Decorative plate mounting system

A technology for installation systems and decorative panels, applied in covering/lining, construction, building structure, etc., can solve the problems of large surface spacing, time-consuming and laborious nailing, occupation, etc., to reduce installation spacing, save man-hours and labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

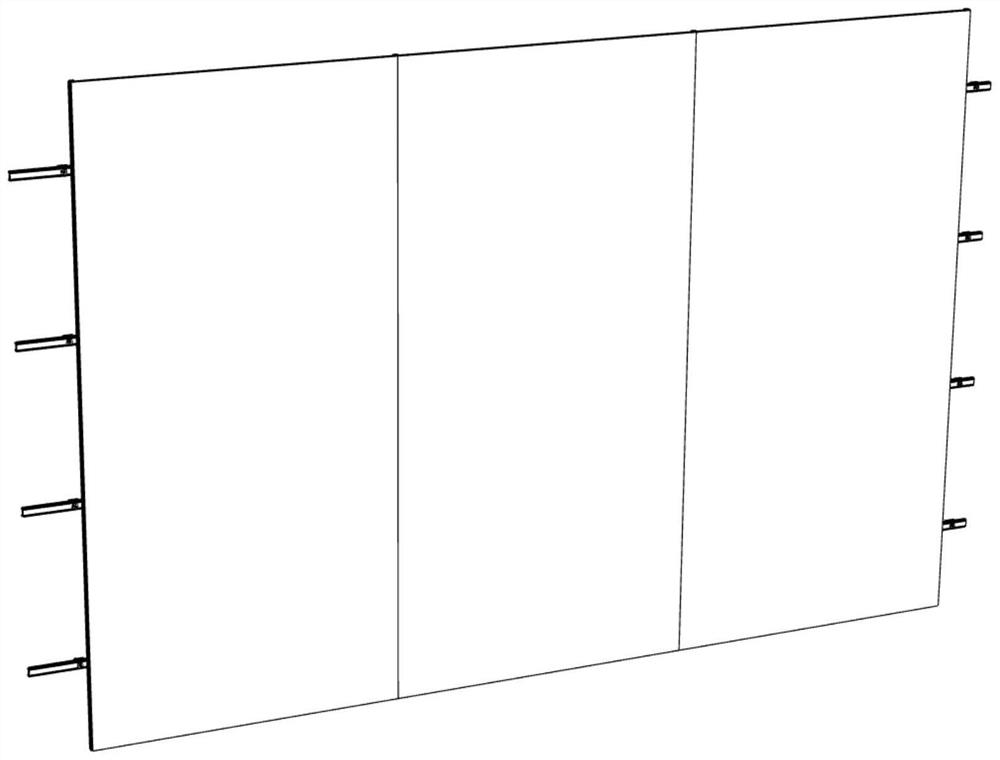

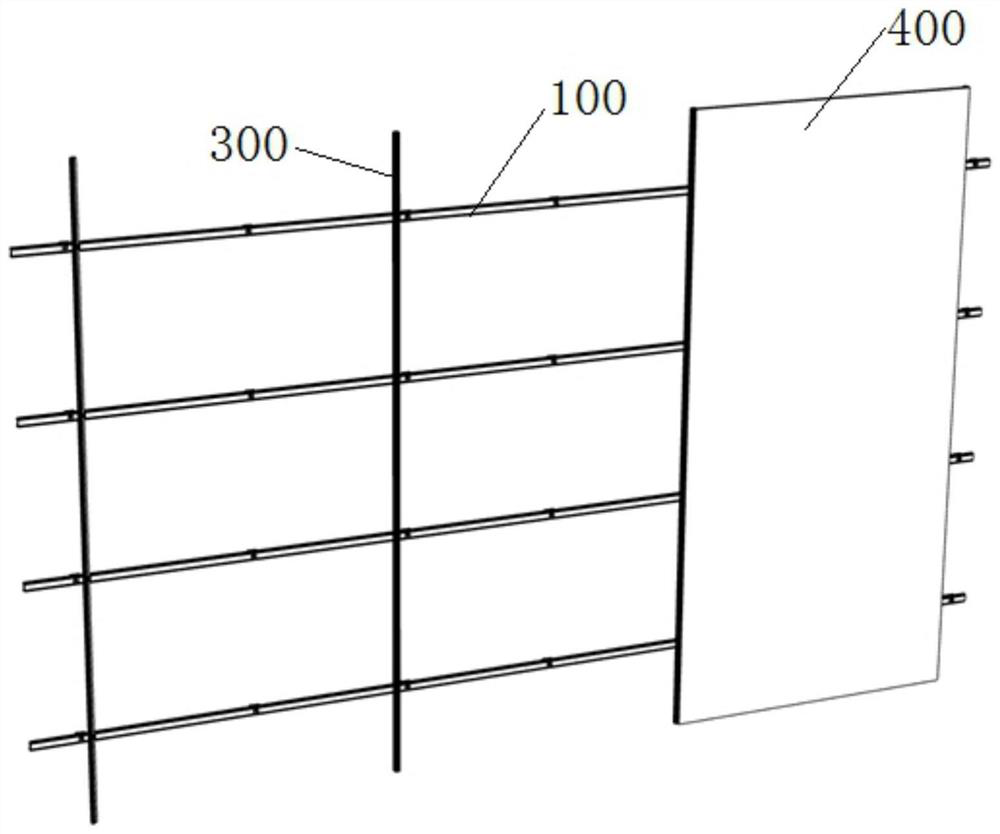

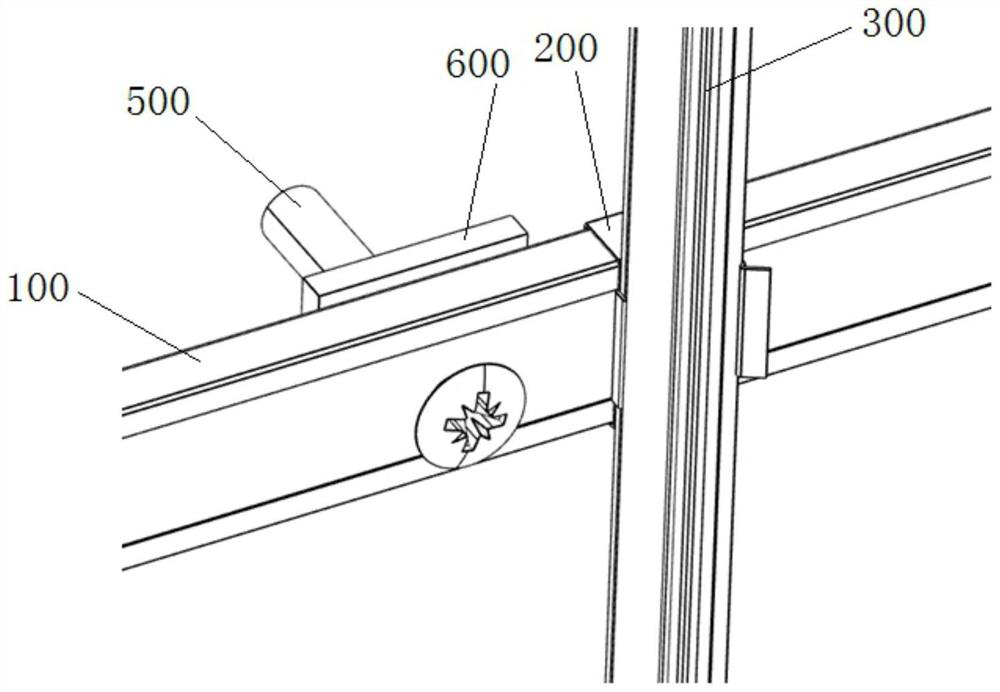

[0053] Embodiment 1, as figure 1 and figure 2 As shown, four keels 100 are arranged horizontally on the wall, four vertical clamping profiles 300 are arranged on the keels 100 , and three decorative panels 400 are arranged inside the clamping profiles 300 .

Embodiment 2

[0054] Embodiment 2, as Figure 12 As shown (decorative panels are not shown in the figure), the wall surface is divided into a first part and a second part arranged up and down, two keels 100 are arranged on the first part, and four vertical clamping profiles 300 are arranged on the two keels 100 , three decorative panels 400 are arranged in the clamping profiles 300, and two keels 100, four clamping profiles 300, and three decorative panels 400 are arranged in the second part as in the first part, in order to close the edges of the decorative panels 400, Six vertical keels 100 are provided at the three positions above the first part, below the second part and between the first part and the second part, and the six keels 100 at the three positions are all provided with transverse clamping profiles 300 , the upper and lower clamping profiles 300 are single-sided clamping profiles 301 , the middle clamping profile 300 is double-sided clamping profiles 302 , and the decorative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com