A preparation liyo 2 battery material method

A technology for battery materials and raw materials, applied in the preparation/processing of rare earth metal compounds, battery electrodes, secondary batteries, etc., can solve problems such as no research reports on battery materials, and achieve low investment in production equipment, stable cycle performance, and preparation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

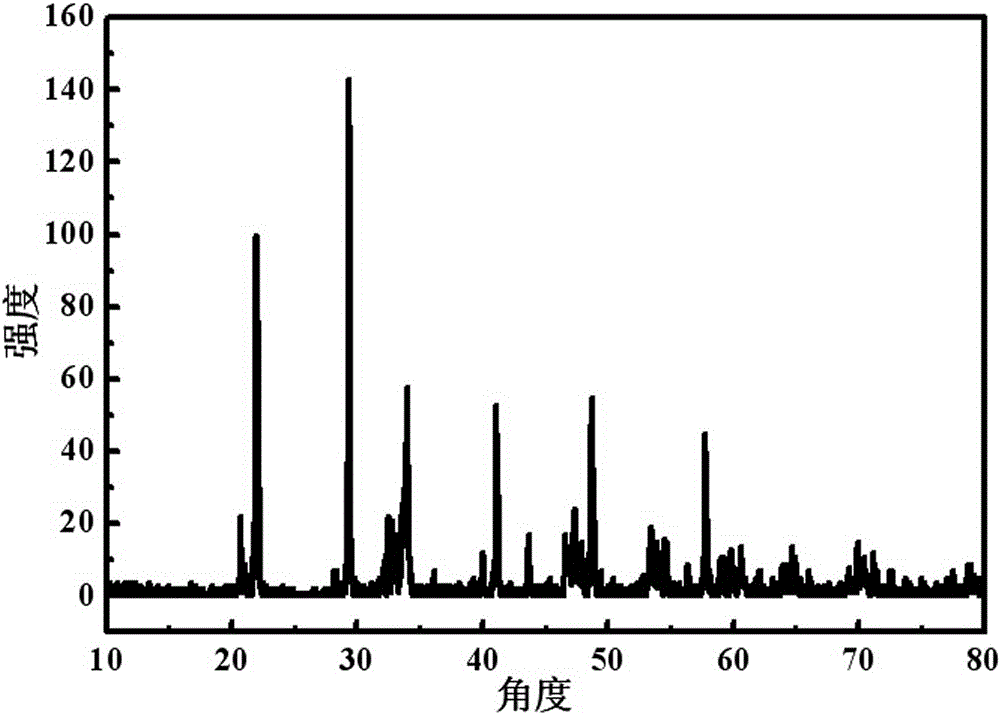

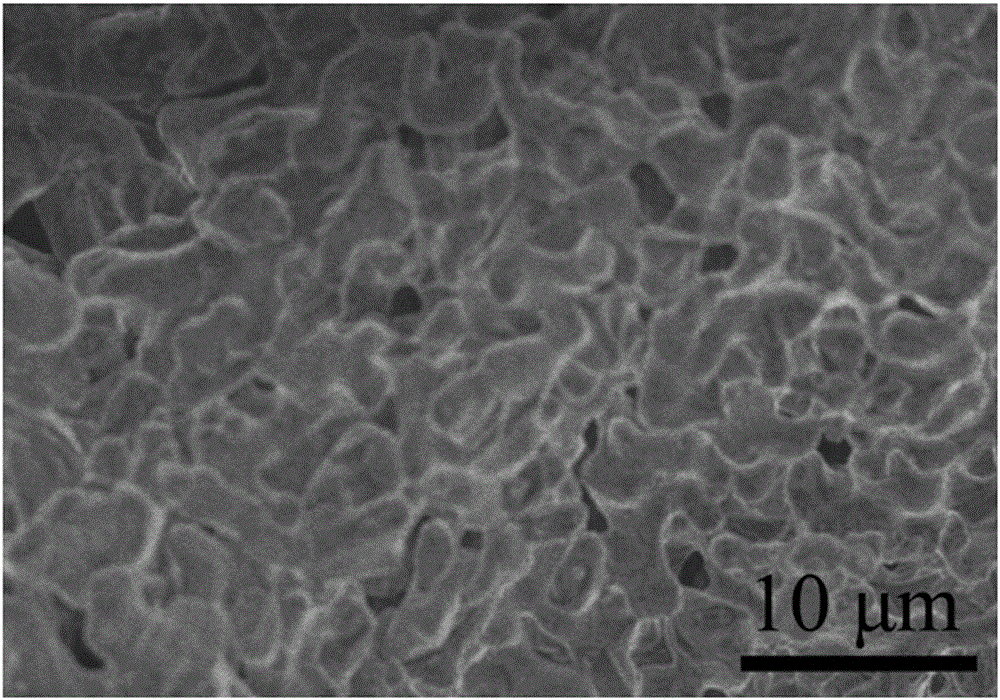

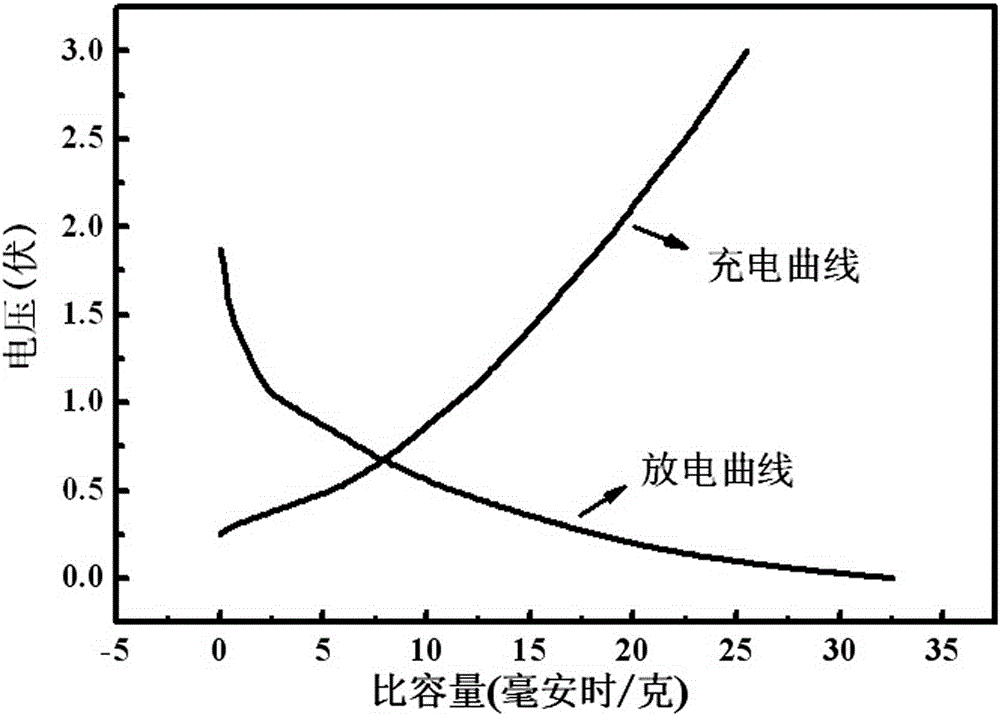

[0024] Weigh 0.350g LiAc2H 2 O, 0.323g Y 2 o 3 Dissolve in a mixed solvent composed of 20mL deionized water and 30mL ethanol, and stir for 1h. The mixed product was placed in a blast drying oven and dried at 150°C. The precursor was obtained by drying for 3 hours. After the precursor was fully ground in an agate mortar, it was pressed into tablets in a tablet machine, and calcined in a muffle furnace at a constant temperature of 800°C for 10 hours, and then naturally dropped to room temperature. The product was ground to obtain LiYO 2 powder. figure 1 It is the X-ray diffraction spectrum figure of this product, as can be seen from the figure, the diffraction peak intensity is higher, illustrates that the crystallinity of this product is better, and this spectrum figure can be compared with LiYO 2 standard card (00-024-0671), indicating that the product is LiYO 2 . figure 2 It is an electron microscope (SEM) photo of the product. It can be seen that the product is comp...

Embodiment 2

[0030] Weigh 0.200g Li 2 CO 3 , 0.510gY 2 o 3 Dissolve in a mixture of 30mL deionized water and 40mL ethanol

[0031] Mixing solvent, stirred for 1.5h. The mixture was placed in a blast drying oven and dried at 80 °C. The precursor was obtained after drying for 5 hours. After the precursor was fully ground in an agate mortar, it was pressed in a tablet machine, calcined in a muffle furnace at a constant temperature of 500 °C for 7 h, and then naturally dropped to room temperature. The product was ground to obtain LiYO 2 powder. The resulting LiYO 2 The first discharge specific capacity of the material within 2.3-0.01V reaches 35.90 mAhg -1 . at 50 mAg -1 Charge and discharge under the current density, the battery capacity has no obvious decay after 20 cycles.

Embodiment 3

[0033] Weigh 0.400g LiAc2H 2 O, 0.570gY 2 o 3 Dissolve in a mixed solvent composed of 35mL deionized water and 45mL ethanol, and stir for 1.2 h. The mixed product was placed in a blast drying oven and dried at 90°C. After drying for 5.5 hours, the precursor was obtained. After the precursor was fully ground in an agate mortar, it was pressed into tablets in a tablet machine, and calcined in a muffle furnace at a constant temperature of 650°C for 9 hours, and then naturally dropped to room temperature. LiYO was obtained by grinding 2 powder. The first discharge specific capacity of this material in 2.3-0.01V is 37.80 mAhg -1 . at 60mAg -1 The capacity has no obvious decay after charging and discharging for 30 times under the current density.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com