Eddy current tuned mass damper with adjustable frequency that can be assembled in series

A technology of tuning mass damping and eddy current, applied to bridge parts, bridges, buildings, etc., to achieve the effects of avoiding wear, eliminating frictional damping, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The multi-angle anti-vibration frequency-adjustable eddy current tuned mass damper of this embodiment is used to resist the vertical vibration response of the bridge structure under external loads such as earthquakes, wind, and vehicles, the corresponding horizontal vibration and the three-dimensional vibration of multi-directional combinations response. It includes two parts: cylinder body and damping part.

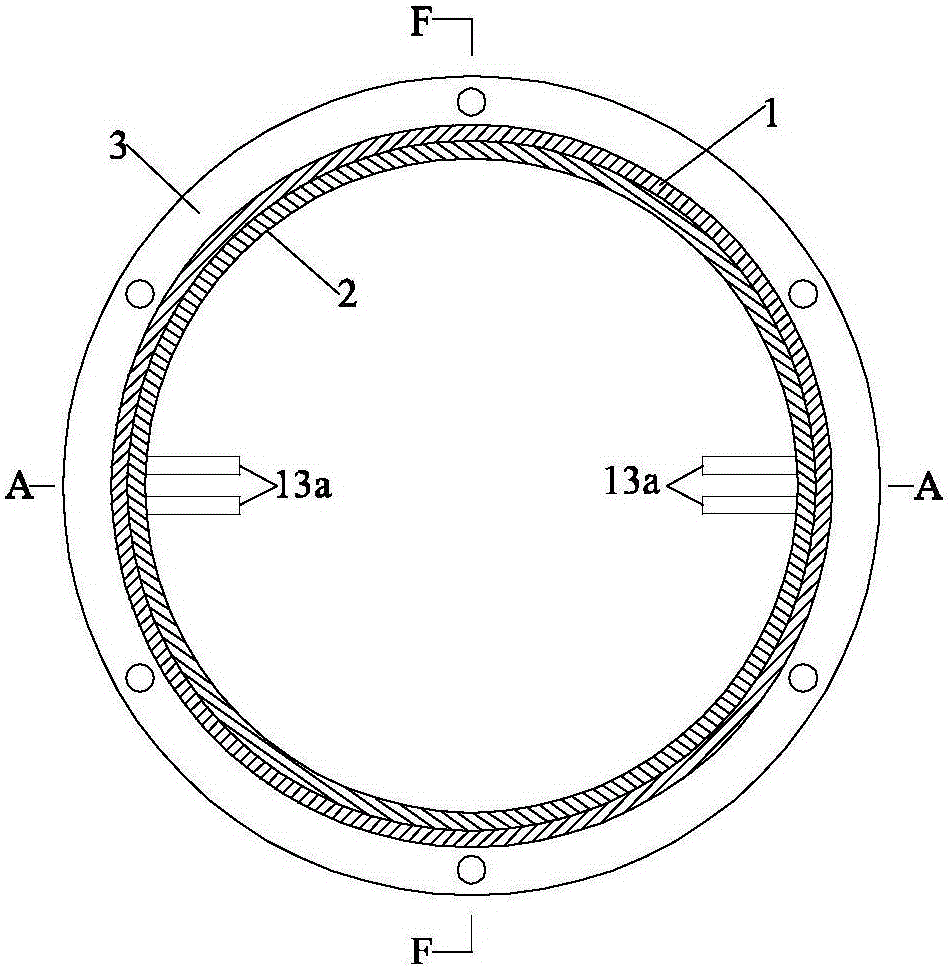

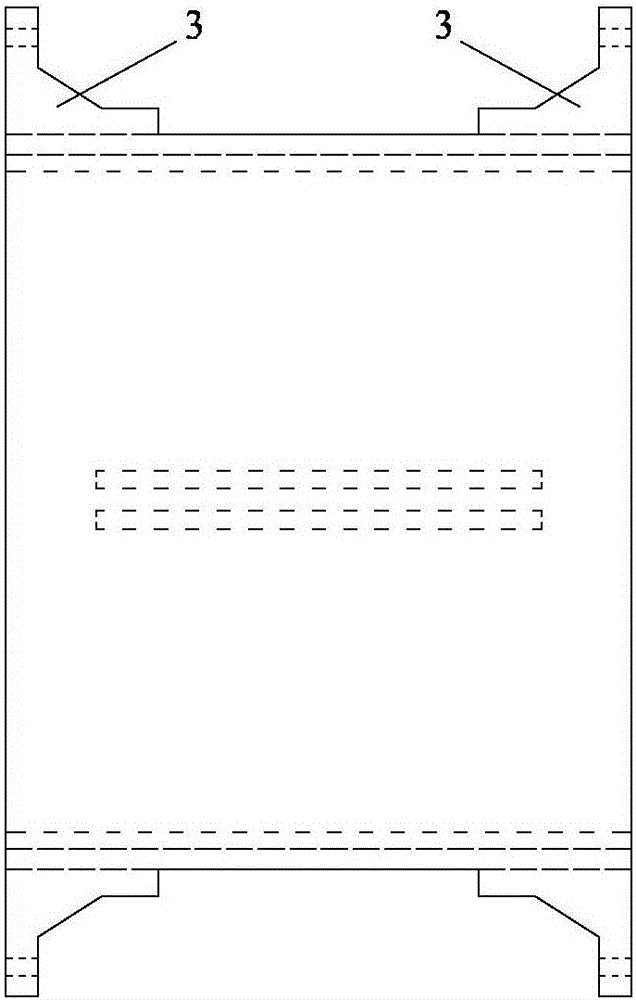

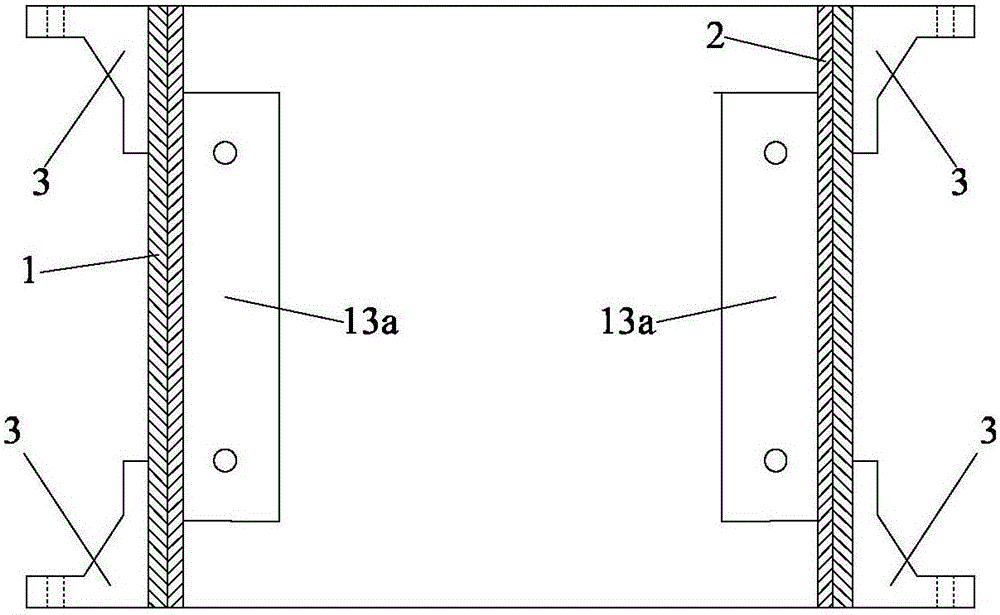

[0047] Barrel such as Figure 1-Figure 4 As shown, it includes outer cylinder 1, inner cylinder 2, flange 3 and connector a13a.

[0048] The damping part is installed inside the cylinder, such as Figure 5-Figure 10 shown. The damping part is composed of bottom plate 4, end vertical plate a5, end vertical plate b6, cover plate 7 and TMD part. The four end vertical plates are installed on the base plate, and form a box together with the base plate. The shape of the end riser a5 is a square, which is slightly smaller than the inscribed square of the inner tube....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com