Three-layer-structured polyaniline@molybdenum disulfide@ferriferrous oxide composite nanowire wave-absorbing material and preparation method

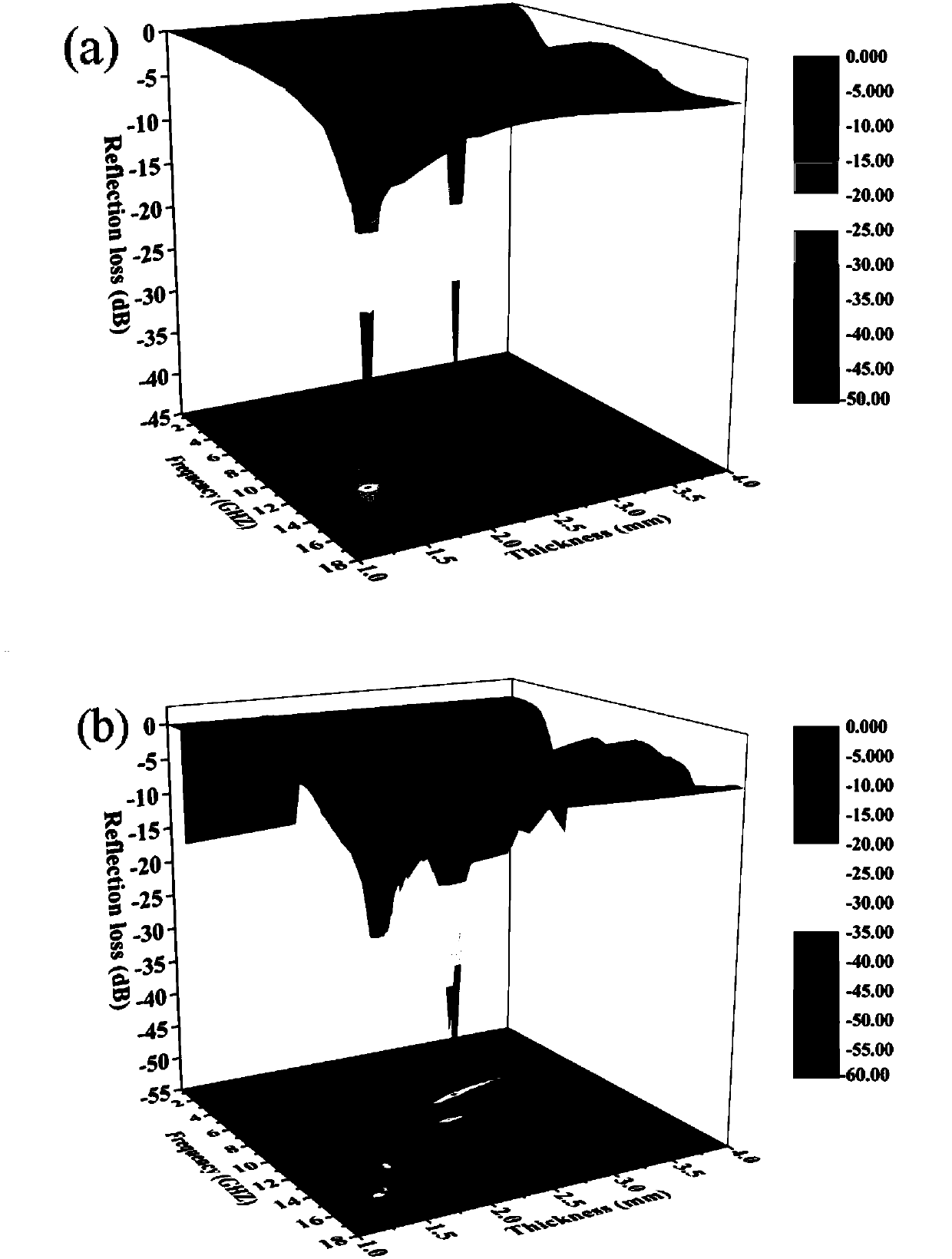

A technology of molybdenum disulfide and three-layer structure, which is applied in the direction of electrical components, magnetic field/electric field shielding, etc., to achieve the effect of improving impedance matching performance and microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

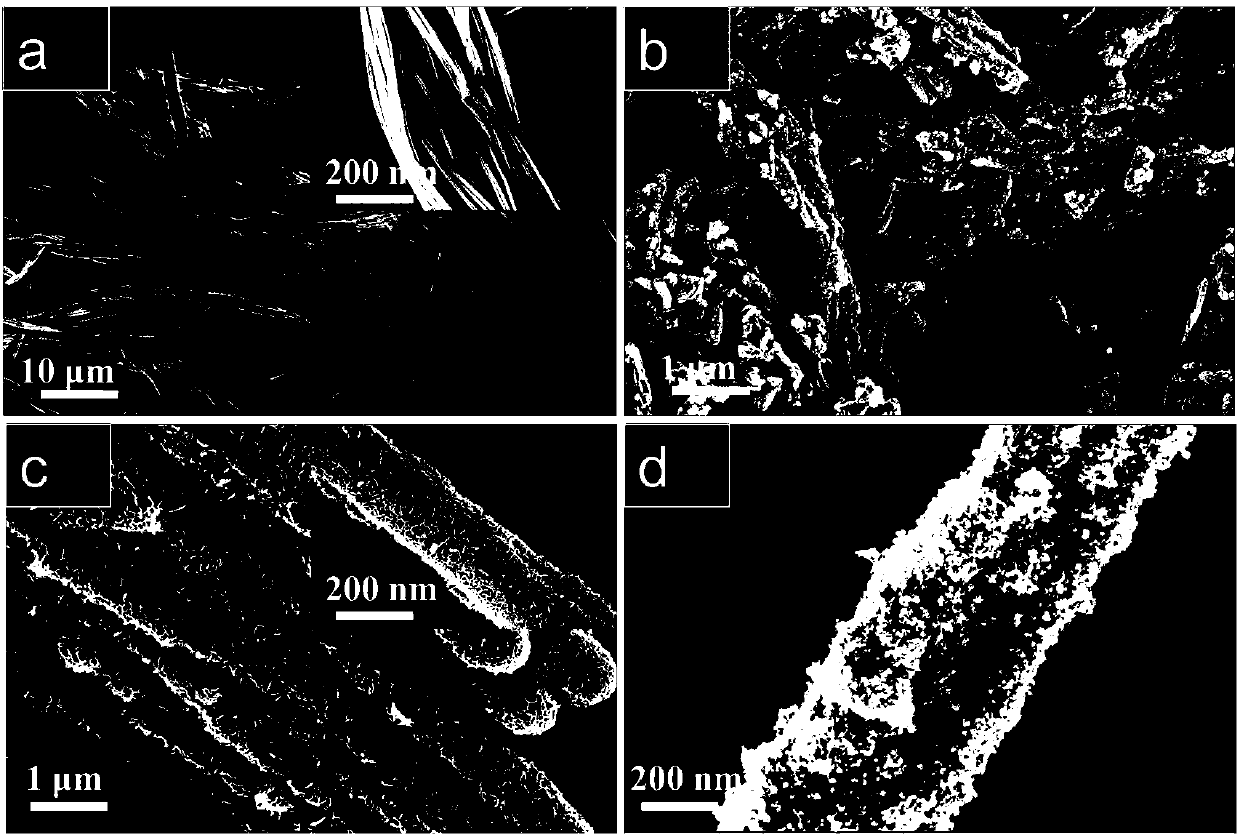

Image

Examples

preparation example Construction

[0024] The preparation method steps are as follows:

[0025] Step 1: Sodium molybdate and aniline monomer synthesize molybdenum polysalt nanowire;

[0026] Step 2: Prepare molybdate nanowires by in-situ polymerization to obtain polyaniline@molybdenum polyacidate nanowires;

[0027] Step 3: Polyaniline@molybdenum polyacid salt nanowires are prepared by hydrothermal reaction in the presence of a reducing agent to obtain polyaniline@molybdenum disulfide composite nanowires;

[0028] Step 4: In order to improve the impedance matching performance of polyaniline@molybdenum disulfide composite nanowires to electromagnetic waves, polyaniline@molybdenum disulfide@ferric oxide composite nanowires were prepared again by hydrothermal reaction.

Embodiment

[0030] 1. Synthesis of molybdenum polyacid salt nanowires

[0031] Dissolve 2-3g ammonium molybdate tetrahydrate and 2-3g aniline monomer in 30-50ml deionized water, and then add 1M hydrochloric acid solution dropwise to the mixed solution under constant stirring until a white precipitate appears (approx. 3-5ml), then stirred and reacted at 40-60°C for 2-6 hours, filtered, washed 3 times with pure ethanol, and dried at 60°C to obtain white molybdenum polyacid salt nanowires.

[0032] 2. Preparation of polyaniline@molybdenum polyacid salt nanowires

[0033] Weigh 2-5g of the above-prepared molybdenum polyacid salt nanowires and 2.5-4g of ammonium molybdate tetrahydrate, add 400ml of deionized water, stir to dissolve them all, quickly add 4-7g of ammonium persulfate, and then stir vigorously Adjust the pH of the above system to 2 with 1M hydrochloric acid solution, and then start the reaction for 6 hours. Stop stirring, filter, wash once with deionized water, then wash three t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com