Vertical continuous tempering furnace

A tempering furnace and vertical technology, which is applied in the field of vertical continuous tempering furnace, can solve the problems of high workpiece temperature and low production capacity of tempering furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

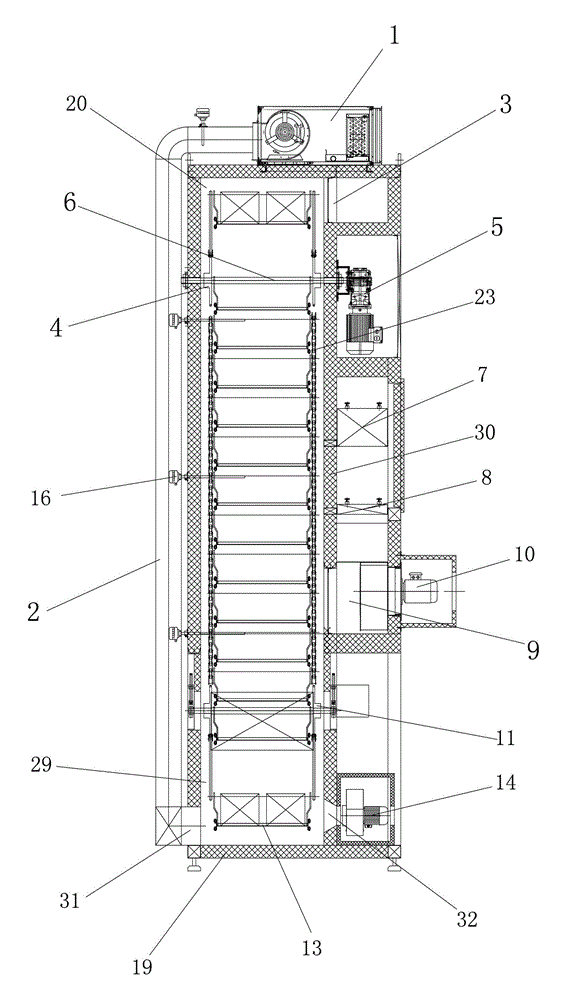

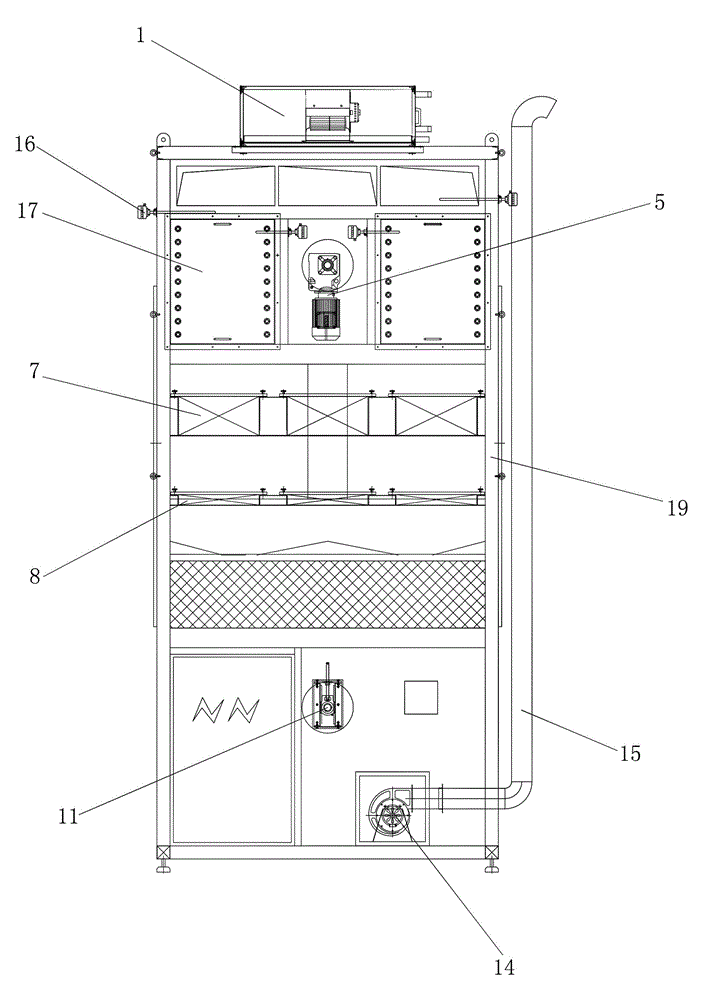

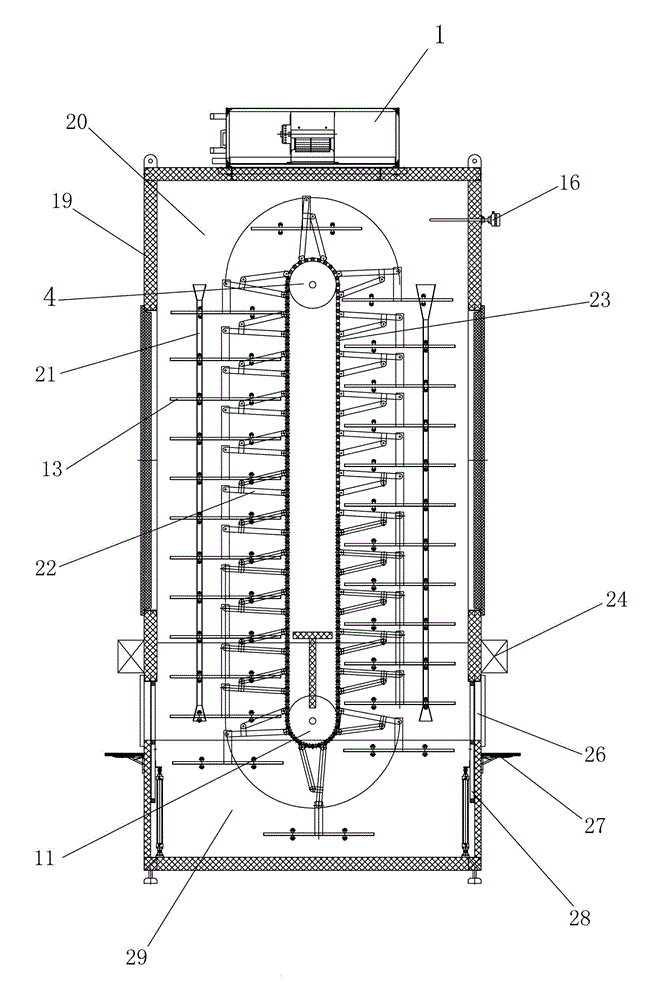

[0021] Such as figure 1 , figure 2 , image 3 Shown, a kind of vertical continuous tempering furnace comprises furnace body 19, and furnace body 19 adopts frame welding structure, inner plug insulation cotton, is provided with heating zone 20 and cooling zone 29 in the furnace body 19; Heating zone 20 and cooling zone Feeding and discharging opening 26 are arranged between the districts 29; Feeding and discharging opening 26 are located in the cooling zone 29; The inner side wall of the heating zone 20 is provided with an air supply passage through the partition plate 30, and the air supply passage is provided with an air inlet passage opening 9 and The air outlet channel port 3; the air outlet channel port 3 is located at the inner top of the furnace body 19; the air inlet channel port 9 is used for air suction, and the air outlet channel port 3 is used for air supply. The temperature of the channel is more uniform than that of the air supply on both sides; the furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com