A kind of bagasse activated carbon and preparation method thereof

A technology of bagasse and activated carbon, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low utilization value and achieve strong adsorption capacity, large specific surface area, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

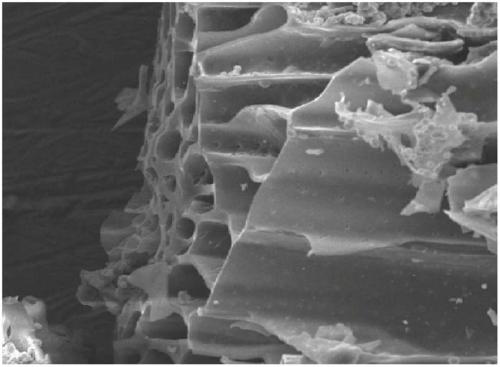

Image

Examples

Embodiment 1

[0033] The method for preparing bagasse activated carbon comprises the following steps:

[0034] 1) Take the dried bagasse, wash it with water three times to remove the residual sugar, and dry it in the sun or in an oven to obtain dry bagasse;

[0035] 2) Activate the dry bagasse with 15wt% zinc chloride solution as the activator, wherein the mass ratio of the dry bagasse to the volume of activator A is 1g:4.5mL, the activation time is 8h, and the activation is at room temperature conduct;

[0036] 3) Dry the bagasse obtained in step 2) at 100°C for 2 hours and dehydrate;

[0037] 4) Carbonize the bagasse treated in step 3) at 500°C for 1 hour to obtain semi-finished activated carbon;

[0038] 5) Soak semi-finished activated carbon in dilute hydrochloric acid with a concentration of 0.01mol / L for 30 minutes;

[0039] 6) Use a voltage of 4.5V to oxidize the surface of the semi-finished activated carbon after step 5) for 2.5 hours;

[0040] 7) Wash the semi-finished activate...

Embodiment 2

[0044] The method for preparing bagasse activated carbon comprises the following steps:

[0045] 1) Take the dried bagasse, wash it with water three times to remove the residual sugar, and dry it in the sun or in an oven to obtain dry bagasse;

[0046] 2) Activate the dry bagasse with 20wt% potassium hydroxide solution as the activator, wherein the mass ratio of the dry bagasse to the volume of activator A is 1g:5mL, the activation time is 24h, and the activation is carried out at room temperature ;

[0047] 3) Dry the bagasse obtained in step 2) at 60°C for 24 hours and dehydrate;

[0048] 4) Carbonize the bagasse treated in step 3) at 500°C for 2 hours to obtain semi-finished activated carbon;

[0049]5) Soak the semi-finished activated carbon in dilute hydrochloric acid with a concentration of 0.05mol / L for 30 minutes;

[0050] 6) Use a voltage of 4.5V to oxidize the surface of the semi-finished activated carbon after step 5) for 0.5h;

[0051] 7) Wash the semi-finished...

Embodiment 3

[0055] The method for preparing bagasse activated carbon comprises the following steps:

[0056] 1) Take the dried bagasse, wash it with water three times to remove the residual sugar, and dry it in the sun or in an oven to obtain dry bagasse;

[0057] 2) Activate the dry bagasse with 20wt% zinc chloride solution as the activator, wherein the mass ratio of the dry bagasse to the volume of activator A is 1g:4.5mL, the activation time is 24h, and the activation is at room temperature conduct;

[0058] 3) Dry the bagasse obtained in step 2) at 70°C for 15 hours and dehydrate;

[0059] 4) Carbonize the bagasse treated in step 3) at 500°C for 1 hour to obtain semi-finished activated carbon;

[0060] 5) Soak semi-finished activated carbon in dilute hydrochloric acid with a concentration of 0.1mol / L for 30 minutes;

[0061] 6) Use a voltage of 4.5V to oxidize the surface of the semi-finished activated carbon after step 5) for 1.5h;

[0062] 7) Wash the semi-finished activated car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com