Melting solidification integrated method and system for incineration of hazardous wastes and incinerated fly ash

A technology of hazardous waste, melting and solidification, applied in combustion methods, incinerators, combustion types, etc., can solve the problem of high cost of fly ash stabilization and disposal, and achieve the effect of treating waste with waste, social economic benefits, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

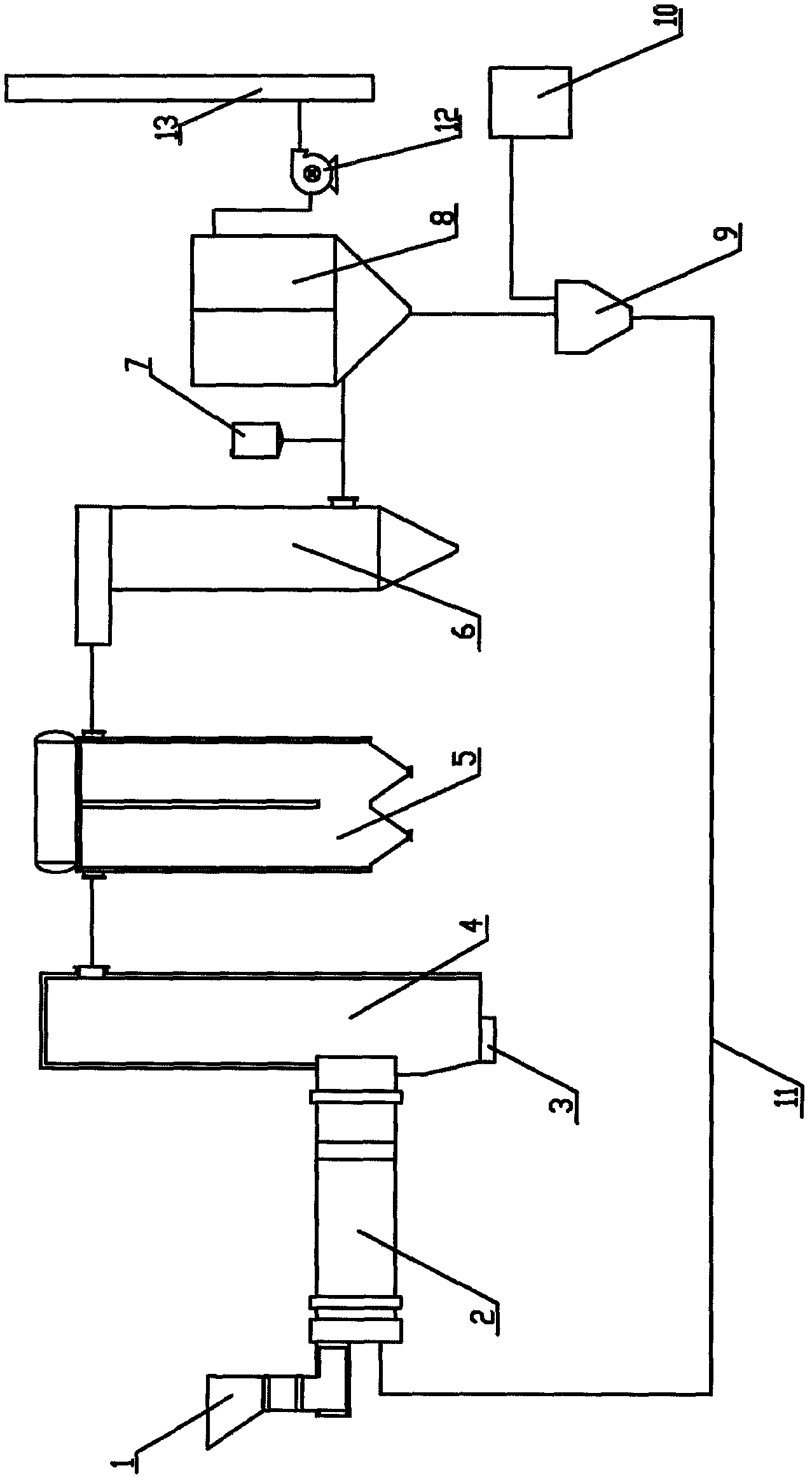

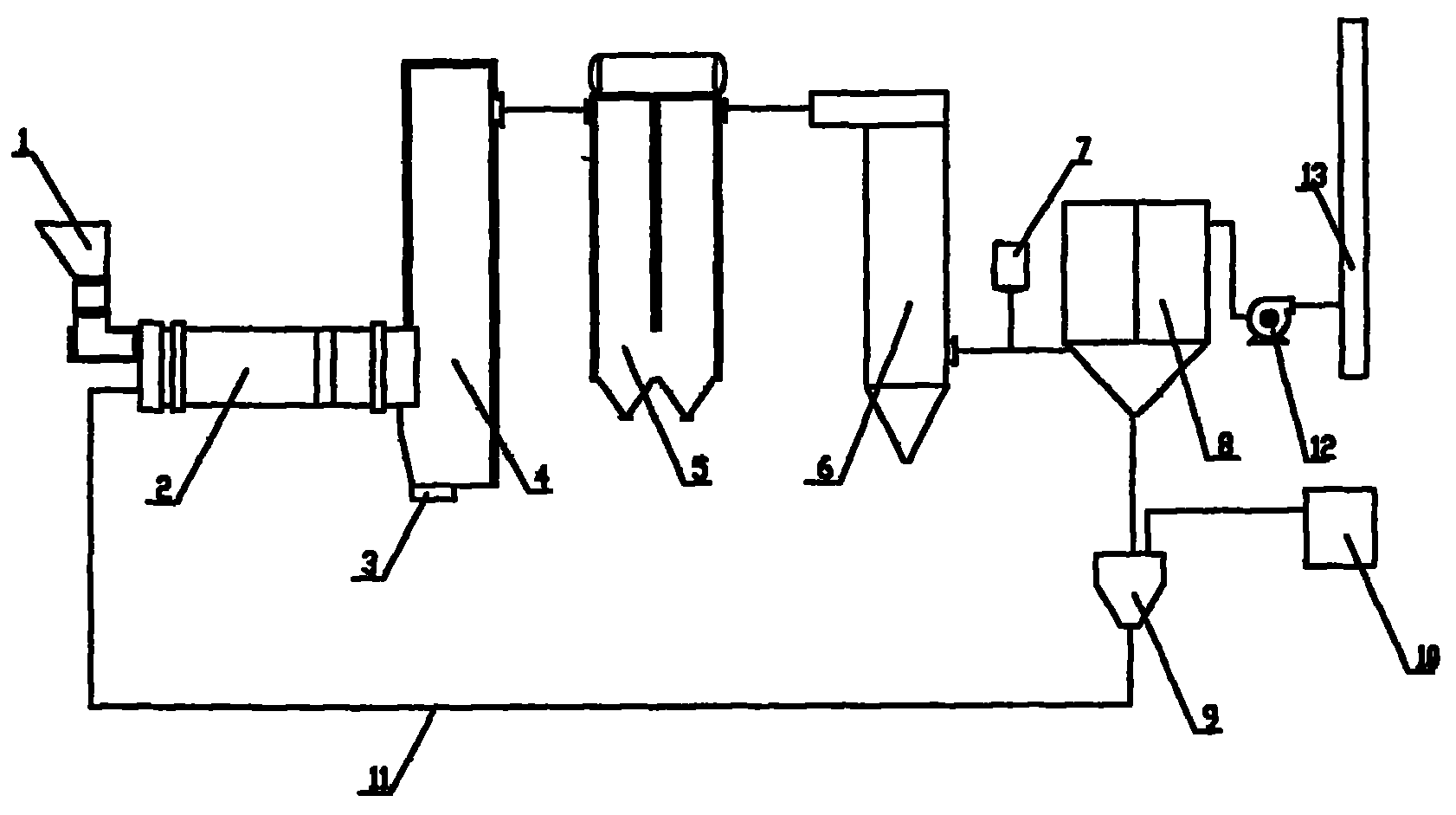

[0021] As shown in the accompanying drawings, an integrated system of hazardous waste incineration and incineration fly ash melting and solidification of the present invention includes a feed hopper 1, a slag type rotary kiln 2, a slag outlet 3, a secondary combustion chamber 4, a waste heat boiler 5, a quenching Deacidification tower 6, activated carbon injection adsorption device 7, bag filter 8, warehouse pump 9, air compressor 10, fly ash return pipeline 11, induced draft fan 12 and chimney 13; the feed port of slag type rotary kiln 2 and The feed hopper 1 is connected, the flue gas outlet of the slag-type rotary kiln 2 is connected with the second combustion chamber 4, the second combustion chamber 4 is connected with the waste heat boiler 5, the outlet of the waste heat boiler 5 is connected with the rapid cooling deacidification tower 6, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com