Preparation method of binder-free lithium ion battery negative electrode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, electrode manufacturing, electrode forming, etc., can solve the problems of unobvious charge and discharge potential platform, affect the popularization and application of materials, and poor conductivity, and achieve good charge and discharge cycle Performance, low production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below through preferred specific embodiments.

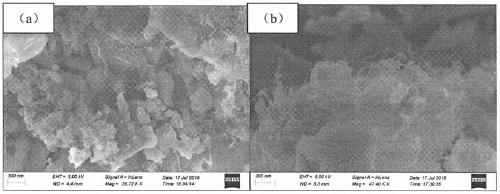

[0013] In the embodiment of the present invention, the scanning electron microscope characterization and analysis of the electrode material of the silicon-based lithium-ion battery hybrid structure is carried out by the Zeiss Sigma-500 electron scanning electron microscope.

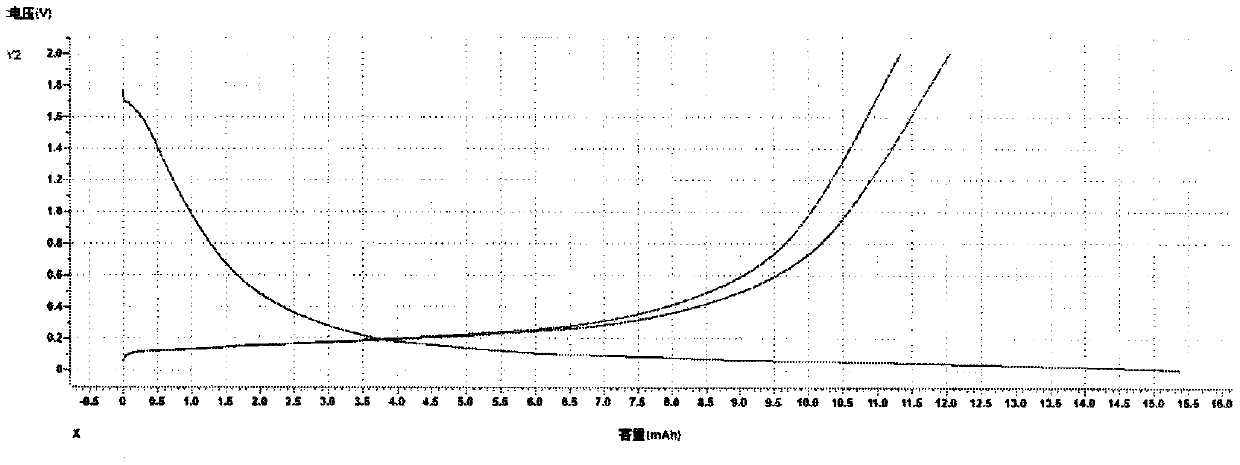

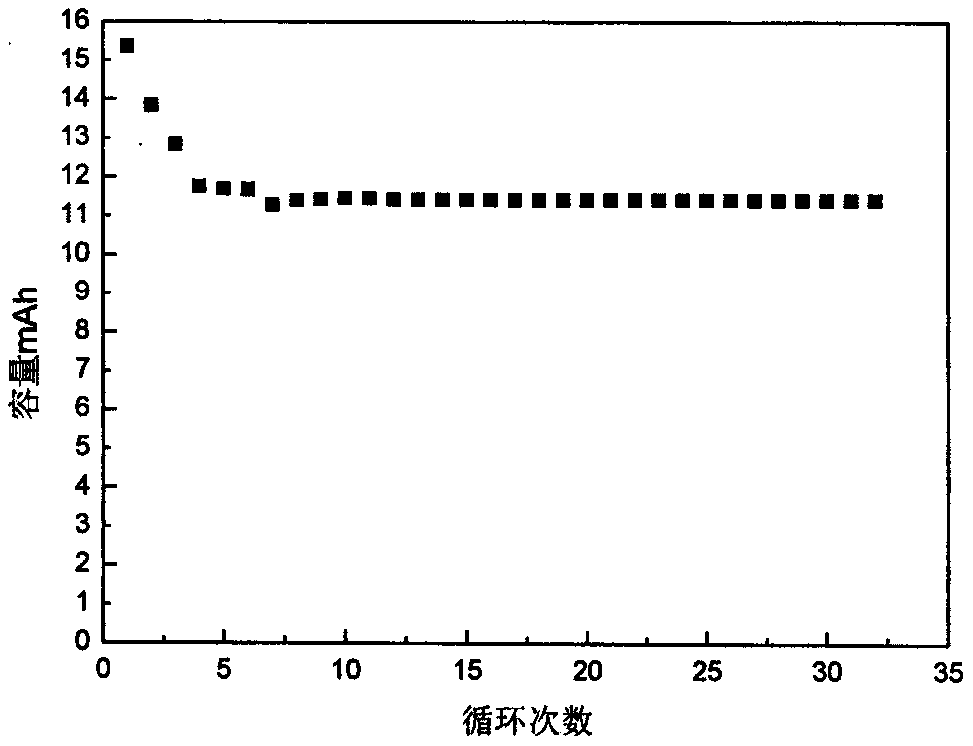

[0014] In the embodiment of the present invention, the electrical cycle performance test of the electrode material of the hybrid structure of the silicon-based lithium ion battery adopts the electrochemical comprehensive analysis tester of Shenzhen Xinwei Company for analysis and testing.

[0015] A method for preparing a binder-free lithium ion battery negative electrode material is characterized in that it comprises the following steps:

[0016] Step 1. Under the protection of argon gas, take the waste silicon powder produced by the single crystal truncation and sinter it directly at 800°C for 2 hours, then bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com