Preparation method of general-purpose multi-metal sulfide nano-material

A multi-metal and nanomaterial technology, applied in the field of nanomaterials, can solve the problems of difficult to control size and valence state, low product phase state purity, harsh preparation conditions, etc., to achieve uniform and controllable morphology and size, and easy control of reaction conditions. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

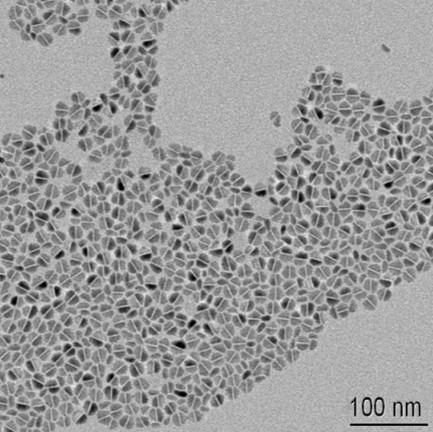

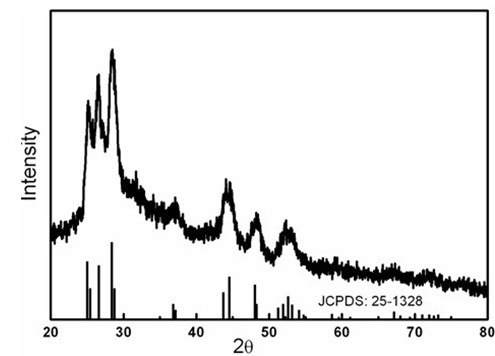

[0023] Example 1: Orthorhombic AgInS 2 Synthesis of Nanomaterials. Weigh 0.05mmol of silver diethyldithiocarbamate and 0.05mmol of indium diethyldithiocarbamate as raw materials, and dissolve them into a three-necked flask containing a mixed solvent of dodecanethiol and oleic acid (15g:7g) In the process, vacuumize at room temperature and keep it for 10 minutes, then raise the temperature to 200°C under an inert atmosphere and keep it for 2 hours. Finally, after the solution is naturally cooled to room temperature, add an appropriate amount of absolute ethanol, centrifuge, wash and dry, and the obtained red powder material is dispersed. In polar solvents, with a transmission electron microscope (eg figure 1 shown) and by X-ray diffraction (as figure 2 shown) confirmed that the obtained red powder material is orthorhombic AgInS 2 nanomaterials.

Embodiment 2

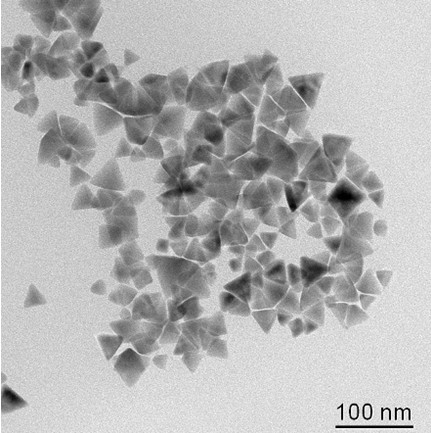

[0024] Example 2: Cu 12 Sb 4 S 13 Synthesis of Nanomaterials. Weigh 0.05mmol copper diethyldithiocarbamate and 0.1mmol antimony diethyldithiocarbamate as raw materials, and dissolve them into a three-necked flask filled with a mixed solvent of dodecanethiol and oleylamine (20mmol: 20mmol) In the process, vacuumize at 120°C and keep it for 15 minutes, then raise the temperature to 220°C under an inert atmosphere and keep it for 0.5 hours. Finally, after the solution is naturally cooled to room temperature, add an appropriate amount of absolute ethanol, centrifuge, wash and dry, and the obtained powder material is dispersed in In polar solvents, use a transmission electron microscope (e.g. image 3 shown) and confirmed by X-ray diffraction that the obtained red powder substance is Cu 12 Sb 4 S 13 nanomaterials.

Embodiment 3

[0025] Example 3: Orthorhombic AgBiS 2 Synthesis of Nanomaterials. Weigh 0.1mmol of silver diethyldithiocarbamate and 0.1mmol of bismuth diethyldithiocarbamate as raw materials, and dissolve them in a three-port container containing a mixed solvent of octadecylamine and octadecene (20mmol: 20mmol). Vacuumize the flask at 100°C for 20 minutes, then raise the temperature to 240°C for 1 hour under an inert atmosphere, and finally cool the solution to room temperature naturally, add an appropriate amount of hot absolute ethanol, centrifuge, wash and dry, and the obtained black Powdered substances dispersed in polar solvents were examined by transmission electron microscopy (eg Figure 4 shown) and by X-ray diffraction, it was confirmed that the obtained black powder material was orthorhombic phase AgBiS 2 nanomaterials. Such as Figure 5 As shown, the obtained nanomaterials have good optical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com