Patents

Literature

36results about How to "Reduce installation spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

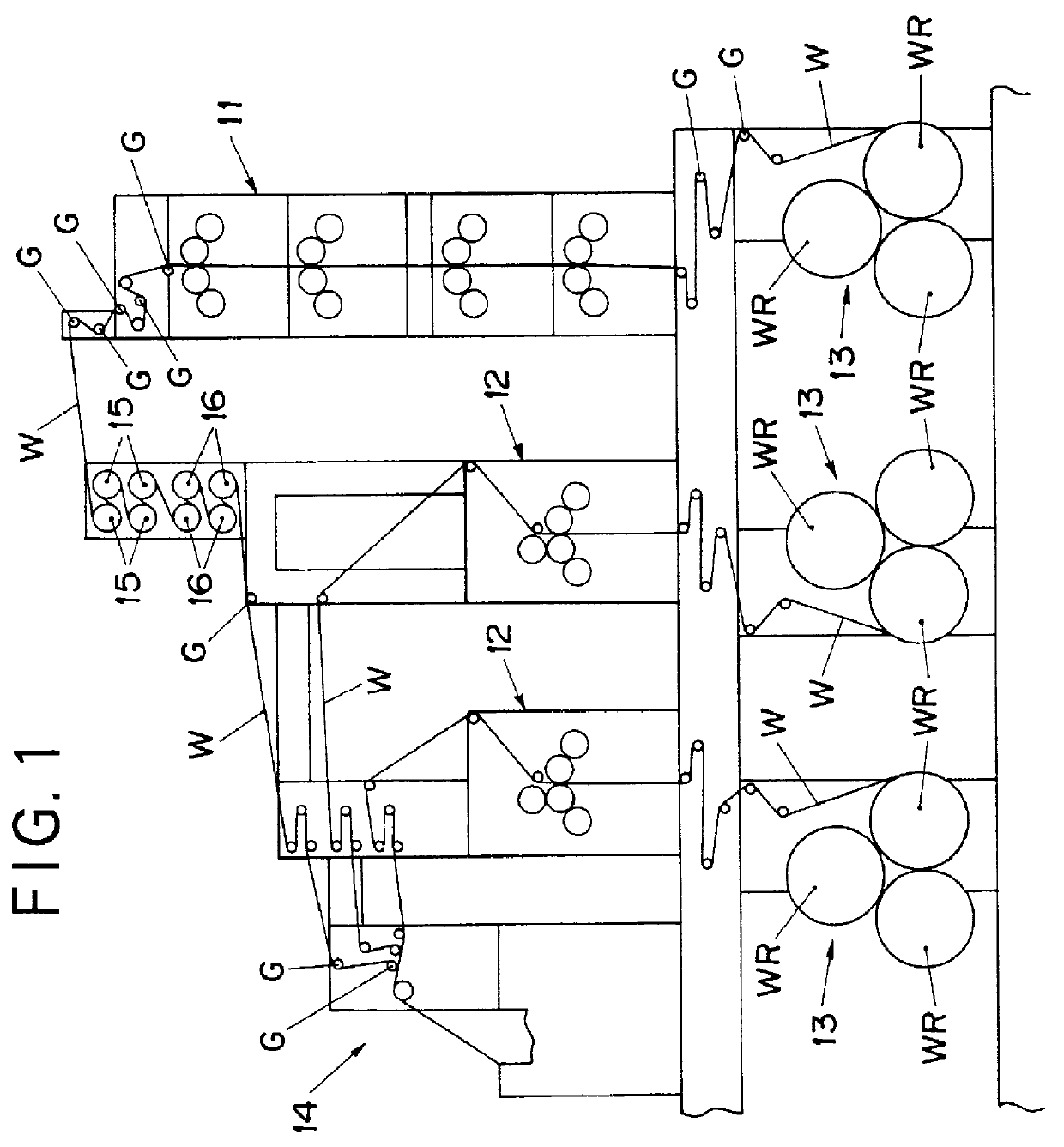

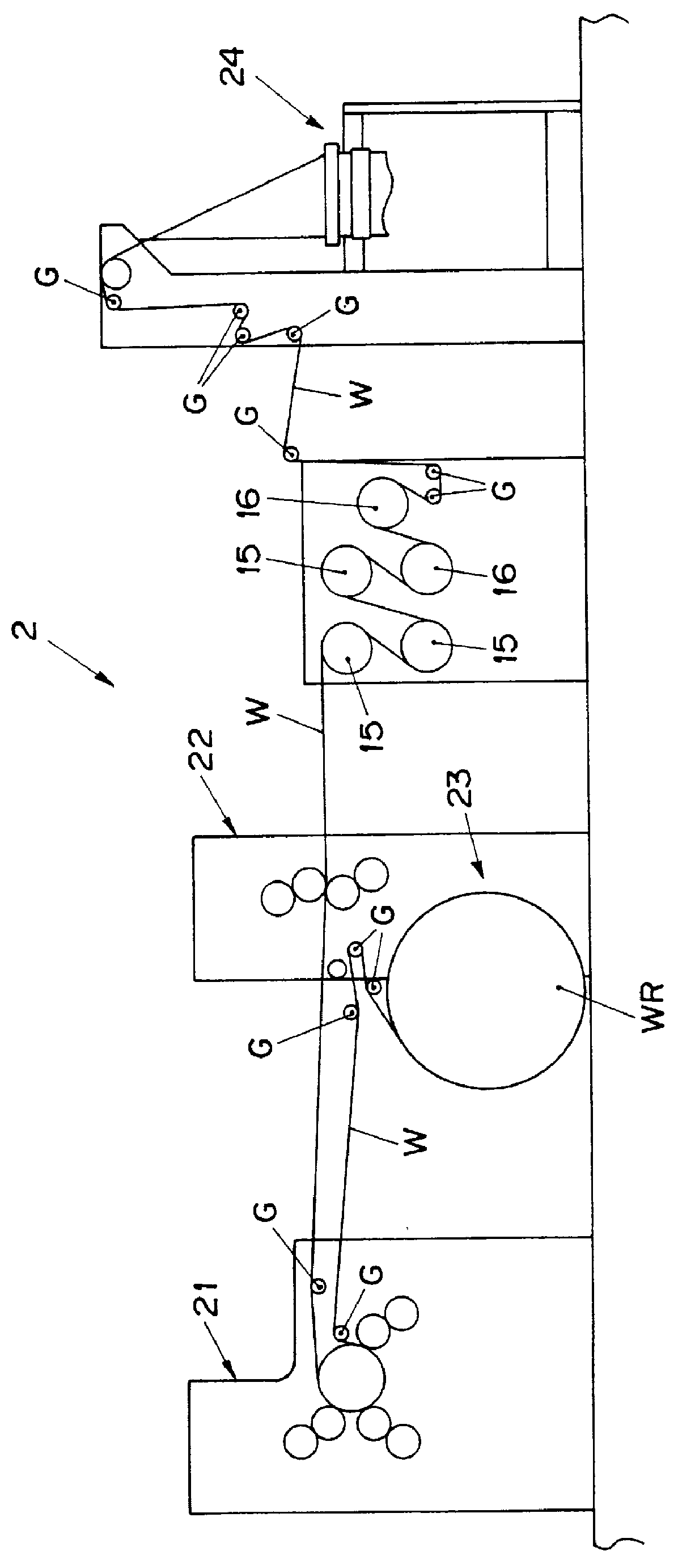

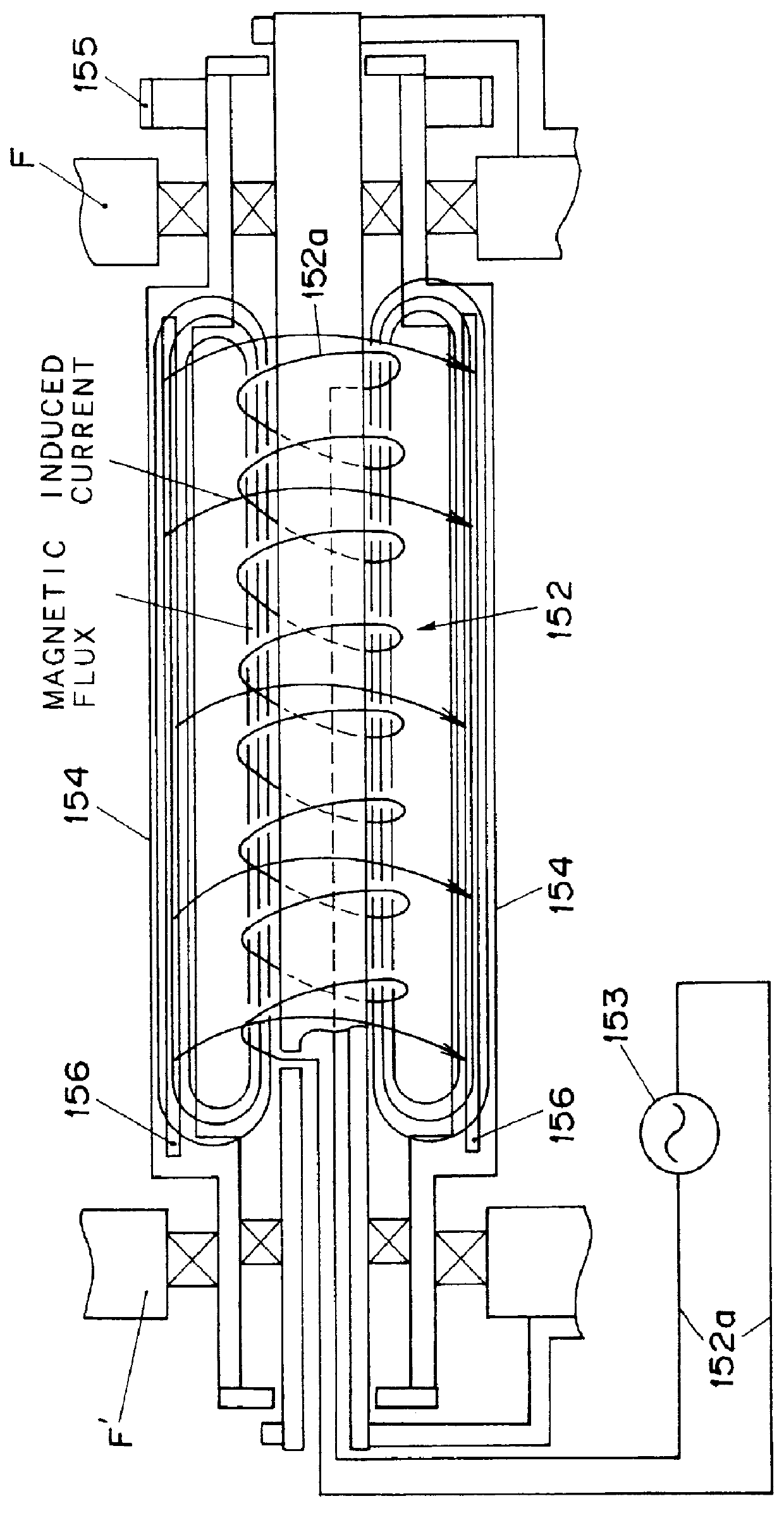

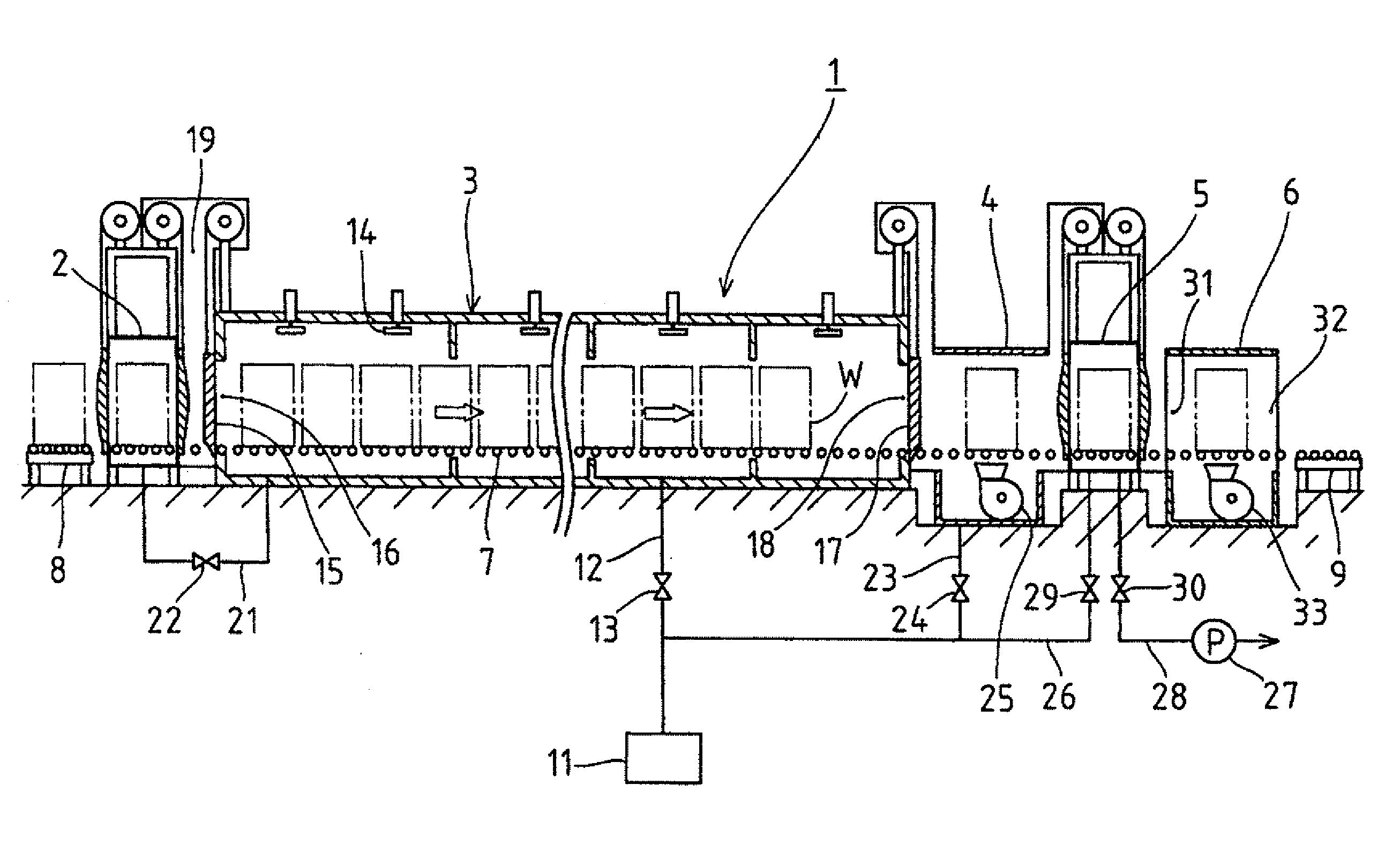

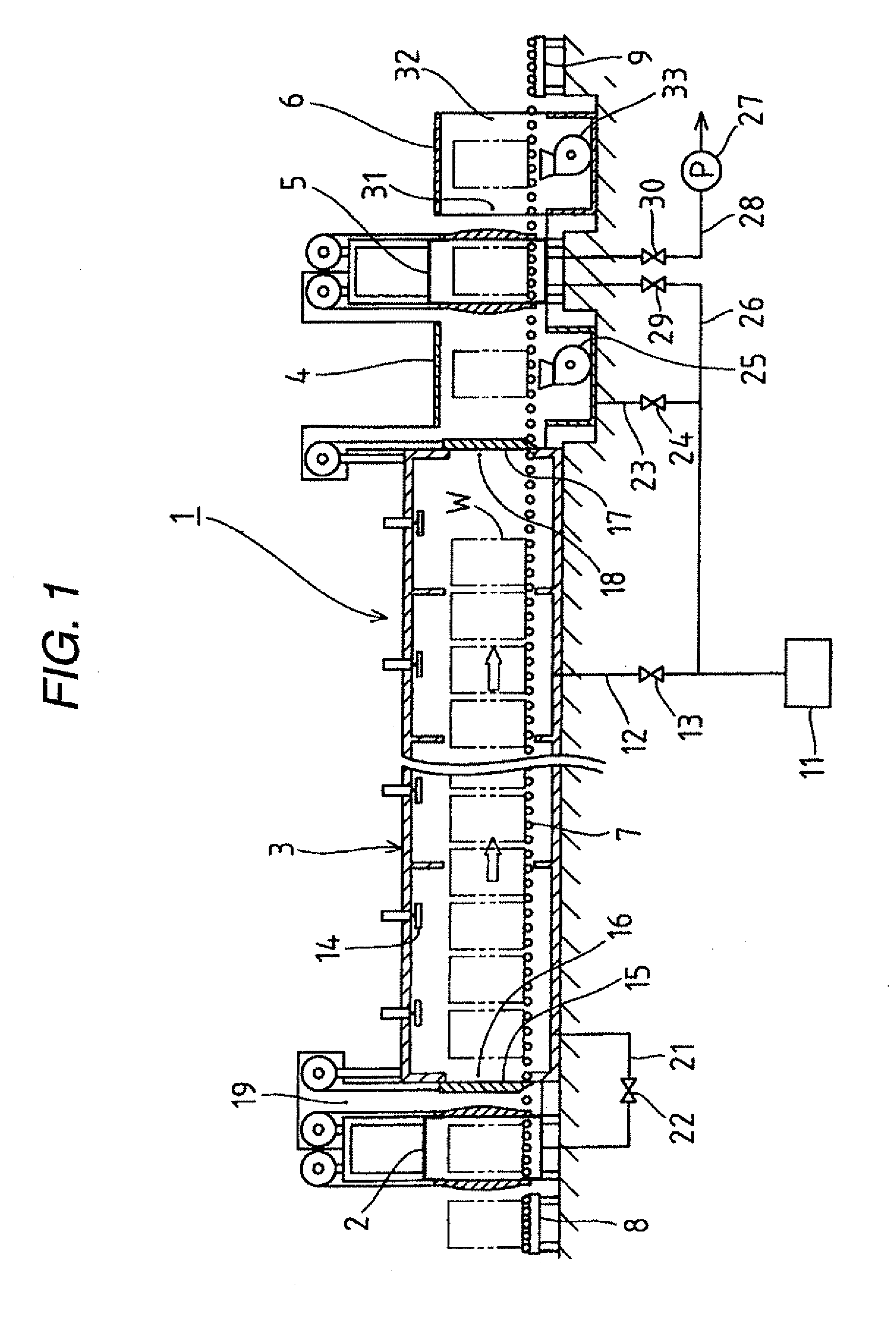

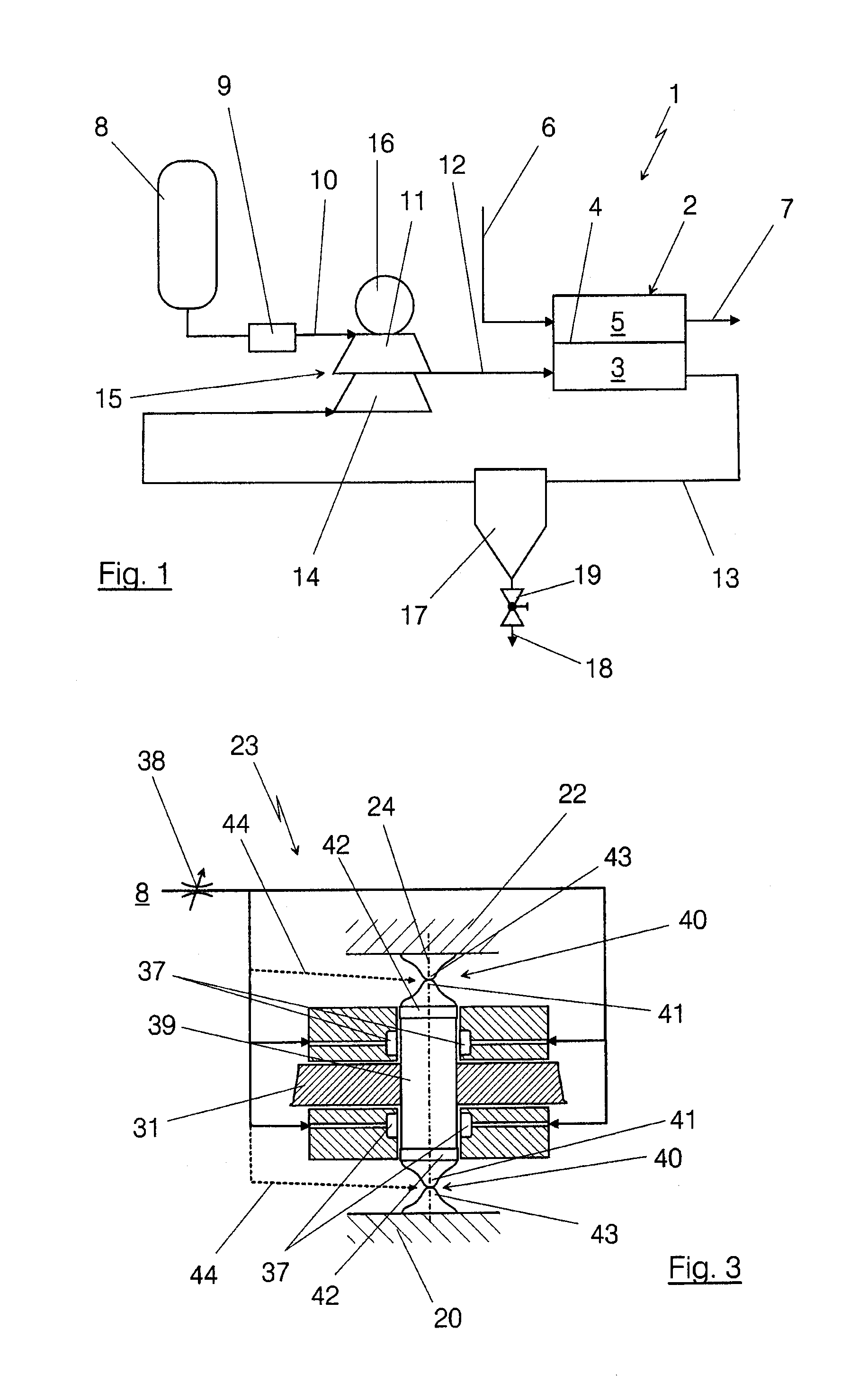

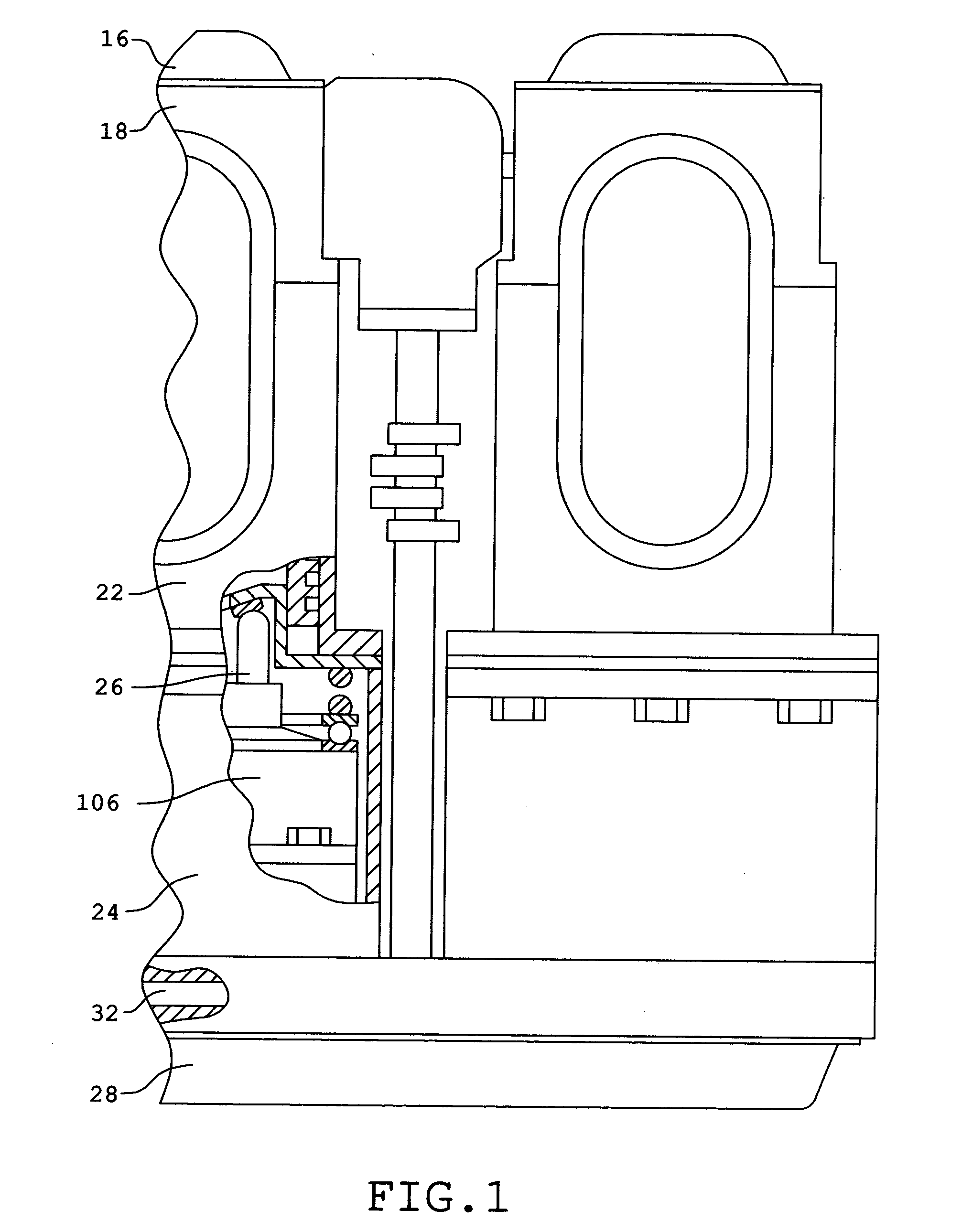

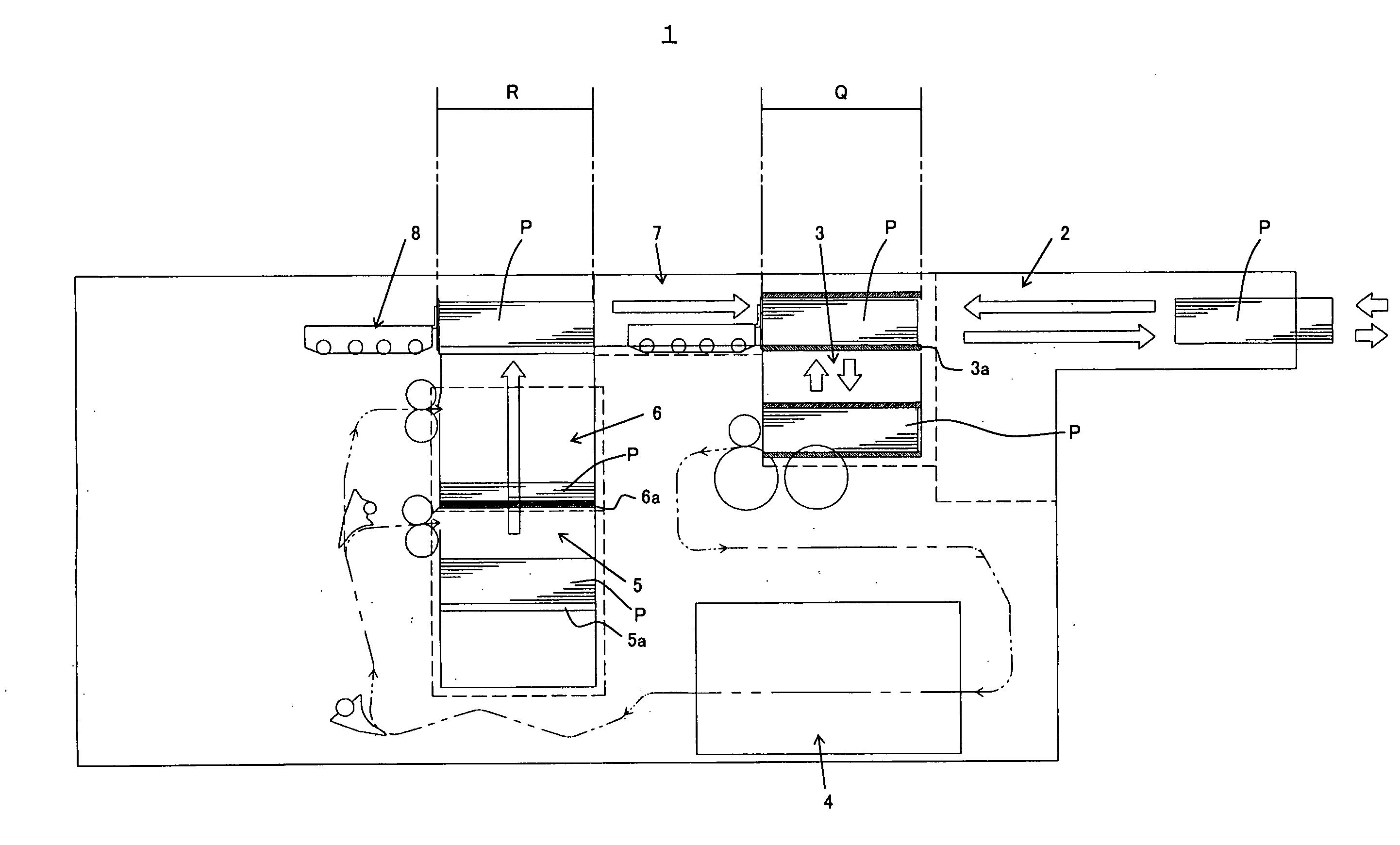

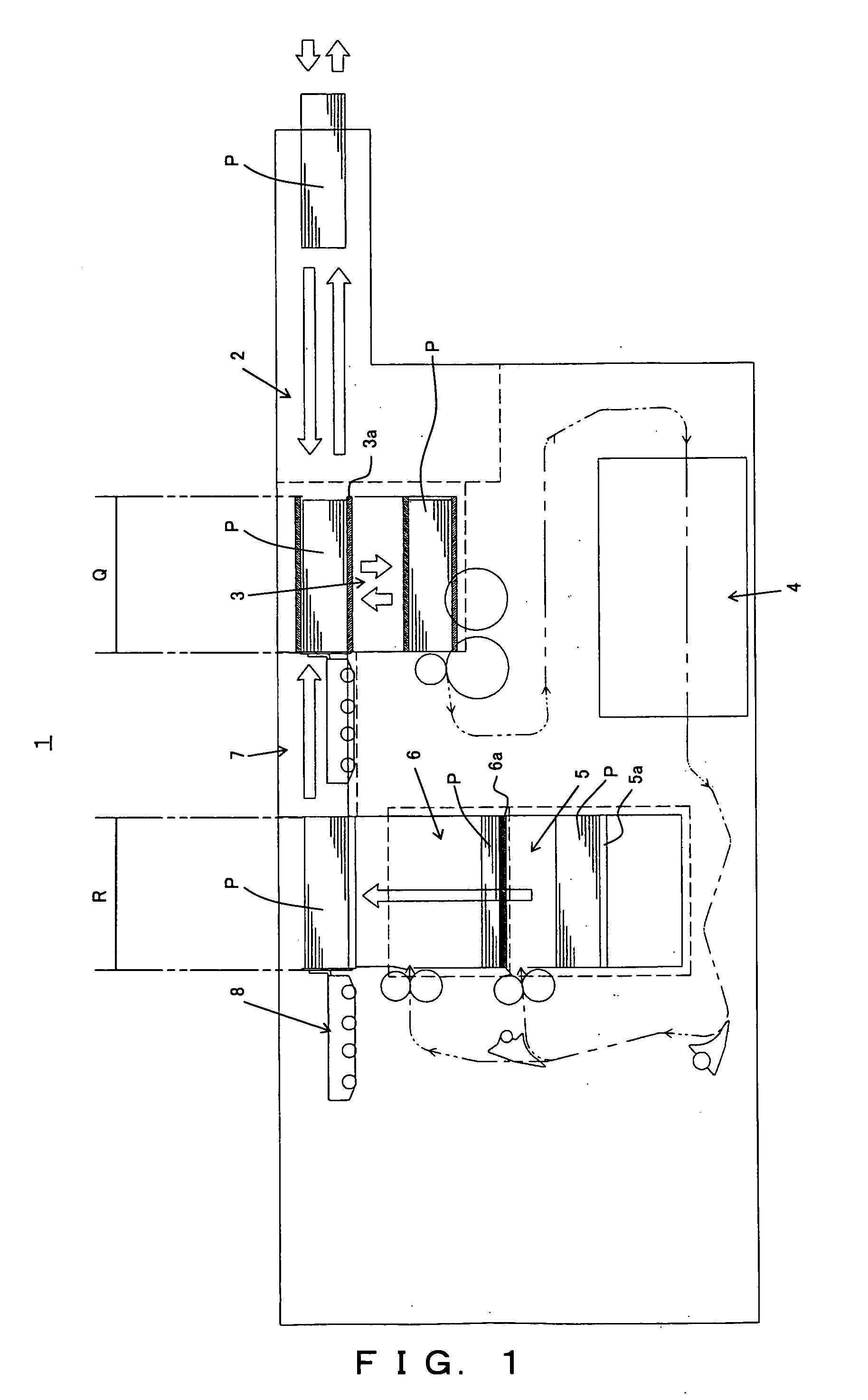

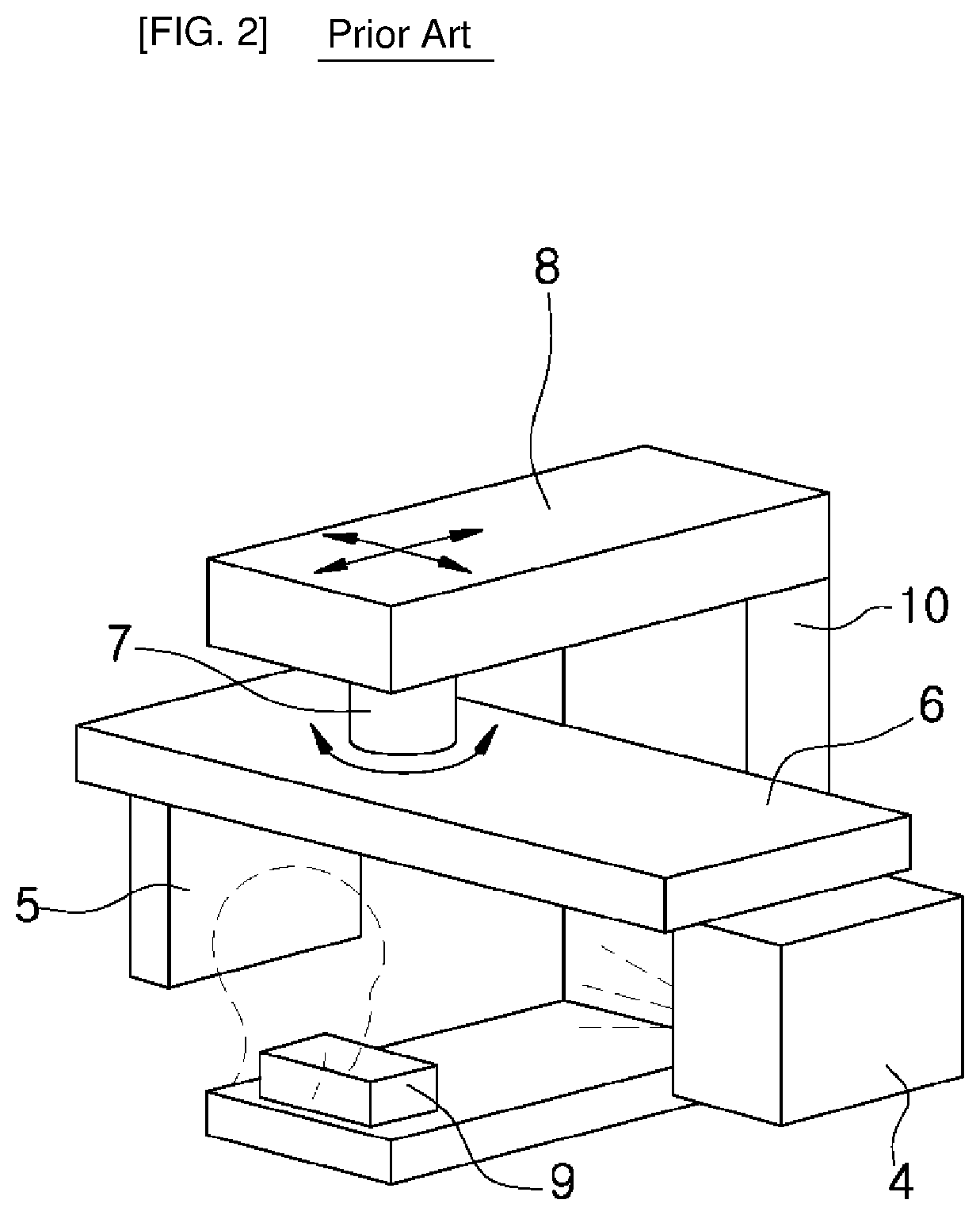

Rotary press having a heating roller for drying

InactiveUS6079330AReduce installation spacingLow running costOffice printingPrinting press partsPulp and paper industryPrinting press

A rotary press has a paper web supply apparatus, a printing apparatus, and a post-printing processing apparatus. The rotary press further includes at least one heating roller provided in a path along which a paper web carrying printed images runs from the printing apparatus to the post-printing processing apparatus, as well as at least one cooling roller provided downstream from the heating roller. The heating roller and the cooling roller are disposed such that the running paper web contacts each of the rollers over at least one-fourth of the circumference thereof. The heating roller is rotated at a circumferential speed different from a running speed of the paper web. The heating roller is a cylindrical body equipped with a built-in coil to which alternating current is supplied. The heating roller has cavities which are formed in a mutually communicating manner in the wall thereof and are filled with a thermal medium, and the outer surface of the heating roller is roughened. The rotary press can decrease installation space, the degree of complexity, manufacturing cost, and running cost of the drying apparatus.

Owner:TOKYO KIKAI SEISAKUCHI LTD +1

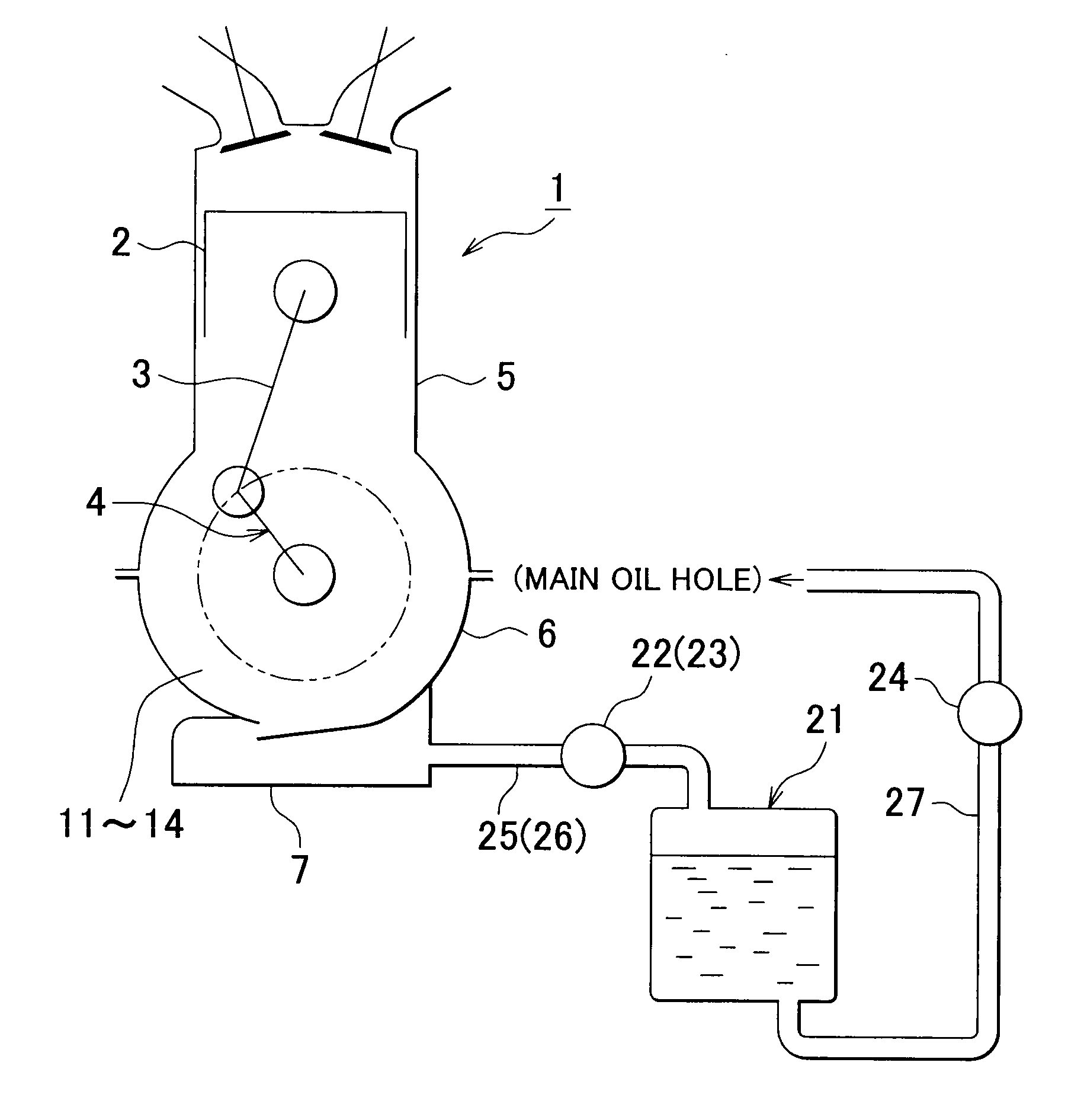

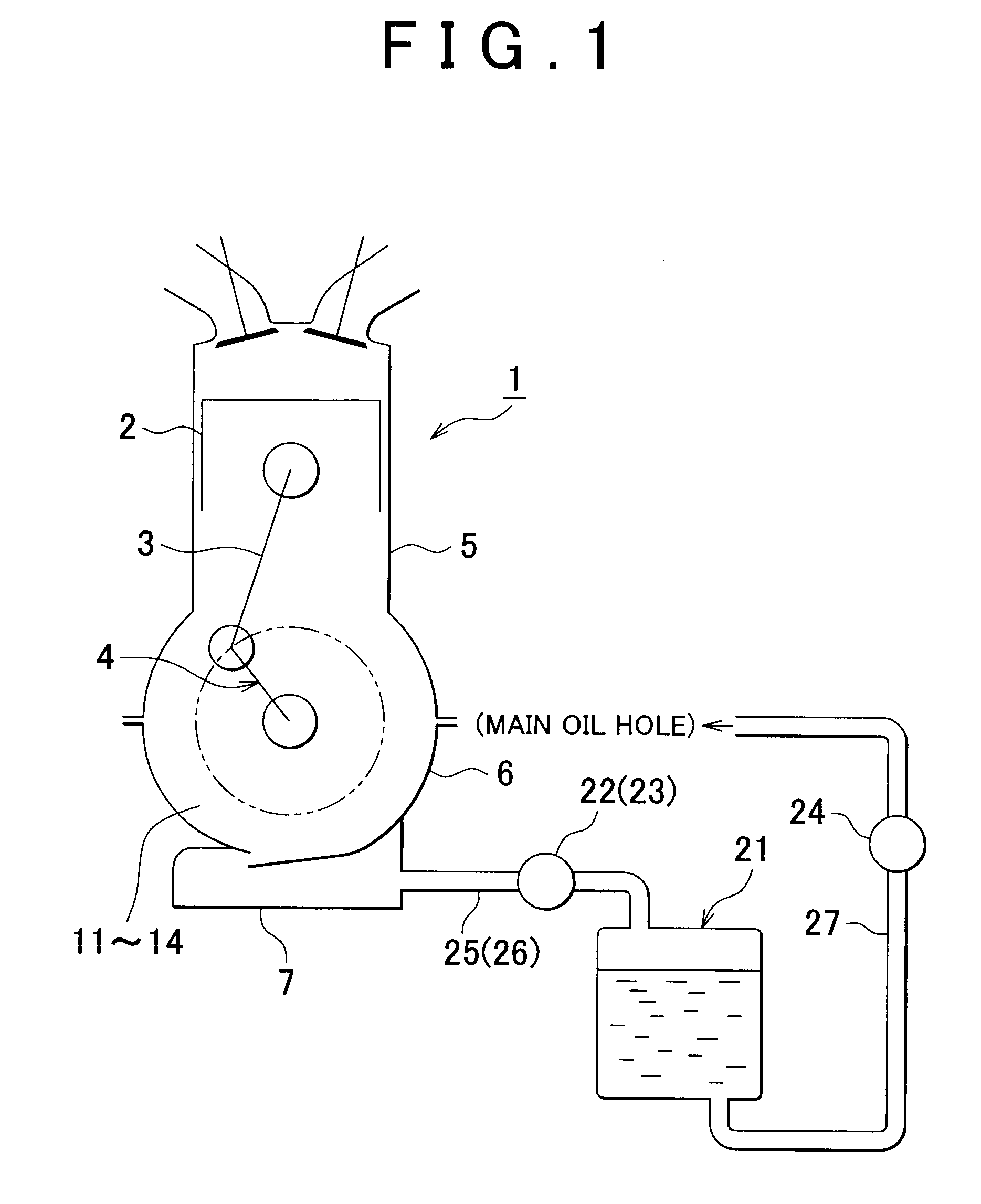

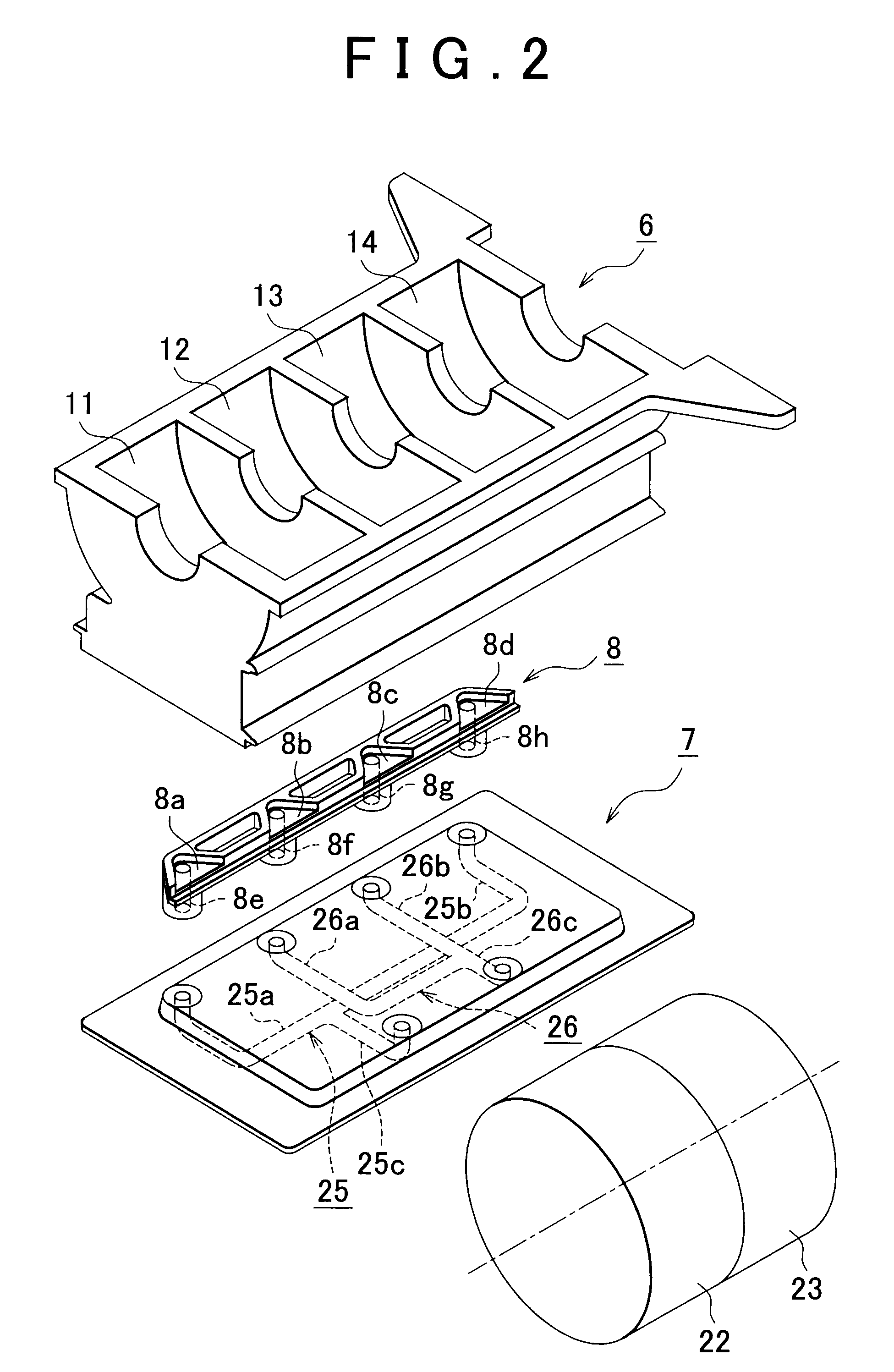

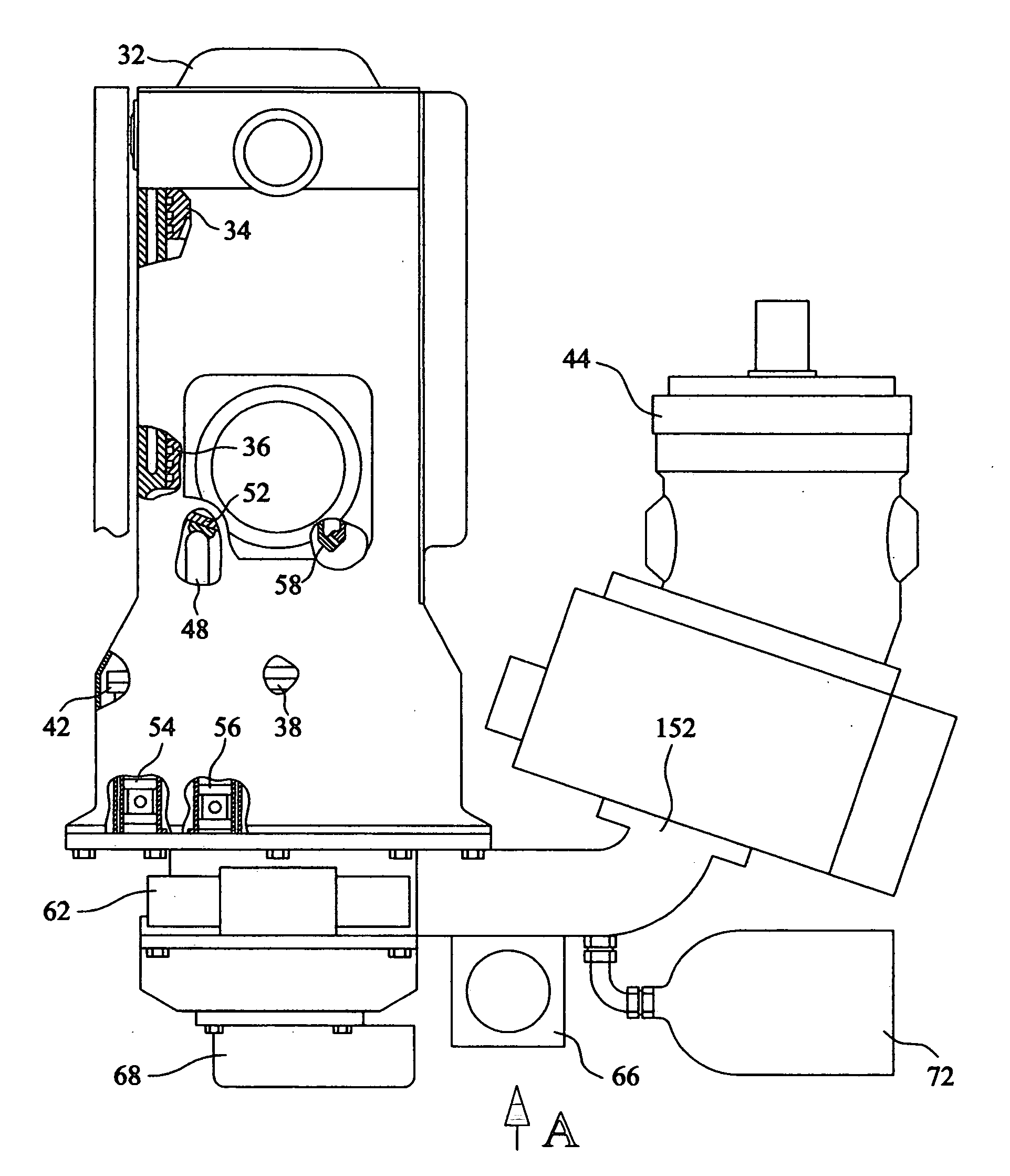

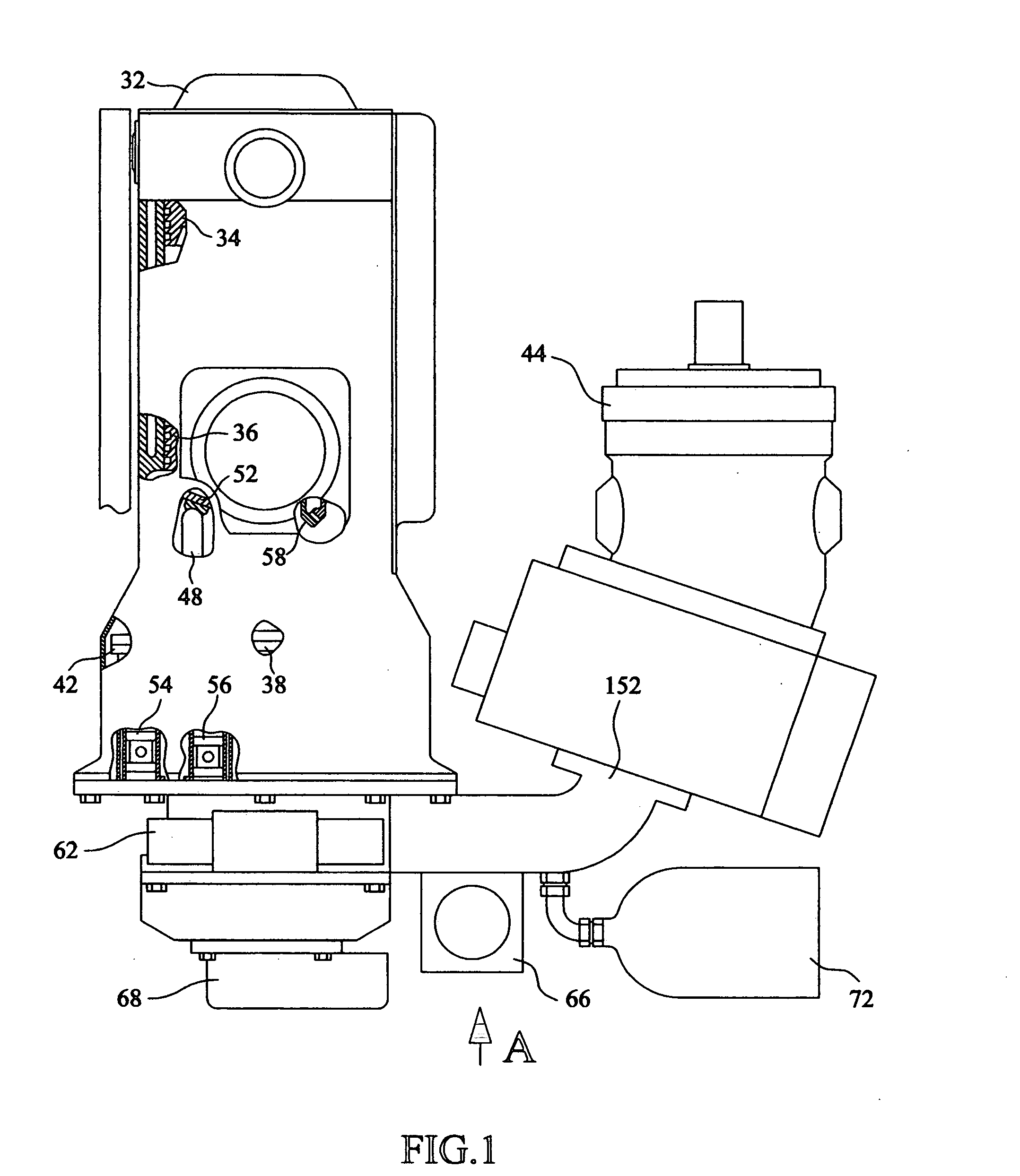

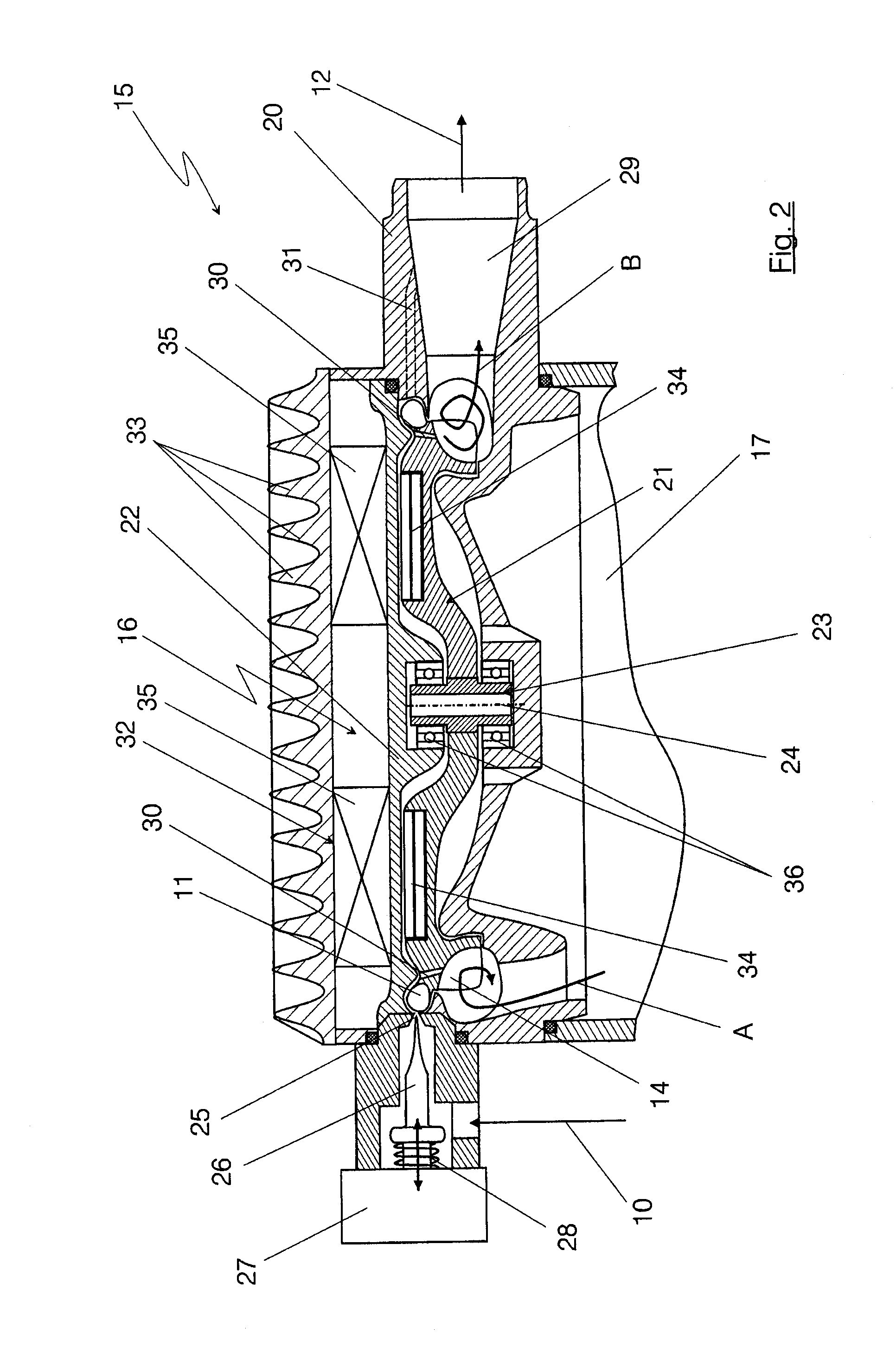

Engine lubrication system

ActiveUS20090218169A1Low costReduce installation spacingMachines/enginesClosed-circuit pressure lubricating systemsCrankcaseLubrication

An engine lubrication system for a multi-cylinder engine, comprising: plurality of crank chambers that are partitioned by crankshaft bearing portions of the engine; pumps that take out oil from a lower portion of the engine; oil collection passages that are respectively provided for the crank chambers, a designated number of the oil collection passages being merged and connected to at least one of suction ports of the pumps; an oil storage section that temporarily stores the oil taken out from the lower portion of the engine; a lubrication part that supplies the oil in the oil storage section to a portion to be lubricated of the engine; and a pressure variation suppression section that is provided between the suction ports of the pumps and the designated number of the crank chambers to be merged, the pressure variation suppression section suppressing pressure variations in the crank chambers.

Owner:TOYOTA JIDOSHA KK +1

Continuous heat treatment furnace

InactiveUS20100068669A1Poor pickling property is preventedReduce the temperatureFurnace typesHandling discharged materialMetallurgyCooling chamber

The present invention provides a continuous heat treatment furnace including: a heating chamber heating a treatment object in an inert gas atmosphere; a front chamber provided at one end of the heating chamber; and a first cooling chamber cooling the treatment object in an inert gas atmosphere, a vacuum purge chamber, and a second cooling chamber cooling the treatment object in an oxidizing gas atmosphere, which are connected in this order to the other end of the heating chamber, in which the treatment object transferred from the front chamber to the heating chamber is subjected to the heating in the heating chamber, and then subjected to one cooling selected from the cooling in the inert gas atmosphere in the first cooling chamber and the cooling in the oxidizing gas atmosphere in the second cooling chamber depending on a type of the treatment object.

Owner:DAIDO STEEL CO LTD

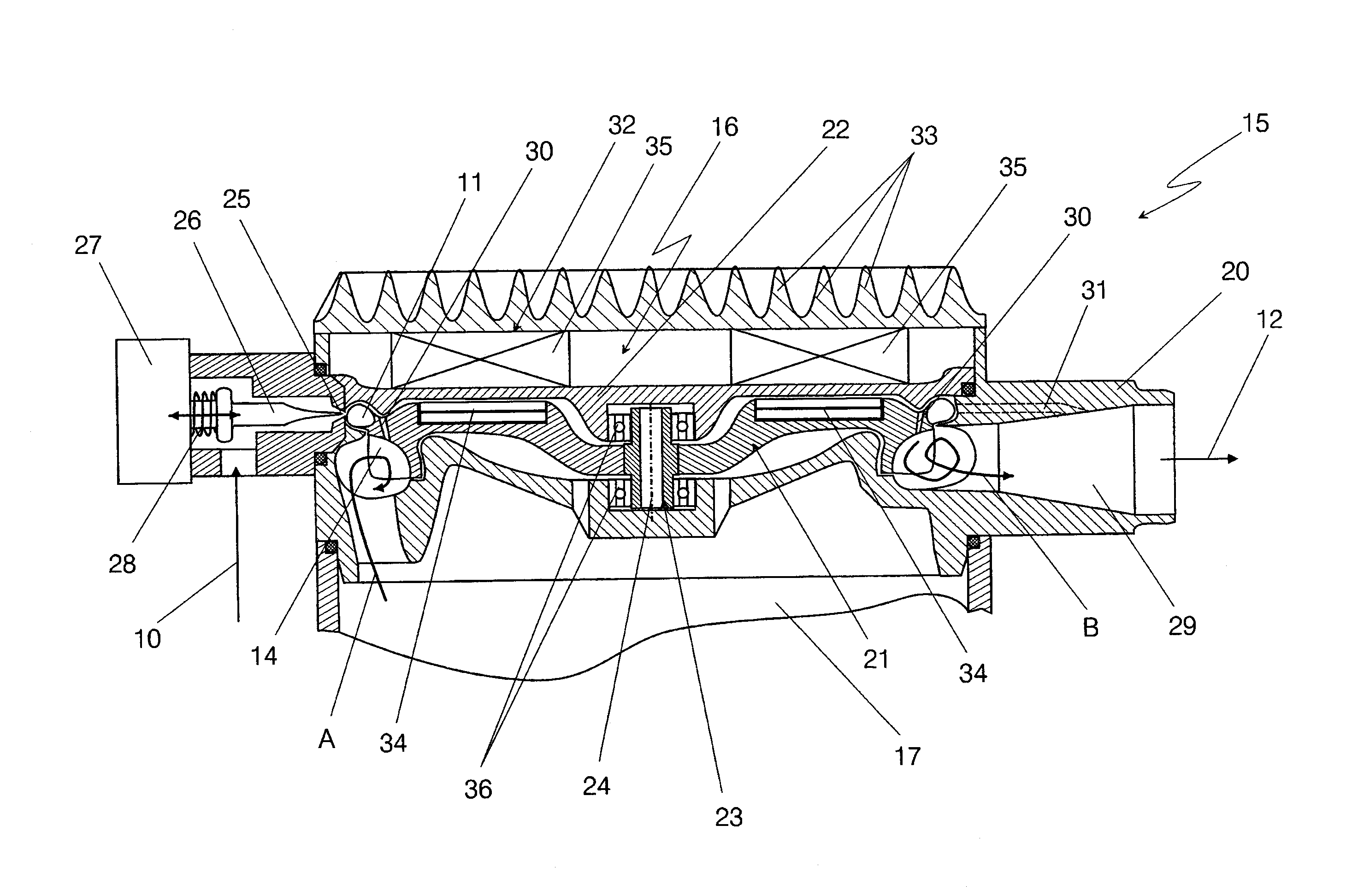

Monocylindrical hybrid powertrain and method of operation

InactiveUS20080134675A1Easy and efficient to manufactureLow priceHybrid vehiclesAuxillary drivesEngineeringHybrid powertrain

The monocylindrical hybrid powertrain comprises a continuously variable volume hybrid engine, pump and hydrostatic motor. The pump plunger fastened to engine piston and the engine cylinder fastened to the hydrostatic motor by valve plate and formed solid monoblock.The hybrid synchronize mechanism swash plate turn changes the engine piston stroke and remains the engine compression ratio. The swash plate shift changes the engine compression ratio for the either kind of fuel use.The hybrid and pneumohydraulic accumulator association transforms the single pump plunger supply pulsation into uniform fluid flow feeding the hydrostatic motor.The hydrostatic motor and the electric motor association allow electric energy accumulation by means of plug-in.Direct energy transmission, variable displacement volume engine, pump and hydrostatic motor and energy recuperation increases the specific power, decreases the weight and installation space and enables to achieve 80 mile per gallon for the car in city conditions.

Owner:EPSHTEYN GRIGORIY

Fuel Cell System Having an Integral Turbine/Compressor Unit

InactiveUS20130157154A1Simple and efficient coolingReduction in condensation of waterFuel cell heat exchangeReactant parameters controlImpellerFuel cells

A fuel cell system includes at least one fuel cell having an anode chamber, a cathode chamber, a hydrogen pressure reservoir, a recirculation line connecting an outlet of the anode chamber to an inlet of the anode chamber, a recirculation conveyor with a compressor wheel in the region of the recirculation line, and a turbine for expanding the hydrogen that is under pressure before entry into the anode chamber. The recirculation conveyor is driven at least partially by the turbine. The turbine and the compressor wheel are formed in one component.

Owner:DAIMLER AG

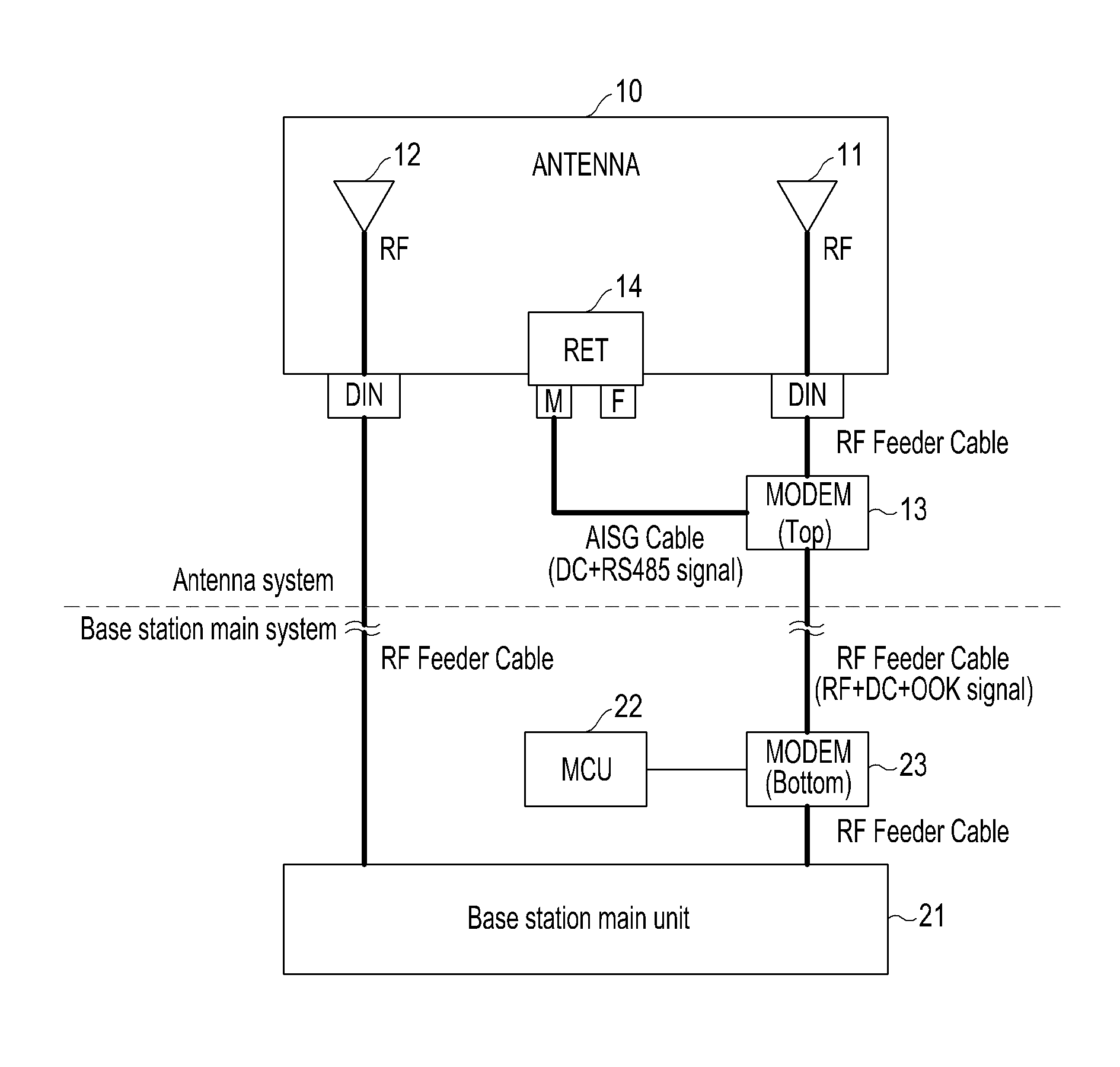

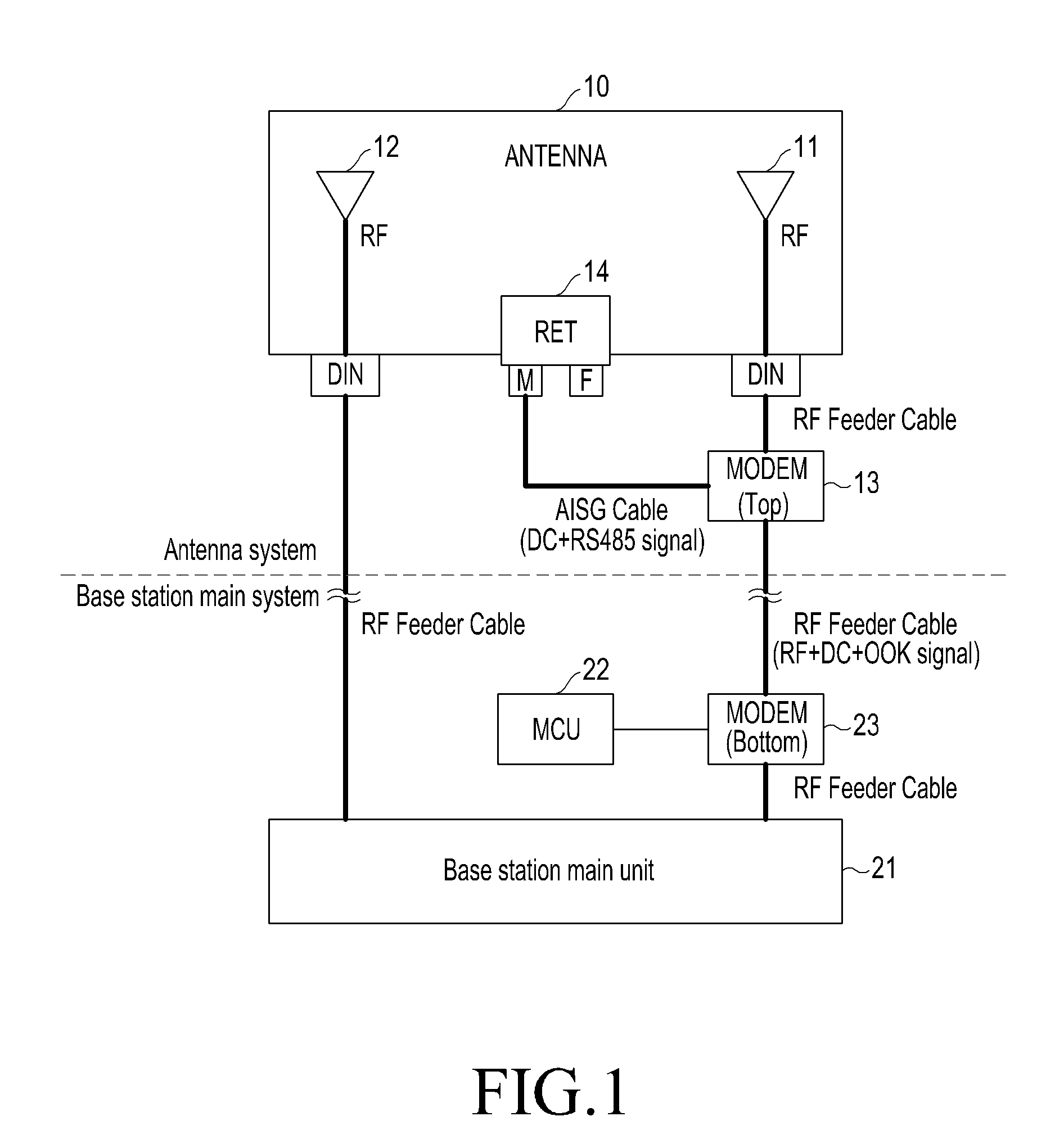

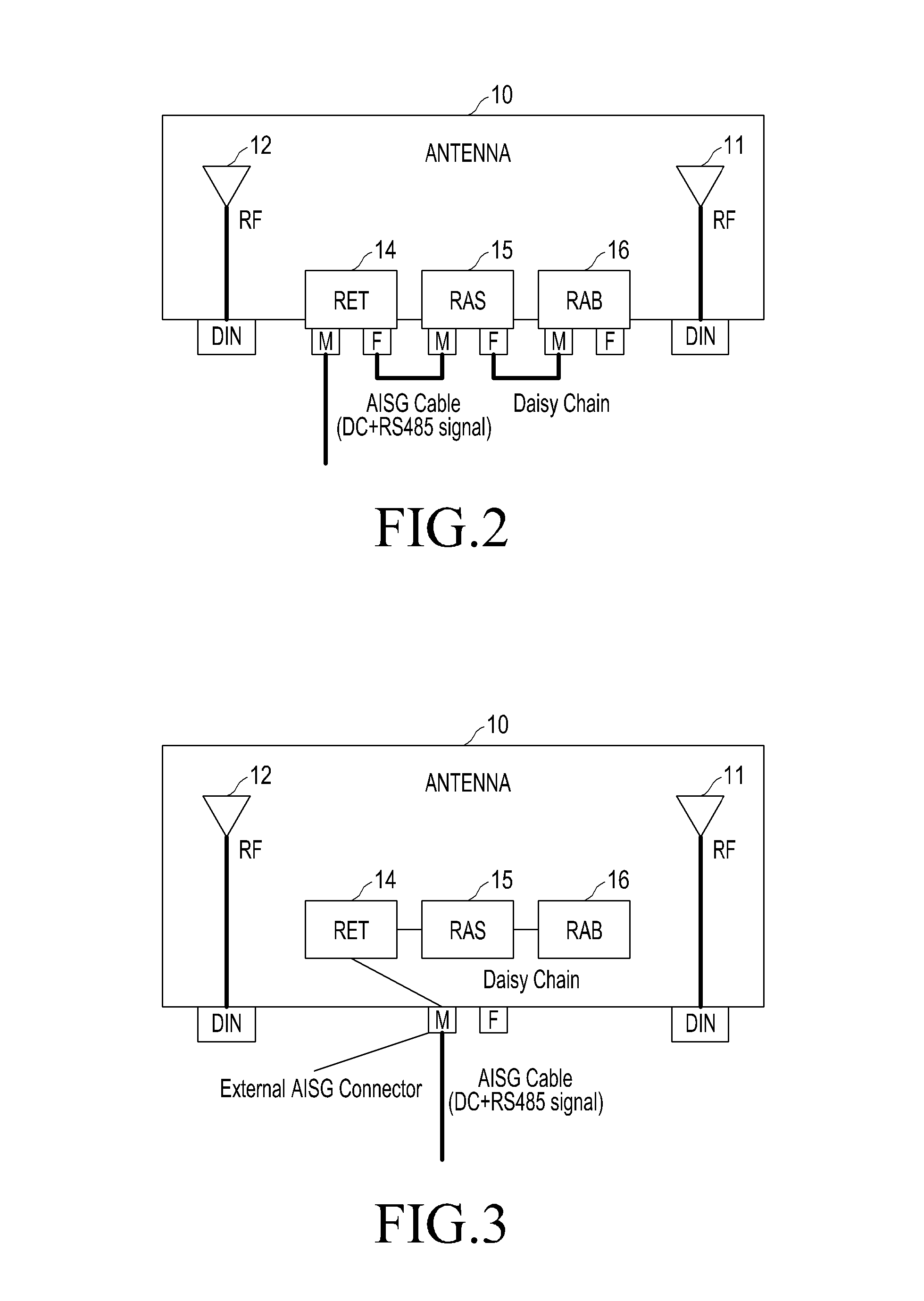

Antenna of mobile communication base station and method for controlling same

ActiveUS20150244069A1Low costReduce installation spacingSubstation equipmentIndependent non-interacting antenna combinationsDrive motorMechanical devices

The present invention relates to an antenna of a mobile communication base station, comprising; an RET driving unit, an RAS driving unit, and an RAB driving unit, each comprising a driving motor, for driving electrical and mechanical devices for respectively adjusting RET, RAS and RAB; and multi-function equipment for controlling the driving of the RET driving unit, the RAS driving unit and the RAB driving unit by communicating with a main system of a base station such that at least a control signal for controlling the RET, the RAS, and the RAB is received.

Owner:KMW INC

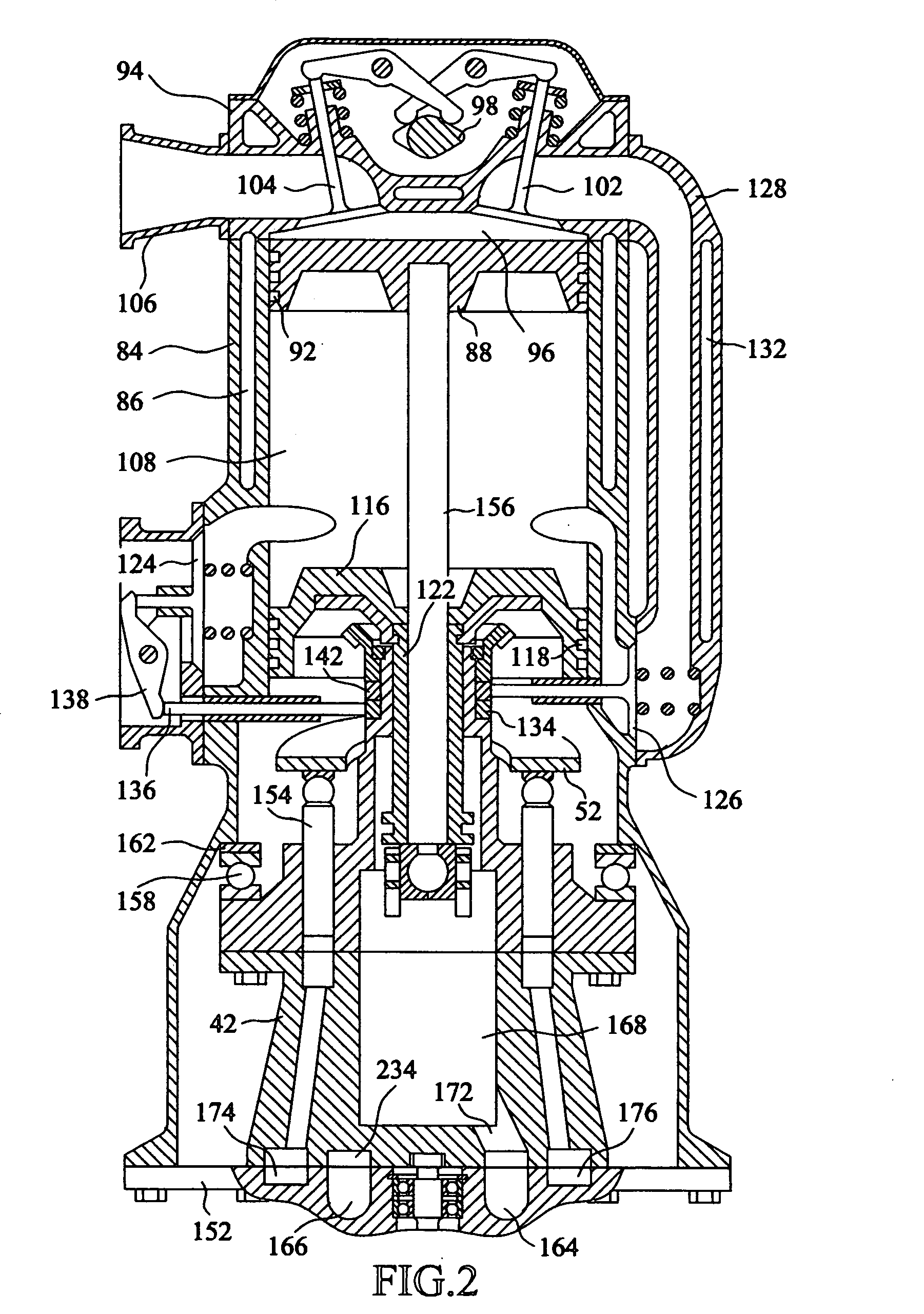

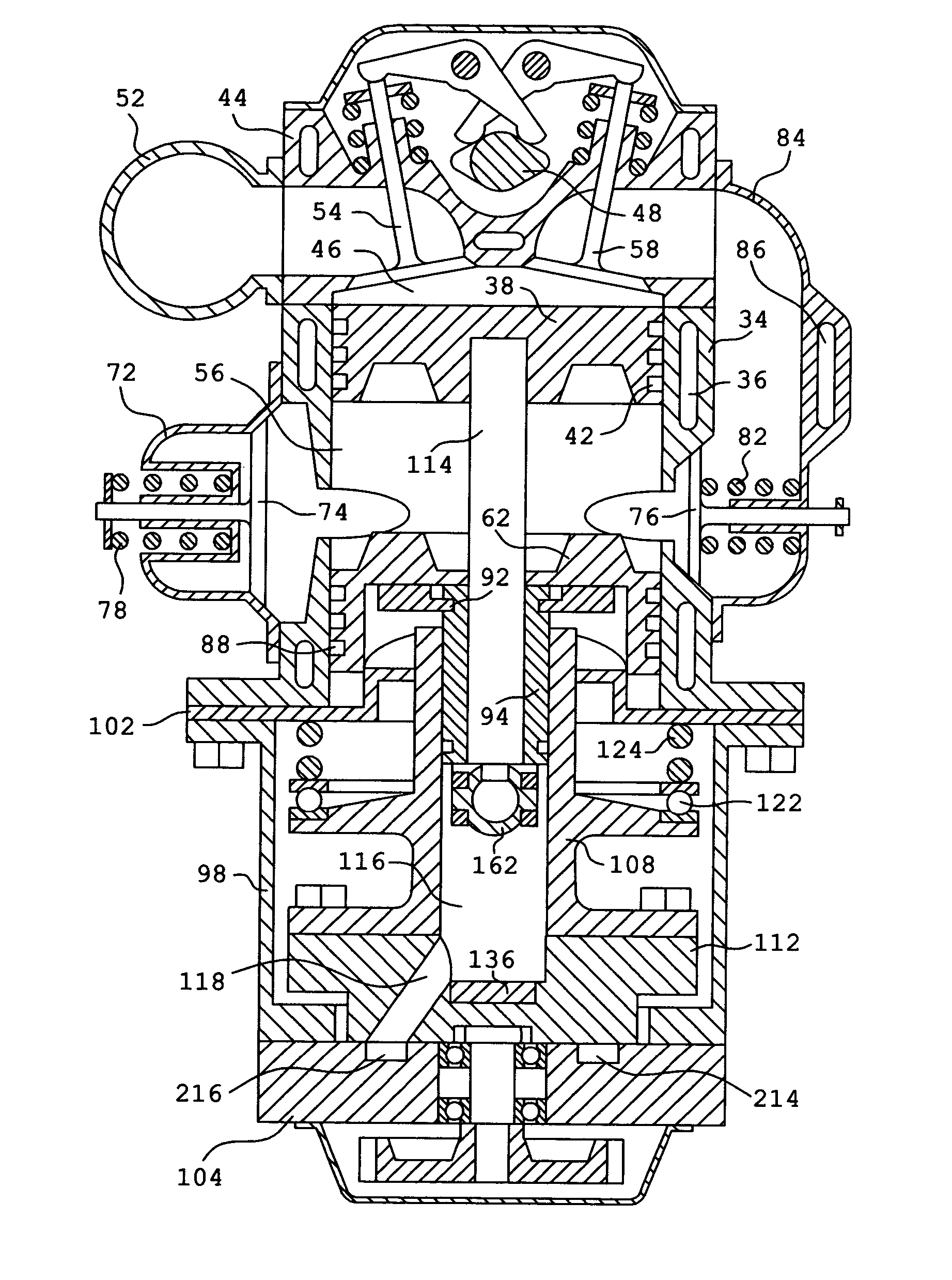

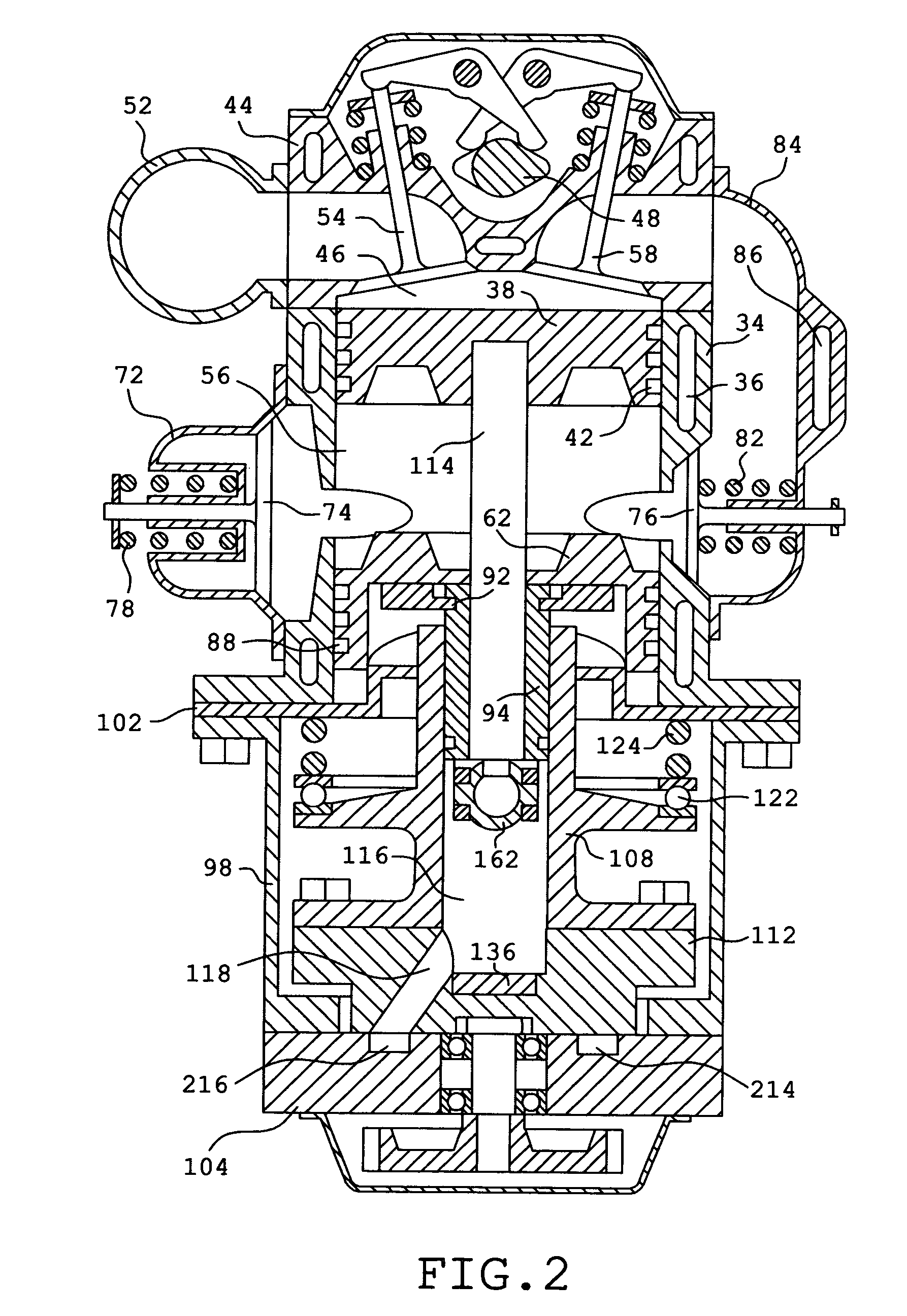

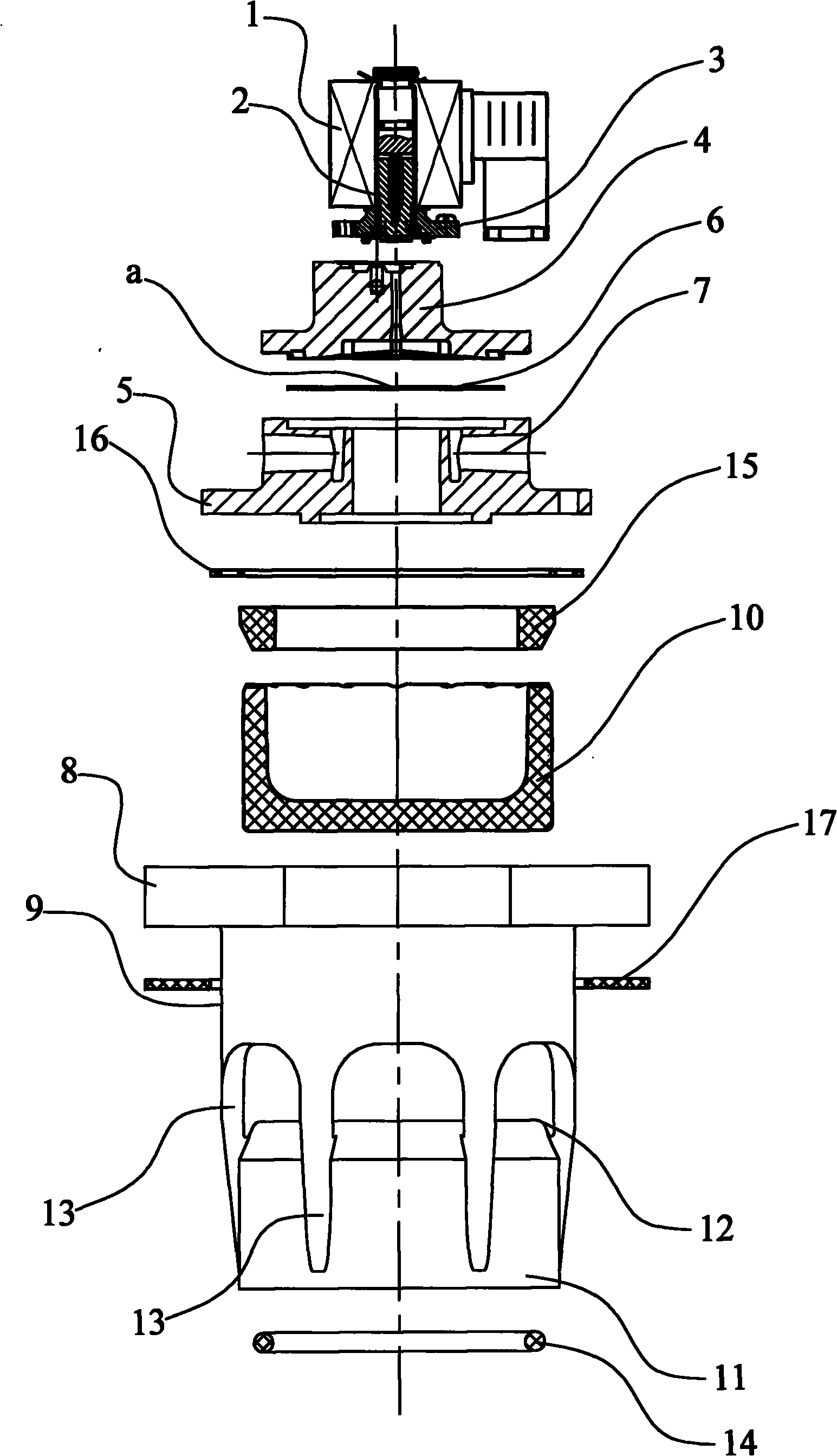

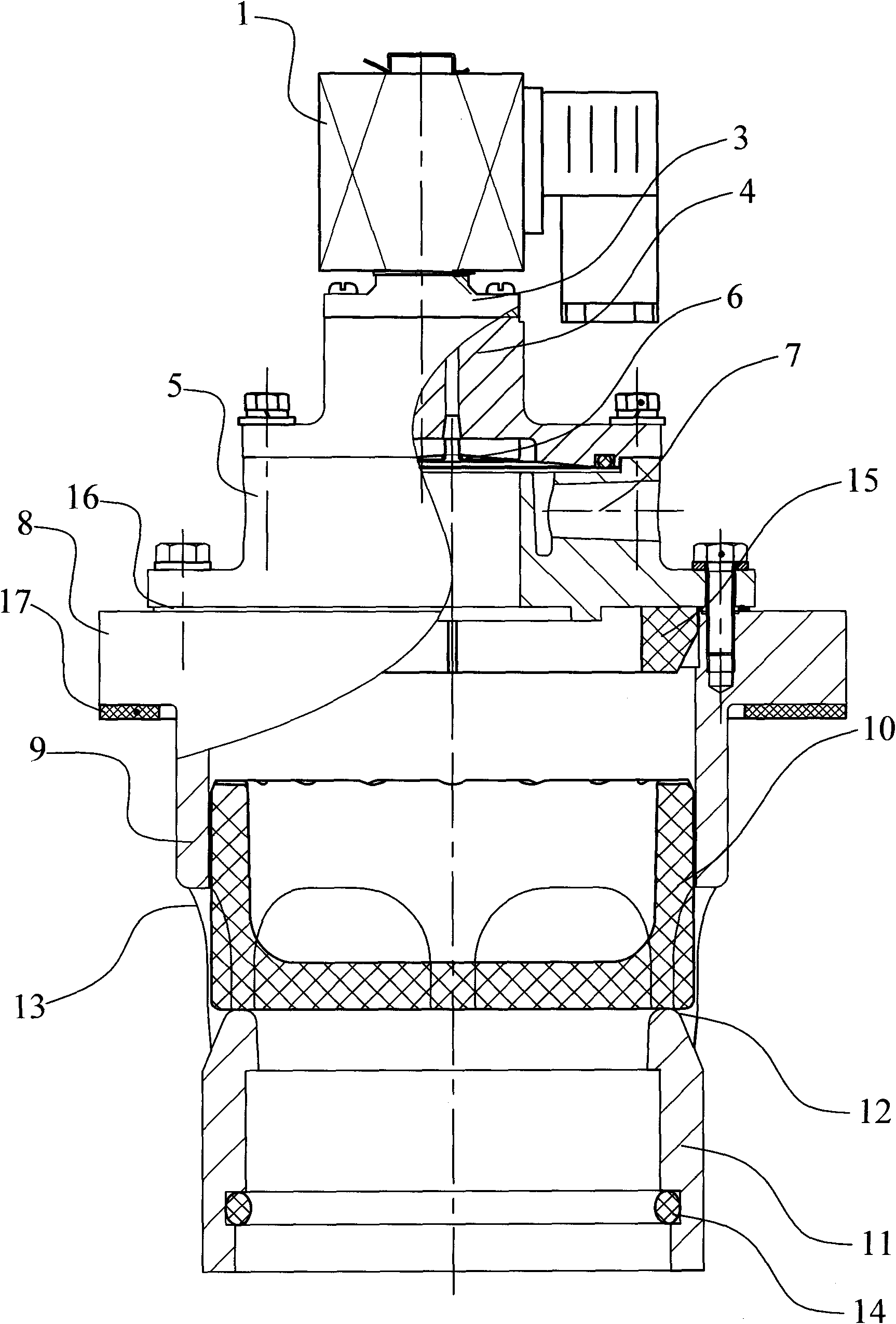

Hybrid two cycle engine, compressor and pump, and method of operation

InactiveUS20050028759A1Easy and efficient to manufactureLow priceFluid couplingsPlural diverse prime-mover propulsion mountingHydraulic pumpEngineering

The hybrid (16) comprises a two cycle engine (18), boosted by the engine power compressor (22) and a hydraulic pump (24). The pump plunger (114) fastened to engine piston (38) and located coaxially with the compressor piston (62) and pump (24) rotor (106), provide direct energy transmission to the compressor and pump. The plunger (114) and compressor piston (62), each connected to one of two diametrically opposite axial push rods (138), (142) of the rotor (106). The push rods synchronize and balance the pistons (38), (62) which move opposite directions into underside of the engine piston space. The rotor canals (118), (226) interact with the valve plate (104) and communicate fluid flow from a pumps of separate rotors. The reducer (28) synchronizes the motion of the separate rotors, activate engine and compressor camshafts (48), (64) and conventional accessory units. The engine can be high power started and restarted irrespective of parking time, since the start, idling and work modes provide a hydraulic distributor (272), pneumohydraulic accumulator (296) and starter pump (298) with pedal (302). Because of direct energy transmission the hybrid increases efficiency and specific power, while minimizing the weight, installation space and fuel consumption necessary in particular for automobile hydrostatic transmission.

Owner:EPSHTEYN GRIGORIY

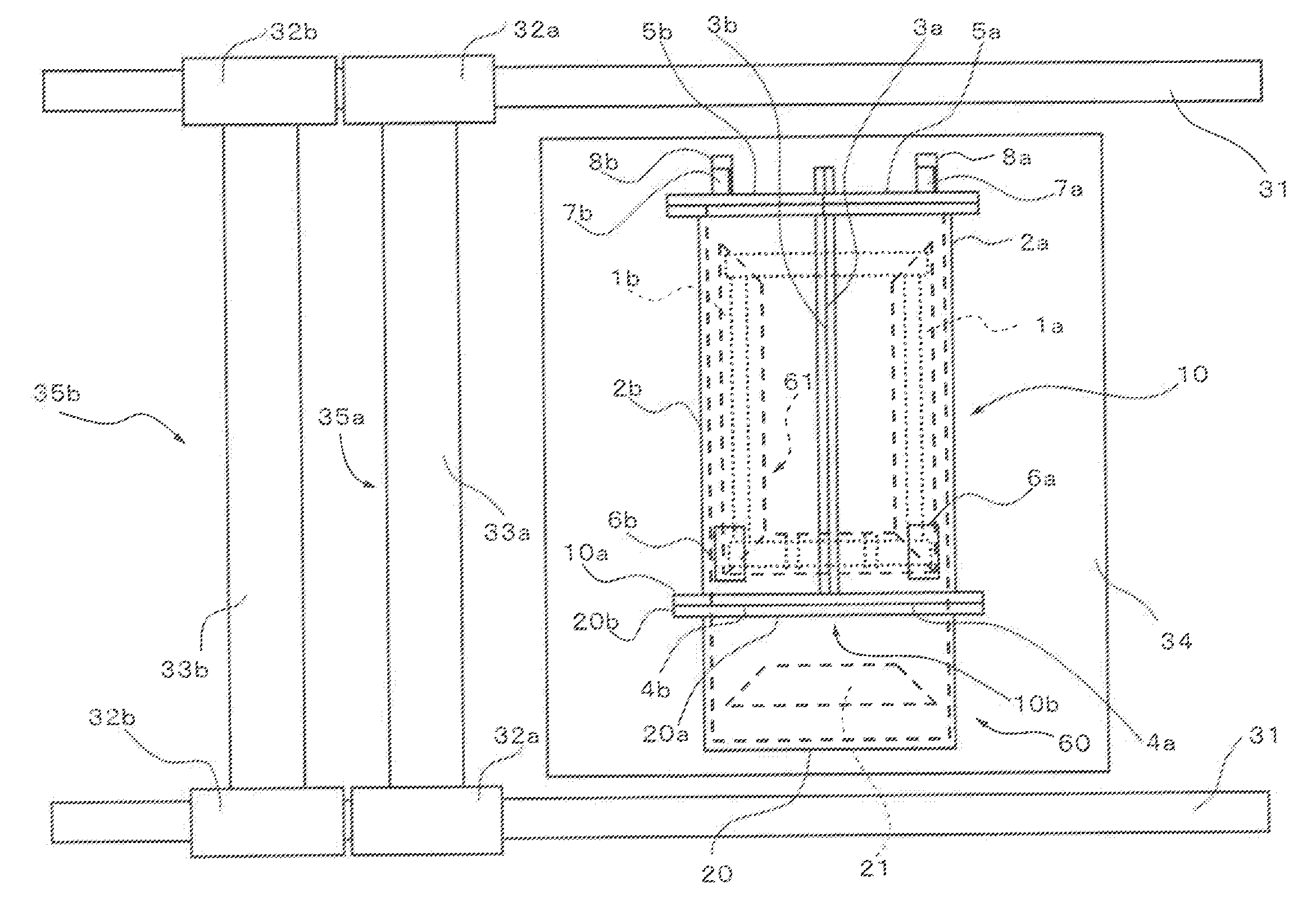

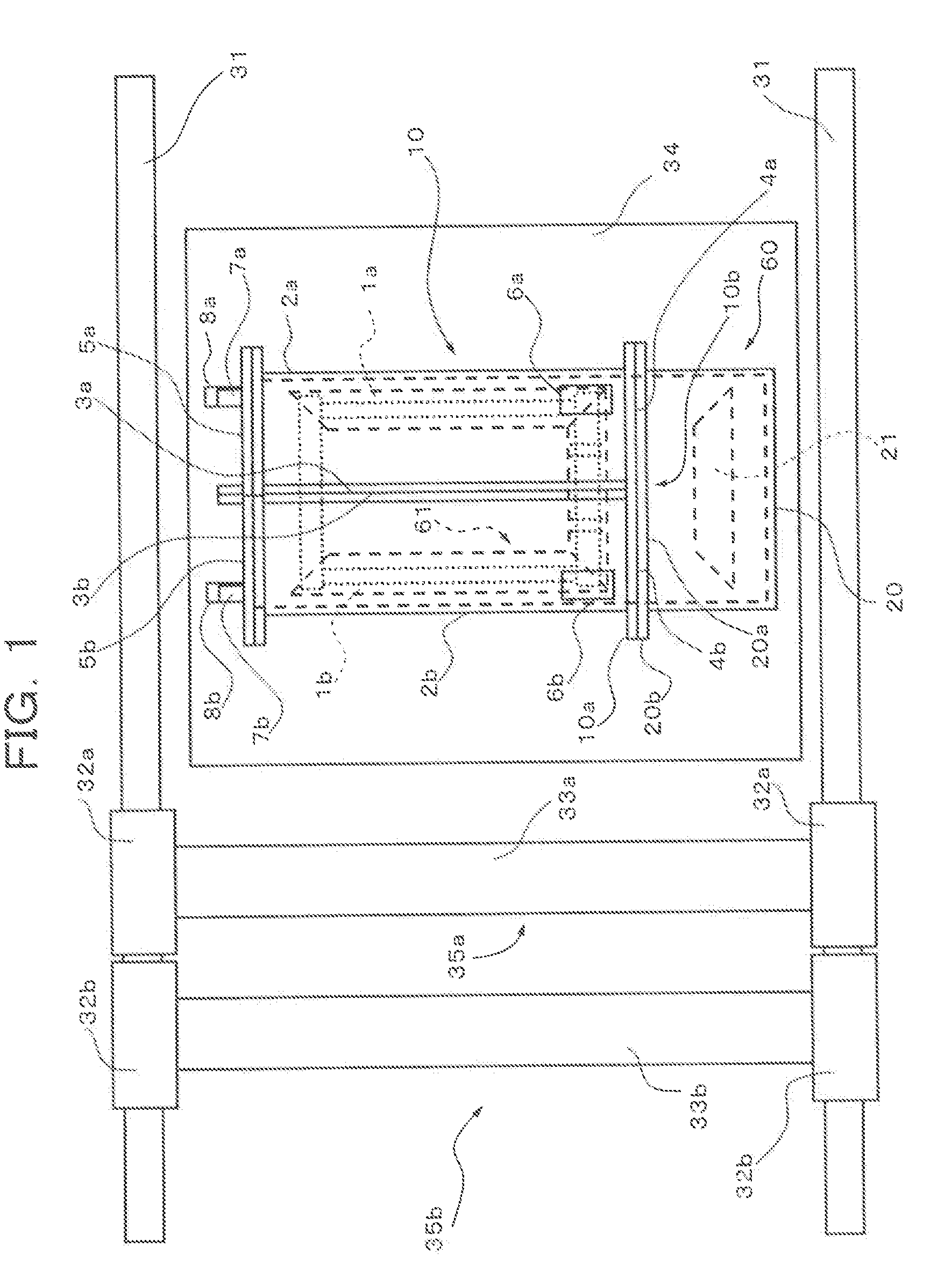

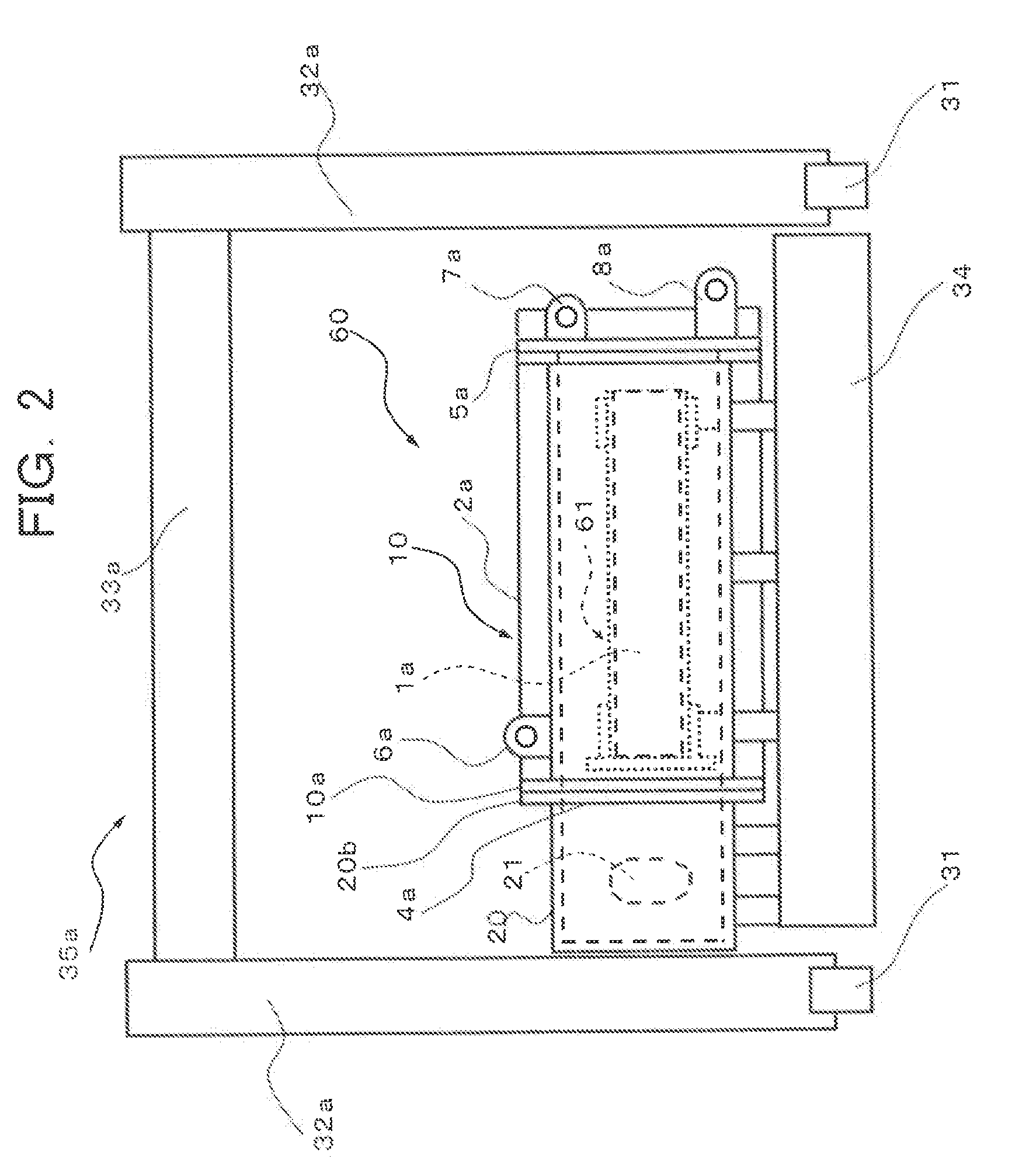

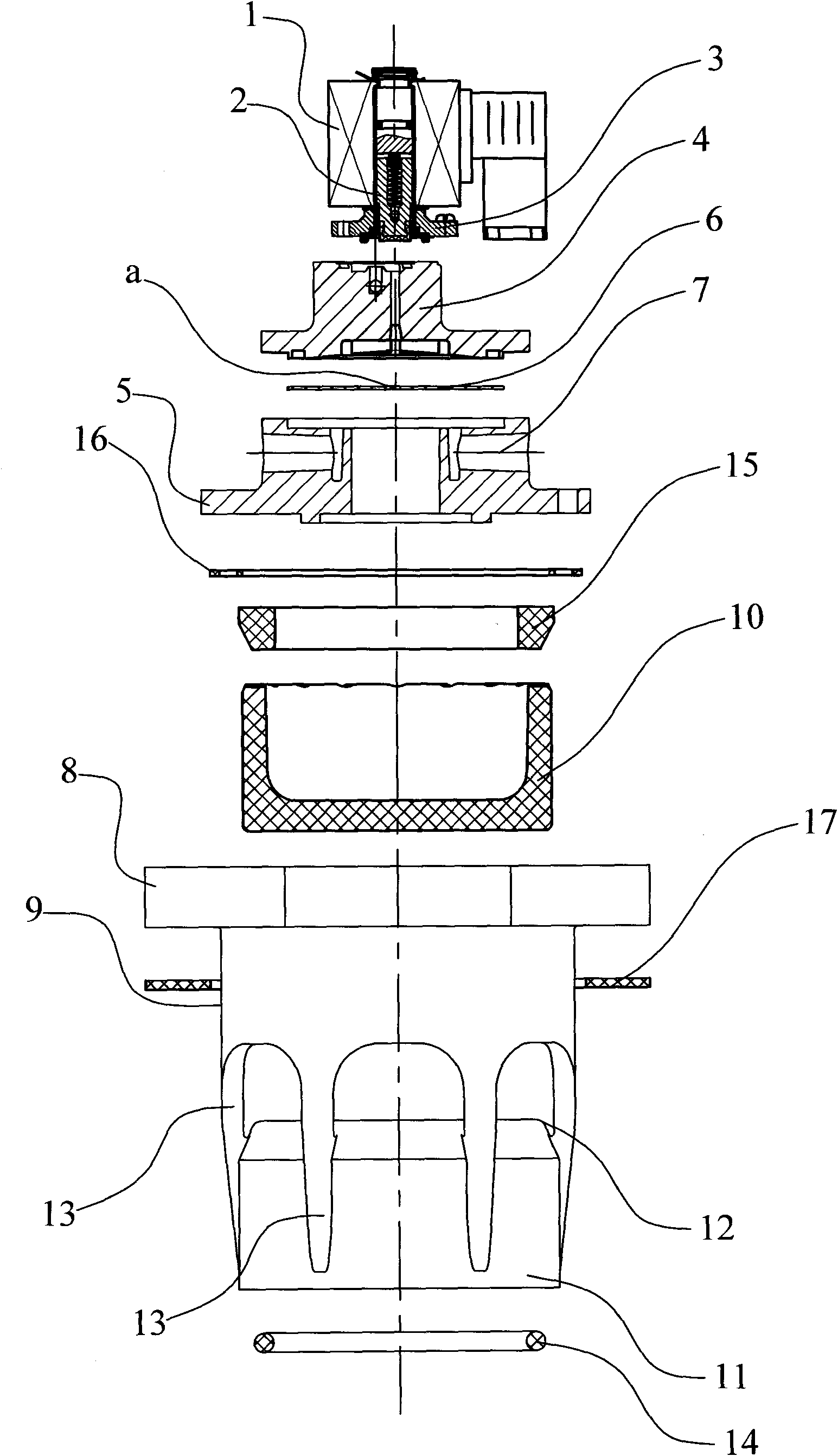

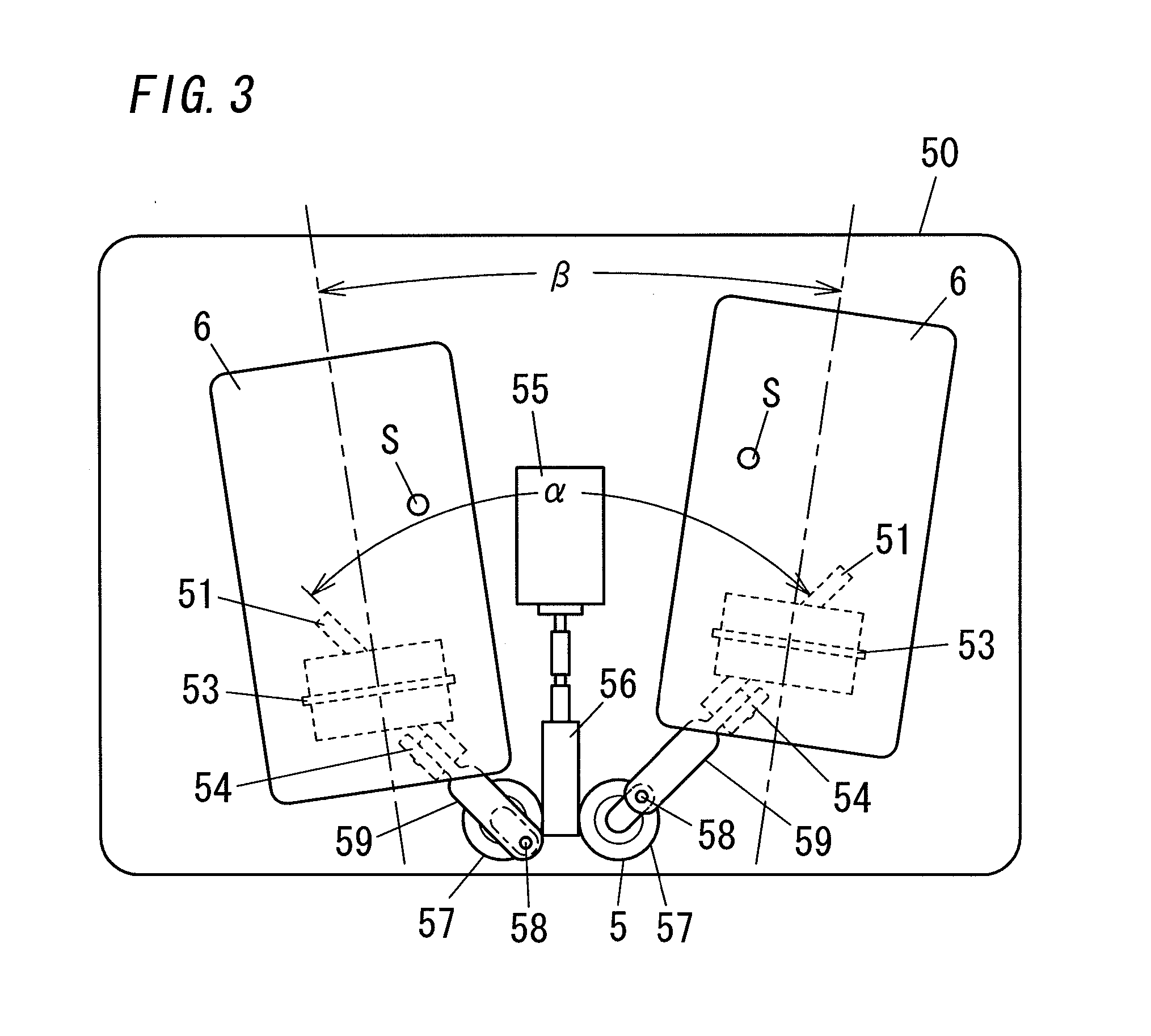

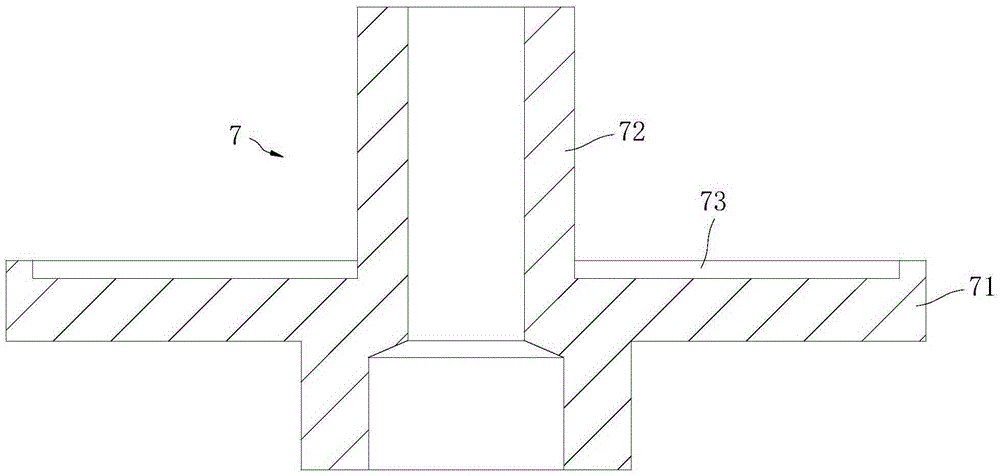

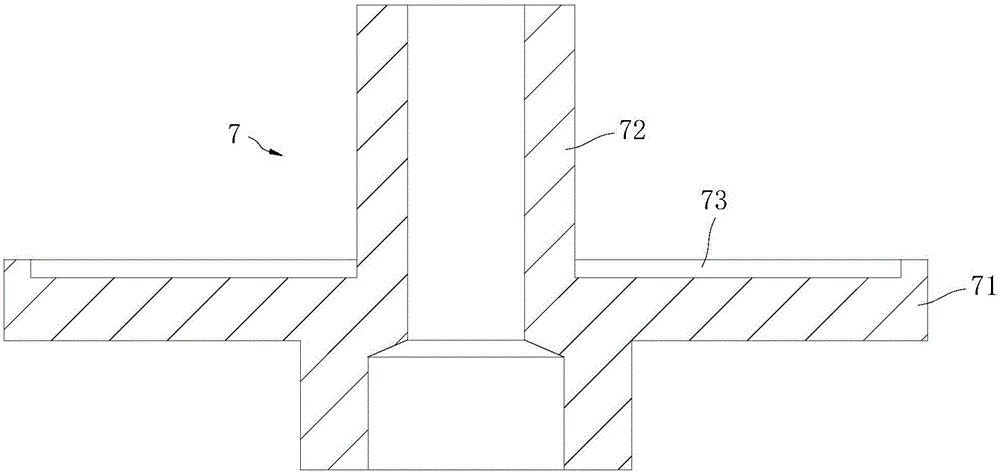

Transformer transporting/assembling method and u-shaped iron core assembling device

ActiveUS20100154202A1Reduce installation spacingShorten the maintenance periodWave amplification devicesTransformers/inductances magnetic coresTransformerMechanical engineering

A transformer transporting / assembling method comprises a transportation step of transporting a U-shaped iron core with an iron plate horizontally extending to a place near an installation site and an erection step of erecting the U-shaped iron core together with an erection tank from a state that the iron plate extends horizontally to a state that the iron plate extend vertically, with the U-shaped iron core contained in the erection tank. The erection step includes a sub-step in which a portal lifter composed of two booms which are vertically expandable and parallel movable with a predetermined distance therebetween and between which the erection tank is disposed and a beam horizontally connecting the two booms and vertically moved as the booms expands or contracts is used, the beam supports the erection tank through a flexible member at predetermined support portions, and the beam is vertically moved by expanding / contracting the booms.

Owner:KK TOSHIBA

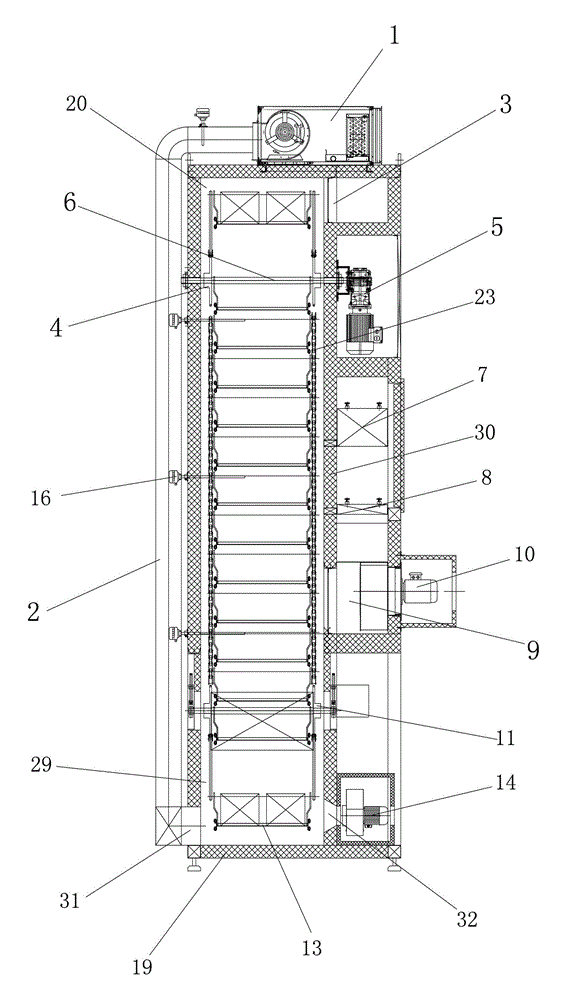

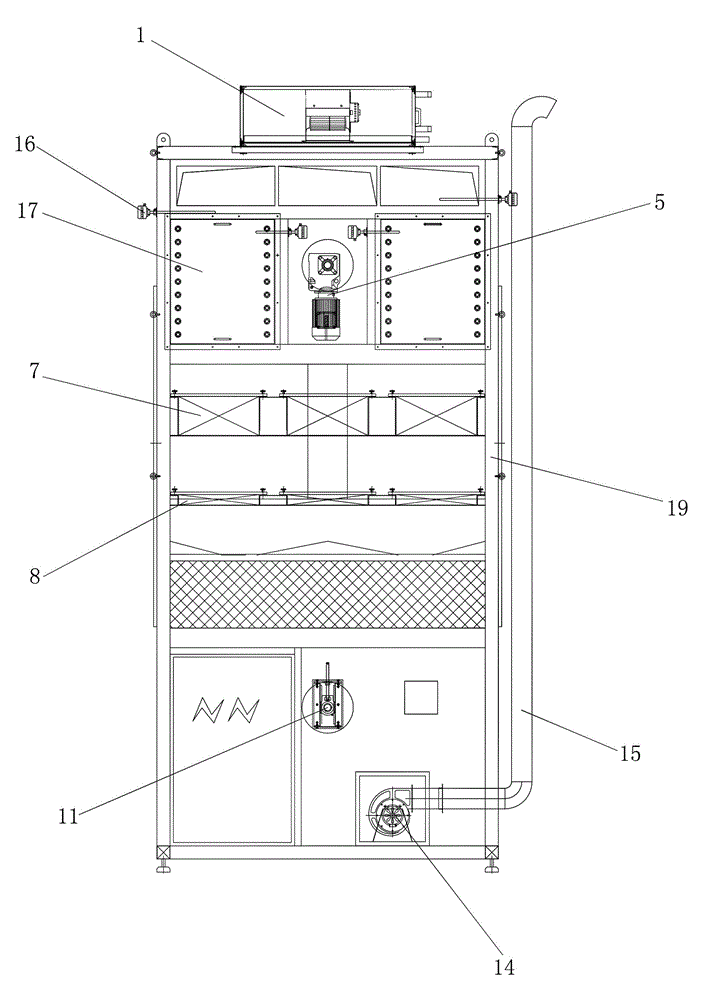

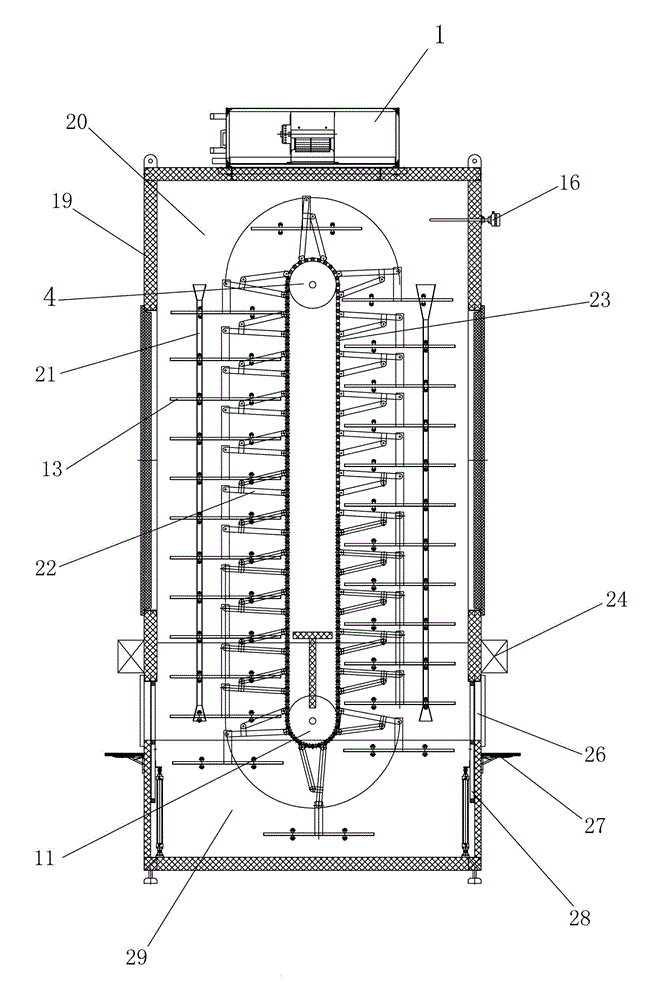

Vertical continuous tempering furnace

ActiveCN104480276AReduce installation spacingIncrease productivityFurnace typesHeat treatment furnacesHanging basketDrive motor

The invention discloses a vertical continuous tempering furnace which comprises a furnace body, wherein a heating zone and a cooling zone are arranged in the furnace body; charging and discharging ports are formed between the heating zone and the cooling zone; an air supply channel is formed in the inner side wall of the heating zone; heating pipes, a circulating fan and filters are arranged on the furnace body; a drive sprocket and a tensioner sprocket are arranged in the furnace body; the drive sprocket is connected with a drive motor; a circulating chain is connected between the drive sprocket and the tensioner sprocket; hanging baskets are connected onto the circulating chain; an air conditioning refrigeration unit is arranged at the top of the furnace body and communicated with a cooling air inlet; and a cooling exhaust fan is arranged on the cooling zone. The vertical continuous tempering furnace is energy-saving; the temperature uniformity and stability are good with adoption of an upper feeding and lower returning type air supply structure on the furnace body, a one-way cycle operation manner is adopted, and the equipment occupation area is reduced due to height increase; and meanwhile, an air conditioning is adopted to cool a workpiece, the workpiece temperature is reduced to be lower than 40 DEG C during workpiece discharging, and the workpiece temperature during workpiece taking is reduced.

Owner:WENTON IND EQUIP JIANGSU

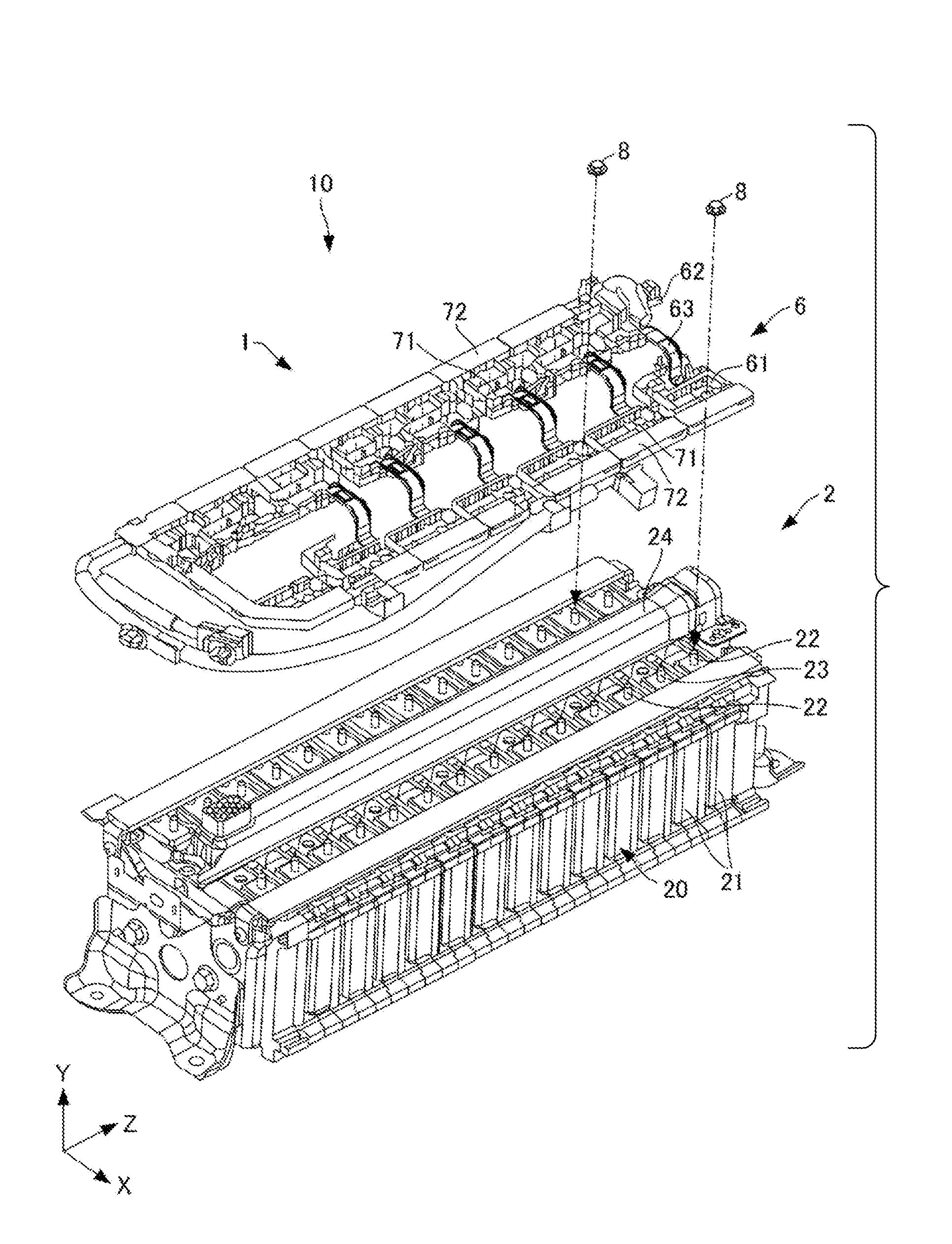

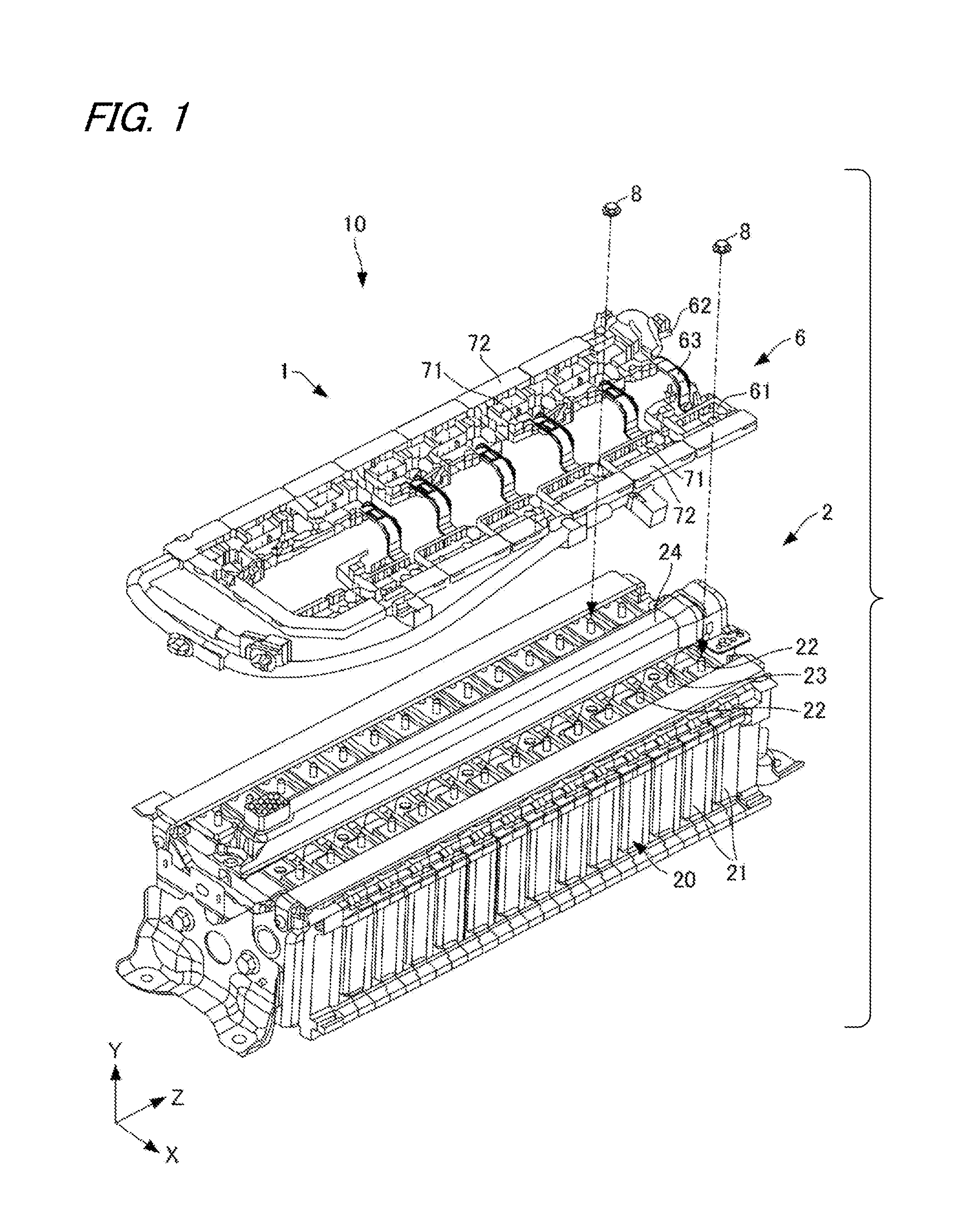

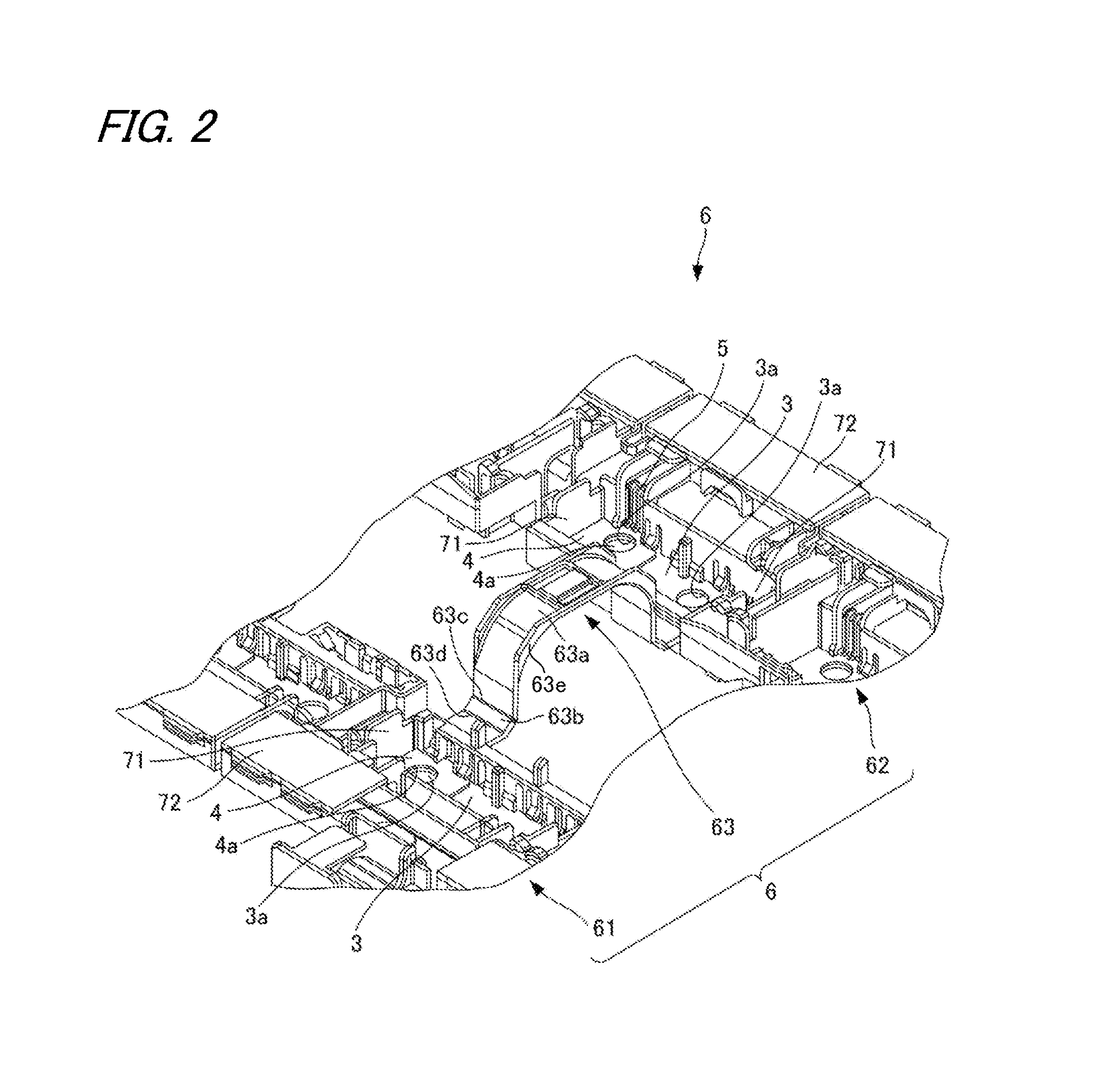

Bus bar module

ActiveUS20140305698A1Increase the gapReduce loadPrinted circuit detailsSecondary cellsMechanical engineeringBattery cell

A bus bar module includes a holding member for holding the plural bus bars with a mutual distance between the bus bars maintained. The holding member includes a first holding member for holding the plural bus bars in one electrode line of the plural battery cells, a second holding member for holding the plural bus bars in the other electrode line of the plural battery cells, and a joining member for structurally joining the first holding member to the second holding member. The joining member is formed in an arch shape upwardly projected from inside ends of the first holding member and the second holding member. The joining member has a rigid part adapted to maintain the arch shape and a flexible part adapted to vertically bend by a load from above.

Owner:YAZAKI CORP

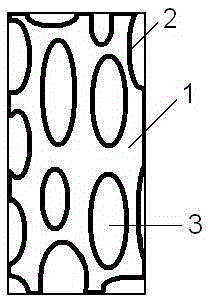

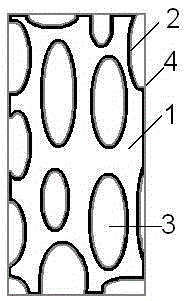

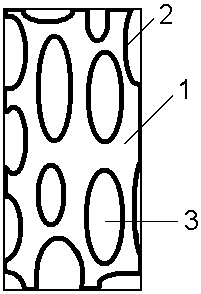

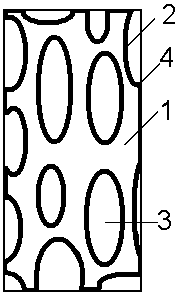

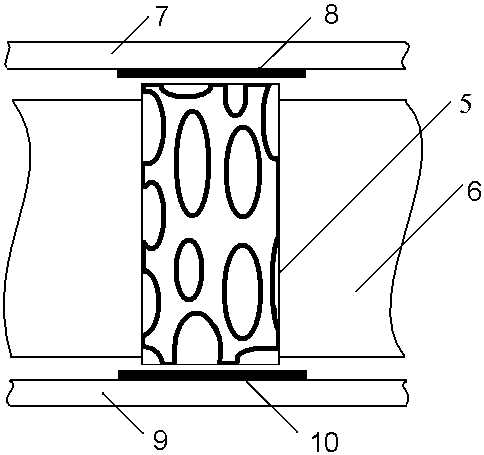

Composite foam metal contact

ActiveCN105406229AReliable contactIncrease profitCoupling contact membersElectrical conductorSkin effect

The invention discloses a composite foam metal contact. The composite foam metal contact comprises an elastic porous polymer skeleton; the porous polymer skeleton is provided with a plurality of mutually communicated holes and is a three-dimensional net type perforated structure; and metal conductor layers are arranged in the communicated holes and on the surface of the porous polymer skeleton. When the composite foam metal contact disclosed by the invention is adopted to be electrically connected with a conductor, with the help of self elastic contact, welding is unnecessary; the composite foam metal contact is reliable to contact, assurable in performance, reusable and high in utilization rate; the equipment purchase cost is reduced; a single structure is simple to install and maintain; due to the large specific surface area, the skin effect of high-frequency signals can be effectively reduced; the composite foam metal contact is particularly suitable for high-frequency signal transmission; the production process is simple; and the consistency of finished products is good.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

Steering stabilizing means

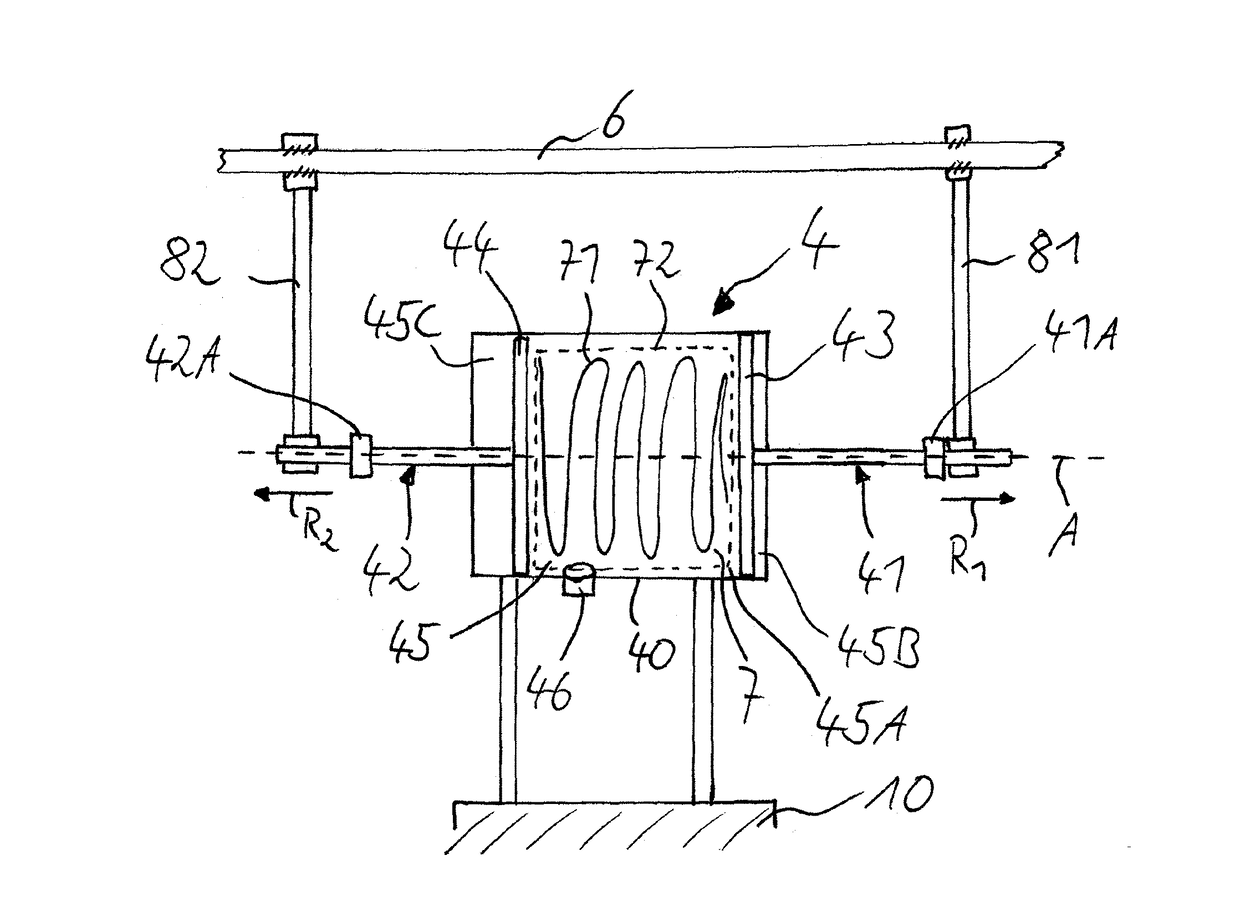

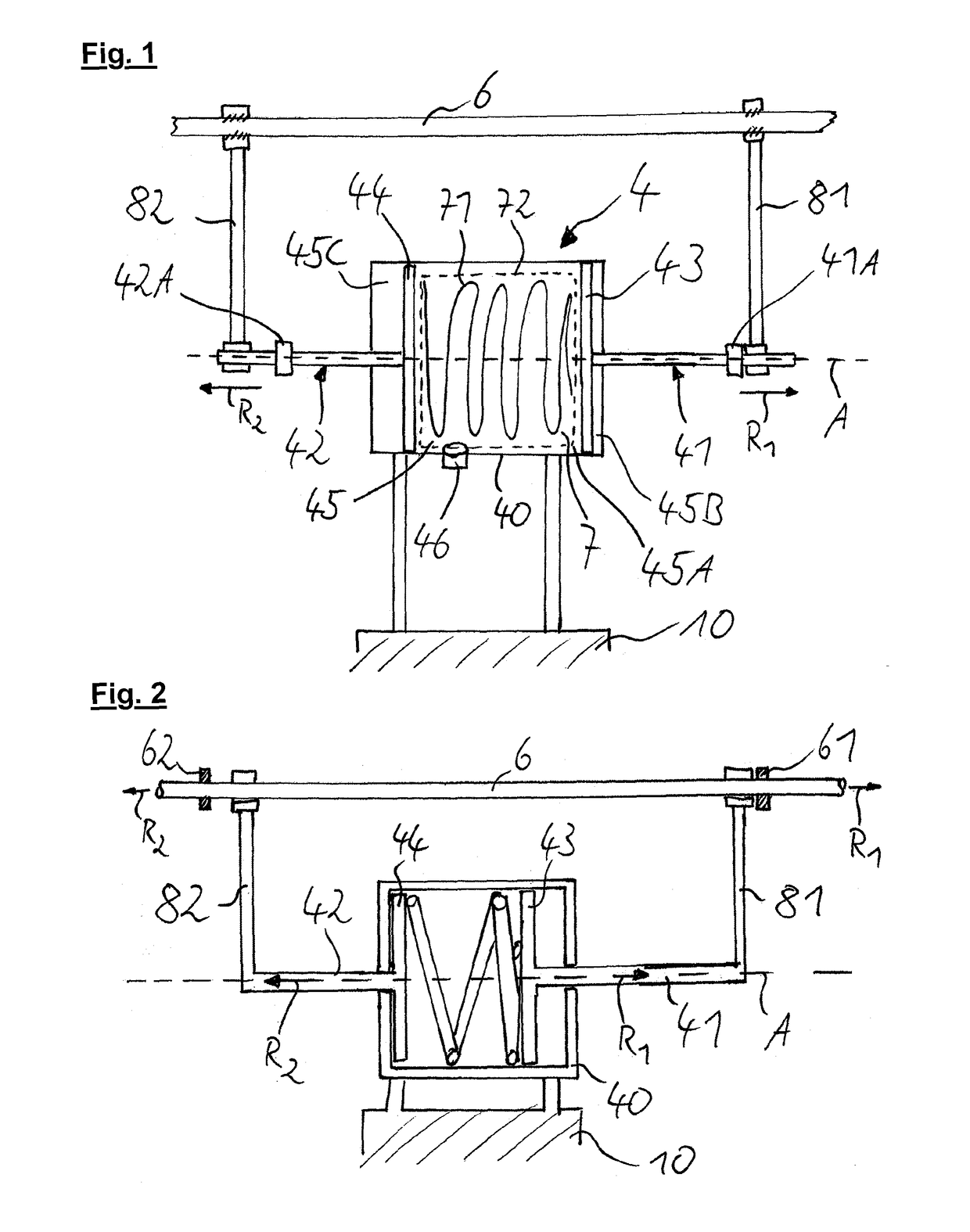

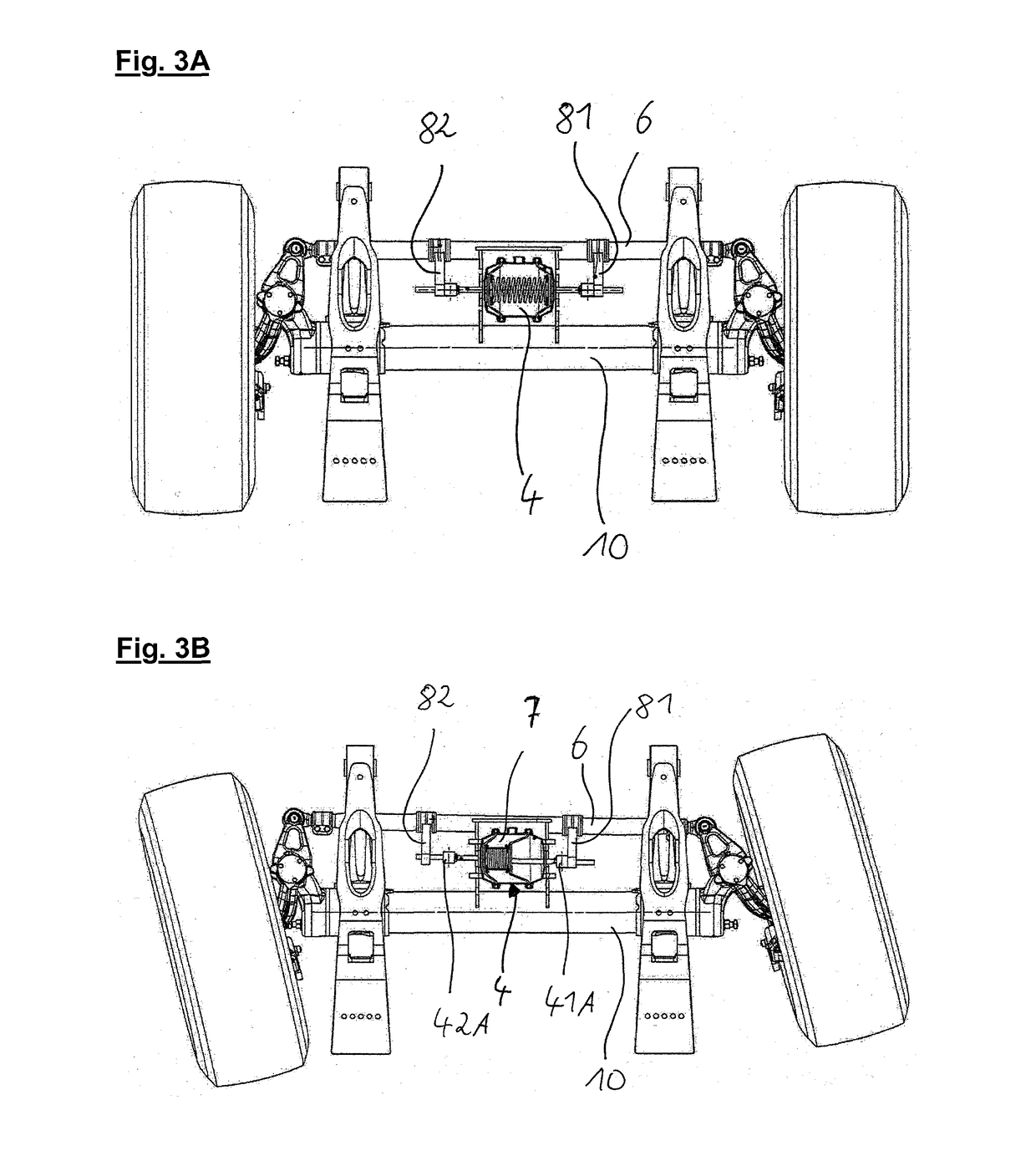

ActiveUS20180009475A1Reduce installation spacingReduce weightSpringsSteering linkagesRestoring forceElectrical and Electronics engineering

An actuating unit for use in a steering stabilizing apparatus that includes a housing, a first transmission element and a second transmission element, wherein the first transmission element and the second transmission element protrude into the housing from the outside and are configured to be displaced along a restoring axis, wherein the first transmission element engages a first pressure element at the first end of the first transmission element and wherein the second transmission element engages a second pressure element at the first end of the second transmission element, and wherein the first pressure element and the second pressure element are disposed within a chamber of the housing and are subjected by a restoring arrangement to a restoring force acting along the restoring axis.

Owner:SAF HOLLAND GMBH

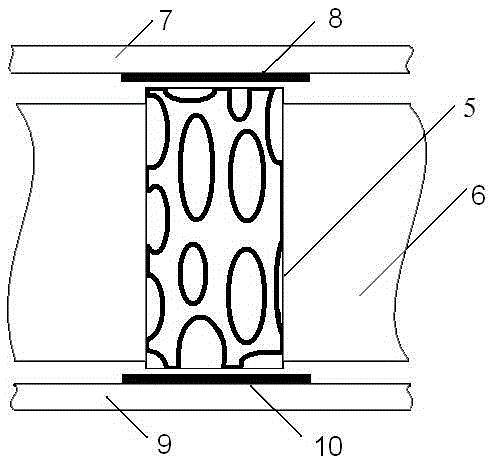

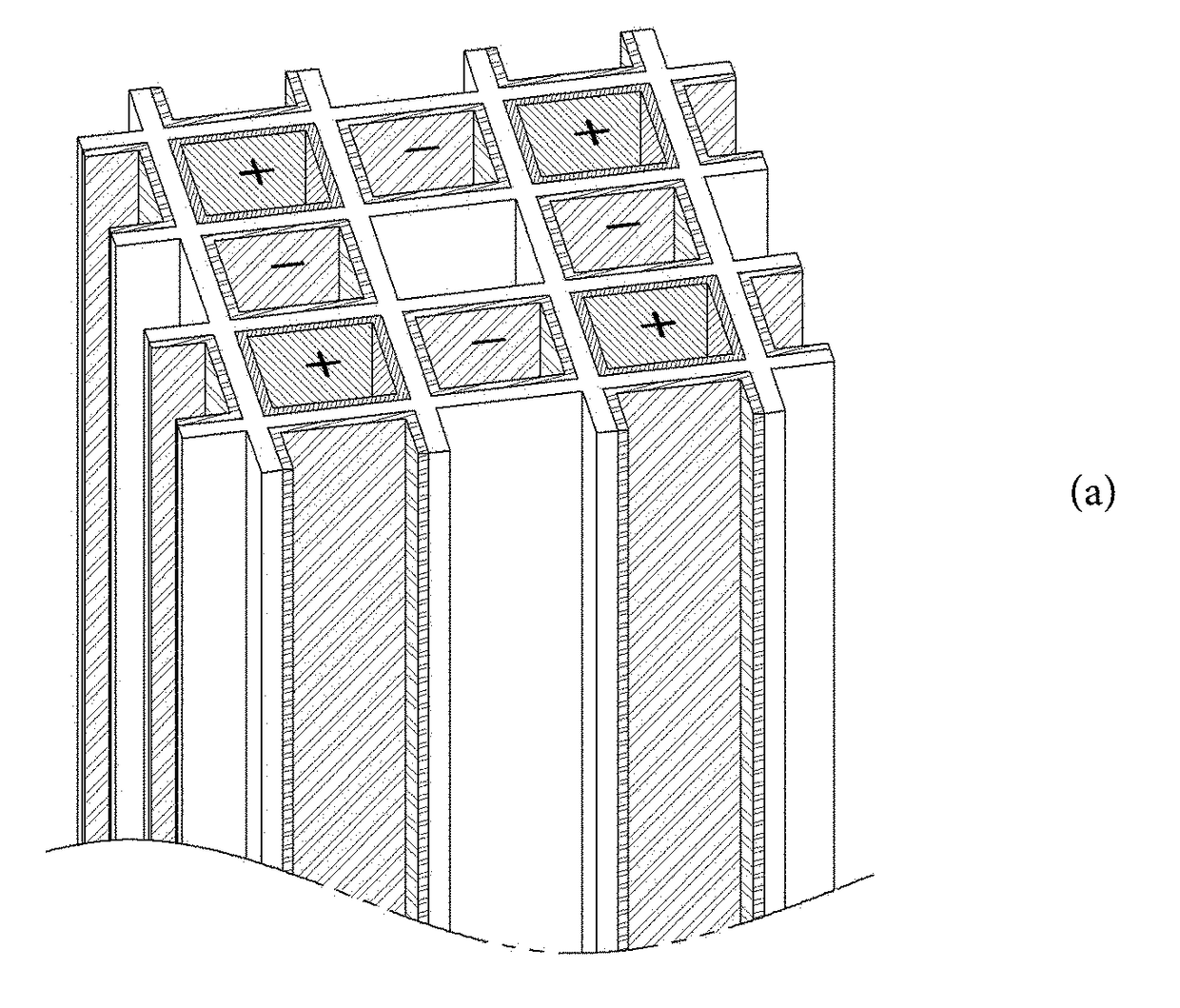

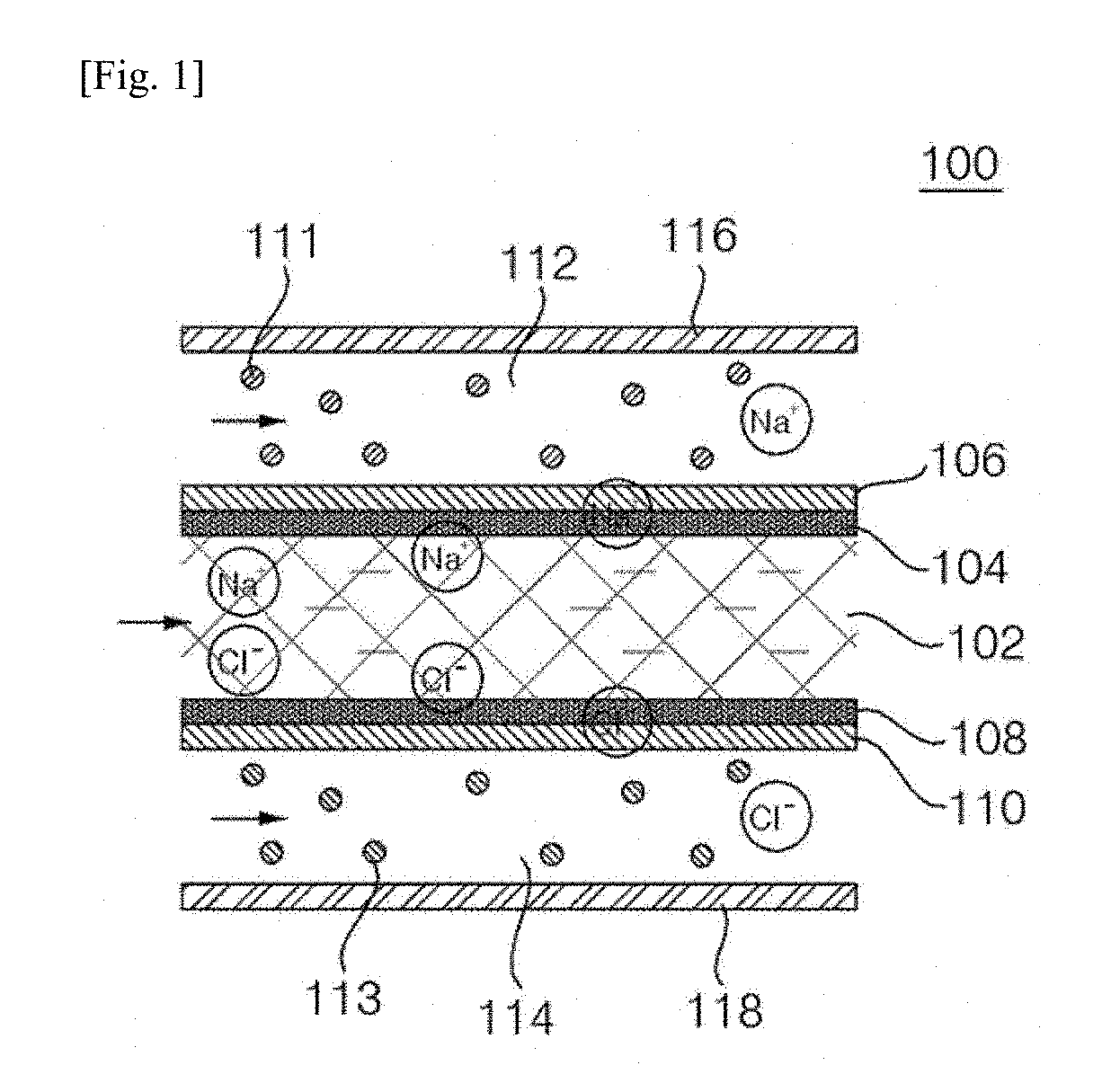

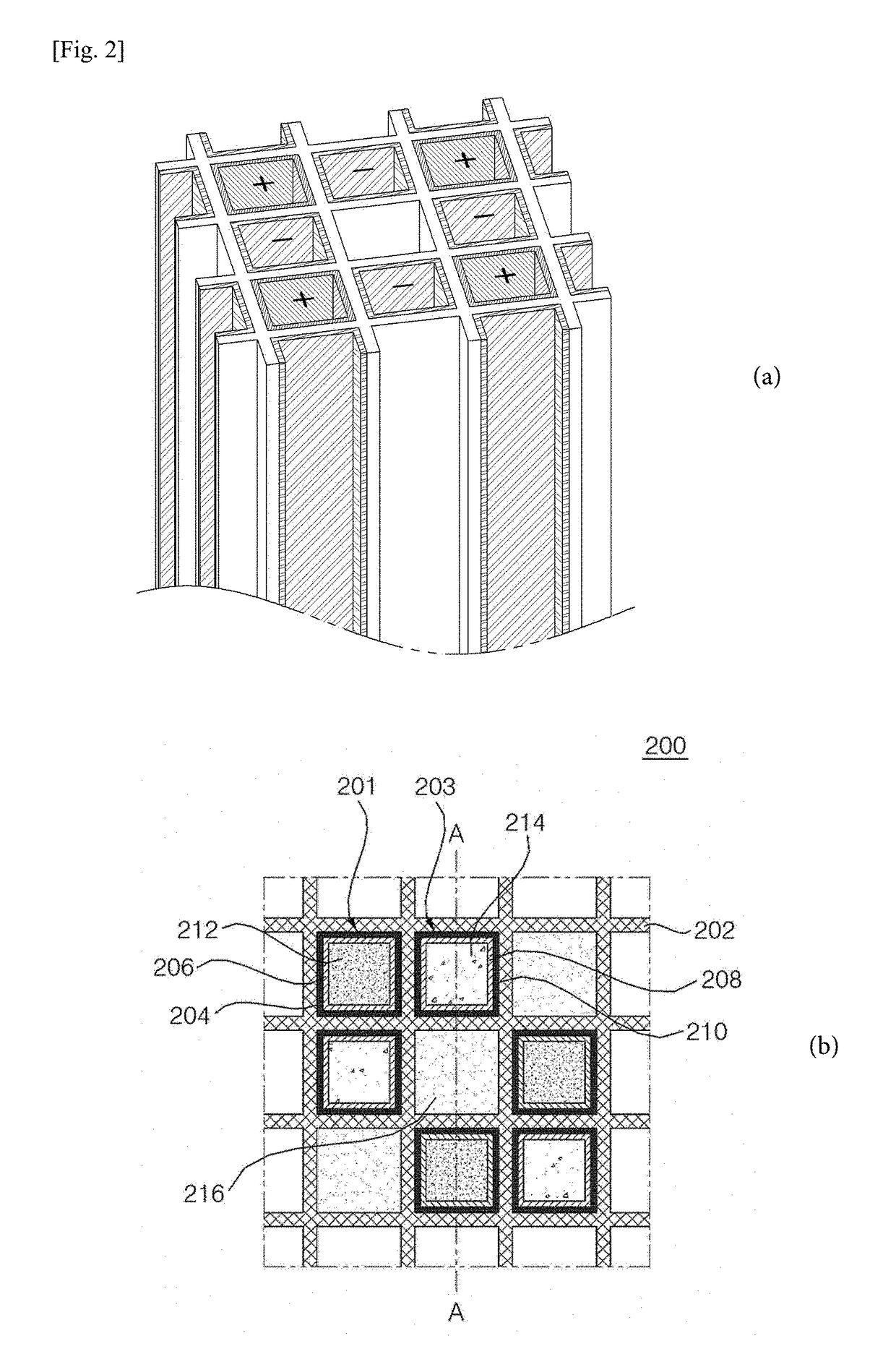

Electrochemical cell comprising channel-type flowable electrode units

ActiveUS20180123145A1Reduce manufacturing costReduce installation spacingGeneral water supply conservationWater/sewage treatment by electrochemical methodsManufacturing cost reductionElectrical battery

The present invention relates to an electrochemical cell having a channel-type flow-electrode unit.The channel-type flow-electrode structure according to the present invention, which has at least two channel-type flow-electrode units, can significantly reduce manufacturing costs and installation space by reducing the number of parts while extending the electrode capacity to be suitable for large-scale plants for electricity generation, energy storage, desalination, etc. In addition, the channel-type flow-electrode structure can be applied not only to a capacitive flow-electrode device and / or a redox flow battery device, but also to all of the devices for electricity generation, energy storage, and desalination while moving ions or protons.

Owner:KOREA INST OF ENERGY RES

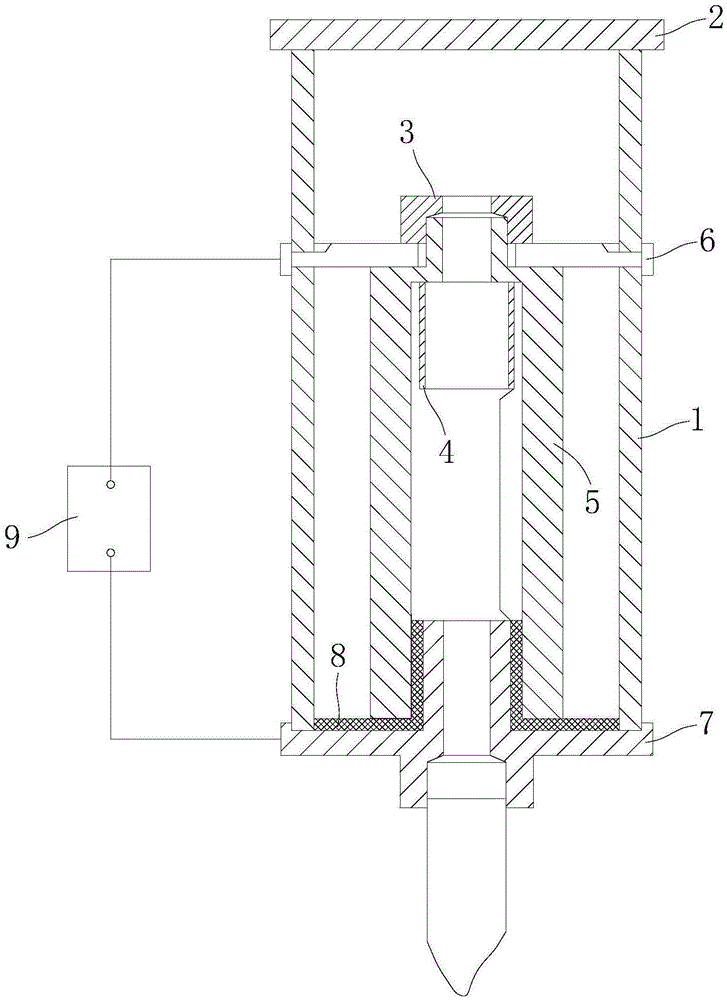

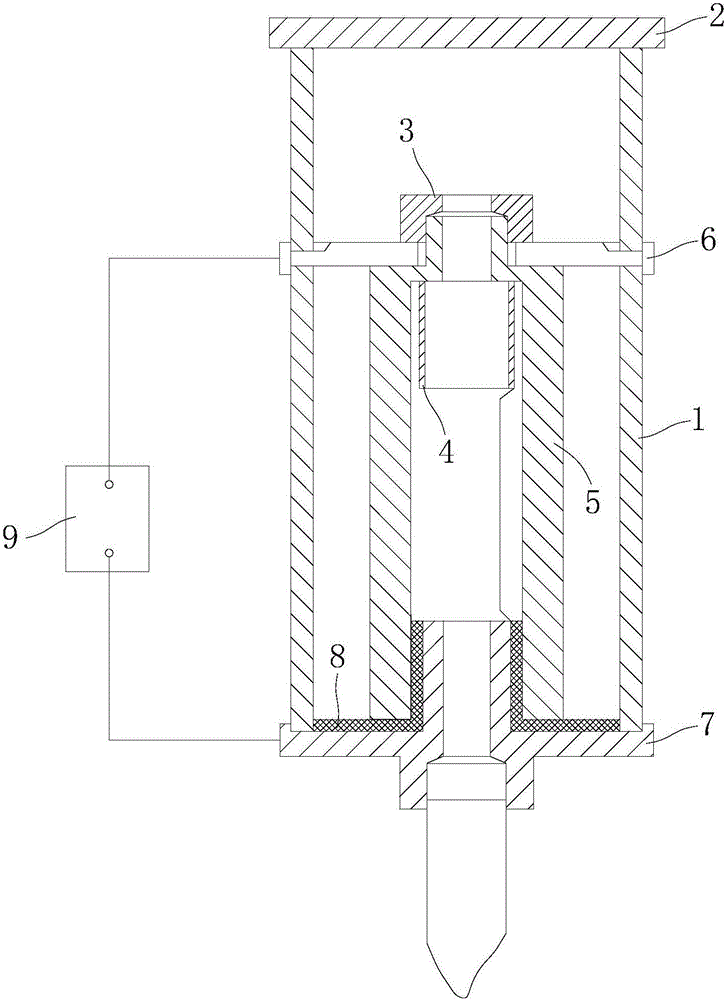

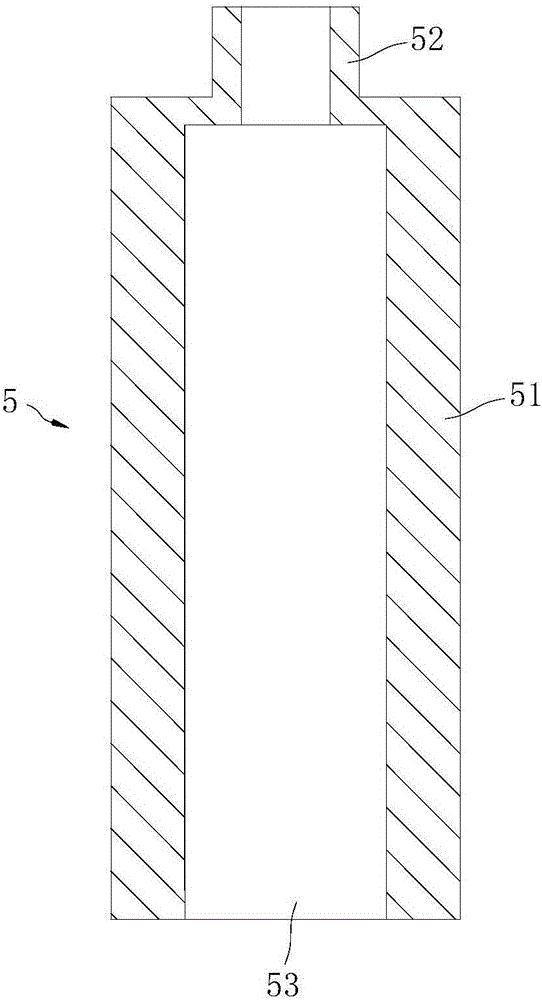

Electromagnetic pulse rigid shaft sliding valve

InactiveCN101813212AExtend your lifeImprove performanceOperating means/releasing devices for valvesEngineeringElectromagnetic pulse

The invention discloses an electromagnetic pulse rigid shaft sliding valve which comprises a pilot head component, a pilot head pressure plate, a pilot base and a valve cover. The pilot head component is controlled by an electromagnetic coil, the pilot head pressure plate, the pilot base and the valve cover are sequentially connected, a flexible diaphragm is mounted in the valve cover and internally provided with a damping hole, balance holes are arranged on the valve cover, a valve seat is connected with the lower part of the valve cover and provided with a central through hole which extends downwards to form a sleeve, the sleeve is internally provided with a bowl-shaped rigid shaft with a U-shaped section, the lower part of the valve seat sleeve is connected with an air vent connecting tube; and the bowl-shaped rigid shaft is arranged on the top end surface of the air vent connecting tube. The bowl-shaped rigid shaft substitutes for a diaphragm component of a diaphragm-type electromagnetic pulse valve working cavity in the electromagnetic pulse rigid shaft sliding valve to save a pressure spring on the diaphragm and greatly prolong the service life of the electromagnetic pulse valve; in addition, by adopting the circular end surface in a closing and start-type bowl-shaped rigid shaft structure, the electromagnetic pulse rigid shaft sliding valve has easy manufacture and reliable working performance; moreover, the electromagnetic pulse rigid shaft sliding valve has stronger pulse blowing performance and less mounting distance. Blowing tubes are better arranged when a bag-type dust collector blowing system is designed.

Owner:XIECHANG ENVIRONMENTAL PROTECTION TECH CO LTD

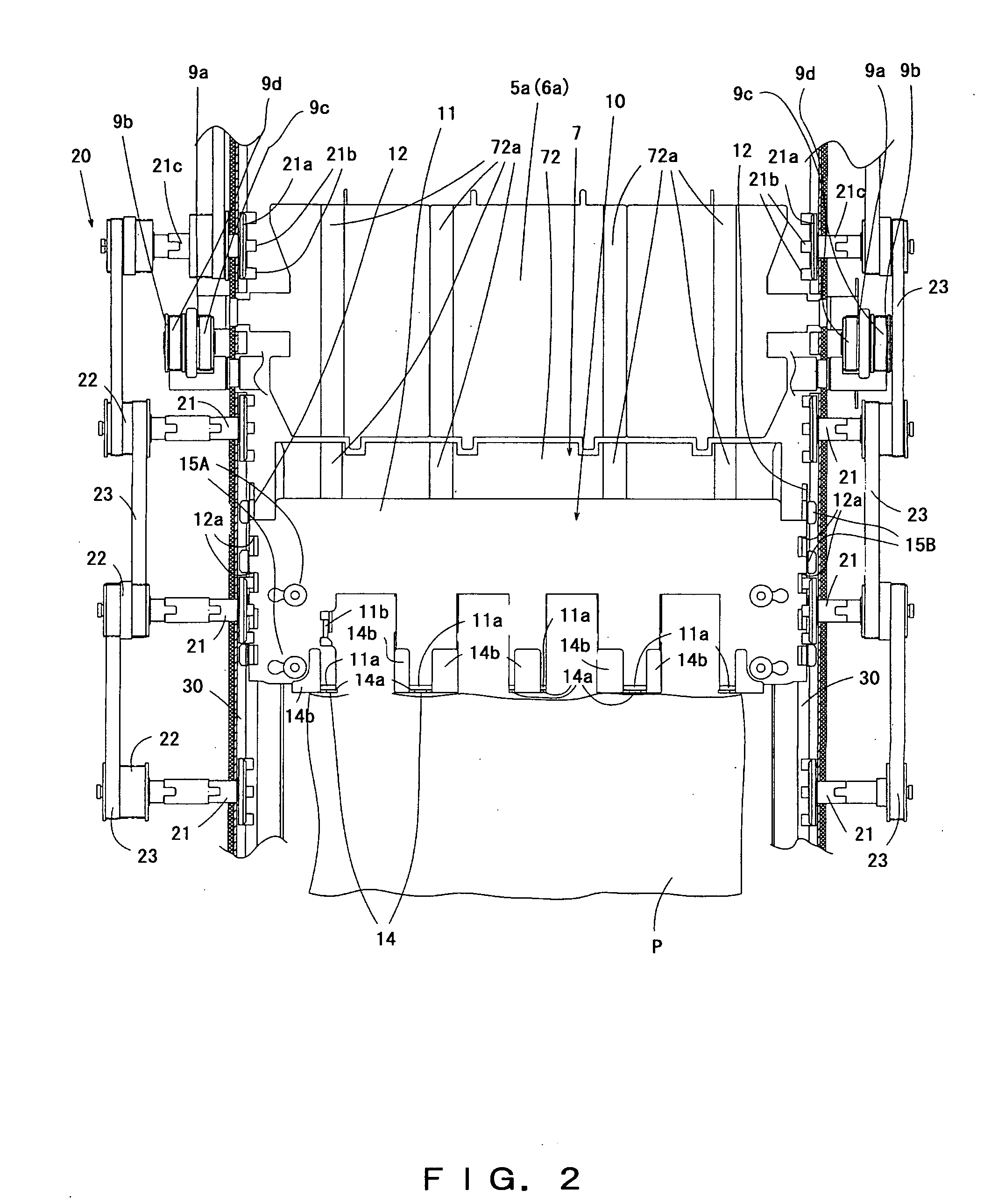

Bundle transport apparatus for paper sheet materials and handling apparatus for the same

InactiveUS20070007712A1Wide versatilityReducing required componentCoin countersSemiconductor/solid-state device manufacturingCentre of rotationMaterial transport

The configuration comprises a carrier equipping an ejection plate on the front for ejecting the bundled-paper sheet material P and equipping a plurality of cutout parts, which are open in their top parts, at a predetermined interval on both the left and right sides; and a drive transmission unit being equipped by a plurality of drive rollers, each of which comprises a plurality of bosses in a predetermined interval on a single circumference around the rotation center thereof, in a predetermined interval on both the left and right sides of the bundled-paper sheet material transport path, wherein a drive force is transmitted by allowing bosses of each drive roller, which rotates by receiving a drive force from a drive source, engage in the respective cutout parts of the carrier sequentially, thereby allowing the carrier travel in the front and back directions of the bundle transport path.

Owner:FUJITSU LTD

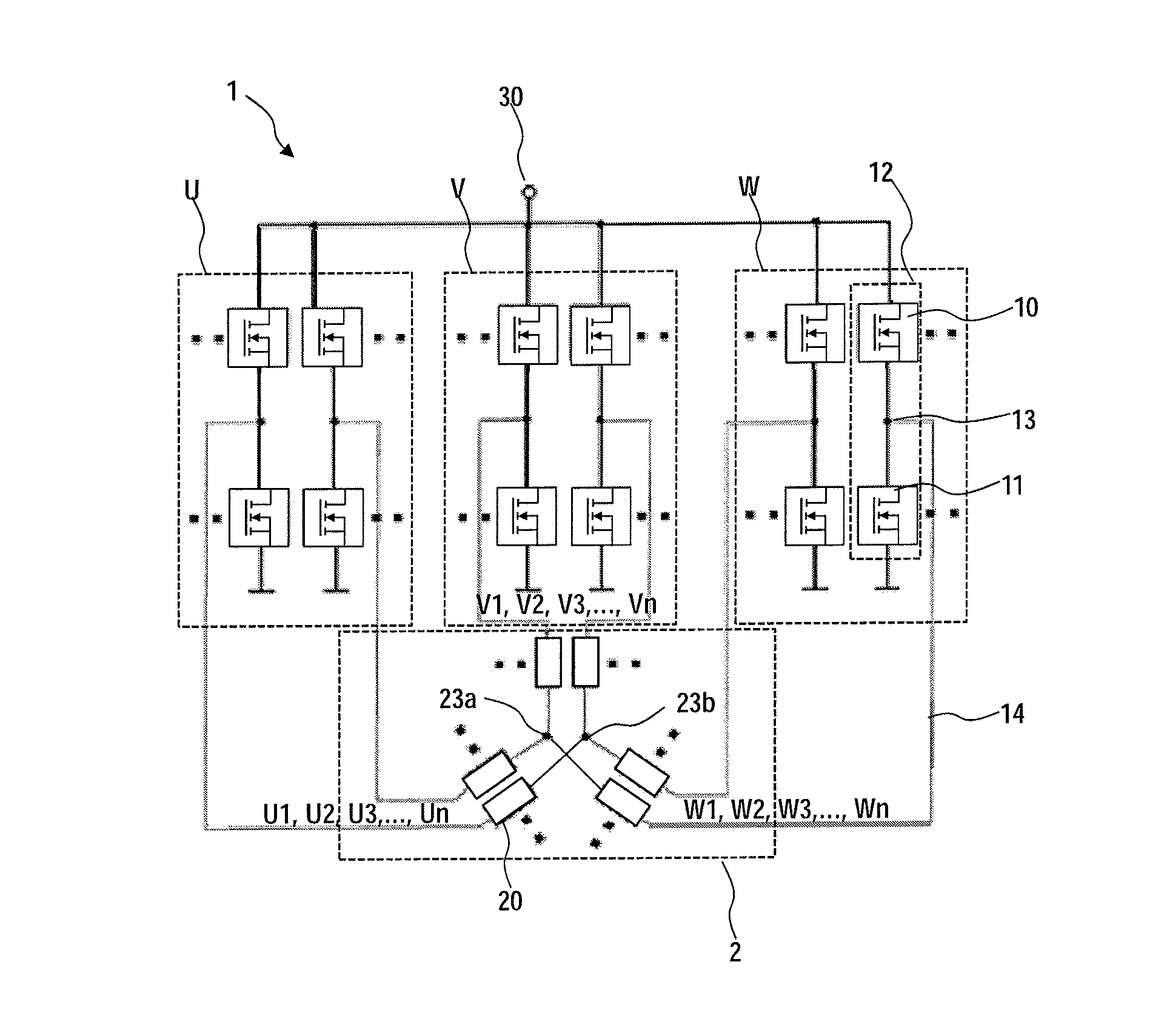

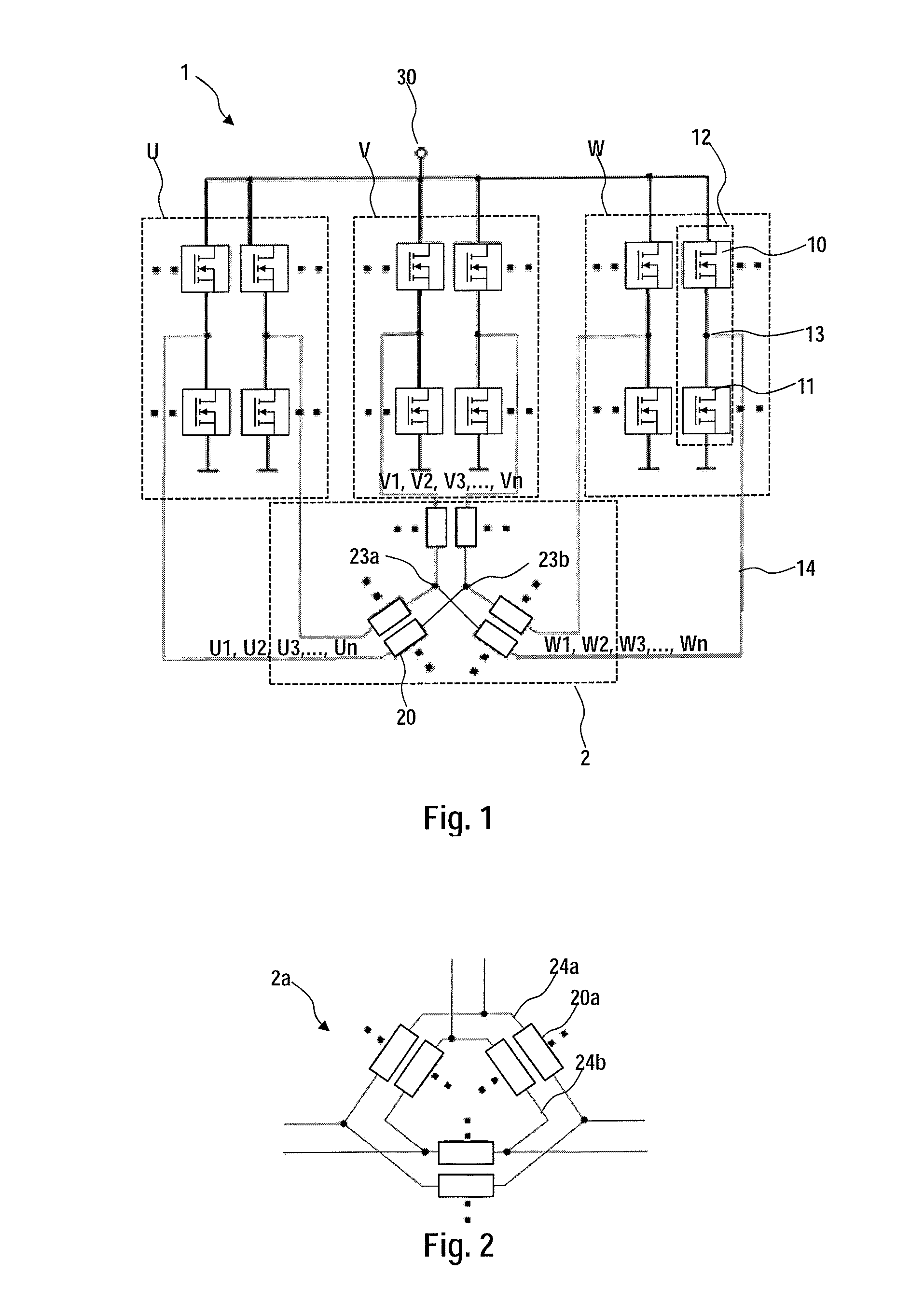

Circuit arrangement having redundant half bridges for operating an electric machine

InactiveUS20160087571A1Improve reliabilityLow costAC motor controlElectric motor controlElectricityElectric machine

A circuit arrangement for operating an electric machine, which has a plurality of lines, each for one phase of an alternating current to the electric machine, each line having a plurality of series-connected switching elements that form a half bridge, the half bridge having a terminal between two switching elements, and the circuit arrangement being electrically couplable to the electric machine via the terminals of the half bridge. The circuit arrangement is characterized in that each line has a plurality of half bridges, which are electrically connected parallel to each other.

Owner:CONTINENTAL AUTOMOTIVE GMBH

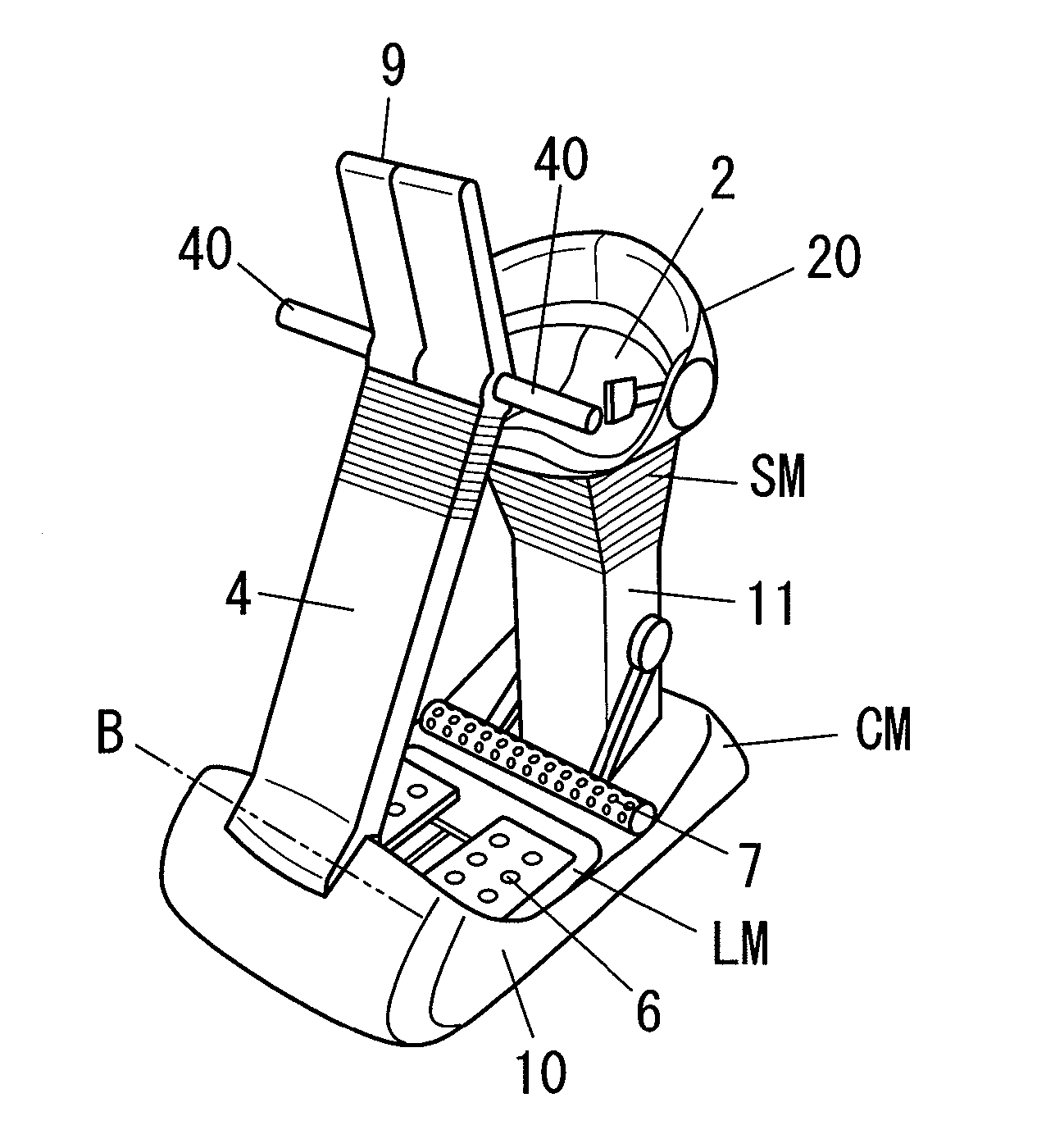

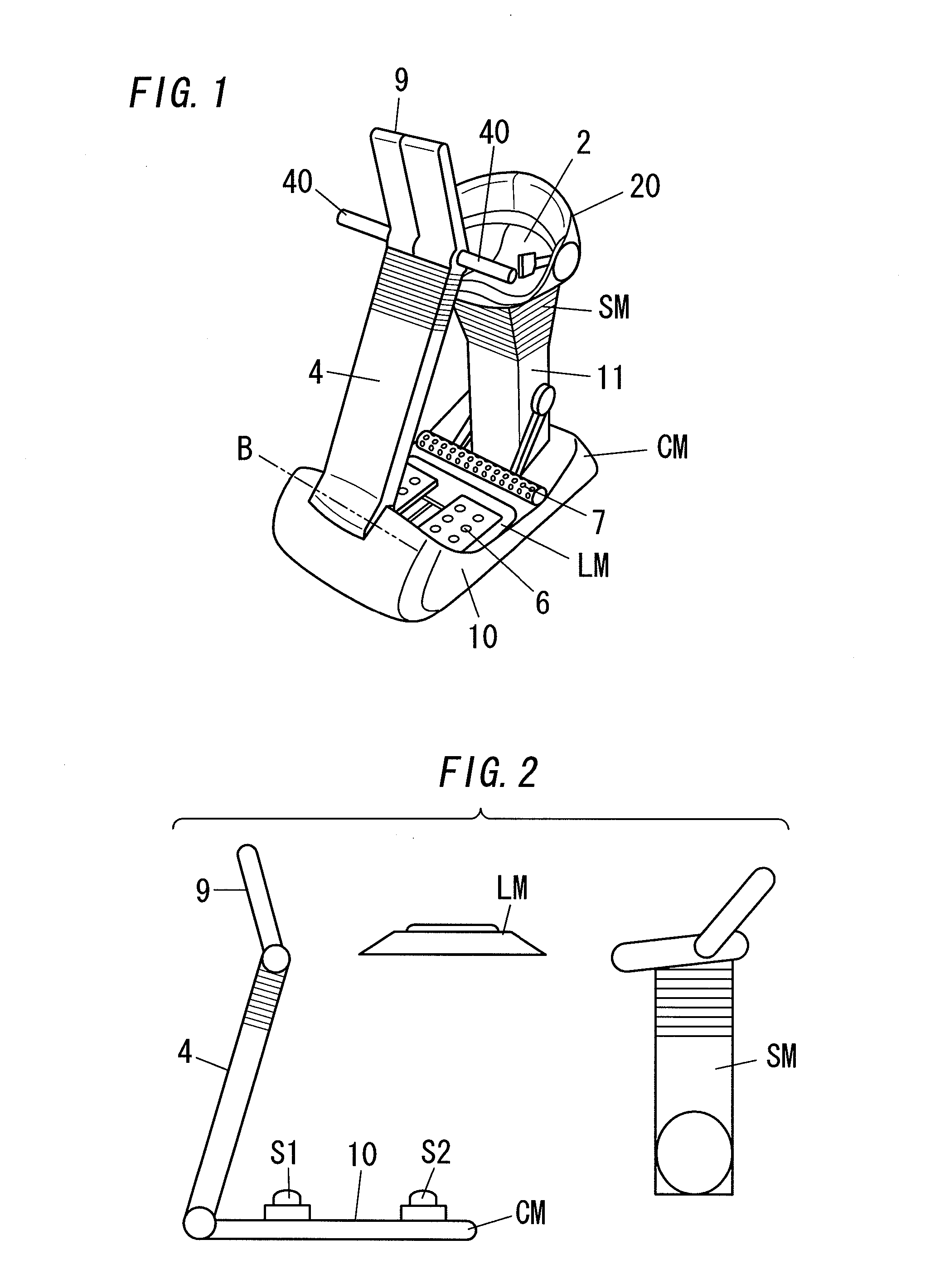

Exercising device

InactiveUS20110130248A1Low costReduce installation spacingChiropractic devicesMovement coordination devicesEngineering

Owner:PANASONIC CORP

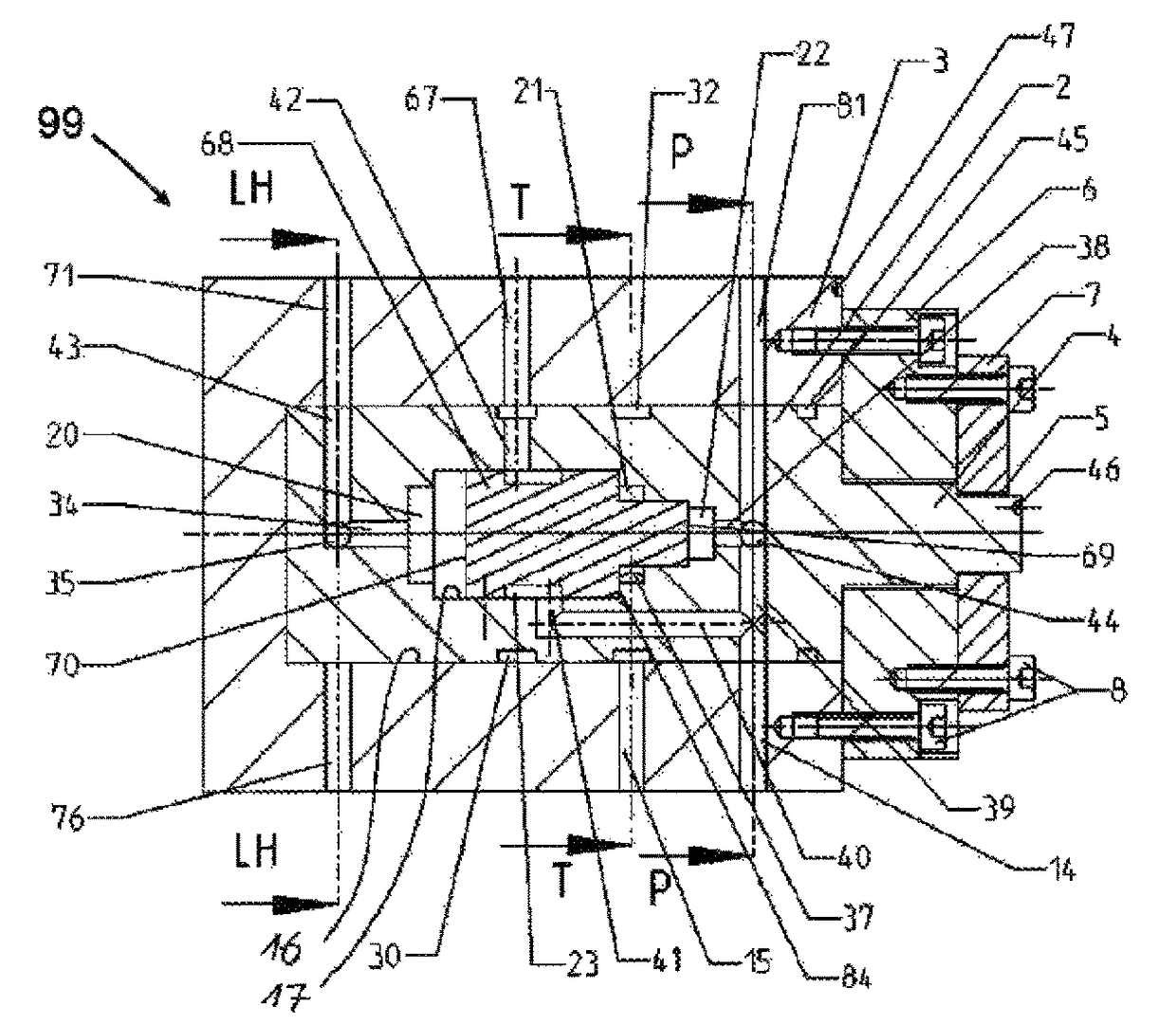

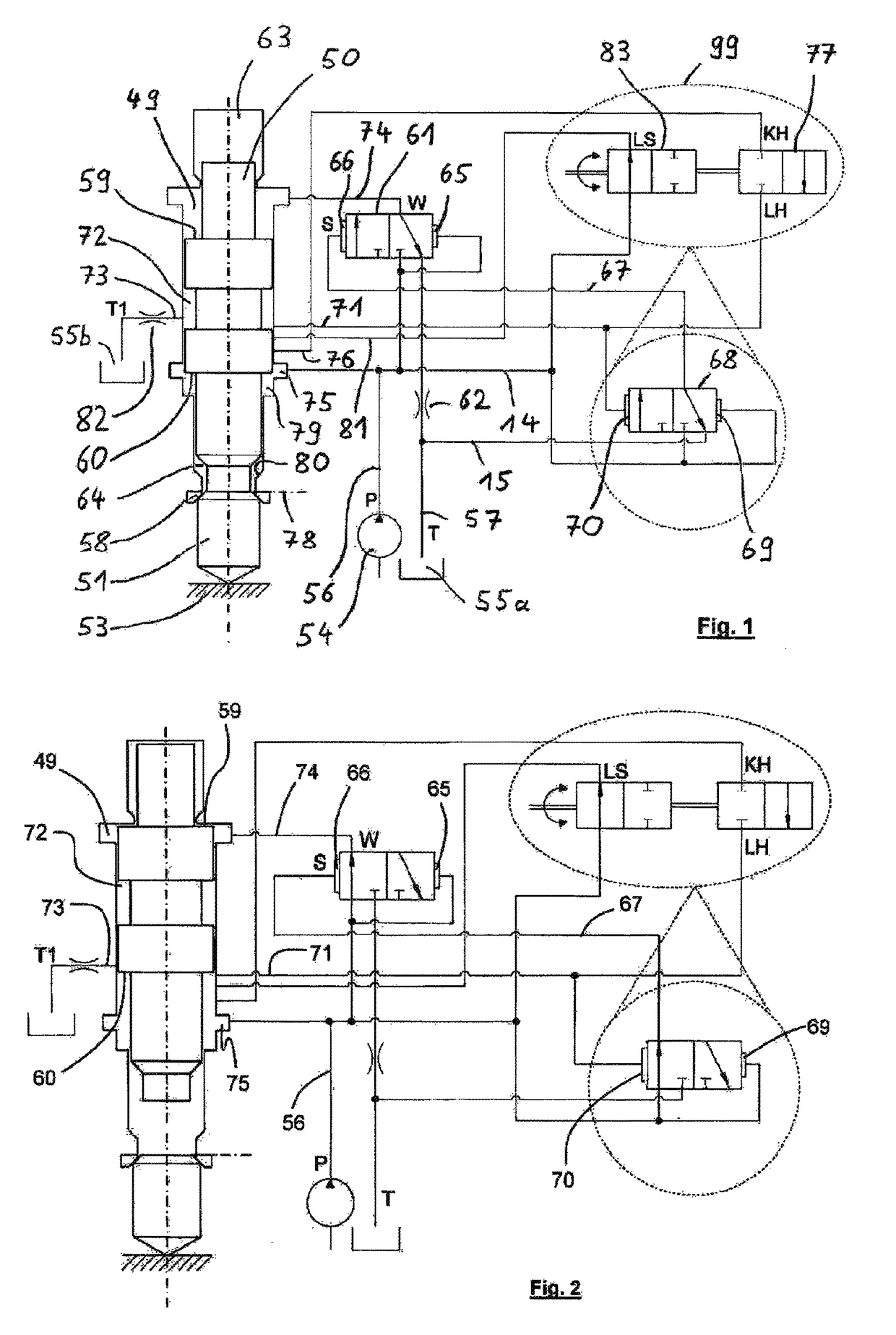

Valve

InactiveUS9868197B2Reduce installation spacingLow production costServomotor componentsMechanical machines/dredgersRotary valveEngineering

Owner:CONSTR TOOLS

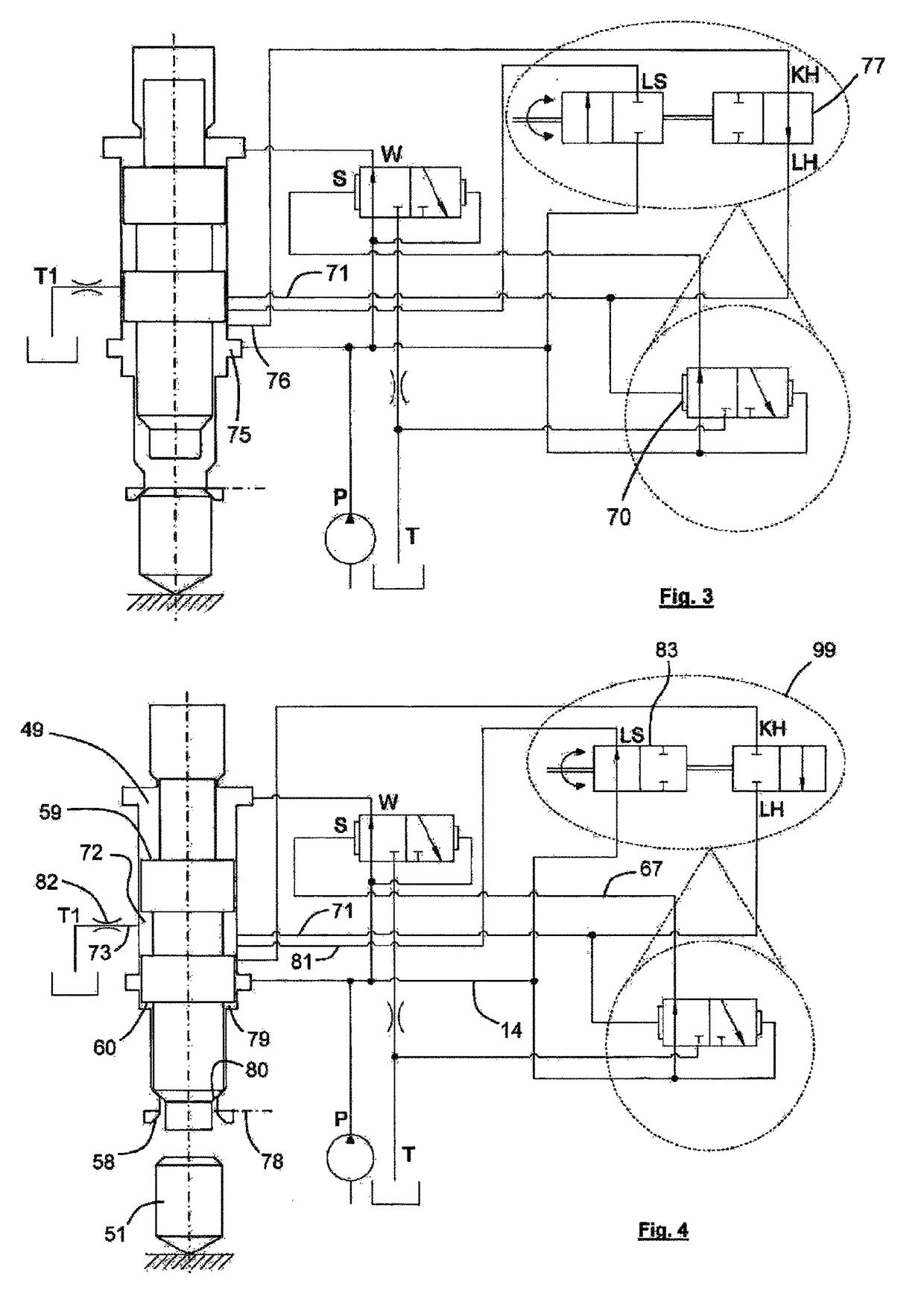

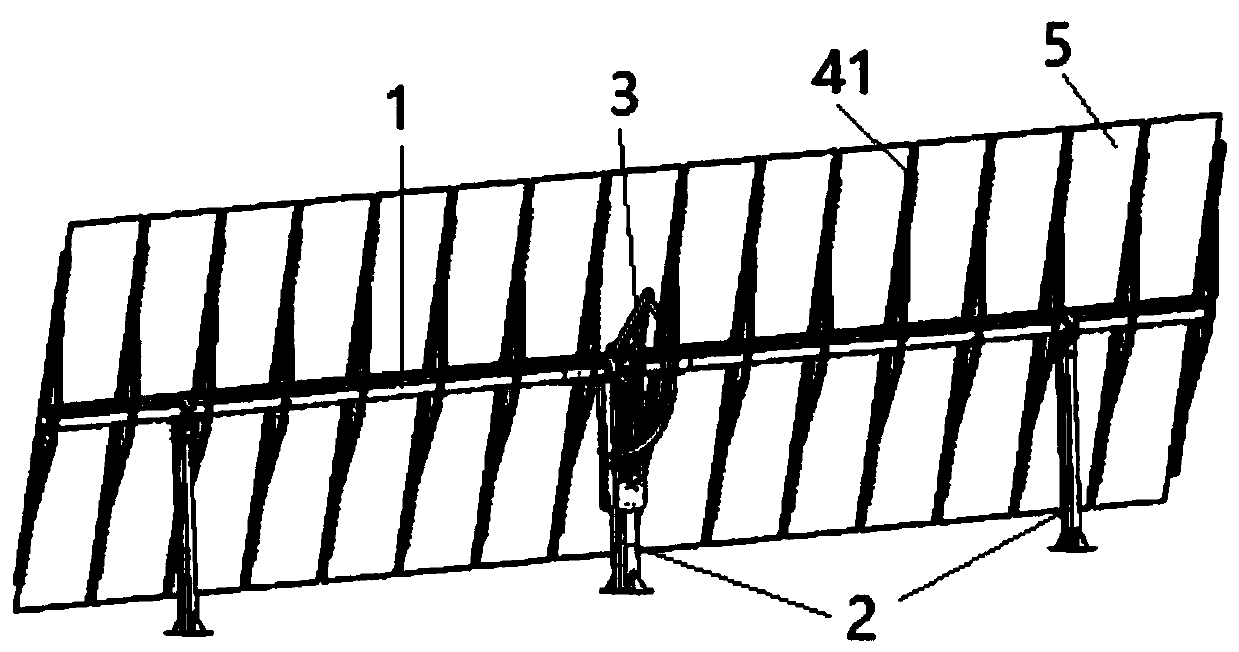

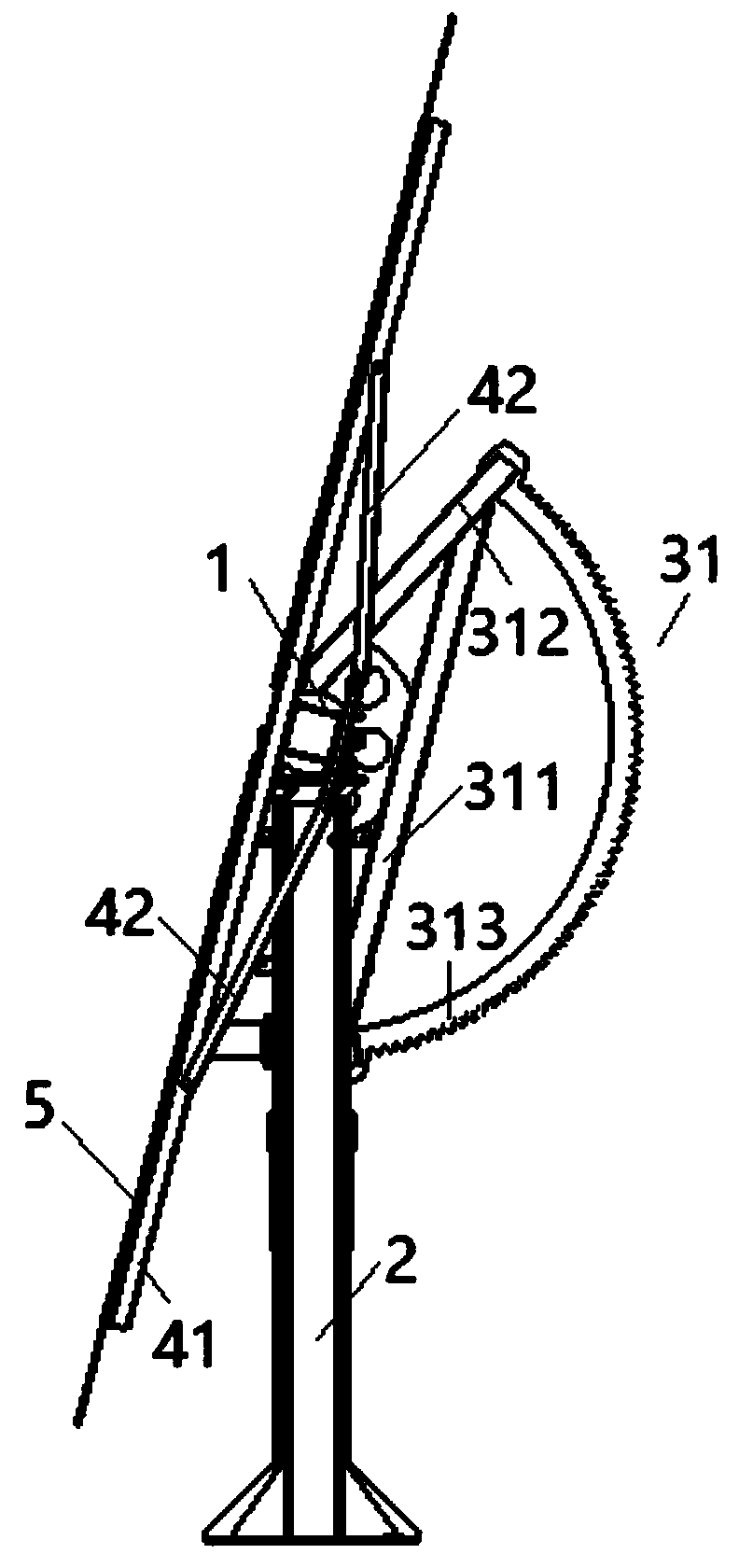

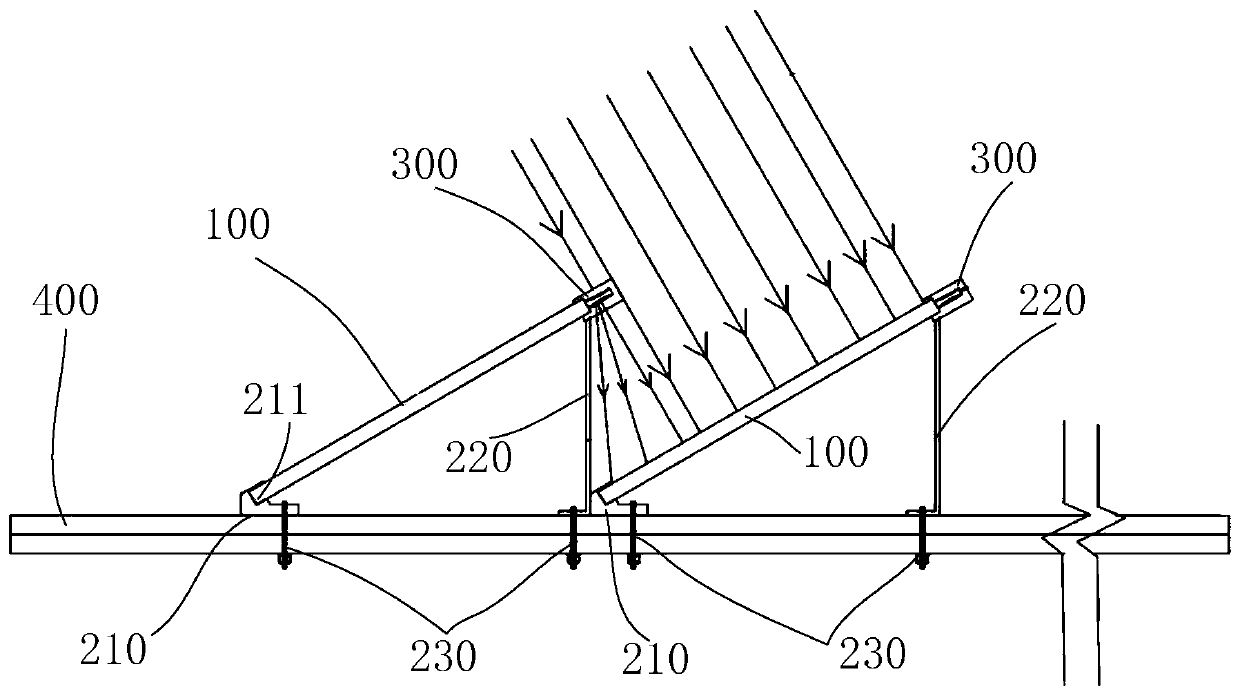

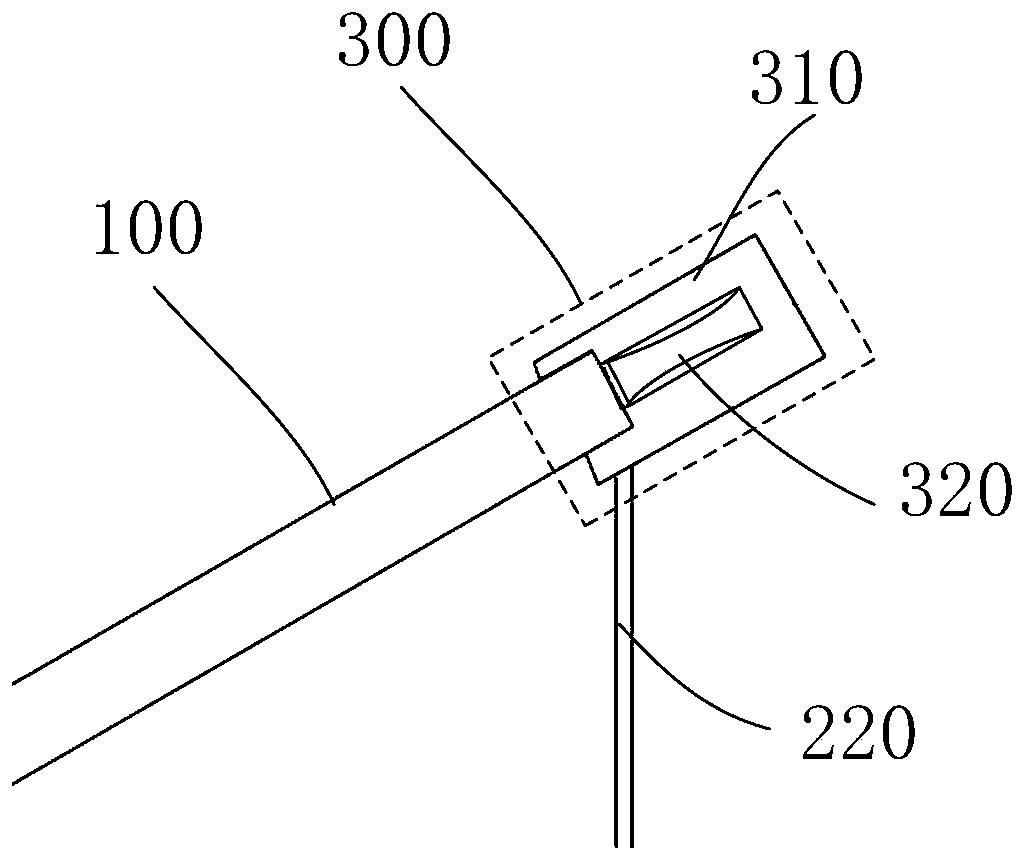

Novel sun-chasing transmission tracing system and photovoltaic system comprising same

PendingCN109889154AHigh mechanical strengthGood limit performancePhotovoltaic supportsSolar heating energyDrive motorRadiation

The invention discloses a novel sun-chasing transmission tracing system and a photovoltaic system comprising the same. The novel sun-chasing transmission tracing system comprises a multi-square arc tube, a vertical post and a shift wheel transmission mechanism, wherein the multi-square arc tube is used for supporting a photovoltaic panel, the vertical post is used for the multi-square arc tub, theshift wheel transmission mechanism comprises a driving motor, fan-shaped shift teeth and a roller, annular teeth are arranged on a peripheral wall of the fan-shaped shift teeth and are engaged with the roller, the driving motor drives the roller to rotate so as to drive the fan-shaped shift teeth to rotate so that the multi-square arc tub is driven to do sun-chasing motion by the fan-shaped shiftteeth; limitation teeth are arranged at initial ends and tail ends of the fan-shaped shift teeth along extension directions of the annular teeth and protrude outwards in a radial direction, and the sizes of the limitation teeth along a radiation direction of the fan-shaped shift teeth are larger than the sizes of teeth of the annular teeth along the radial direction of the fan-shaped shift teeth.The novel sun-chasing transmission tracing system is high in mechanical strength, favorable in limitation performance and simple in structure, is easy to implement and is reliable; and since the limitation teeth are arranged at two ends, the limitation position is clear and is convenient to maintain, and the maintenance difficulty is reduced.

Owner:ARCTECH SOLAR CHANGZHOU CO LTD

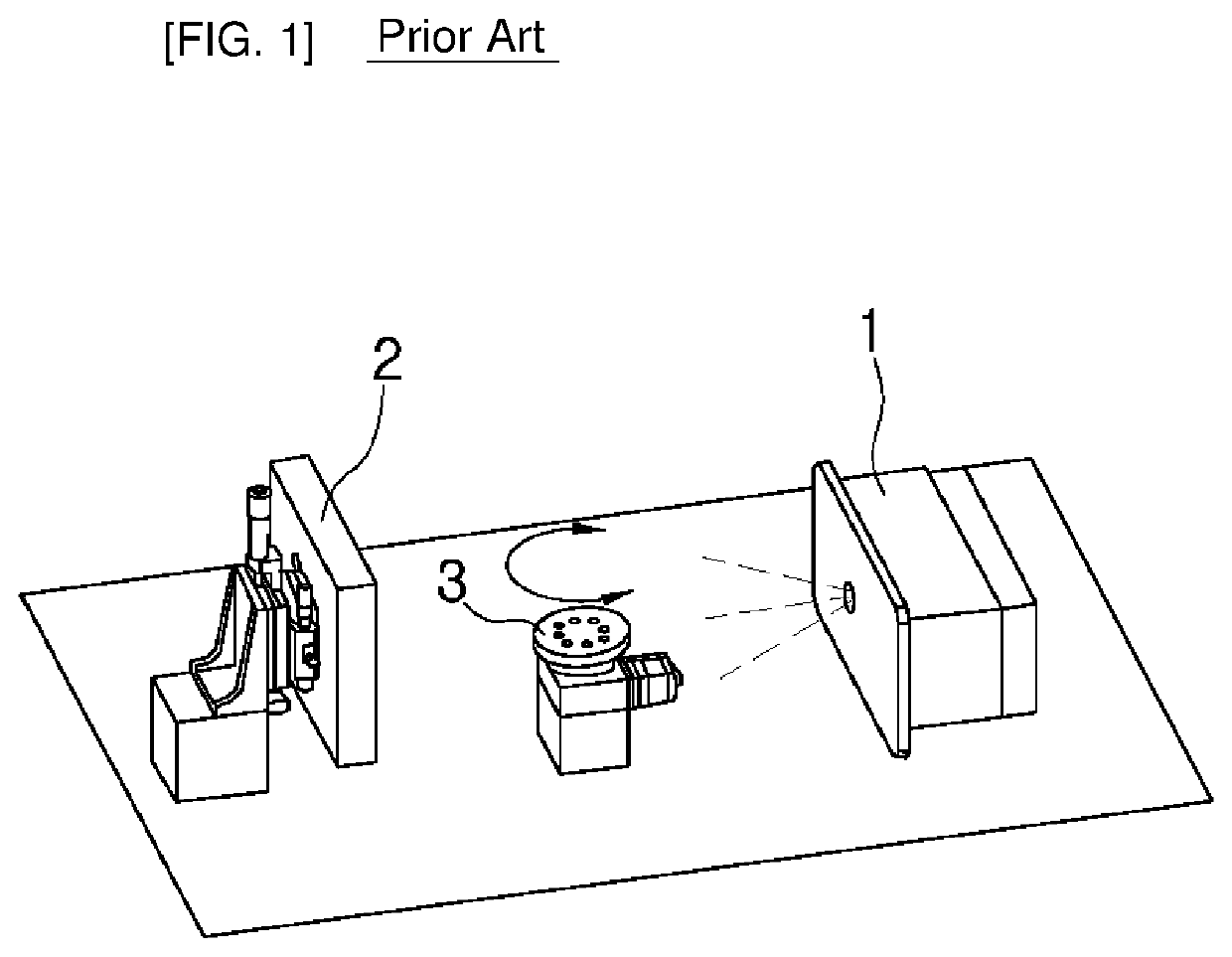

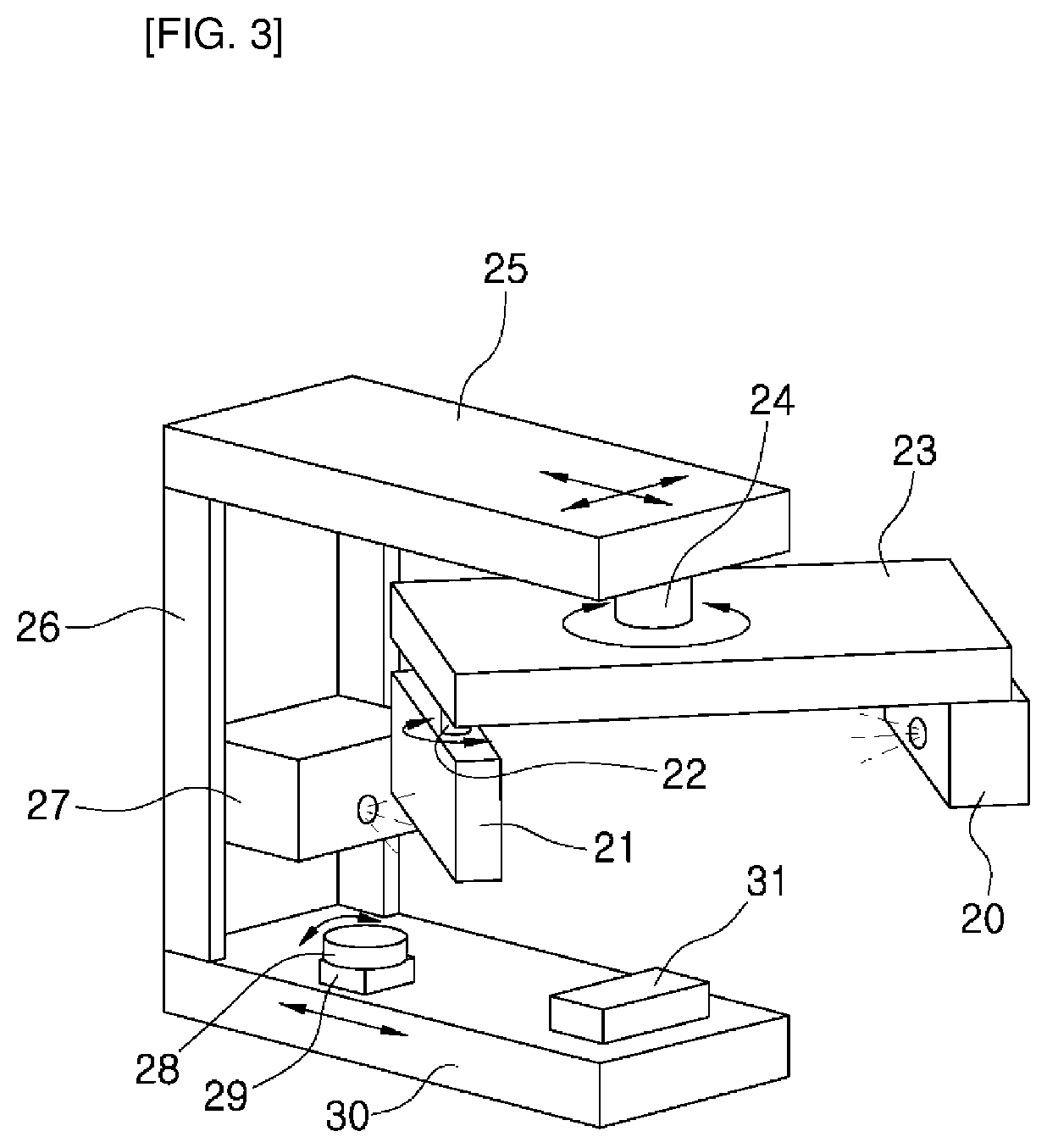

X-ray computed tomography apparatus with scanner function

ActiveUS20210030382A1Perform operationHigh resolutionMaterial analysis using wave/particle radiationPatient positioning for diagnosticsHelical computed tomographyTomography

An X-ray computed tomography apparatus with a scanner function includes a vertical frame, a patient support arm provided below the vertical frame, a horizontal support arm extending horizontally from a top portion of the vertical frame, a rotary arm drive unit provided at an end of the horizontal support arm, a horizontal rotation arm provided horizontally below the rotary arm drive unit to rotate 360 degrees, a general CT imaging X-ray source provided at one end of the horizontal rotation arm, and an X-ray detector provided at the other end of the horizontal rotation arm to face the general CT imaging X-ray source. A micro CT imaging X-ray source is provided on the vertical frame, a rotary table for seating and rotating an object to be imaged is provided above the patient support arm, and the X-ray detector is composed of a common X-ray detector.

Owner:RAY

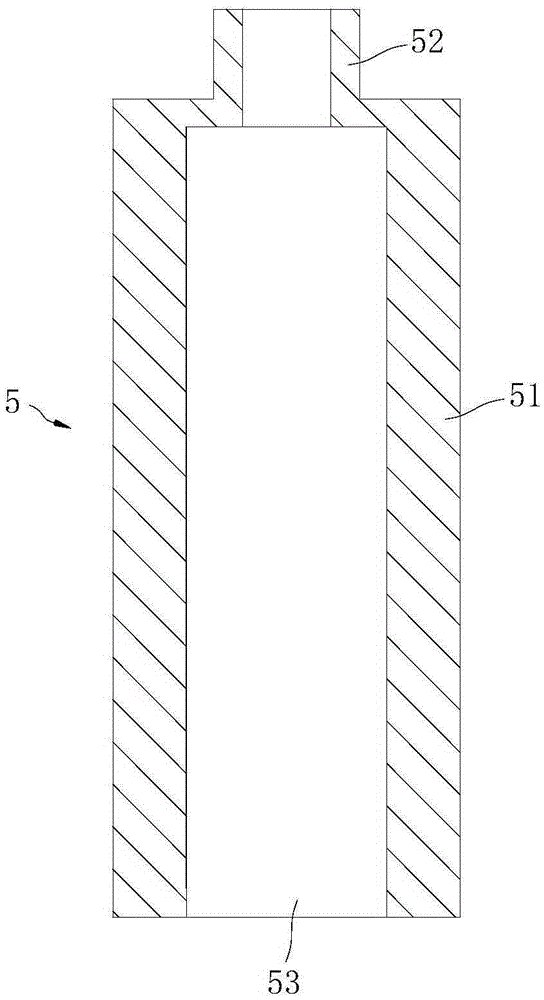

Ultraviolet discharge lamp

ActiveCN105428202AExtend working lifeImprove breakdown voltageGas discharge lamp detailsGlow dischargeOptoelectronics

The invention discloses an ultraviolet discharge lamp, which comprises a lamp tube, an output window, a first electrode, a second electrode, a ceramic tube, a first electrode holder and a second electrode holder, wherein the ceramic tube is arranged in the lamp tube; the first electrode is arranged at the outer side of one end, close to the output window, of the ceramic tube; and one end, close to the second electrode holder, of the first electrode holder and / or one end, close to the first electrode holder, of the second electrode holder are / is coated with an insulating structure. The ultraviolet discharge lamp has the beneficial effects that the insulating structure coating the first electrode holder and / or the second electrode holder is adopted by the ultraviolet discharge lamp; and breakdown voltage between the first electrode holder and the second electrode holder is increased, so that the possibility of glow discharge between the first electrode holder and the second electrode holder is greatly reduced; the operating life of the ultraviolet discharge lamp is prolonged; and the stability of the ultraviolet discharge lamp is improved.

Owner:SHENZHEN NUOAN ENVIRONMENTAL & SAFETY INC +1

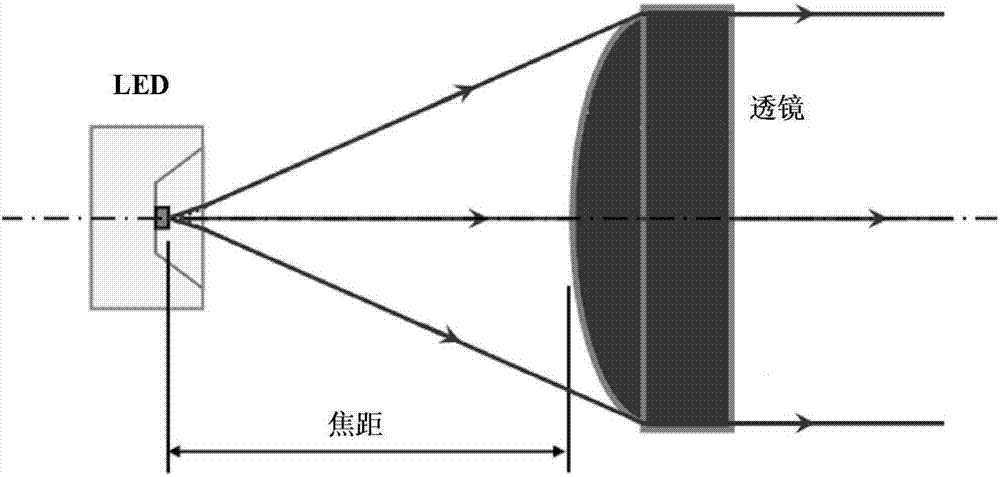

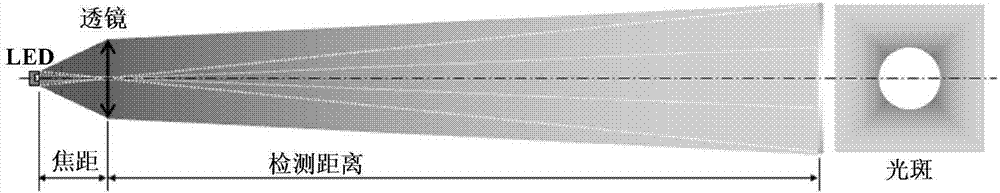

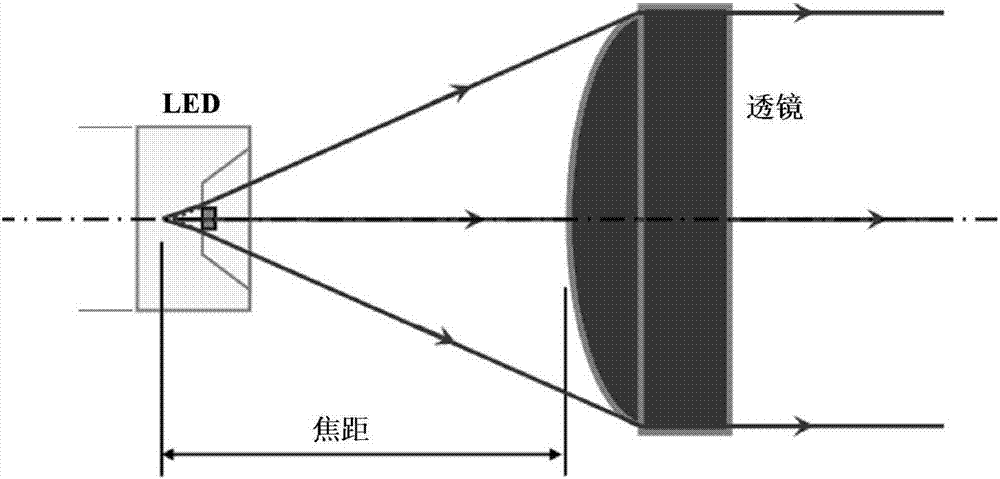

Opposite irradiation type photoelectric sensor and target detection system

InactiveCN107966741AReduce installation spacingEnsure consistencyOptical detectionPhotometry electrical circuitsOptical axisLight spot

The embodiment of the invention relates to an opposite irradiation type photoelectric sensor and a target detection system. The opposite irradiation type photoelectric sensor comprises a light projector and light receiver, wherein the light projector comprises a light emitting element, a first lens, a first baffle plate, the light emitting element emits light, the first lens converts the light emitted by the light emitting element into parallel light, the first baffle plate is located between the light emitting element and the first lens, the first baffle plate is provided with a first throughhole, the center of the first through hole is overlapped with the focus of the first lens, and the field of view formed by the light emitted from the light emitting element is controlled through thefirst through hole. According to the embodiment of the invention, a sufficient-light light spot of a required shape can be obtained, a small installation distance between the opposite irradiation typephotoelectric sensors can be met, and the consistency of optical axes can also be ensured.

Owner:ORMON CORP

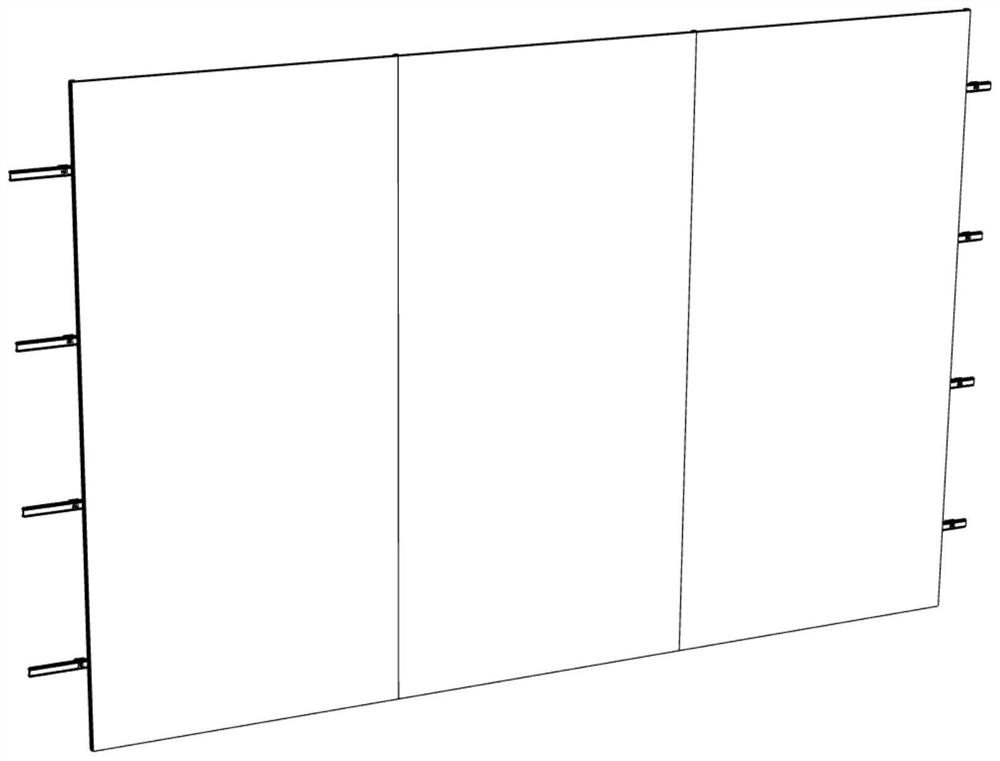

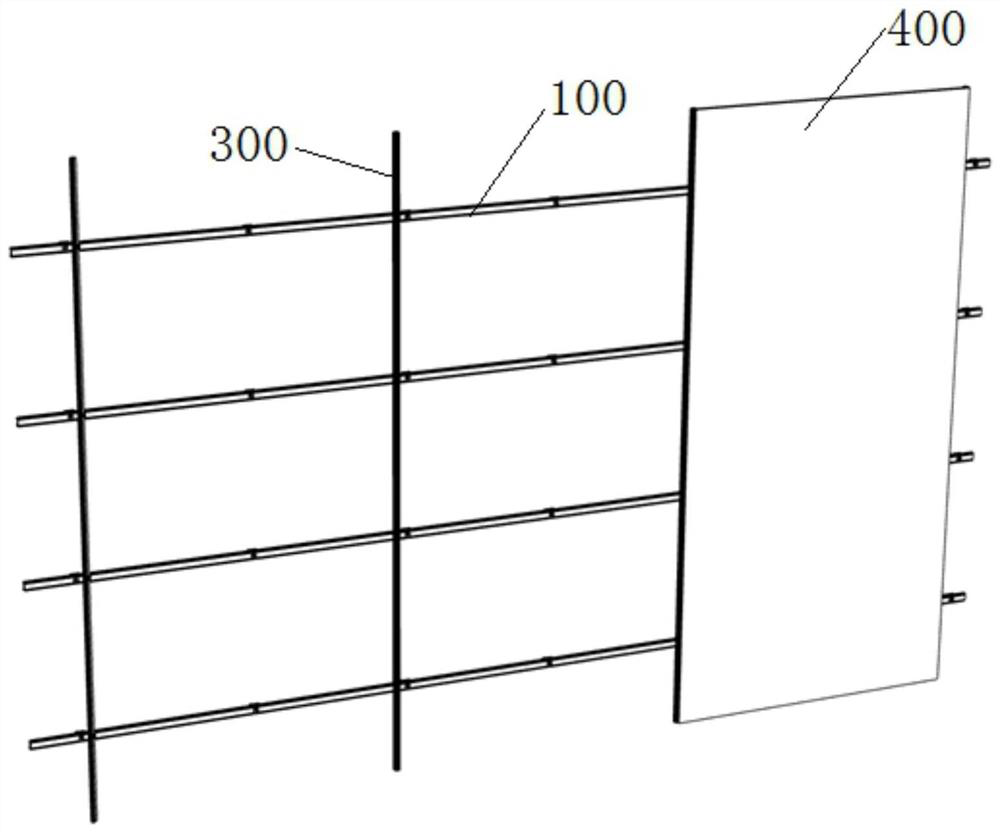

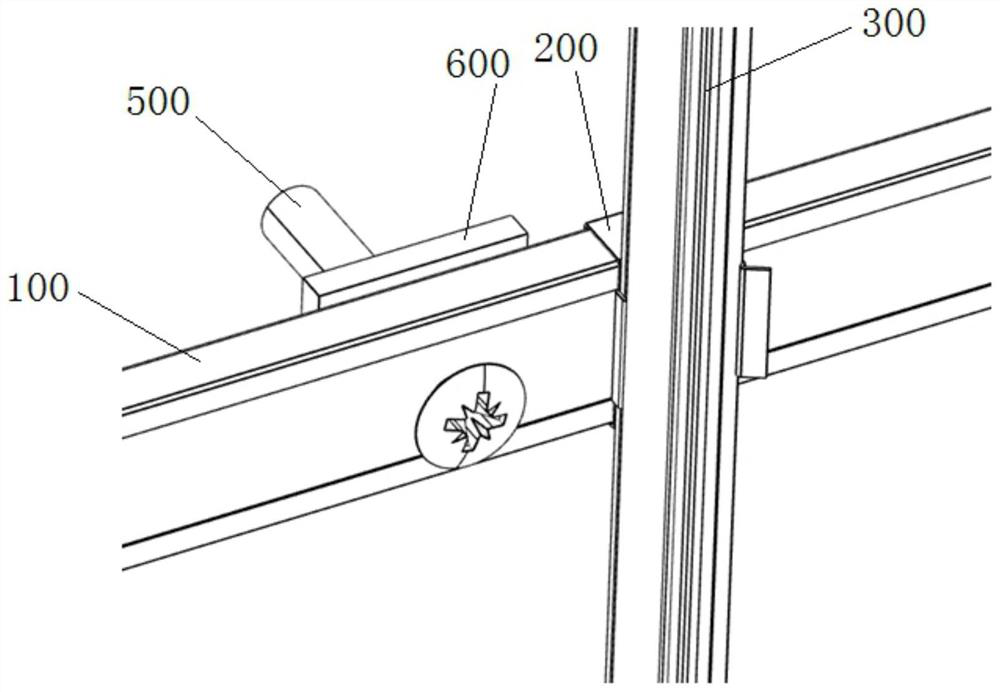

Clamping fastener

PendingCN112376842ASave human effortReduce installation spacingCovering/liningsBuckle FastenerEngineering

The invention relates to a clamping fastener. The clamping fastener is characterized in that a rear clamping slot is formed in the rear surface of the clamping fastener for clamping the clamping fastener onto a keel, wherein a front clamping slot is formed in the front surface of the clamping fastener for clamping a clamping profile. The clamping fastener is used for assembling a decorative platemounting system, so that working hours and labor power are saved during decorative plate mounting construction, a mounting spacing between a decorative plate and a wall surface is reduced, and modularized mounting is realized.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

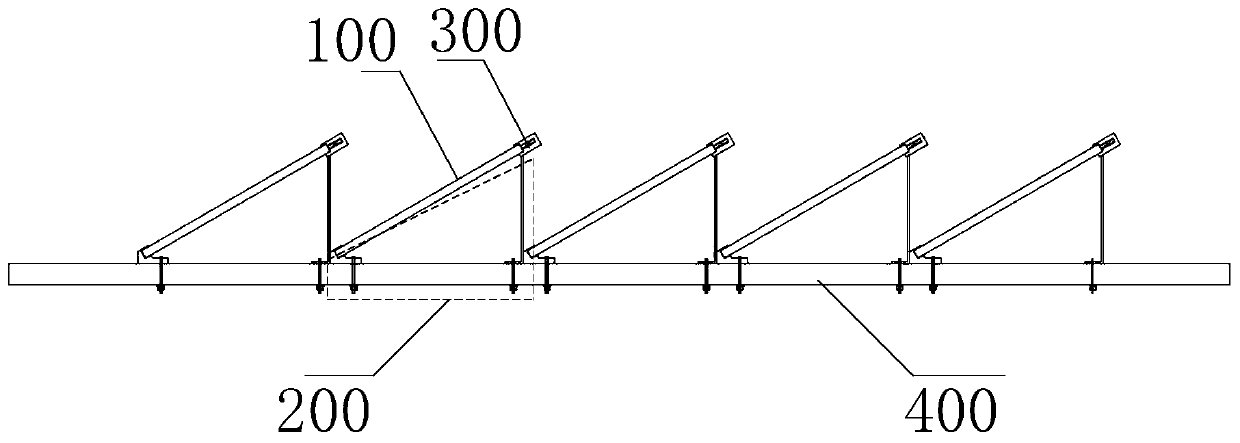

Photovoltaic tracker rotor with fully distributed components

PendingCN110635759AReduce installation spacingIncrease installed capacityPhotovoltaic supportsSolar heating energyElectrical and Electronics engineeringDivergence

The invention provides a photovoltaic tracker rotor with fully distributed components, which comprises photovoltaic assemblies, assembly fixing mechanisms, light divergence mechanisms and a main shaft, wherein the multiple photovoltaic assemblies are sequentially arranged along the main shaft; each photovoltaic assembly is fixedly connected to the top of the main shaft through the assembly fixingmechanism and has an inclination angle facing the incident direction of light; the front end of each photovoltaic module extends into the shadow coverage area of the back of the previous photovoltaicmodule in the light incident direction, the light diverging mechanisms are arranged at the rear ends of the photovoltaic modules; and the light divergence mechanisms can diverge received incident light to the shadow coverage area. According to the photovoltaic tracker rotor, the light divergence mechanism is arranged at the rear end of each photovoltaic module, so that light can be diverged to a shadow coverage area at the back of the module, the influence of shadow shielding on the power generation power of the module is effectively avoided while the mounting distance of the modules is shortened, and the assembly installation capacity of the rotor is further increased.

Owner:ZHEJIANG ZHENGTAI NEW ENERGY DEV CO LTD

UV discharge lamp

ActiveCN105428202BExtend working lifeImprove job stabilityGas discharge lamp detailsGas-discharge lampUltraviolet

The invention discloses an ultraviolet discharge lamp, which comprises a lamp tube, an output window, a first electrode, a second electrode, a ceramic tube, a first electrode holder and a second electrode holder, wherein the ceramic tube is arranged in the lamp tube; the first electrode is arranged at the outer side of one end, close to the output window, of the ceramic tube; and one end, close to the second electrode holder, of the first electrode holder and / or one end, close to the first electrode holder, of the second electrode holder are / is coated with an insulating structure. The ultraviolet discharge lamp has the beneficial effects that the insulating structure coating the first electrode holder and / or the second electrode holder is adopted by the ultraviolet discharge lamp; and breakdown voltage between the first electrode holder and the second electrode holder is increased, so that the possibility of glow discharge between the first electrode holder and the second electrode holder is greatly reduced; the operating life of the ultraviolet discharge lamp is prolonged; and the stability of the ultraviolet discharge lamp is improved.

Owner:SHENZHEN NUOAN ENVIRONMENTAL & SAFETY INC +1

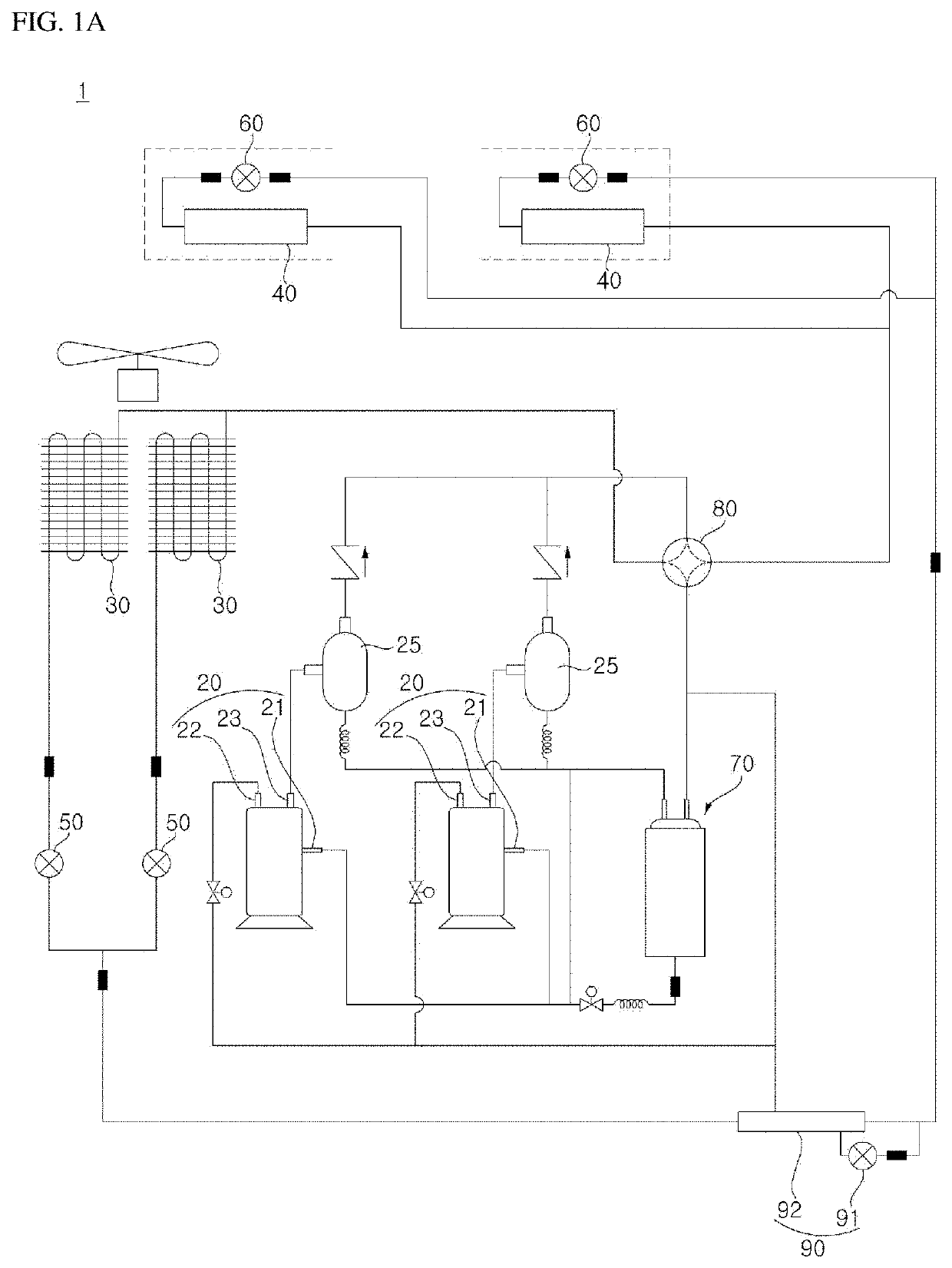

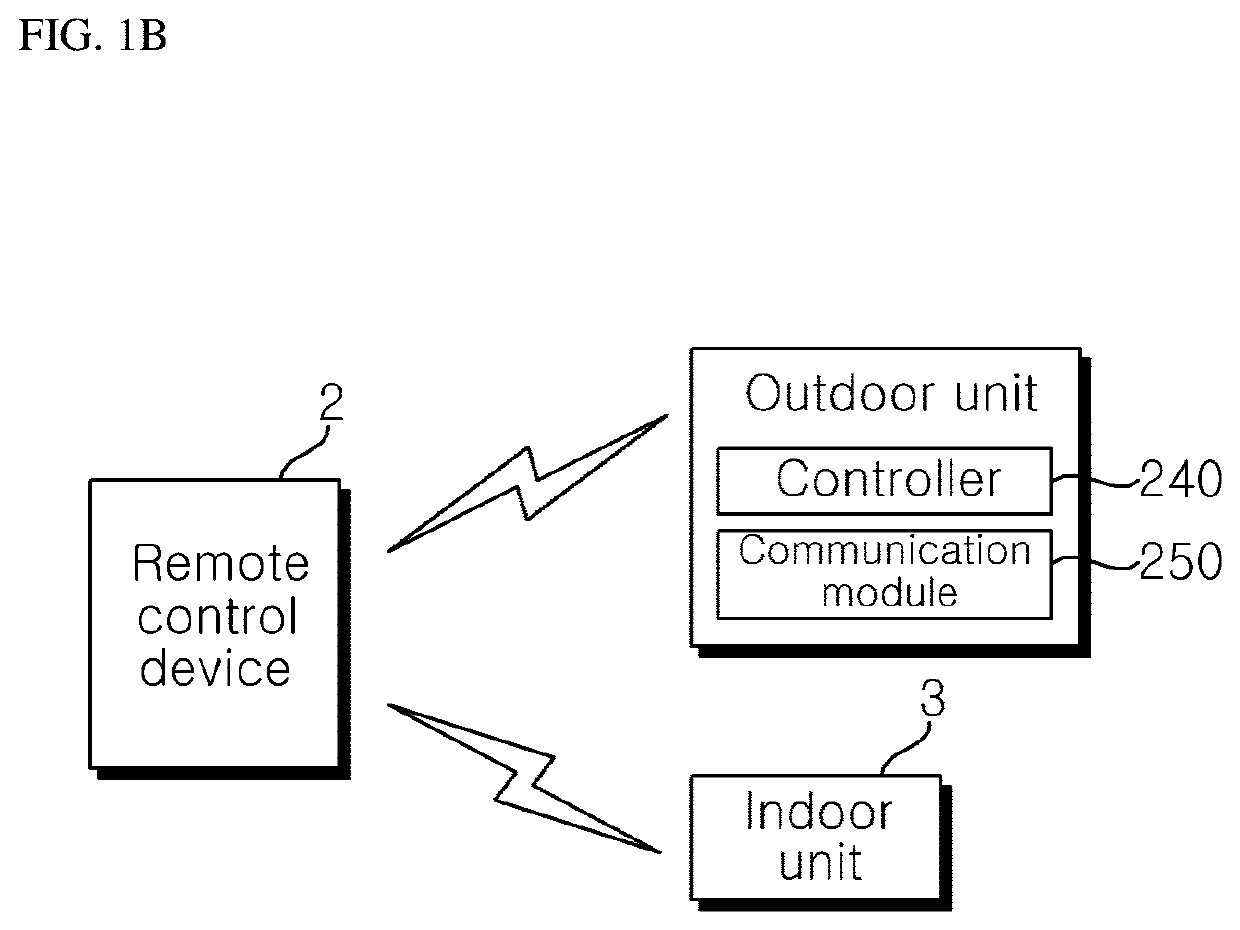

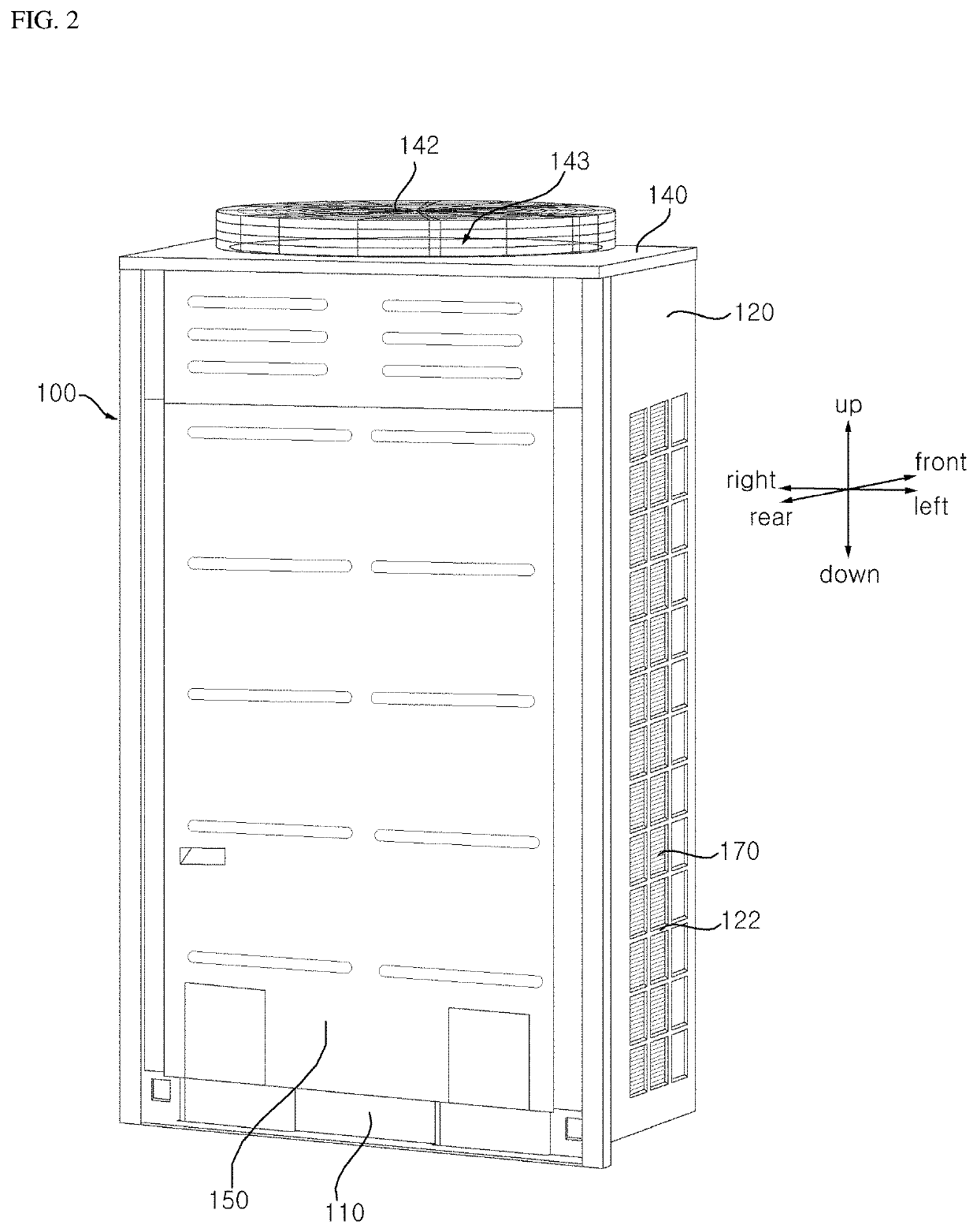

Outdoor unit of air conditioner

PendingUS20220090799A1No damageReduce installation spacingMechanical apparatusLighting and heating apparatusEngineeringMechanical engineering

The present disclosure relates to an outdoor unit of an air conditioner including: a case that forms an outer shape; a controller that is disposed inside the case and controls the operation of various components of the air conditioner; a heat dissipation member connected to the controller to dissipate heat generated by the controller; and a support member that is coupled with the heat dissipation member to fix the position of the heat dissipation member, and has an insertion hole into which the heat dissipation member is inserted, wherein the heat dissipation member is disposed to face the controller with respect to the support member, and at least partial area of the heat dissipating member penetrates the insertion hole to prevent damage to a structure that dissipates heat of the controller to an outdoor unit of the air conditioner that is in contact with the controller.

Owner:LG ELECTRONICS INC

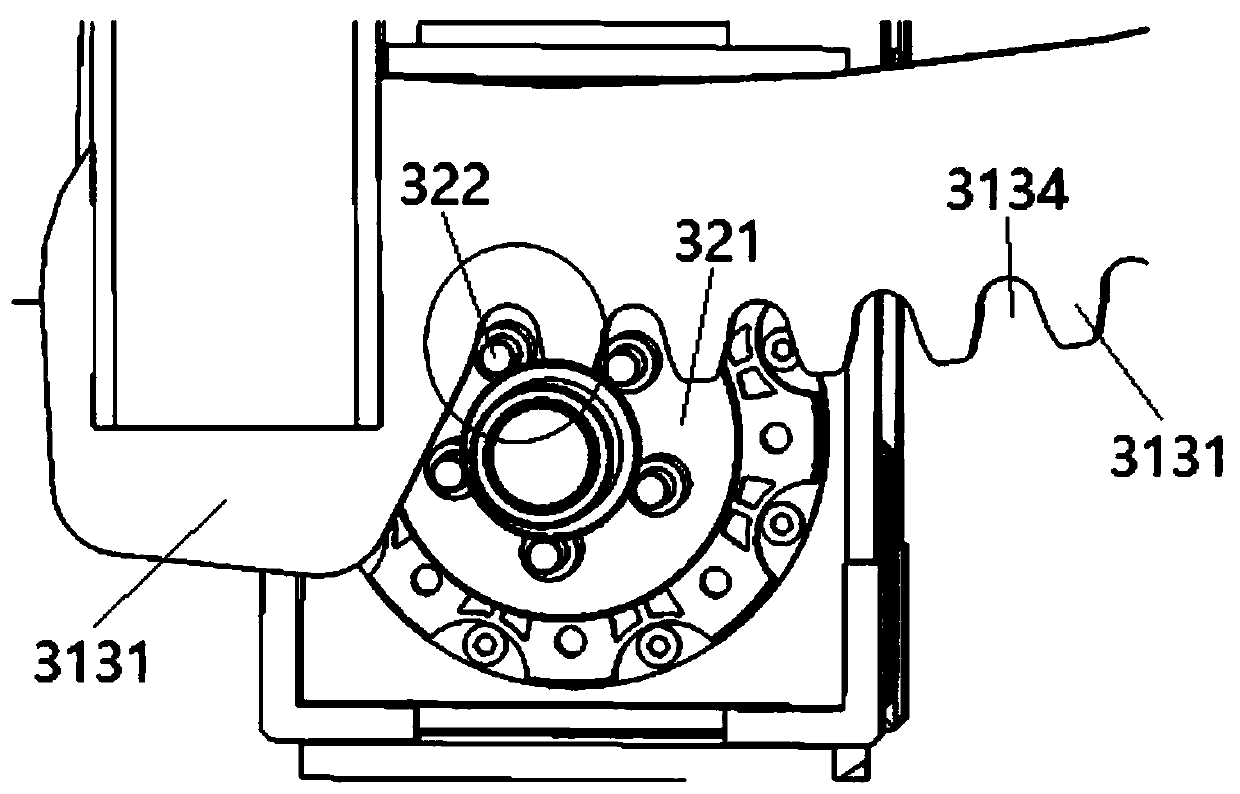

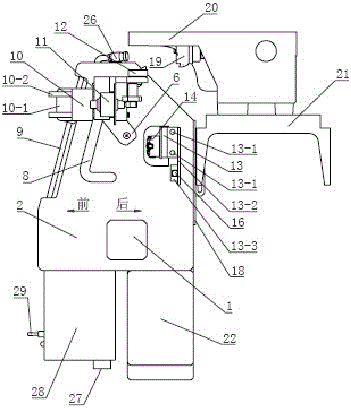

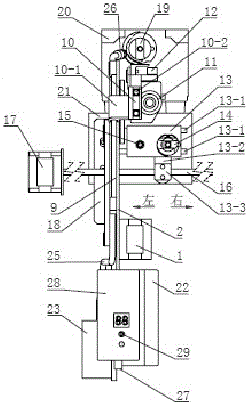

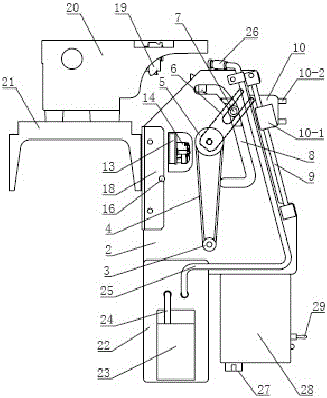

A separate bobbin thread changing device for a multifunctional embroidery machine

ActiveCN105734864BIncrease productivityHigh degree of production automationAuxillary devicesBobbinInjection pump

Owner:FOSHAN QICHUANG TECH DEV

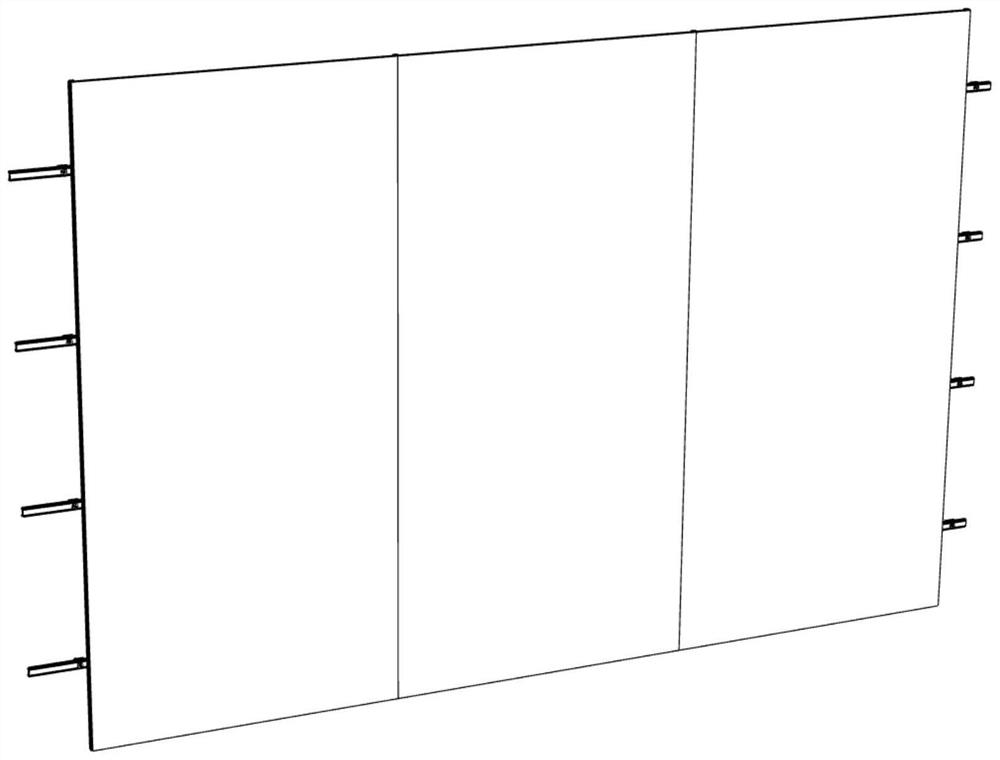

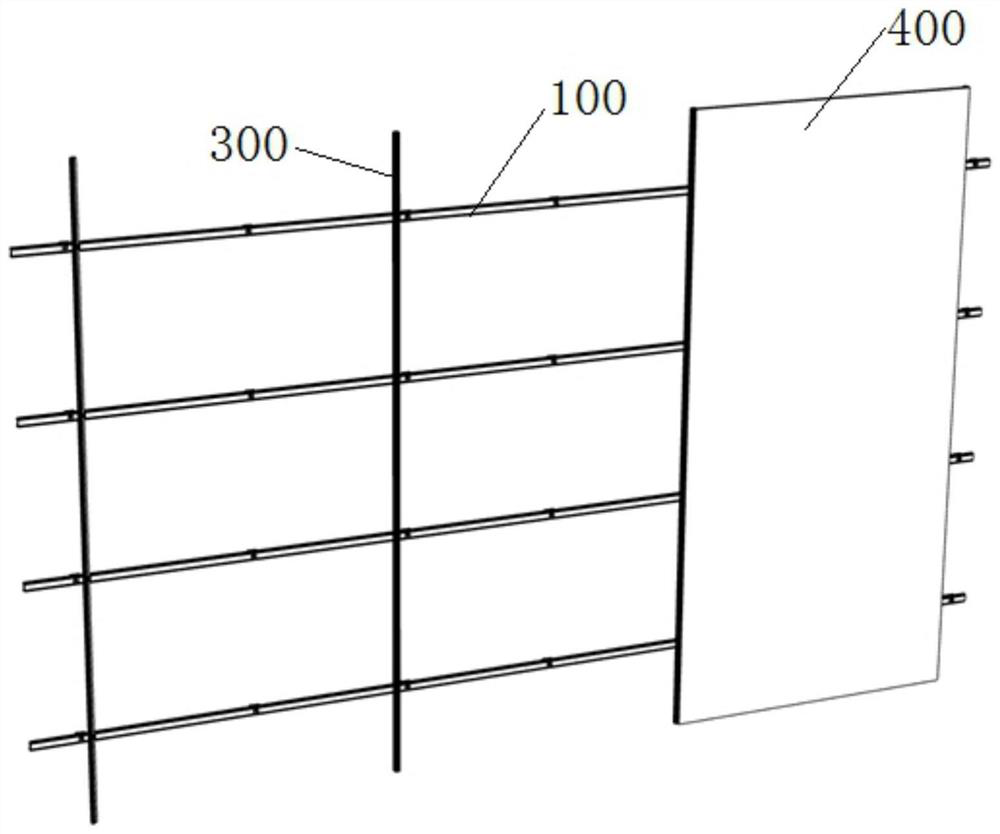

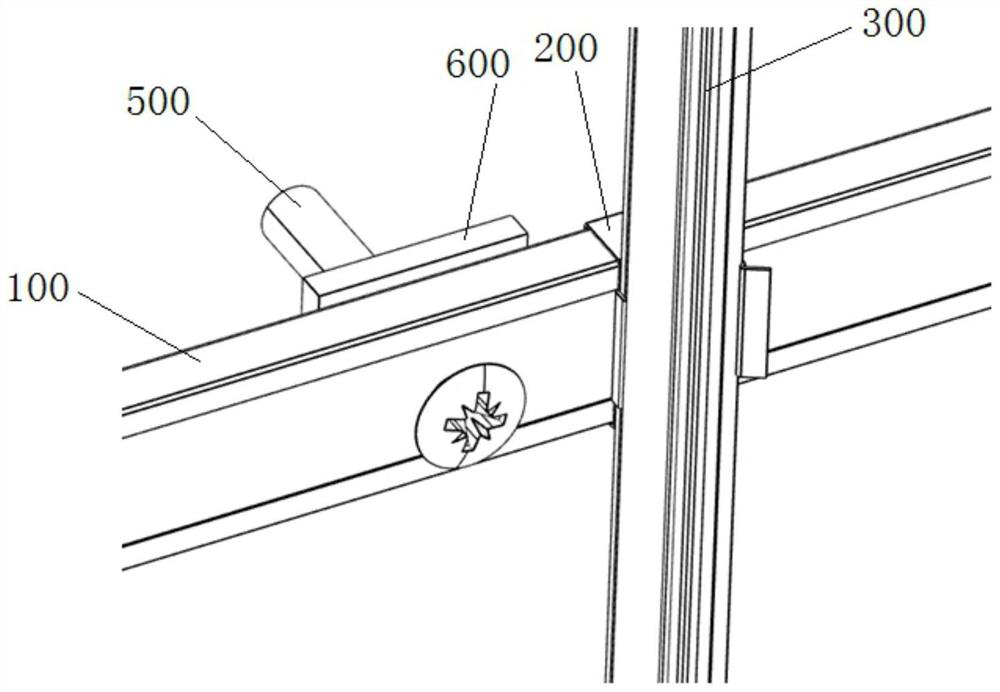

Decorative plate mounting system

The invention relates to a decorative plate mounting system. The decorative plate mounting system is characterized by comprising keels (100), clamping fasteners (200), clamping profiles (300) and a decorative plate (400), wherein rear clamping slots are formed in the back surfaces of the clamping fasteners; the rear blocking slots are used for clamping the clamping fasteners onto the keels; frontclamping slots are formed in front surfaces of the clamping fasteners for clamping the clamping profiles; the clamping profiles are used for clamping the decorative plate; and a crossed angle is formed between the rear clamping slots and the front clamping slots. The decorative plate mounting system disclosed by the invention saves working hours and labor power during decorative plate mounting construction, reduces a mounting spacing between the decorative plate and a wall surface, can accomplish integral mounting without other parts by only needing buckling operation after keels are mounted,and realizes modularized mounting.

Owner:JIANGSU PIVOT NEW DECORATIVE MATERIALS

A composite foam metal contact piece

ActiveCN105406229BReliable contactIncrease profitCoupling contact membersElectrical conductorSkin effect

The invention discloses a composite foam metal contact. The composite foam metal contact comprises an elastic porous polymer skeleton; the porous polymer skeleton is provided with a plurality of mutually communicated holes and is a three-dimensional net type perforated structure; and metal conductor layers are arranged in the communicated holes and on the surface of the porous polymer skeleton. When the composite foam metal contact disclosed by the invention is adopted to be electrically connected with a conductor, with the help of self elastic contact, welding is unnecessary; the composite foam metal contact is reliable to contact, assurable in performance, reusable and high in utilization rate; the equipment purchase cost is reduced; a single structure is simple to install and maintain; due to the large specific surface area, the skin effect of high-frequency signals can be effectively reduced; the composite foam metal contact is particularly suitable for high-frequency signal transmission; the production process is simple; and the consistency of finished products is good.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

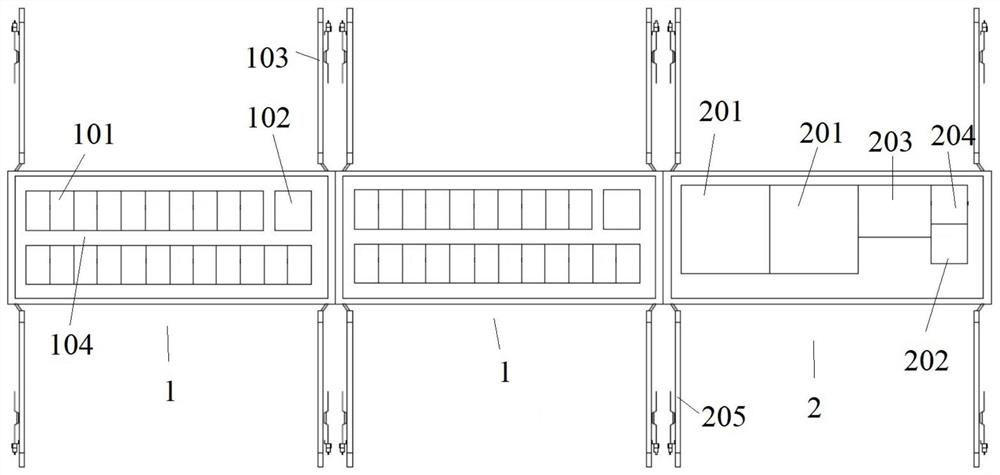

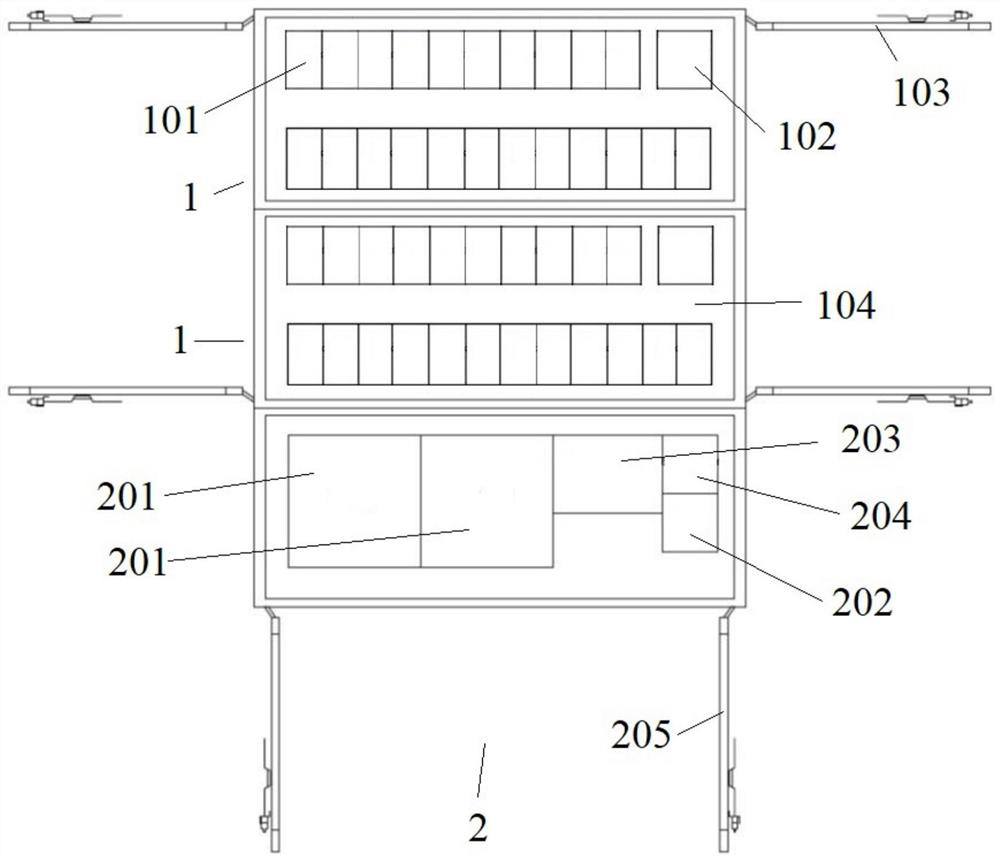

High-energy-density and convenient-to-transport energy storage system

PendingCN113629337AEasy connectionReduce difficultyBatteries circuit arrangementsElectric powerElectrical batterySea transport

The invention relates to a high-energy-density and convenient-to-transport energy storage system, which comprises at least one battery bin and a control bin. The battery bin and the control bin are in a container type and are detachably connected, a plurality of battery cabinets, confluence cabinets and fire-fighting modules are arranged in the battery bin, the fire-fighting modules are connected to a cooling water pipe and a fire-fighting pipe, the outer wall of the battery bin is provided with a first fire-fighting fast interface and a first circuit fast interface, the control bin is internally provided with an energy storage converter, a control cabinet, a fire-fighting master control center and a liquid-cooled air conditioner, and the outer wall of the control bin is provided with a second fire-fighting fast interface and a second circuit fast interface. Compared with the prior art, the weight of each bin is controlled within the maximum weight requirement of sea transportation; all control systems are integrated in the control bin, so that the capacity of the battery bin can be increased, and maintenance personnel can operate and manage conveniently; expansion is facilitated, and the occupied area is reduced.

Owner:POWERCHINA SPEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com