Ferroferric oxide/molybdenum disulfide/carbon fiber composite wave-absorbing material and two-step reaction preparation method thereof

A composite wave-absorbing material, ferroferric oxide technology, applied in carbon fiber, fiber treatment, textiles and papermaking, etc., to achieve the effects of high resistance loss, high dielectric loss, and high magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

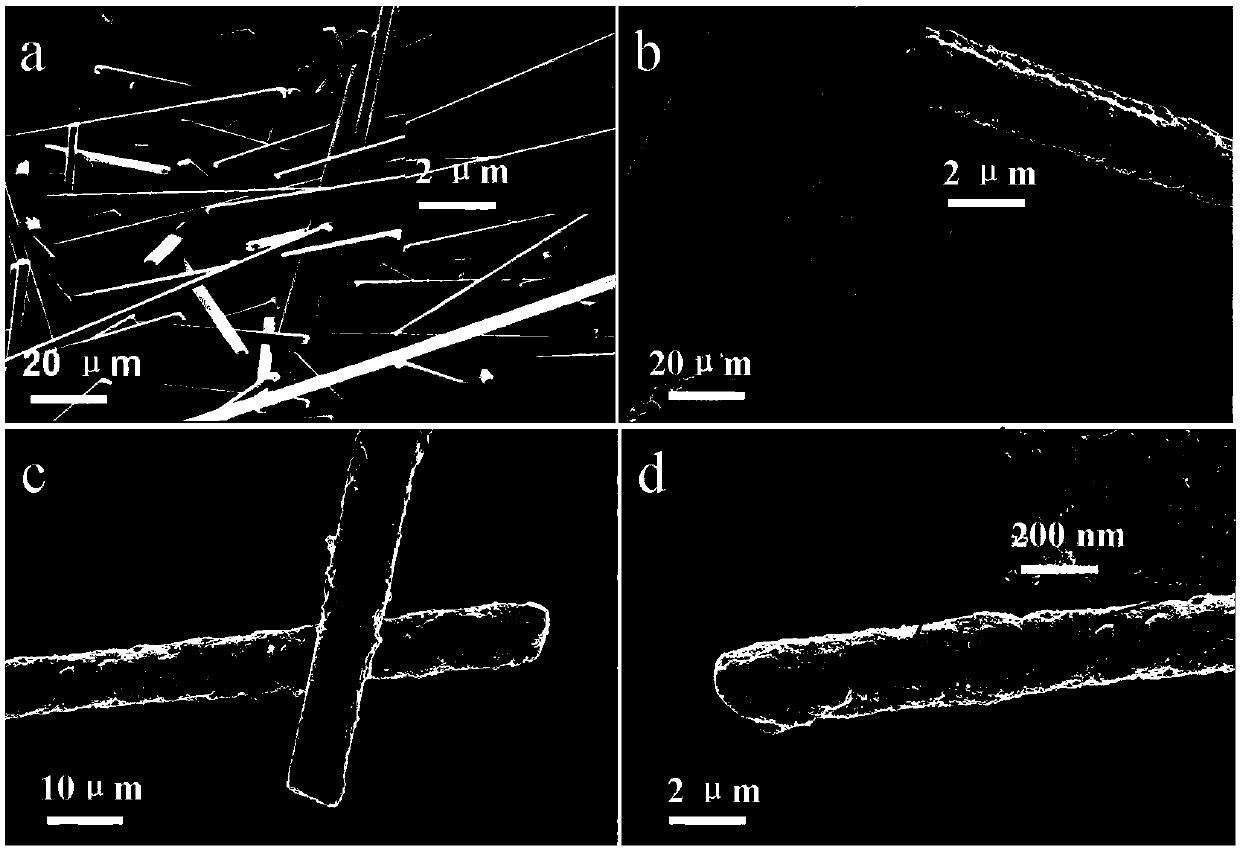

[0024] 1. Pretreatment of carbon fiber

[0025] Add 10g of chopped carbon fiber to 100-300ml of sodium hydroxide (1M) and stir for 30-60min, then wash with deionized water until neutral, then wash with acetone for 3 times, and finally bake in an oven at 120°C for 3 hours, and finally in Burn in a muffle furnace at 200°C for 30 minutes to remove the grease on the surface;

[0026] 2. Preparation of molybdenum disulfide / carbon fiber composites

[0027] Weigh 0.4g of pretreated carbon fiber, add 150ml of deionized water, 1.800g of thiourea and 0.968g of sodium molybdate dihydrate into the above system, ultrasonically disperse for 1 hour, and transfer the obtained uniform mixed liquid to 150ml of water In a thermal reaction kettle, seal the kettle, react at 200°C for 48 hours, automatically cool down to room temperature, open the kettle, filter, wash with deionized water and absolute ethanol three times, and dry at 60°C for 8 hours to obtain black powder molybdenum disulfide / Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com