Spring stiffness adjustable tuning quality damper

A technology of tuning mass and spring stiffness, which is applied in the direction of spring/shock absorber, shock absorber, solid shock absorber, etc., can solve the problem of difficult machining of spring stiffness, rough method of changing tuning mass, waste of materials and manpower And other problems, to achieve the effect of perfect vibration reduction, simplify the difficulty of adjustment work, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

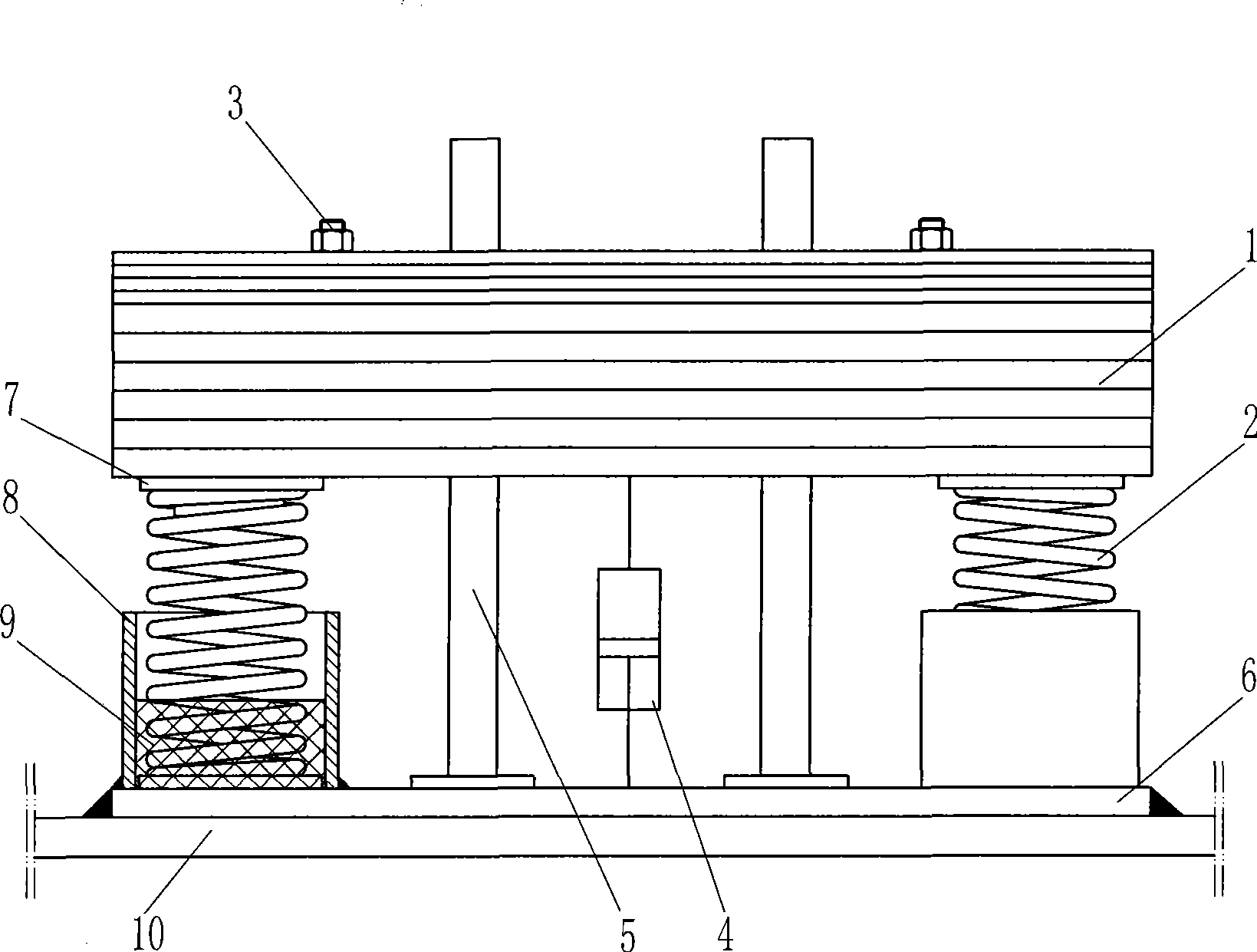

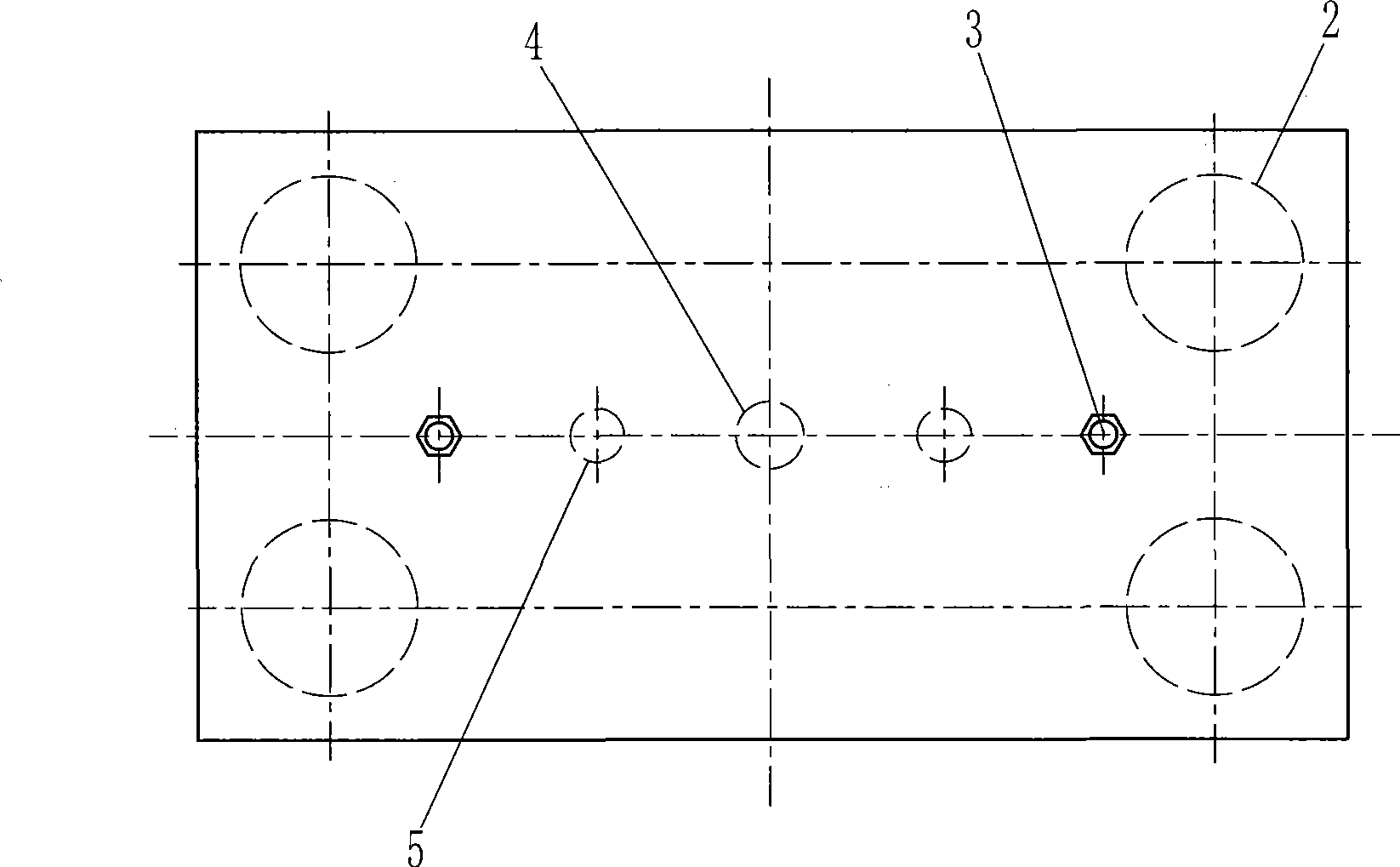

[0022] Such as figure 1 , figure 2 The spring rate adjustable tuned mass shock absorber of the present invention shown includes a tuned mass 1, four springs 2, a damper 4, and a base 6. The spring 2 is a coiled steel spring. In order to facilitate the positioning of the spring, the base 6 A spring positioning seat 7 is welded to the adjacent mass block of the spring 2. In order to facilitate accurate adjustment of the natural frequency of the adjustable spring stiffness tuned mass damper of the present invention, a stiffness adjustment device is also provided at the lower end of the spring 2. The stiffness adjustment device includes a curing cylinder 8 and a curing material 9 arranged in the curing cylinder. The material is metallic lead. Utilizing the characteristics of low melting point of metal lead and solidification at room temperature, the lead is melted into lead water and injected into the solidification cylinder to solidify it with the immersed spring part. In this way,...

Embodiment 2

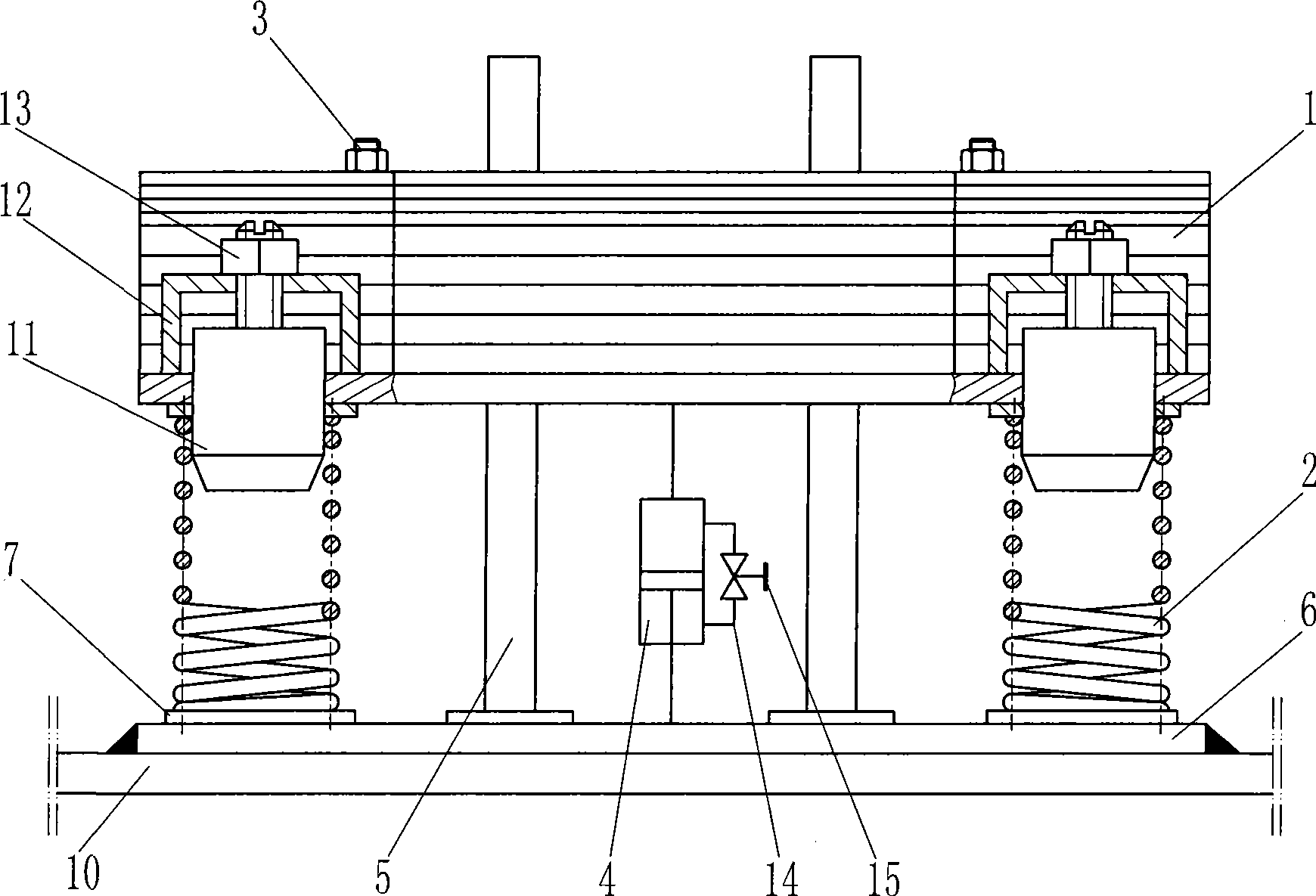

[0028] Such as image 3 , Figure 4 As shown, the difference from the first embodiment is that the stiffness adjusting device adopts a restraining block 11 inserted into the spring 2 from above, and the restraining block 11 is connected with the bracket 12 welded on its adjacent mass by a threaded structure, and is locked with a nut 13 . Since the restraining block 11 and the inner ring of the spring 2 adopt an interference fit, the elasticity of the spring section contacting the restraining block 11 is bound to be greatly restricted. In this way, the stiffness of the spring can be artificially controlled by adjusting the depth of the restraining block 11 inserted into the spring. Furthermore, the purpose of controlling the natural frequency of the spring-stiffness-adjustable tuned mass damper of the present invention is achieved. In addition, in order to facilitate the adjustment of the system damping ratio, a communication pipeline 14 is provided between the chambers at both end...

Embodiment 3

[0032] Such as Figure 5 The difference between the spring stiffness adjustable tuned mass damper of the present invention and the second embodiment is that the stiffness adjustment device adopts a restraining block 11 screwed into the spring 2 from above, and the spring 2 is arranged on the surface of the restraining block 11. The spiral protrusion 16 corresponds to the gap between the spring wires. After the constraining block 11 is screwed into the spring, the protrusion 16 on the surface of the constraining block is caught between the spring wires, so that the spring elasticity of the screwed-in section is lost, thereby realizing the function of changing the spring stiffness. The restraining block 11 is connected with the bracket 12 welded on the adjacent mass block by a threaded structure and locked with a nut 13. In addition, the damper used in this example is an adhesive damper composed of a damping cylinder 21, an adhesive damping fluid 23 (herein, silicone oil), and a pis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com