A separate bobbin thread changing device for a multifunctional embroidery machine

An embroidery machine and multi-functional technology, which is applied in the field of the bobbin thread changing device of the discrete multi-function embroidery machine, can solve the problem that it is difficult to realize the miniaturization of the bobbin thread changing device, reduce the installation space of the bobbin thread changing device, and increase the number of heads of a single embroidery machine, etc. problems, to achieve the effect of reducing the number of spare bobbins, reducing the installation space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail by the following examples.

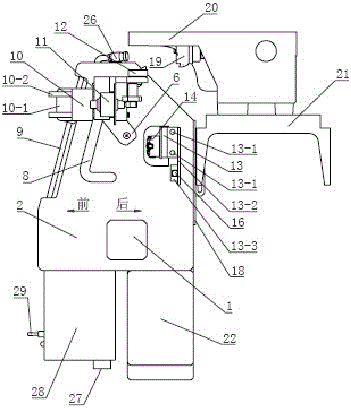

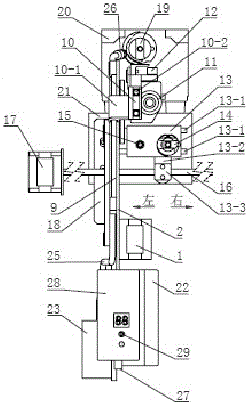

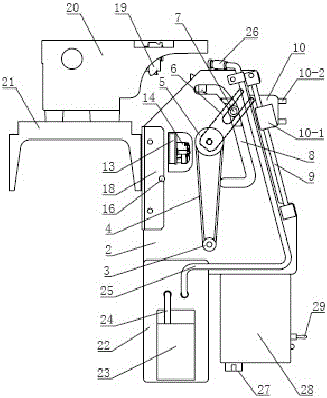

[0032] see Figure 1 ~ Figure 3 As shown, a discrete multifunctional embroidery machine bobbin thread changing device consists of a base plate connection angle 18, a mounting base plate 2, a pulley 10 disposed on the mounting base plate 2, a pulley motor 1, a shuttle row 13, and a fuel injection pump for the fuel injection system. 22. Oil storage box 23, fuel injection nozzle 26 and independent controller 28 are formed.

[0033] The installation substrate 2 is an independent substrate, which is fixedly connected to the hook box base 21 through the substrate connection angle 18, and the installation substrate 2 is provided with " L " shape, bottom edge and upper end section all take the acute angle pulley guide groove 8 of horizontal direction, be provided with the guide shaft 9 parallel with the hypotenuse direction of pulley guide groove 8 along the left side of installation substrate 2 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com