A kind of preparation method of binderless lithium ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insignificant charge-discharge potential platform, volume expansion, and high electrode potential, and achieve good charge-discharge cycle performance and high electrical conductivity. rate and specific capacity, the effect of increasing electrode capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

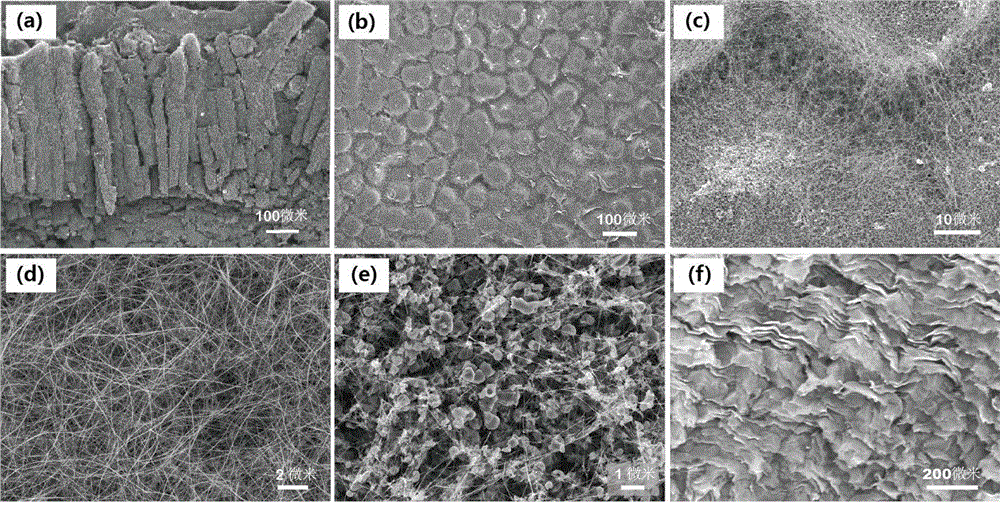

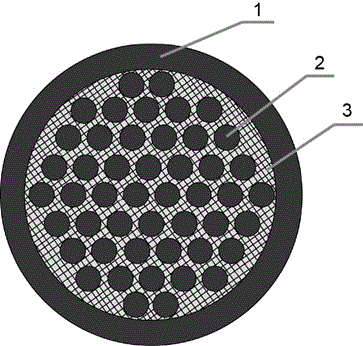

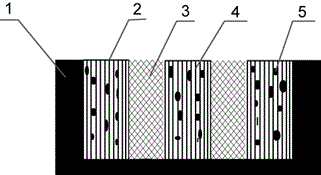

Embodiment 1

[0028] Place two pure graphite rods with diameters of 8 and 10 mm vertically or horizontally in the arc discharge chamber, the graphite rod with the smaller diameter is used as the anode, and the graphite rod with the larger diameter is used as the cathode; Contact arcing discharge, adjust the discharge current to 60A, and keep the current constant; after 5 minutes of arc discharge, a cylindrical object (that is, a circular cake-shaped multi-walled carbon nanotube-graphite sheet mixed structure) is deposited on the surface of the cathode graphite rod Electrode material), the electrode material with a thickness of about 3~5mm prepared by the arc discharge method is cut into a thin sheet with a thickness of 1~2mm, and then placed in the air atmosphere Heat treatment at 700°C for 15 minutes. Assemble the CR2016 button cell in a glove box with a high-purity argon inert atmosphere, in which the counter electrode is a lithium sheet, and the electrolyte is 1mol / LLiPF 6 Ethylene carb...

Embodiment 2

[0030] Place two pure graphite rods with diameters of 8 and 10 mm vertically or horizontally in the arc discharge chamber, the graphite rod with the smaller diameter is used as the anode, and the graphite rod with the larger diameter is used as the cathode; Contact arcing discharge, adjust the discharge current to 80A, and keep the current constant; after 3 minutes of arc discharge, a cylindrical object (that is, a circular cake-shaped multi-walled carbon nanotube-graphite sheet mixed structure) is deposited on the surface of the cathode graphite rod Electrode material), the electrode material with a thickness of about 3~5mm prepared by the arc discharge method is cut into a thin sheet with a thickness of 1~2mm, and then placed in the air atmosphere Heat treatment at 750 degrees Celsius for 15 minutes. Assemble the CR2016 button cell in a glove box with a high-purity argon inert atmosphere, in which the counter electrode is a lithium sheet, and the electrolyte is 1mol / LLiPF 6...

Embodiment 3

[0032] Place two pure graphite rods with diameters of 8 and 10 mm vertically or horizontally in the arc discharge chamber, the graphite rod with the smaller diameter is used as the anode, and the graphite rod with the larger diameter is used as the cathode; Contact arcing discharge, adjust the discharge current to 100A, and keep the current constant; after 2 minutes of arc discharge, a cylindrical object (that is, a circular cake-shaped multi-walled carbon nanotube-graphite sheet mixed structure) is deposited on the surface of the cathode graphite rod Electrode material), the electrode material with a thickness of about 3~5mm prepared by the arc discharge method is cut into a thin sheet with a thickness of 1~2mm, and then placed in the air atmosphere Heat treatment at 800 degrees Celsius for 15 minutes. Assemble the CR2016 button cell in a glove box with a high-purity argon inert atmosphere, in which the counter electrode is a lithium sheet, and the electrolyte is 1mol / LLiPF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com