gel solution and stir evenly so that the final concentration of penicillin is 800 i.u / ml.

[0030] Step 4. Construction of composite skin: the gel solution containing microparticles is pressed at 2 mg / cm 2 It is coated on the upper surface of the dermis material, placed in a vessel to solidify at 4°C, then pla...

Embodiment 3

[0032] Step 1. The dermis layer is made of loose and porous decellularized cowhide matrix material (available from Sigma), with a diameter of 7 cm and a thickness of 2 mm. Prepare the polyglycolic acid gel solution as the cuticle material.

[0033] Step 2. The construction of composite skin: the polyglycolic acid gel solution is pressed at 1mg / cm 2 Evenly coated on the upper surface of the dermis material, placed in a vessel to solidify at 4°C, then placed in a -80°C refrigerator for 16 hours, and then vacuum freeze-dried to obtain a cell-free composite artificial skin product. The preparation steps of the skin are simple, the storage time is long, and the skin can be widely used in the treatment of burn and scald wounds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com