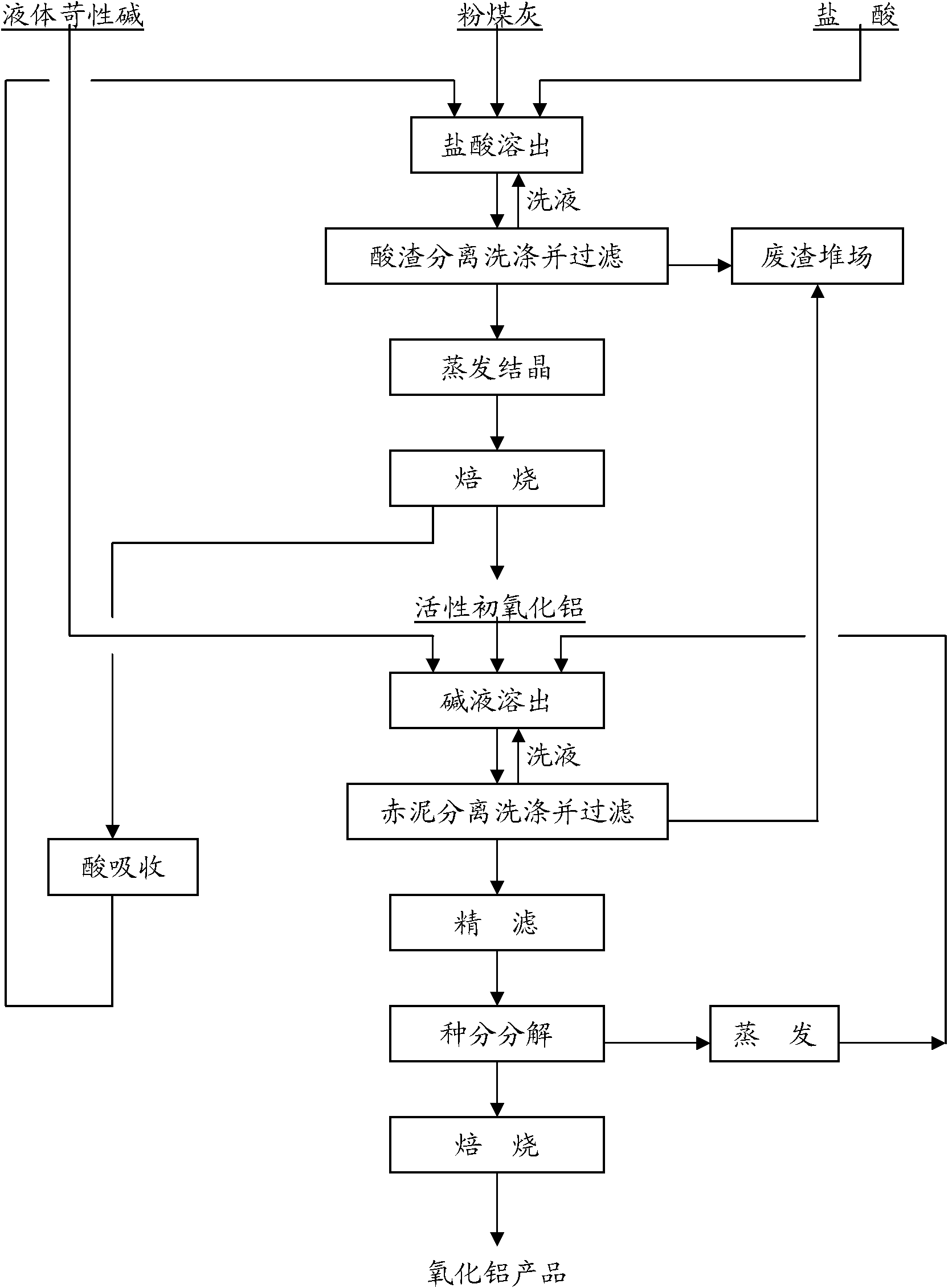

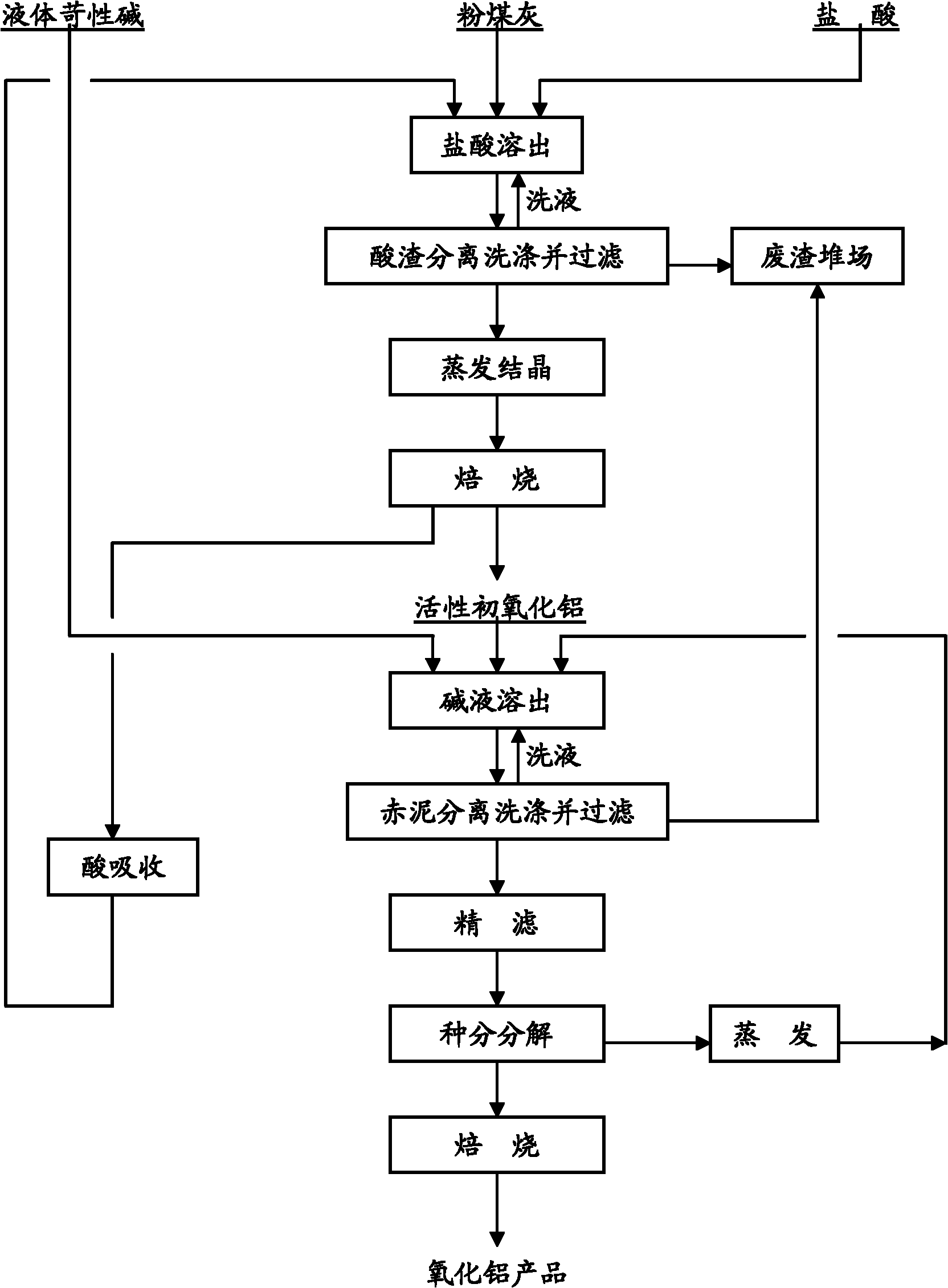

Method for extracting alumina from fly ash

A technology of fly ash and alumina, which is applied to the removal of alumina/hydroxide and solid waste, etc. It can solve the problem that it cannot be used industrially, can only be used for laboratory research, increases the production cost of alumina, and affects the surrounding environment to improve the dissolution effect, facilitate the sedimentation of slag, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] By 85% Al 2 o 3 Dissolution rate calculates the consumption of hydrochloric acid, the high aluminum fly ash (Al 2 o 3 Content 48.2wt%, SiO 2 content of 38.33wt%) and hydrochloric acid with a concentration of 28wt% to make fly ash slurry, sent to the dissolution device lined with polytetrafluoroethylene material, stayed at 150 ° C for 1.5 hours and kept stirring, and the dissolved material Slurry is sent to the settling tank for primary separation, the underflow acid slag from the settling tank enters the washing tank, and reverse washing is carried out 5 times with hot water at 85°C. The dissolved slurry can be diluted, the acid slag after the last washing is filtered through the filter, the filtrate is returned to the washing tank, the water content of the filter cake is controlled to be ≤35wt%, the filter cake is sent to the waste residue yard, and the overflow of the settling tank is sent to Go to the 3-effect forced circulation evaporator, and get AlCl after eva...

Embodiment 2

[0044] By 80% Al 2 o 3 Dissolution rate calculates the consumption of hydrochloric acid, the high aluminum fly ash (Al 2 o 3 Content 42.5wt%, SiO 2 Content 40.38wt%) and concentration are 25wt% hydrochloric acid batching to make fly ash slurry, send to the stripper identical with embodiment 1, stay 2.0 hours under 142 ℃ of conditions and constantly stir, the slurry of stripping Send it to the settling tank for a separation, send the underflow acid slag from the settling tank to the washing tank, and perform 6 reverse washings with 80°C hot water. The amount of hot water added is 2.5t / t of acid slag. The liquid can dilute the dissolved slurry, the acid residue after the last washing is filtered through the filter, the filtrate is returned to the washing tank, the moisture content of the filter cake is controlled to be ≤35wt%, the obtained filter cake is sent to the waste residue yard, and the overflow of the settling tank is sent to Go to the 4-effect forced circulation eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com