Method of preparing nano hydroxyl zinc stannate and nano zinc stannate

A zinc hydroxystannate, nanotechnology, applied in chemical instruments and methods, zinc compounds, tin compounds, etc., can solve the problems of high price and difficult application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

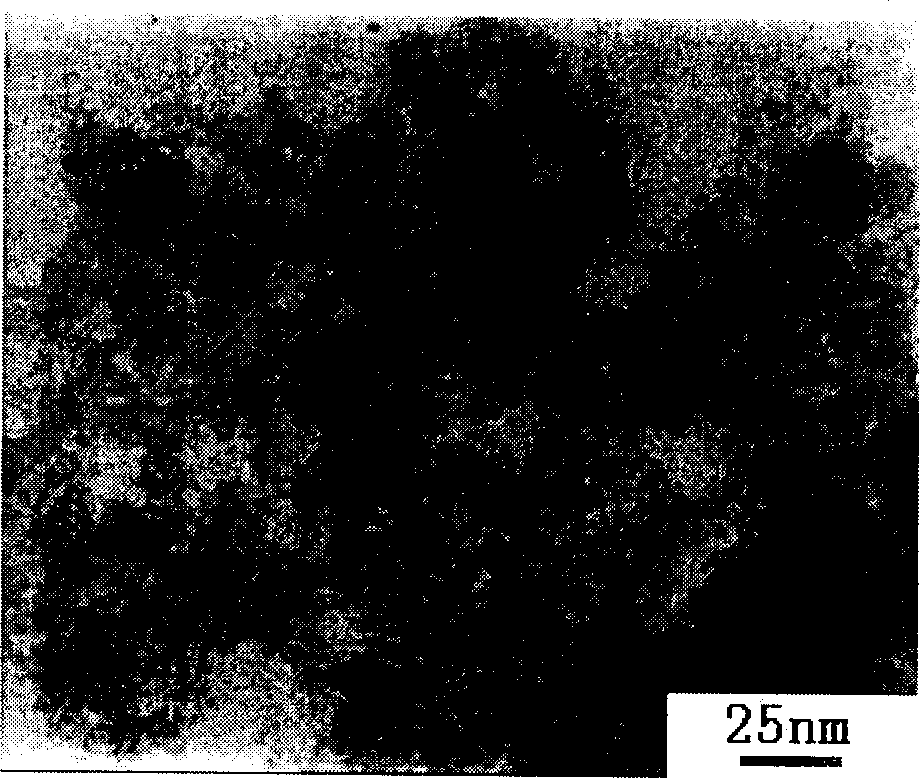

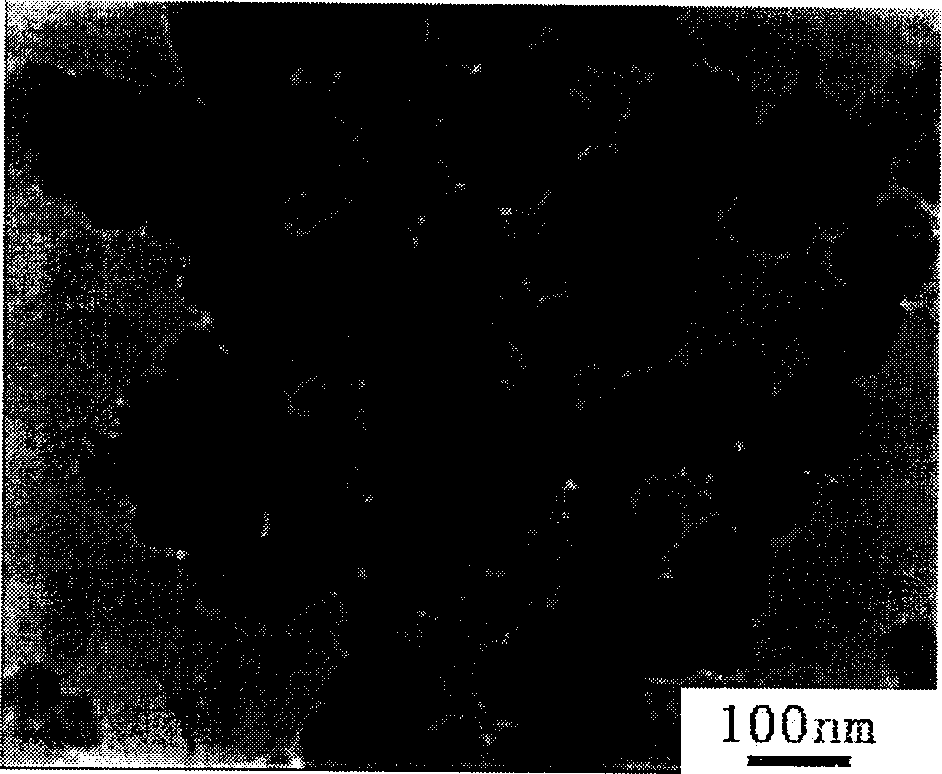

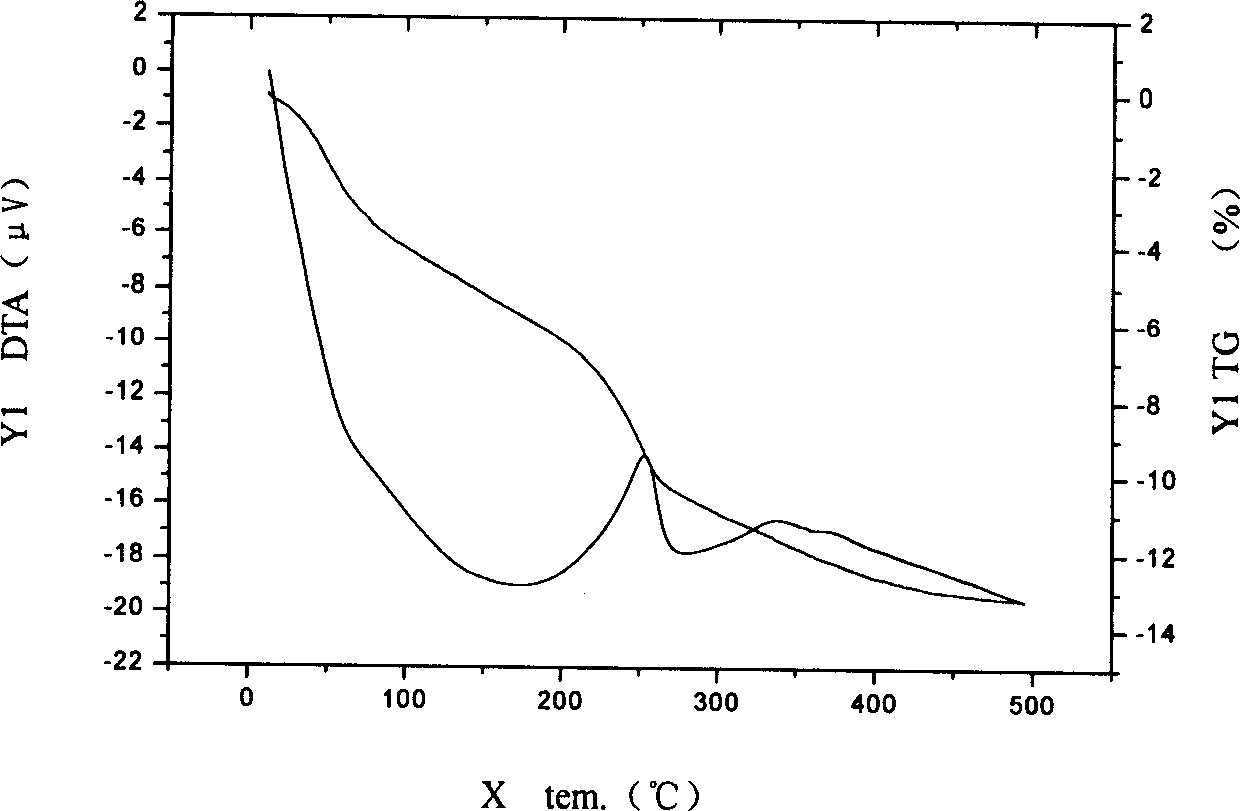

Embodiment 1

[0019] Embodiment 1, 0.9g tin tetrachloride pentahydrate and 0.4g zinc chloride are dissolved in the 0.5moL / L hydrochloric acid solution of 10mL, add distilled water and dilute to 120mL, then add the content of 20mL and be 28% hydrogen peroxide aqueous solution , under the condition of stirring, dropwise add 0.5moL / L sodium hydroxide solution, adjust the pH value to about 8, after the dropwise addition, raise the temperature to 90°C, and react with temperature control for 5 hours, and filter and wash the white precipitate until it is washed with 0.2 moL / L of AgNO 3 Solution test without Cl - After ionization, the precipitate was dispersed into 40 mL of n-butanol and azeotropically distilled. The product obtained by azeotropic distillation was dried at 105° C. for 3 hours to obtain amorphous nano-sized zinc hydroxystannate. The product was burned in a horse boiling furnace at 500°C for 5 hours to obtain amorphous nanometer zinc stannate.

Embodiment 2

[0020] Example 2. Dissolve 0.9g tin tetrachloride pentahydrate and 0.85g zinc sulfate heptahydrate in 10mL of 0.5moL / L hydrochloric acid solution, add distilled water to dilute to 120mL, and add 0.5moL / L hydrogen dropwise under stirring Sodium oxide solution, adjust the pH value to about 8. After the dropwise addition, raise the temperature to 70°C, and control the temperature for 3 hours. The obtained white precipitate is filtered and washed with distilled water until it is washed with 0.5mol / L BaCl 2 Solution test without SO 4 2- ion so far. The precipitate was dispersed in 40 mL of methanol and azeotropically distilled. The product obtained by azeotropic distillation was dried at 120° C. for 3 hours to obtain nano-hydroxyzinc stannate. The product was burned in a horse boiling furnace at 500°C for 5 hours to obtain nanometer zinc stannate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com