Aluminum-tin alloy film for lithium ionic cell negative electrode and method for preparing the same

A lithium-ion battery, aluminum-tin alloy technology, applied in the direction of electrode manufacturing, battery electrodes, ion implantation plating, etc., can solve the problem of electrode capacity reduction, achieve improved cycle performance, high charge and discharge capacity, and increase electrode capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The pure Sn single target with a size of Φ40mm×3mm (purity 99.9%) is used, and the initial pressure in the sputtering chamber before sputtering is 1.0×10 -4 Pa. At room temperature, argon gas was introduced so that the sputtering pressure in the sputtering chamber was 3.0 Pa. The power of the radio frequency power supply is adjusted to 200W, and a pure Sn film is deposited on the copper foil, and the deposition time is 10 minutes.

[0030] The prepared thin film electrodes were assembled into CR2016 button cells according to the method described above. Electrochemical tests show that the initial charge capacity of the Sn thin film electrode prepared according to the magnetron sputtering method of the present invention is 660mAh / g, and the discharge capacity is 570mAh / g, and the capacity remains at 550mAh / g after 30 cycles, and the capacity retention was 83%, and the charge and discharge efficiency was maintained at 90%.

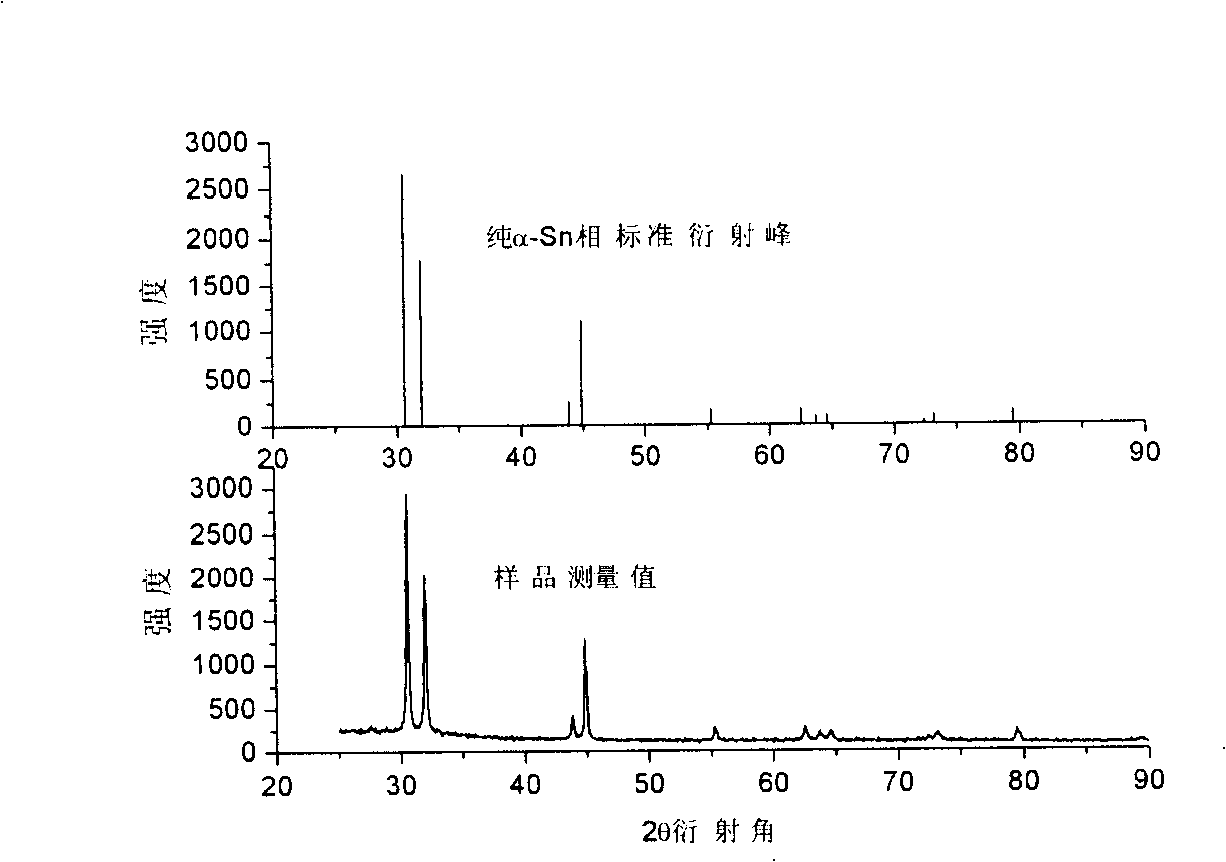

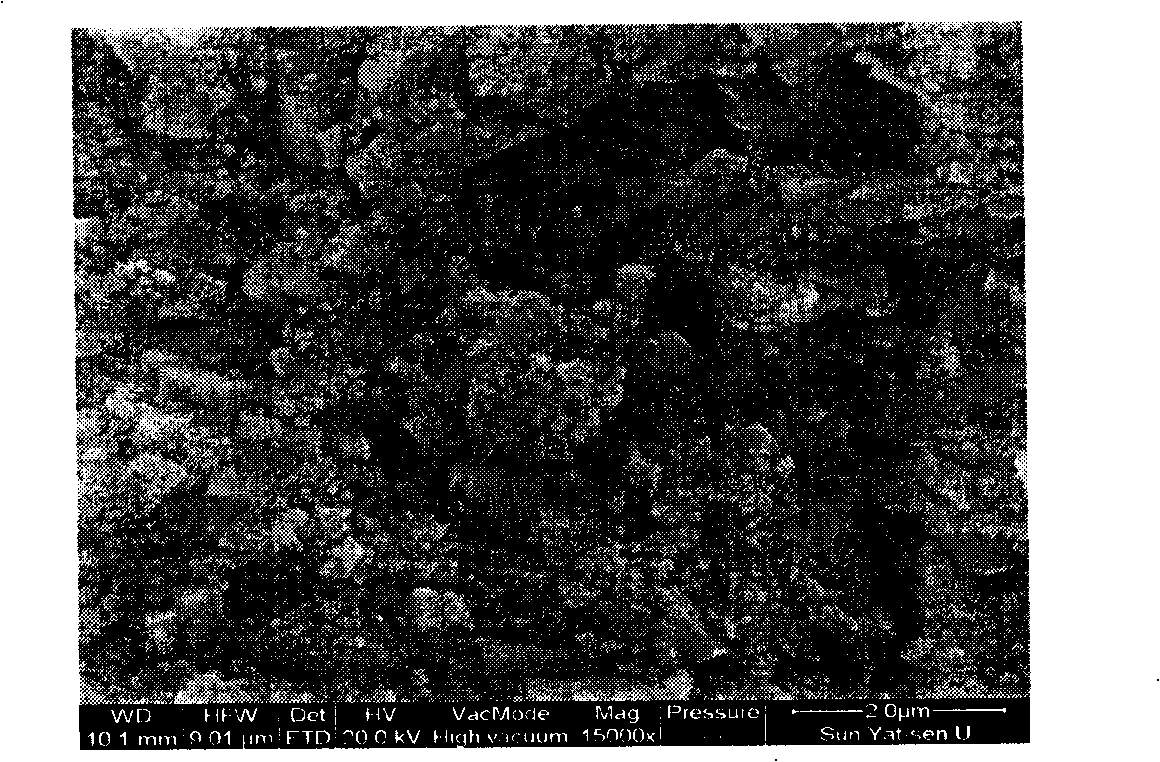

[0031] X-ray diffraction phase analysis was c...

Embodiment 2

[0033] The pure Sn single target with a size of Φ40mm×3mm (purity 99.9%) is used, and the initial pressure in the sputtering chamber before sputtering is 1.0×10 -4 Pa. At room temperature, argon gas was introduced so that the sputtering pressure in the sputtering chamber was 0.1 Pa. Adjust the power of the DC power supply to 10W, and deposit a pure Sn film on the copper foil, and the deposition time is 30 minutes.

[0034] The prepared thin film electrodes were assembled into CR2016 button cells according to the method described above. Electrochemical tests show that the first charge capacity of the Sn thin film electrode prepared according to the magnetron sputtering method of the present invention is 781mAh / g, the first discharge capacity is 500Ah / g, and the capacity remains at 100mAh / g after 30 cycles, and the capacity remains The rate was 13%, and the charge and discharge efficiency was maintained at 90%.

Embodiment 3

[0036] The AlSn alloy target with a size of Φ40mm×3mm and an element mass ratio of Al:Sn=1:3 (purity of 99.95%) was used, and the initial pressure in the sputtering chamber before sputtering was 1.0×10 -4 Pa. At room temperature, argon gas was introduced so that the sputtering pressure in the sputtering chamber was 3.0 Pa. At room temperature, under the condition of argon atmosphere, the power of the radio frequency power supply is adjusted to 200W, and the AlSn thin film is deposited on the copper foil, and the deposition time is 10 minutes.

[0037] The prepared thin film electrodes were assembled into CR2016 button cells according to the method described above. Electrochemical tests show that the initial charge capacity of the AlSn alloy film electrode prepared according to the magnetron sputtering method of the present invention is 905mAh / g, and the discharge capacity is 698Ah / g, and the capacity remains at 768mAh / g after 30 cycles, and the capacity remains The rate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com