Sn-Co/C alloy cathode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and alloy negative electrodes, applied in the field of electrochemistry, can solve problems such as unfavorable environmental protection, atmospheric pollution, and difficult reduction by thermal carbon reduction, and achieve the effects of convenient operation, prevention of pulverization, and increase of electrode capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

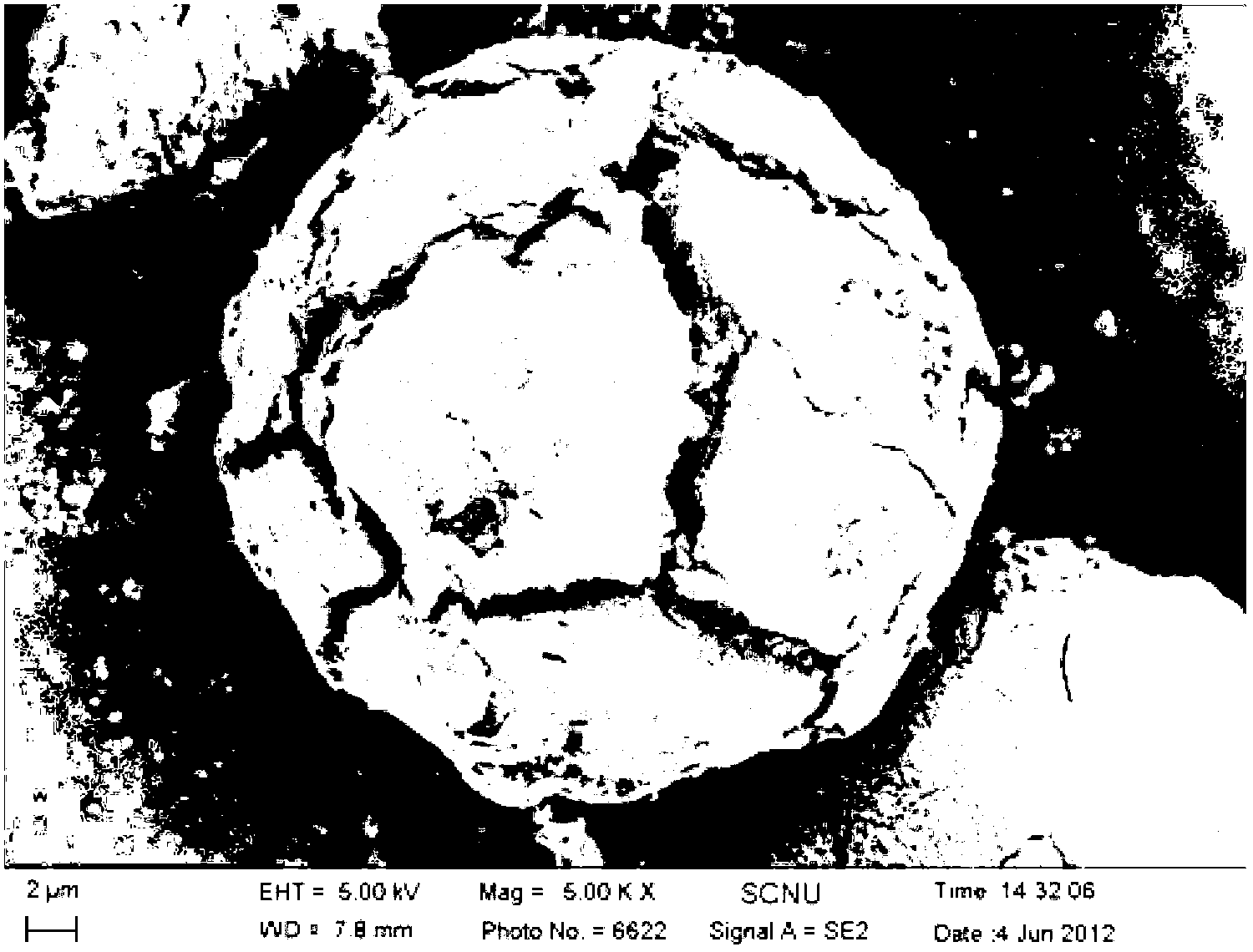

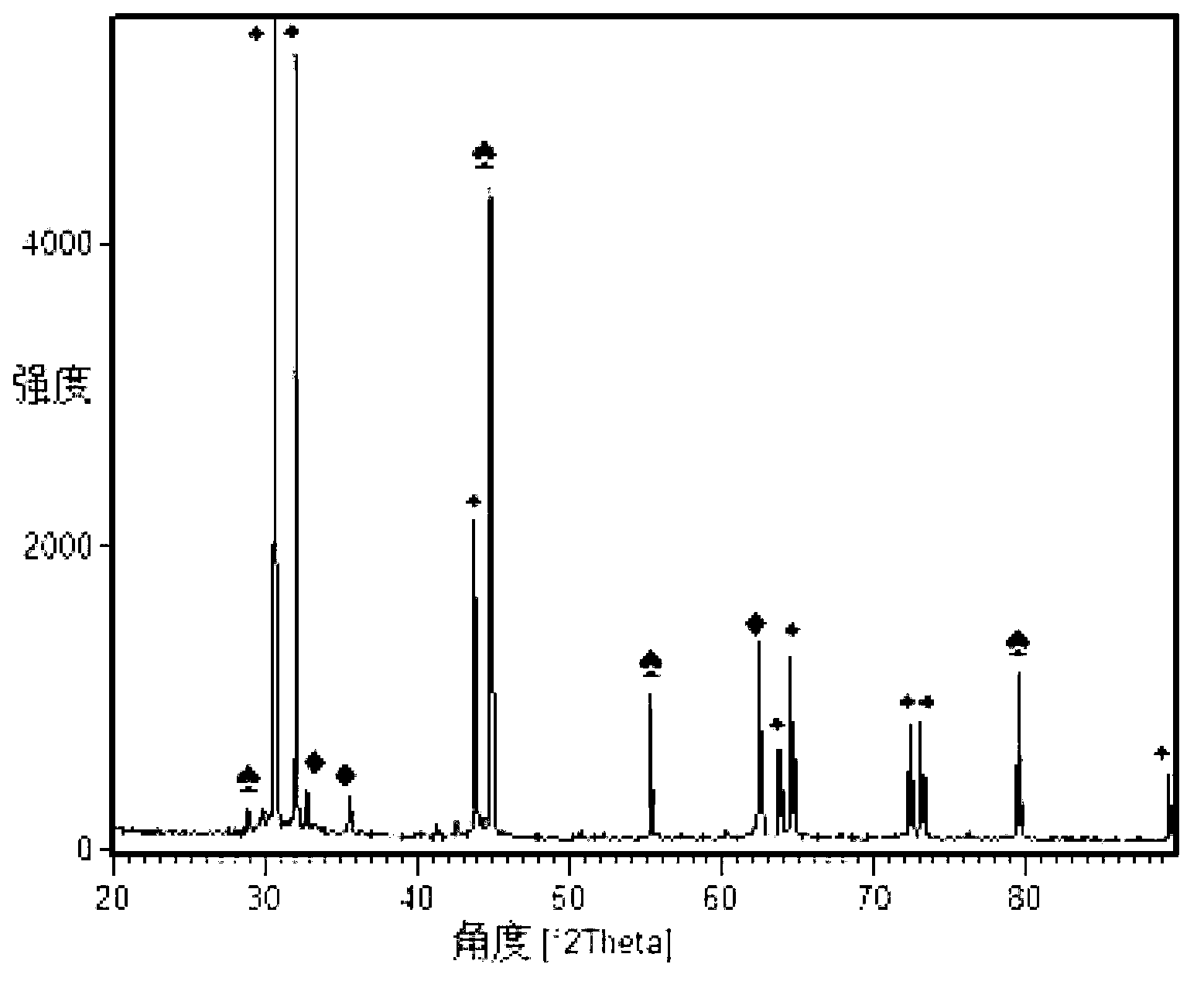

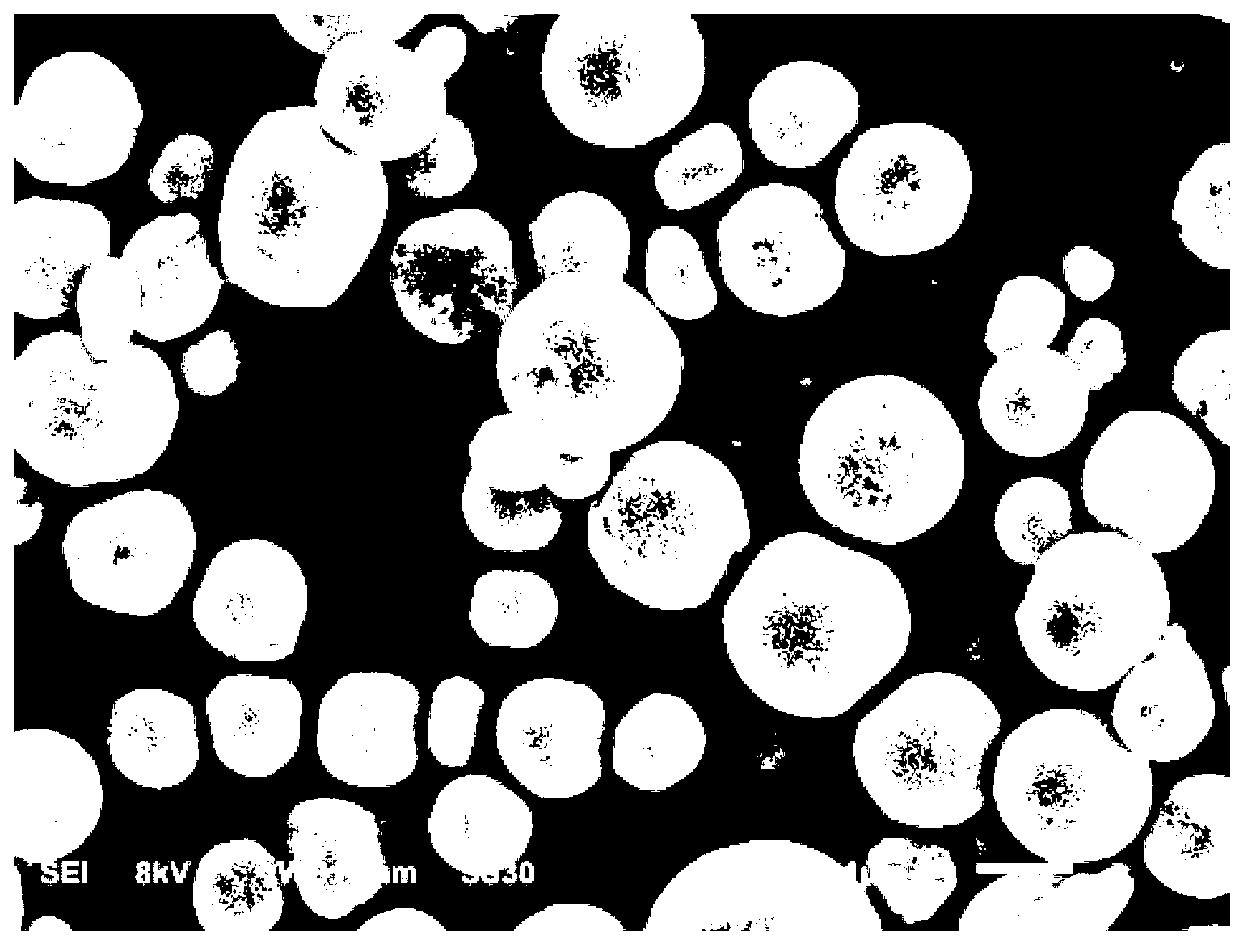

[0051](1) Mix 5.94g of 10μm Sn powder and 0.06g of Co powder evenly, put it into a melting furnace (Guangdong Hengyang Electric Furnace Manufacturing Co., Ltd., GW-30T; the same below.) and vacuumize, melt at 700°C for 1.5h and then transfer Enter the spray tower (Keyi Split Materials Co., Ltd., Gedian Development Zone, Hubei Province, one-way throwing centrifugal spray powder mill; the same below.) for centrifugal spraying, the centrifugal speed is 2000r / min, and finally cool at the discharge port Collect and cool at 53°C to obtain a Sn-Co composite material;

[0052] (2) Add 6g of the Sn-Co composite material in step (1) into 66.6ml, 1mol / L nitric acid solution for acid treatment for 5 hours to obtain the acid-treated Sn-Co material;

[0053] (3) Pour 9.3g of citric acid into 30ml of absolute ethanol for full dissolution, then add 4.2g of the Sn-Co material in step (2), stir evenly, dry in a blast oven at 60°C for 2 hours, then vacuum dry at 50°C 24h, obtain dry material A;...

Embodiment example 2

[0060] (1) Mix 5.88g of 20μm Sn powder and 0.12g of Co powder evenly, put it into the melting furnace and vacuumize it, melt it at 1000℃ for 0.5h, then transfer it to the spray tower for centrifugal spraying, the centrifugal speed is 1000r / min, and finally The feed port is cooled and collected, and the cooling temperature is 10°C to obtain the Sn-Co composite material;

[0061] (2) Add 6g of the Sn-Co composite material in step (1) into 33.3ml, 2mol / L nitric acid solution for acid treatment for 3 hours to obtain the acid-treated Sn-Co material;

[0062] (3) Pour 14.82g of citric acid into 30ml of absolute ethanol for full dissolution, then add 4.2g of the Sn-Co material in step (2), stir evenly, dry in a blast oven at 60°C for 2 hours, then vacuum dry at 90°C 10h, obtain dry material A;

[0063] (4) Place the dried material A in step (3) in a tube furnace, raise the temperature at 2°C / min under the protection of nitrogen, and sinter at 400°C for 5 hours to complete a carbon c...

Embodiment example 3

[0068] (1) Mix 5.88g of 100μm Sn powder and 0.12g of Co powder evenly, put it into the melting furnace and vacuumize it, melt it at 800°C for 2 hours, then transfer it to the spray tower for centrifugal spraying, the centrifugal speed is 2000r / min, and finally discharge The mouth is cooled and collected, and the cooling temperature is 100 ° C to obtain a Sn-Co composite material;

[0069] (2) Add 6g of the Sn-Co composite material in step (1) into 22.2ml, 3mol / L hydrochloric acid solution for acid treatment for 2 hours to obtain the acid-treated Sn-Co material;

[0070] (3) Pour 9.3g of citric acid into 30ml of absolute ethanol for full dissolution, then add 4.2g of the Sn-Co material in step (2), stir evenly, dry in a blast oven at 60°C for 2 hours, and then vacuum dry at 60°C 20h, obtain dry material A;

[0071] (4) Place the dried material A in step (3) in a tube furnace, heat up at 4°C / min under the protection of nitrogen, and sinter at 400°C for 5h to complete a carbon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com