Preparation method with polysaccharide modified activated carbon as supercapacitor electrode material

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of low capacity of manganese oxide, and achieve large specific surface area, easy operation and rich grade pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

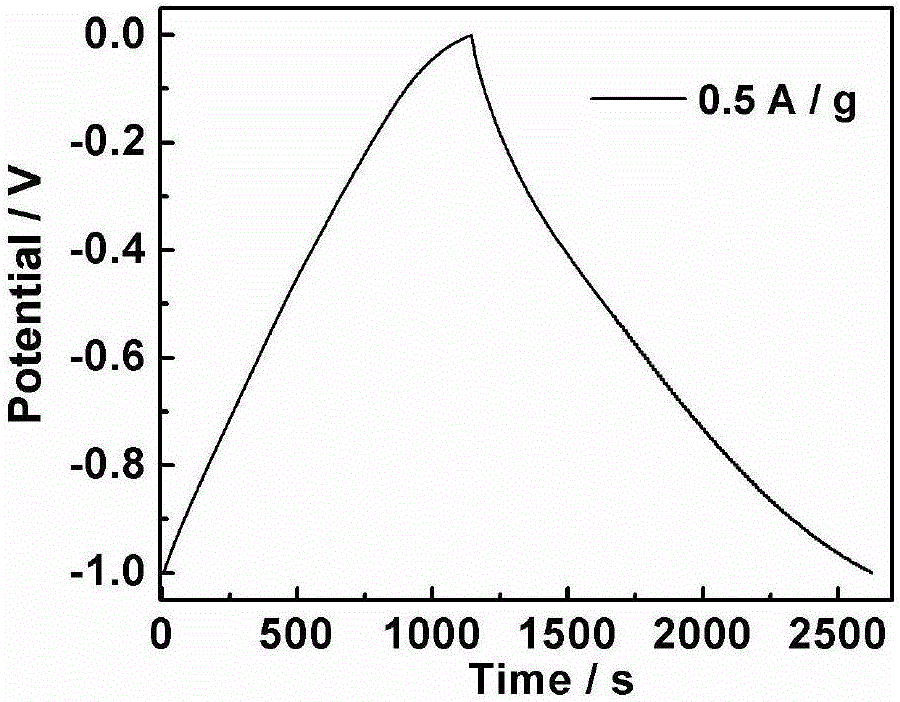

[0028] Referring to accompanying drawing, the present invention is the preparation method of polysaccharide modified activated carbon as supercapacitor electrode material, and its steps are:

[0029] Step 1: Weigh 0.1-10.0g of polysaccharide into a 15-500ml hydrothermal reaction kettle, add water to 1 / 2-5 / 6 of the inner volume of the reaction kettle, and stir to form a clear transparent liquid;

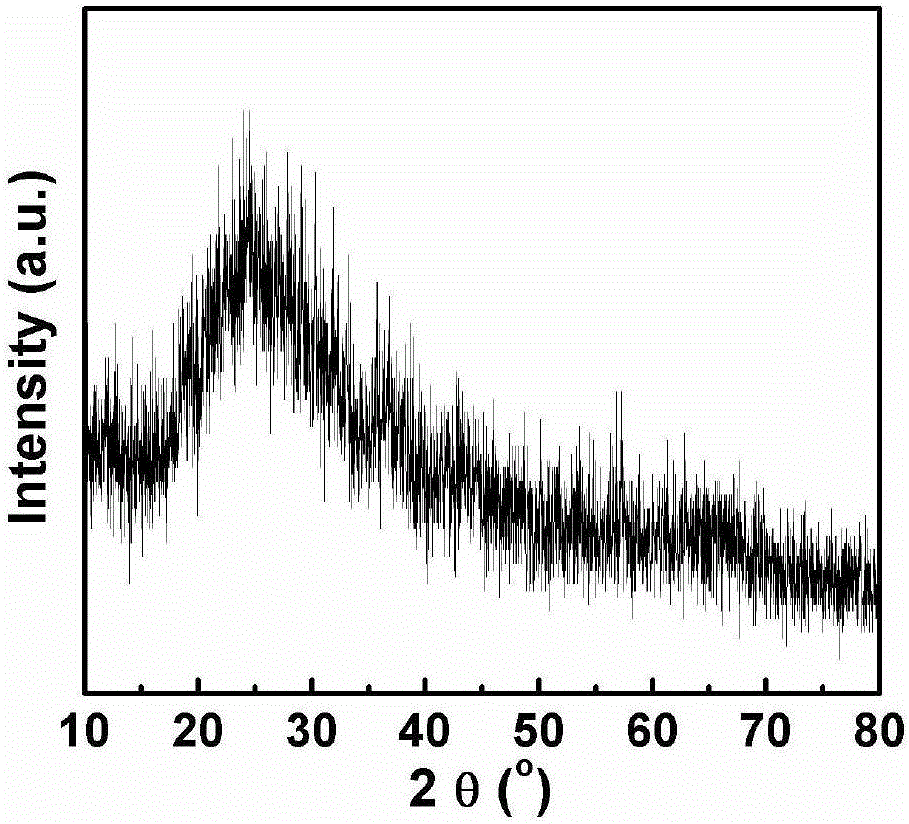

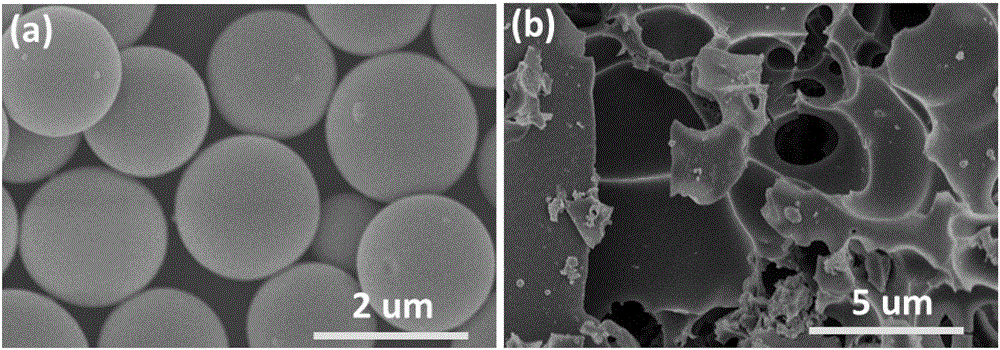

[0030] Step 2: The above-mentioned clear and transparent liquid is subjected to a hydrothermal reaction at a temperature of 160-200°C for 2-24 hours, and then the reaction product is obtained by filtration, and the reaction product is washed with water and ethanol three times respectively, and then the reaction product is put into Drying in an oven at low temperature to obtain carbon spheres;

[0031] Step 3: Weigh 0.1-20.0g of the above-mentioned carbon spheres, add them to 20-500ml of water, then add potassium hydroxide, stir evenly to form a mixed solution, and then let it stand fo...

Embodiment 1

[0045] (1) Preparation of carbon sphere precursor by hydrothermal reaction.

[0046] Weigh 4.0 g of glucose and add it to a 25 ml hydrothermal reaction kettle, add water to 3 / 4 of the inner volume of the reaction kettle, stir for 1 hour, and form a clear transparent liquid.

[0047] The above clear and transparent liquid was subjected to a hydrothermal reaction at 200°C for 2 hours, then filtered to obtain the reaction product, washed with water and ethanol three times respectively, and then put the reaction product into an oven and heated at 80°C Dry under ambient conditions for 3 hours to obtain carbon spheres.

[0048] (2) Potassium hydroxide activated carbon spheres to prepare activated carbon materials

[0049] Weigh 2.0g of carbon spheres and 20g of potassium hydroxide, add them into 150ml of water, stir for 2 hours to form a mixed solution, and then let it stand for 24h.

[0050] The above mixed solution was filtered, and the obtained solid product was put into an oven,...

Embodiment 2

[0054] (1) Preparation of carbon sphere precursor by hydrothermal reaction.

[0055] Weigh 8.0 g of sucrose and add it to a 200 ml hydrothermal reaction kettle, add water to 3 / 4 of the inner volume of the reaction kettle, stir for 1 hour, and form a clear transparent liquid.

[0056] The above clear and transparent liquid was subjected to a hydrothermal reaction for 6 hours at a temperature of 180°C, then filtered to obtain the reaction product, washed with water and ethanol three times respectively, and then put the reaction product into an oven and heated at 80°C Dry under ambient conditions for 48 hours to obtain carbon spheres.

[0057] (2) Potassium hydroxide activated carbon spheres to prepare activated carbon materials

[0058] Weigh 3.0g of carbon spheres and 45.0g of potassium hydroxide, add them into 250ml of water, stir for 3 hours to form a mixed solution, and then let it stand for 12h.

[0059] The above mixed solution was filtered, and the obtained solid produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com