Benzene hydrorefining catalyst, and preparation method and application thereof

A catalyst, benzene hydrogenation technology, applied in catalyst activation/preparation, catalyst, carbon compound catalyst, etc., can solve the problem of poor anti-poisoning performance and anti-carbon deposition performance of catalyst, poor water resistance of benzene hydrogenation catalyst, complicated preparation method, etc. problems, to achieve the effect of enhancing anti-poisoning performance and anti-carbon deposition performance, improving the use of a smaller temperature range and a simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

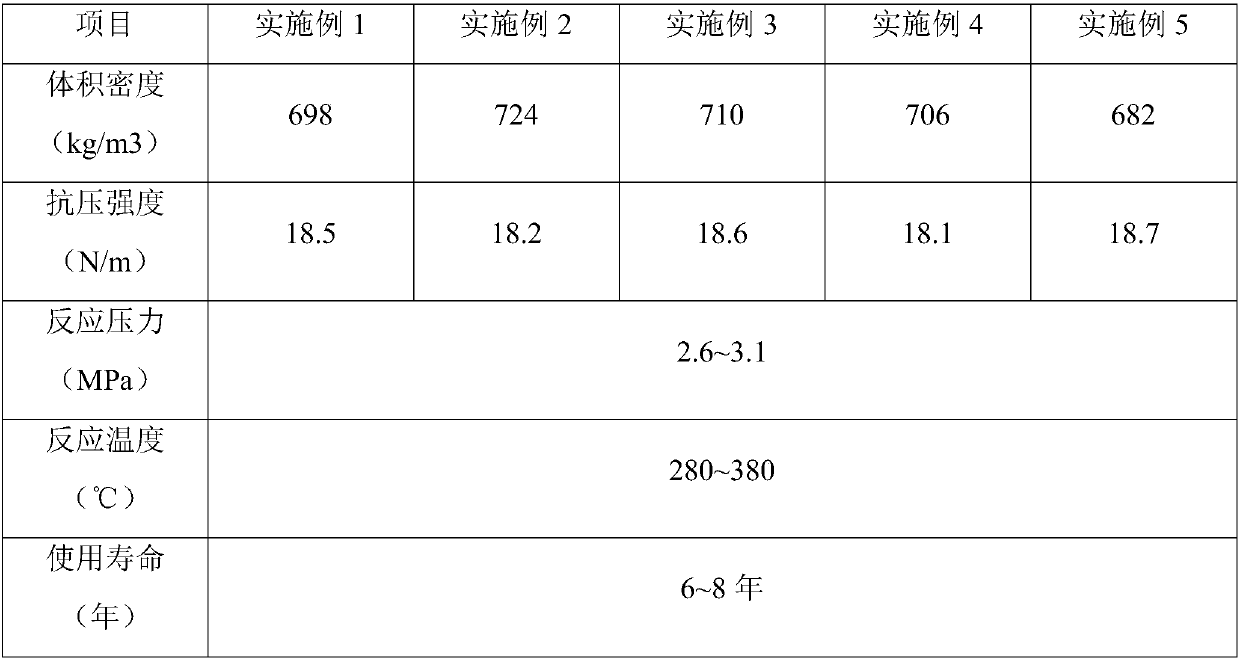

Examples

Embodiment 1

[0026] A preparation method for a benzene hydrotreating catalyst, comprising the following steps:

[0027] S1. Mix the carrier raw materials of the benzene hydrorefining catalyst evenly, extrude and granulate, and sinter and shape at 680-700° C. to obtain a carrier; the carrier raw materials are composed of the following components in mass percentage: 62% Al 2 o 3 , 7%TiO 2 , 16% MoO 3 , 6% CoO 4 , the balance is rare earth;

[0028] S2. Add phosphoric acid to water at 46-50°C, mix evenly, heat to 88-92°C, add cobalt carbonate, add molybdenum trioxide after the reaction and degassing, mix and dissolve to obtain an activation solution; the cobalt carbonate , The mass ratio of molybdenum trioxide, phosphoric acid and water is 1.2:3.2:1:3.3;

[0029] S3. Put the carrier in a closed reactor, dry at 80-90°C for 30 minutes, vacuumize the negative pressure -0.02-0.06MPa, then atomize the activation solution into the closed reactor, let it stand for 15 minutes, and then Dry at 8...

Embodiment 2

[0032] A preparation method for a benzene hydrotreating catalyst, comprising the following steps:

[0033] S1. Mix the carrier raw materials of the benzene hydrorefining catalyst evenly, extrude and granulate, and sinter and shape at 680-700° C. to obtain a carrier; the carrier raw materials are composed of the following components in mass percentage: 64% Al 2 o 3 , 7%TiO 2 , 20% MoO 3 , 8% CoO 4 , the balance is rare earth; the particle size of the carrier material is 400-800 mesh;

[0034] S2. Add phosphoric acid to water at 46-50°C, mix evenly, heat to 88-92°C, add cobalt carbonate, add molybdenum trioxide after the reaction and degassing, mix and dissolve to obtain an activation solution; the cobalt carbonate , The mass ratio of molybdenum trioxide, phosphoric acid and water is 1.4:3.6:1:3.5;

[0035] S3. Put the carrier in a closed reactor, dry at 80-90°C for 50 minutes, vacuumize the negative pressure -0.02-0.06MPa, then atomize the activation solution into the clos...

Embodiment 3

[0038] A preparation method for a benzene hydrotreating catalyst, comprising the following steps:

[0039] S1. Using nitric acid with a mass percent concentration of 8% as a solvent, mix the carrier raw materials evenly, let stand for 24 hours, extrude and granulate, and sinter at 680-700°C to obtain a carrier; the carrier raw materials are composed of the following components: Composition by mass percentage: 63% Al 2 o 3 , 6%TiO 2 , 18% MoO 3 , 7% CoO4 , the balance is rare earth;

[0040] S2. Add phosphoric acid to water at 46-50°C, mix evenly, heat to 88-92°C, add cobalt carbonate, add molybdenum trioxide after the reaction and degassing, mix and dissolve to obtain an activation solution; the cobalt carbonate , The mass ratio of molybdenum trioxide, phosphoric acid and water is 1.3:3.4:1:3.3;

[0041] S3. Put the carrier in a closed reactor, dry it at 80-90°C for 40 minutes, vacuum the negative pressure -0.02-0.06MPa, then atomize the activation solution into the close...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com