Electromagnetic pulse rigid shaft sliding valve

An electromagnetic pulse, rigid shaft technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of large volume of electromagnetic pulse valve, large valve installation distance, affecting the quality of valves, etc., and achieve stable and reliable performance and coaxiality Good, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

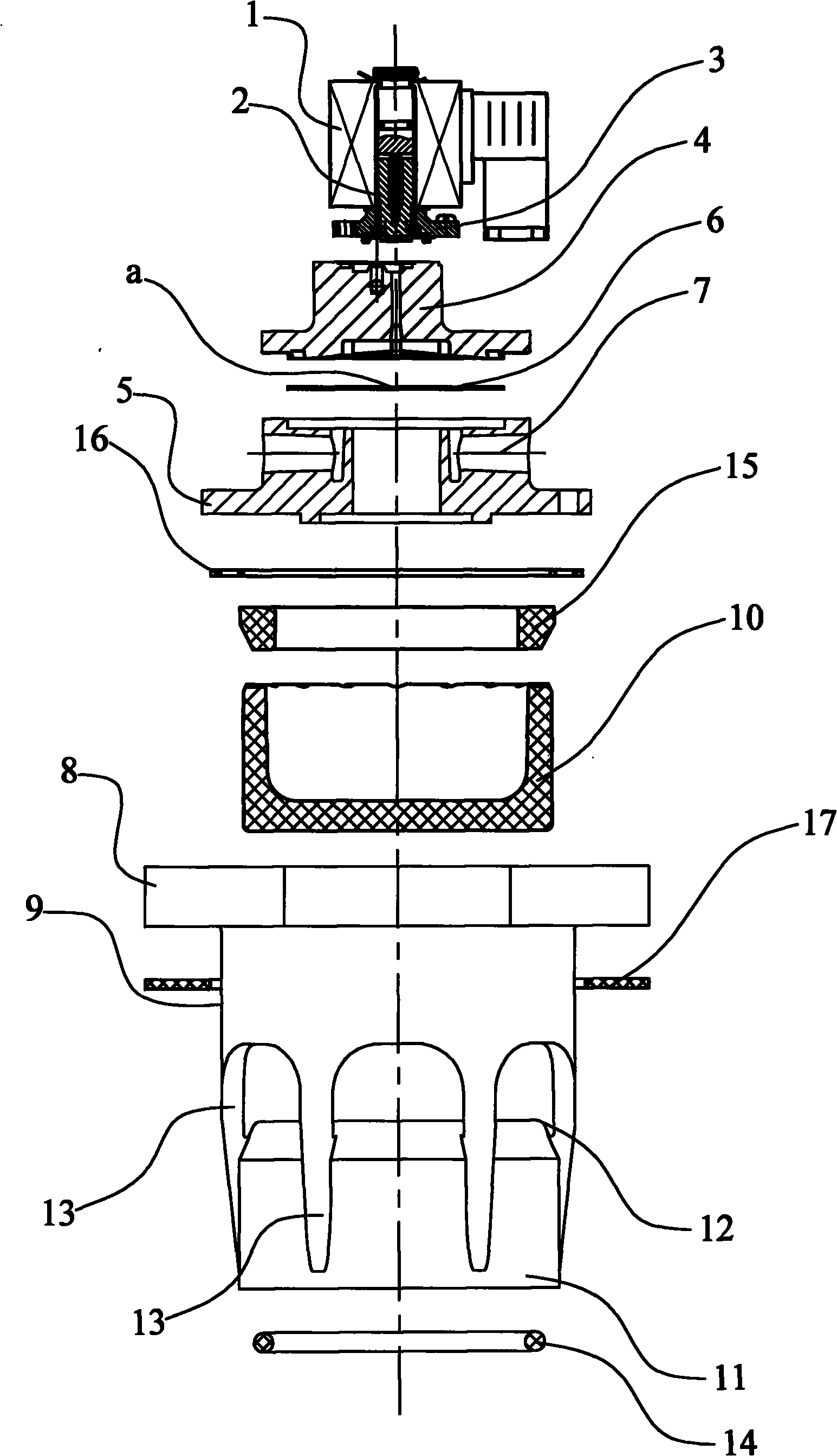

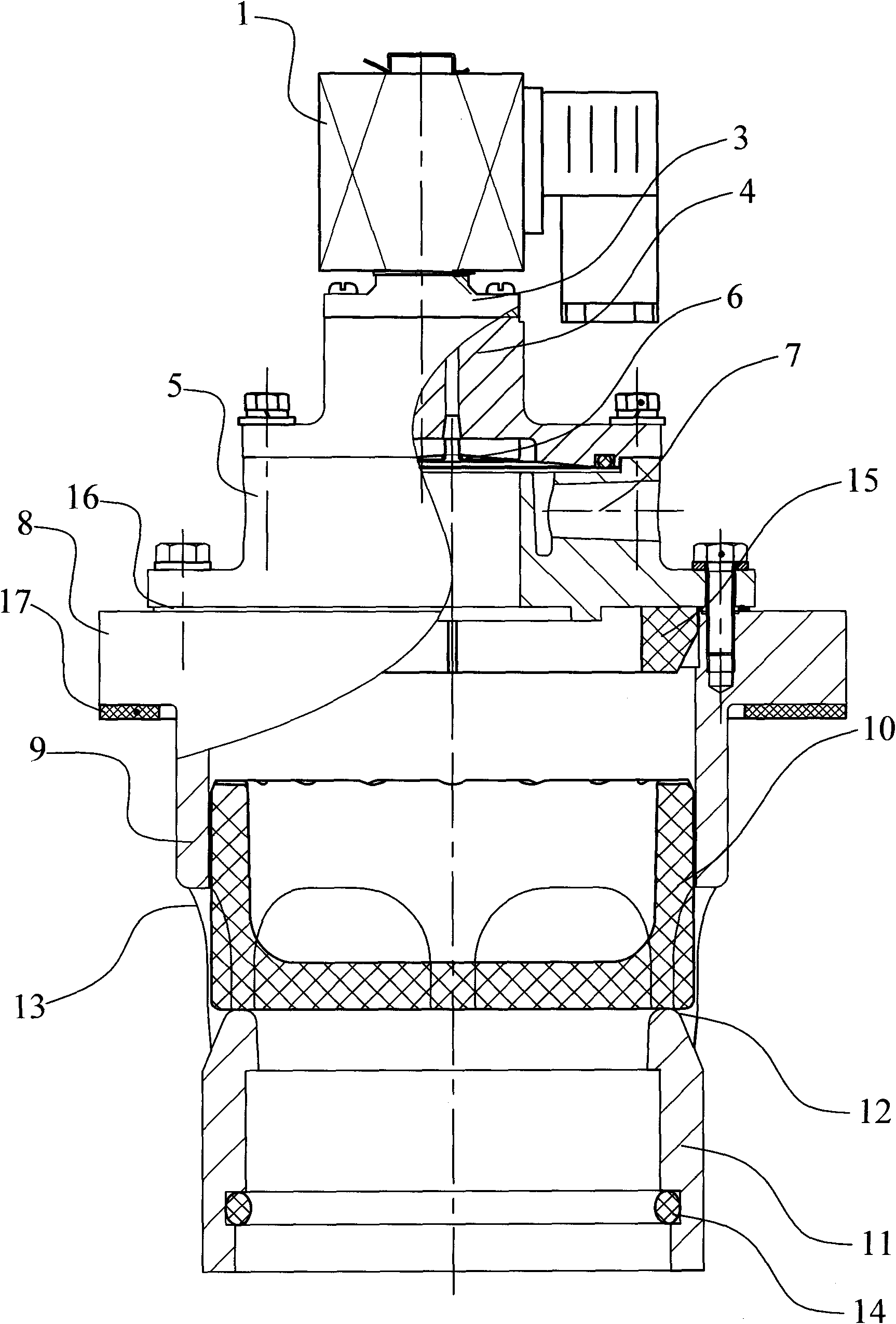

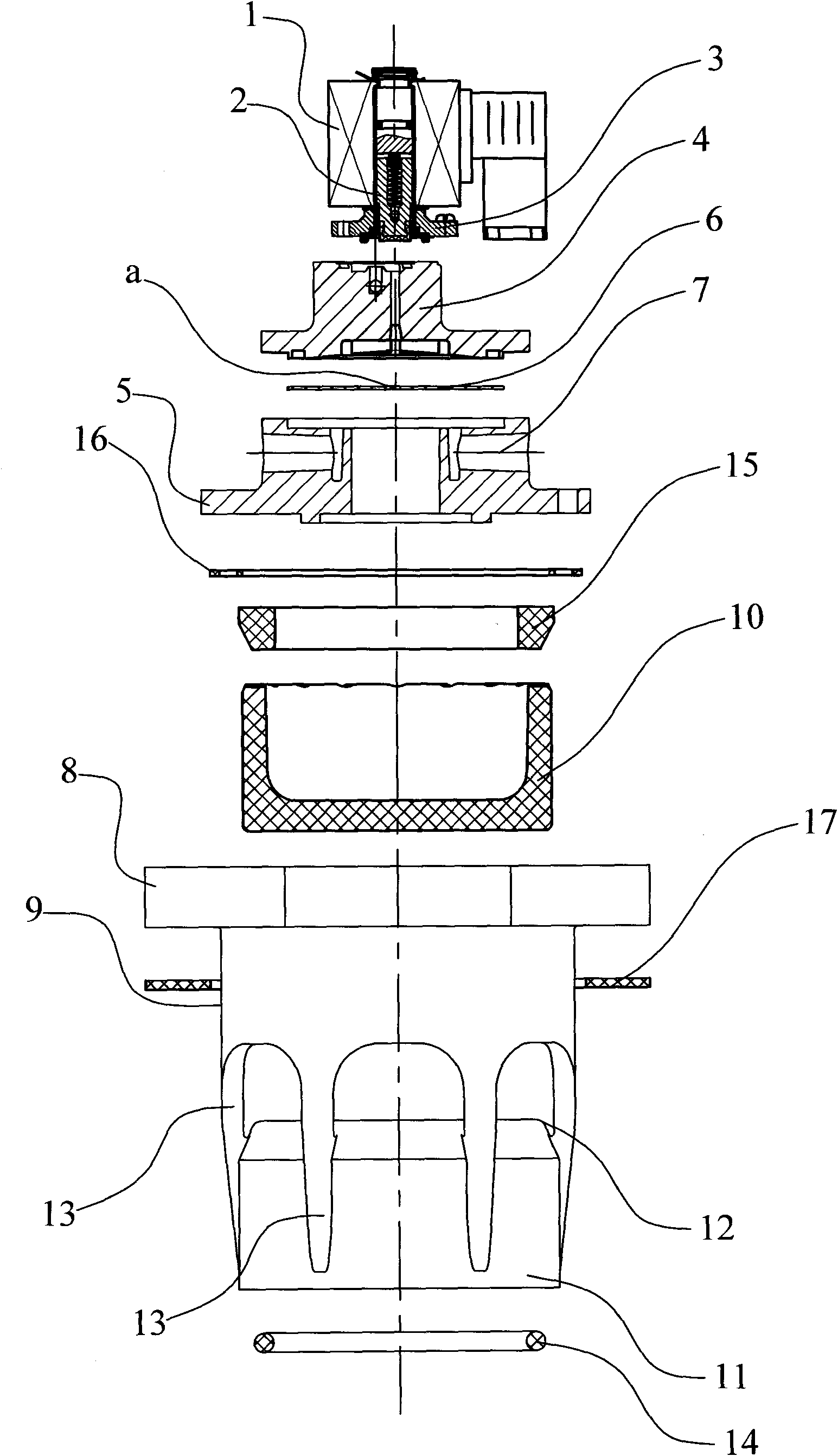

[0023] Fig. 1 is a schematic structural diagram of the present invention, and Fig. 2 is a schematic diagram of an exploded structure of Fig. 1, as shown in Fig. Pilot head pressure plate 3, pilot seat 4, valve cover 5, flexible diaphragm 6 is installed in the valve cover 5, and there is a damping hole a in the flexible diaphragm (the center of the flexible diaphragm at the damping hole, the area ratio relationship between the damping hole and the flexible diaphragm is 1:550~1:5500), the bonnet 5 has an unloading hole 7, the bonnet 5 is connected with a valve seat 8, the valve seat 8 has a central through hole, and the central through hole extends downward to form a sleeve 9 , The sleeve 9 is provided with a bowl-shaped rigid shaft 10 whose cross-section is H-shaped.

[0024] An exhaust outlet connecting pipe 11 is connected under the sleeve 9 of the valve seat 8 , and the bowl-shaped rigid shaft 10 is placed on the top surface 12 of the exhaust outlet connecting pipe 11 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com