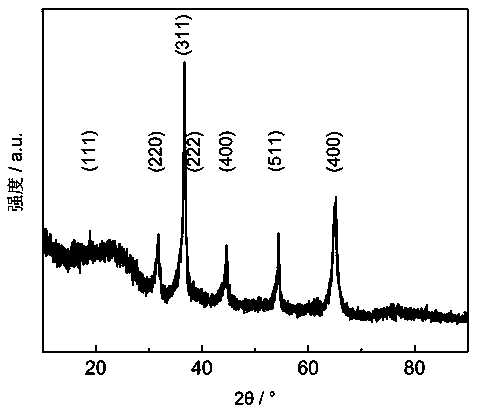

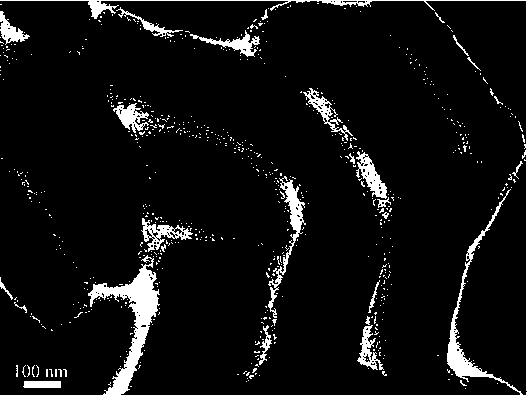

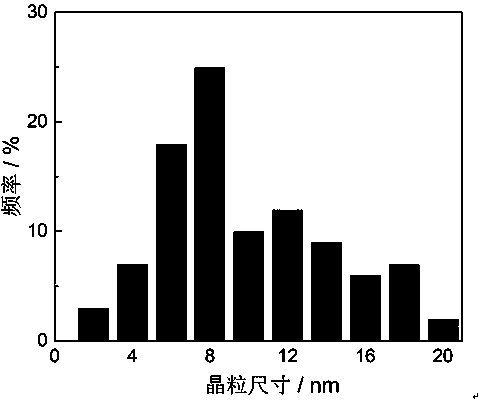

Preparation technology of nitrogen-doped mesoporous carbon composite metal oxide electrode material for supercapacitor

A nitrogen-doped mesoporous carbon, supercapacitor technology, used in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of poor stability, low energy density and power density, weak electrical conductivity, etc. Clear, product size controllable, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 hours under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate was 1: 0.2:0.025: 0.07-0.09, the temperature was controlled at 100 °C for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at 500 °C for 6 h, the white powder SBA- 15;

[0057] (2) Preparation of precursor nitrogen-doped ordered mesoporous carbon:

[0058] a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step (1), and ultrasonically pre-mix for 20 minutes;

[0059] b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat;

[0060] C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenetetramine successi...

Embodiment 2

[0069] (1) Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 hours under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate was 1: 0.2: 0.025:0.07-0.09, the temperature was controlled at 100 °C for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at high temperature 500 °C for 6 h, the white powder SBA- 15;

[0070] (2) Preparation of precursor nitrogen-doped ordered mesoporous carbon:

[0071] a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step (1), and ultrasonically pre-mix for 25 minutes;

[0072] b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat;

[0073] C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenet...

Embodiment 3

[0080] (1) Preparation of SBA-15: Add concentrated hydrochloric acid and deionized water to P123, magnetically stir for 4 hours under temperature control at 40 °C, add tetraethyl orthosilicate and mix well, concentrated hydrochloric acid: deionized water: P123: positive The mass ratio of ethyl silicate was 1: 0.2: 0.025:0.07-0.09, the temperature was controlled at 100 °C for hydrothermal reaction for 24 h, after suction filtration, washing, drying and calcination at high temperature 500 °C for 6 h, the white powder SBA- 15;

[0081] (2) Preparation of precursor nitrogen-doped ordered mesoporous carbon:

[0082] a. Add sugar, concentrated sulfuric acid, and water to the SBA-15 obtained in step (1), and ultrasonically pre-mix for 30 minutes;

[0083] b. Add the mixed solution of urea and hexamethylenetetramine, ultrasonically mix and heat;

[0084] C, add these four kinds of substances of the mixed solution of sucrose, concentrated sulfuric acid, water, urea and hexamethylenet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com