Electrolytic corrosion method of stainless steel/carbon steel composite plate metallographic structure

A technology of electrolytic corrosion and metallographic structure, applied in the field of metallographic corrosion, can solve the problems of laboratory personnel's health injury, large difference in corrosion resistance, poor corrosion resistance of carbon steel, etc., to reduce health injury, simple formula, and corrosion effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

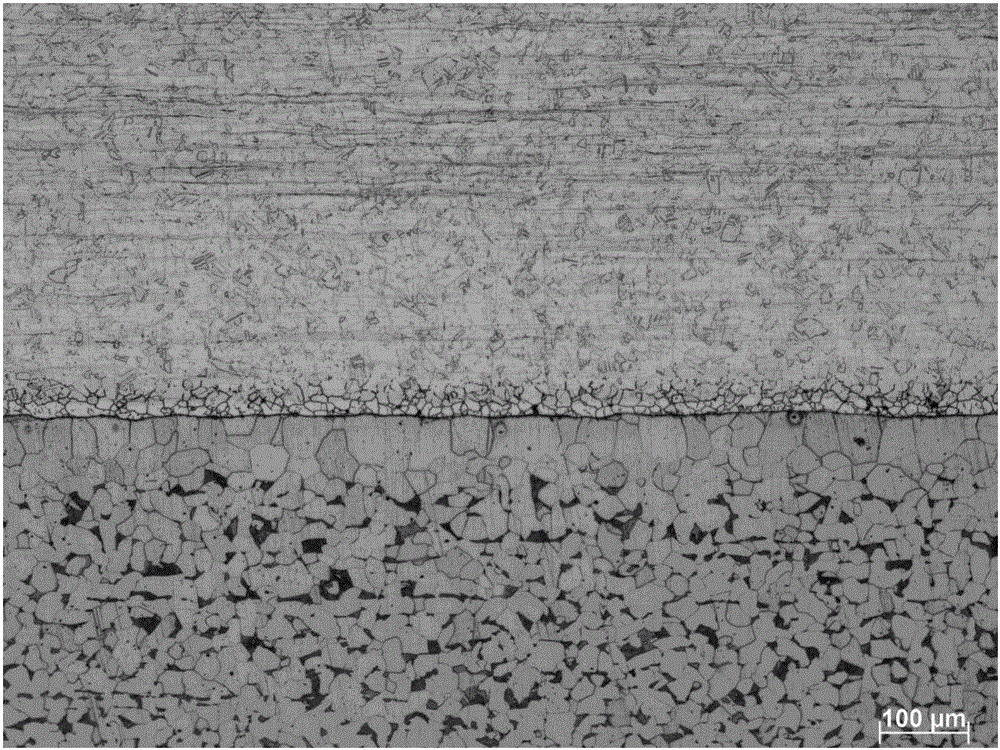

Embodiment 1

[0036] (1) After the stainless steel / carbon steel composite plate samples are polished with 400#, 600#, 800#, 1000#, 1500#, 2000#, 2500#, 3000# water-grinding sandpaper in sequence, and then mechanically polishing;

[0037] (2) Preparation of etchant 1: Take 4ml of nitric acid and 96ml of alcohol with a mass percentage concentration of 65%, slowly pour the measured nitric acid solution into a glass container filled with alcohol along the container wall, and stir evenly with a glass rod ;

[0038] (3) Spray the mechanically polished sample with the etchant 1 prepared in step (2), and the corrosion residence time is 6s.

[0039] (4) Take out the corroded sample in step (3) from the etchant 1, rinse it with absolute ethanol and dry it.

[0040] (5) Preparation of etchant 2: Weigh 10 g of chromium trioxide and 100 ml of deionized water, pour deionized water and chromium trioxide into a glass container successively, and stir with a glass rod until chromium trioxide is completely ...

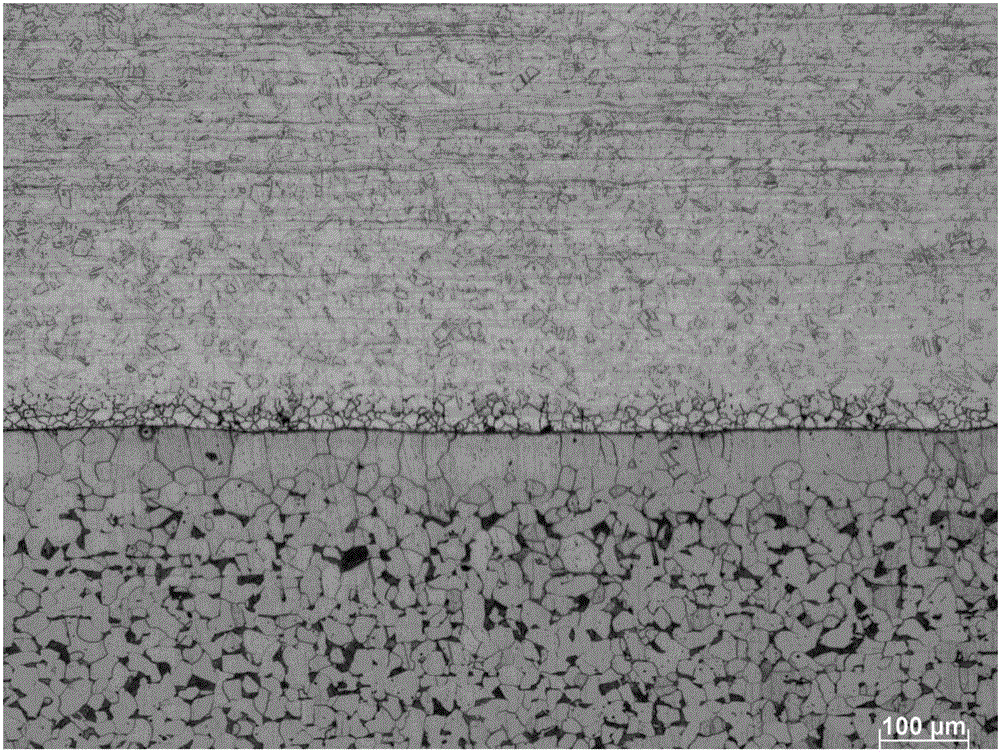

Embodiment 2

[0045] (1) After the stainless steel / carbon steel composite plate samples are polished with 400#, 600#, 800#, 1000#, 1500#, 2000#, 2500#, 3000# water-grinding sandpaper in sequence, and then mechanically polishing;

[0046] (2) Preparation of etchant 1: Take 4ml of nitric acid and 96ml of alcohol with a mass percentage concentration of 65%, slowly pour the measured nitric acid solution into a glass container filled with alcohol along the container wall, and stir evenly with a glass rod ;

[0047] (3) Spray the mechanically polished sample with the etchant 1 prepared in step (2), and the corrosion residence time is 6s.

[0048] (4) Take out the corroded sample in step (3) from the etchant 1, rinse it with absolute ethanol and dry it.

[0049] (5) Preparation of etchant 2: Weigh 10 g of chromium trioxide and 100 ml of deionized water, pour deionized water and chromium trioxide into a glass container successively, and stir with a glass rod until the chromium trioxide is complet...

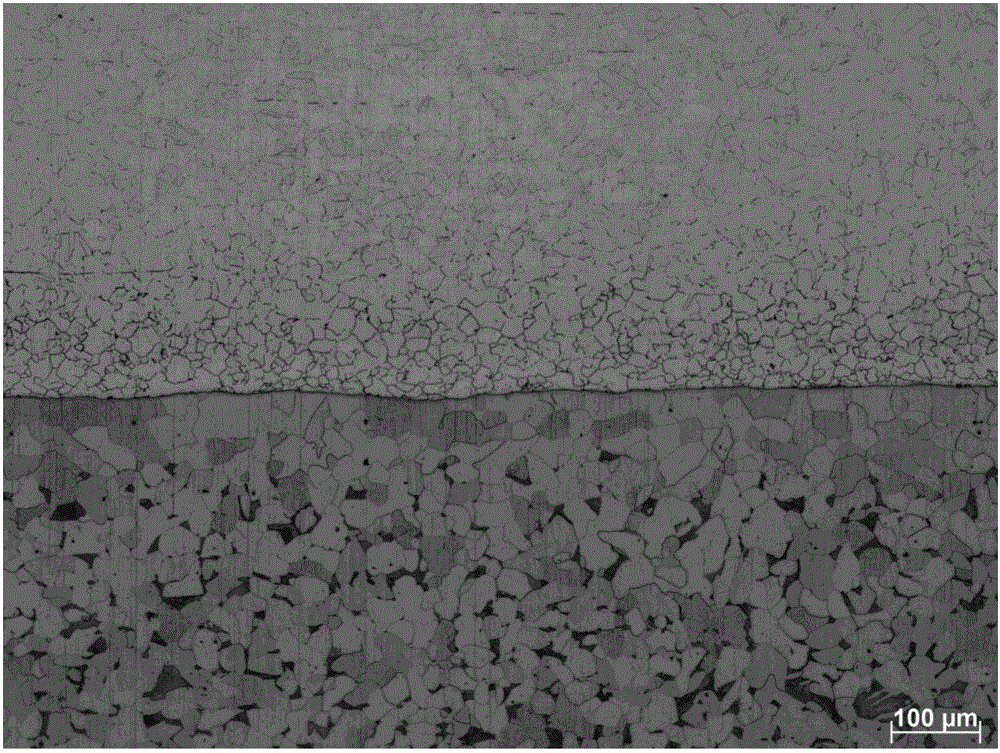

Embodiment 3

[0054] (1) After the stainless steel / carbon steel composite plate samples are polished with 400#, 600#, 800#, 1000#, 1500#, 2000#, 2500#, 3000# water-grinding sandpaper in sequence, and then mechanically polishing;

[0055] (2) Preparation of etchant 1: Take 4ml of nitric acid and 96ml of alcohol with a mass percentage concentration of 80%, slowly pour the measured nitric acid solution into a glass container filled with alcohol along the container wall, and stir evenly with a glass rod ;

[0056] (3) Spray the mechanically polished sample with the etchant 1 prepared in step (2), and the corrosion residence time is 6s.

[0057] (4) Take out the corroded sample in step (3) from the etchant 1, rinse it with absolute ethanol and dry it.

[0058] (5) Preparation of etchant 2: Weigh 25 g of chromium trioxide and 100 ml of deionized water, pour deionized water and chromium trioxide into a glass container successively, and stir until chromium trioxide is completely dissolved with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com