Damping ratio adjustable tuning quality damper

A tuning quality and adjustable technology, applied in the direction of shock absorber, solid shock absorber, shock absorber, etc., can solve the problems of prone to sideways swing, high price of damper, seal damage, etc., to achieve optimal damping ratio, The effect of stable system and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

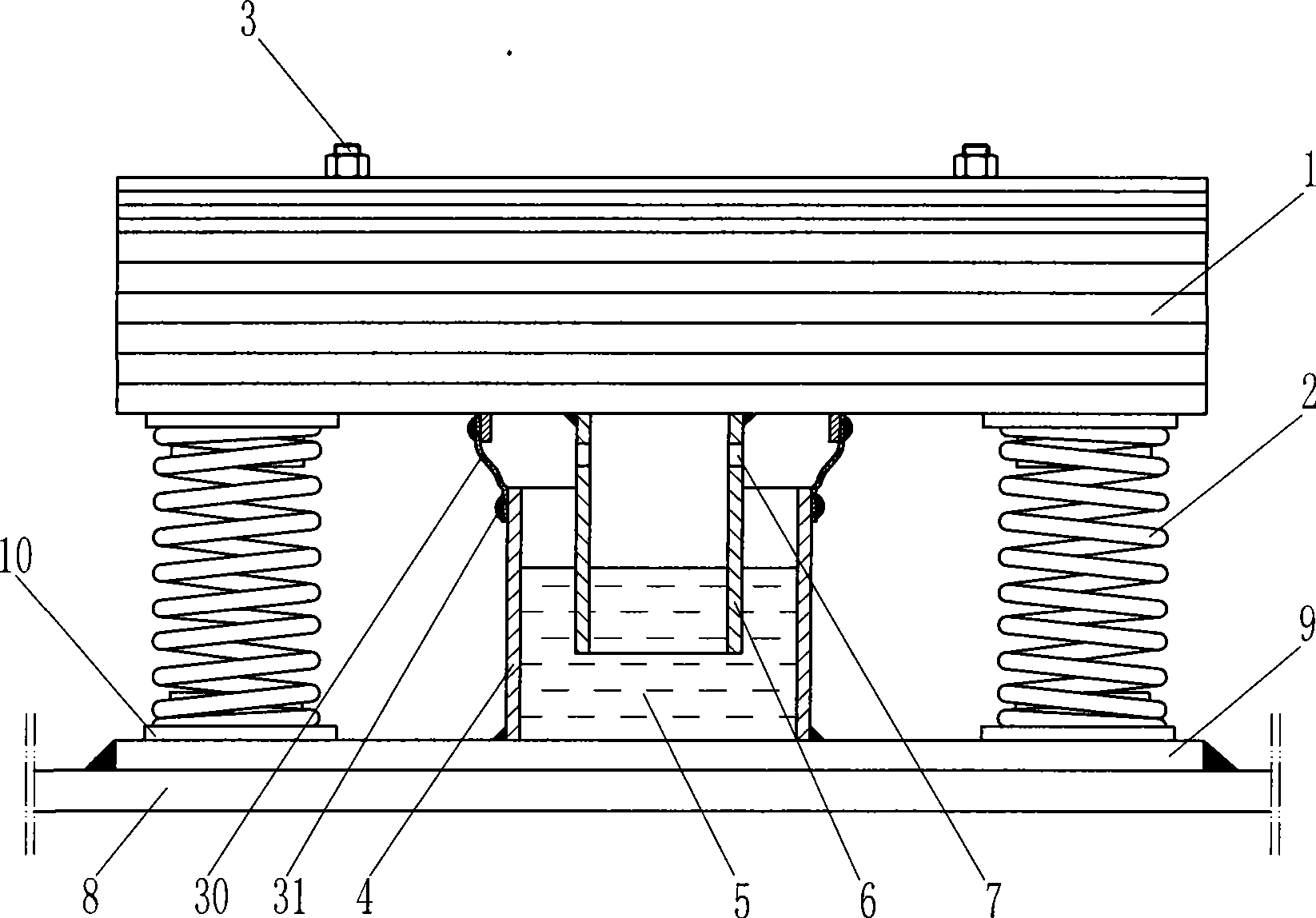

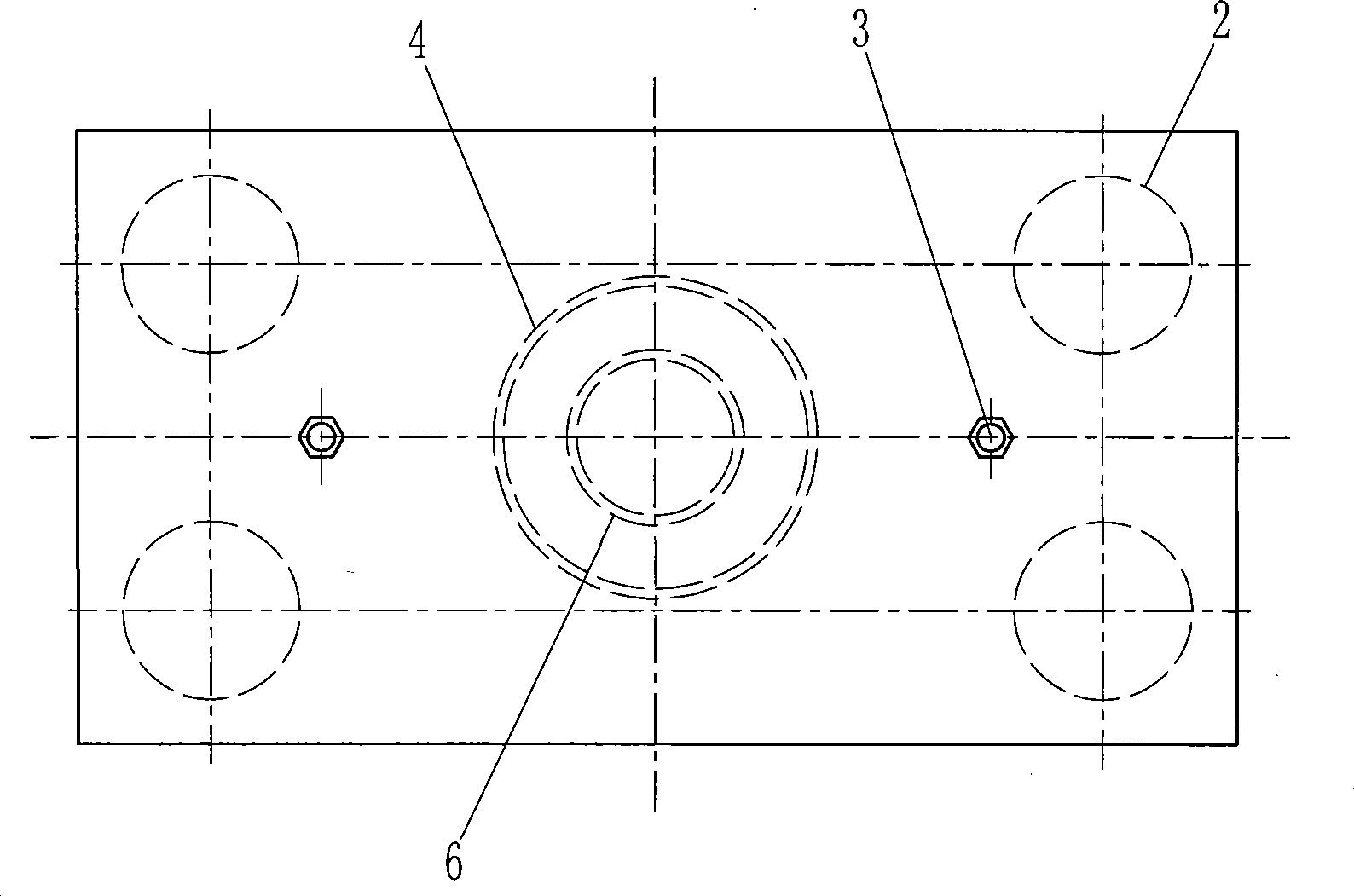

[0029] like figure 1 , figure 2 The tuned mass shock absorber with adjustable damping ratio of the present invention includes a plurality of tuning masses 1, a base 9, four springs 2 and a damper, wherein the spring 2 adopts a helical steel spring, and in order to facilitate the positioning of the spring, the base 9 and the positioning seat 10 are welded on the adjacent mass block of the spring. The damper is an adhesive damper composed of a damping cylinder 4, an adhesive damping fluid 5 (silicon oil here) and a piston 6. The damping cylinder 4 is welded on the base 9, and the adhesive damping fluid 5 is housed in the cylinder. The piston 6 is tubular, its lower end is immersed in the adhesive damping fluid 5, and the upper end of the piston 6 is directly welded to the adjacent tuning mass above it. In order to facilitate the adjustment of the natural frequency of the vibration damping system of the present invention, the tuning mass 1 is combined with multiple steel plate...

Embodiment 2

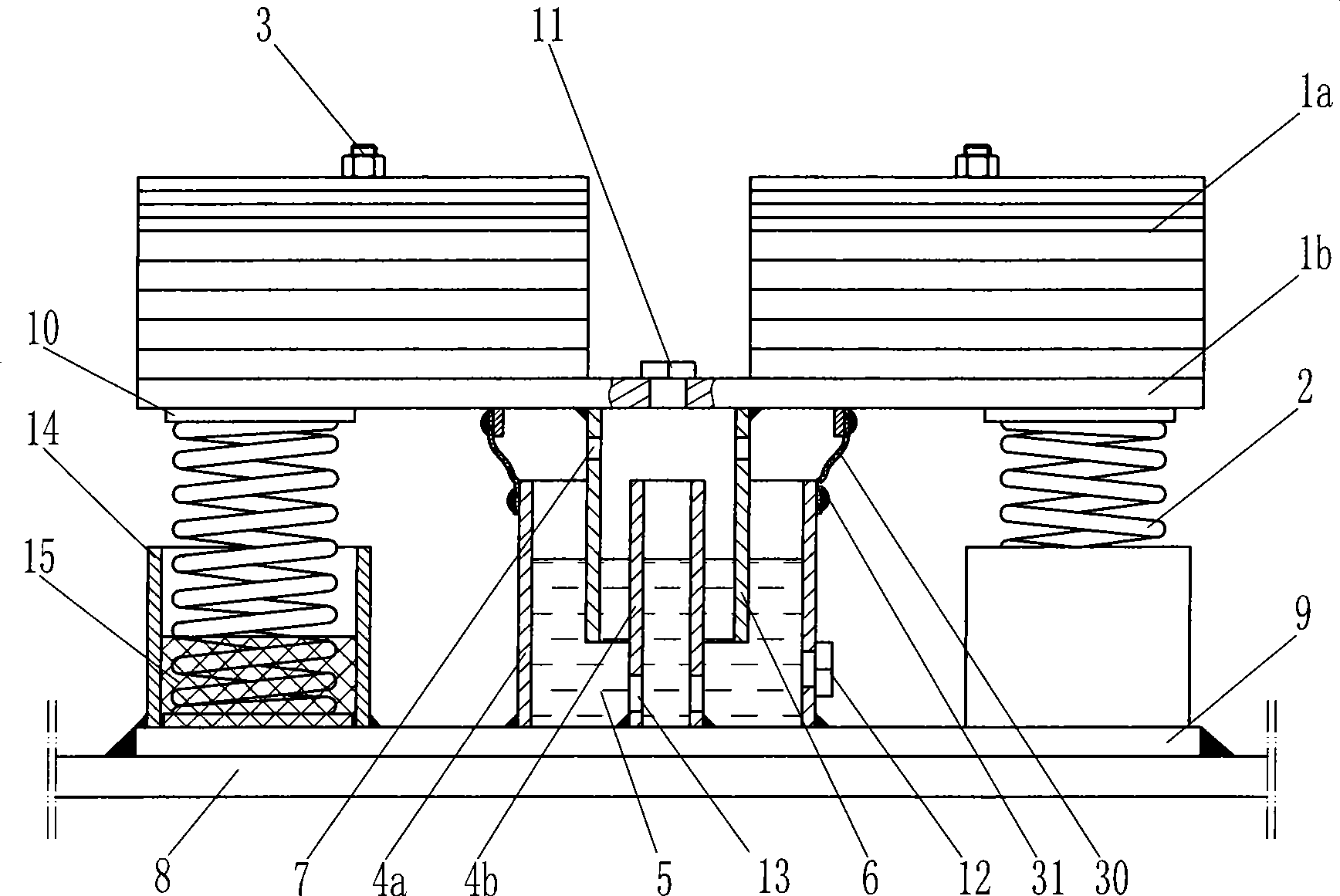

[0034] like image 3 As shown, the difference from the first embodiment is that the tuning mass is arranged in two parts, including the main mass 1b and the adjustment mass 1a symmetrically arranged above the main mass 1b. In order to adjust the damping ratio of the damper conveniently, a damping adjustment device is also provided for the adhesive damper used in the present invention, and the damping adjustment device includes a filling hole and a plug 11 arranged on the main mass 1b and a The drain hole and the plug 12 at the bottom of the damping cylinder 4a. By opening the plug and adding viscous damping fluid or discharging part of the viscous damping fluid, the actual working area of the piston can be changed, thereby achieving the purpose of changing the damping ratio of the damper. A sub-cylinder 4b is added inside the damping cylinder 4a, and the piston 7 cooperates with the damping cylinder 4a and the sub-cylinder 4b at the same time, so as to ensure that the visco...

Embodiment 3

[0038] like Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that, in order to facilitate the adjustment of the damping ratio of the damper, a damping adjustment device is also provided for the adhesive damper used in the present invention, and the damping adjustment device includes a damping adjustment device arranged on the upper part of the damping cylinder 4a The filling hole and the plug 11 and the drain hole and the plug 12 arranged at the lower part of the damping cylinder 4a can change the actual working area of the piston by adding the sticky damping liquid or discharging part of the sticky damping liquid after opening the plug, so that To achieve the purpose of changing the damping ratio of the damper. In order to facilitate accurate adjustment of the natural frequency of the tuned mass shock absorber with adjustable damping ratio of the present invention, a stiffness adjustment device is also provided at the lower end of the spring 2, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com