Industrialized thick GEM (Gaseous Electron Multiplier) manufacturing method

A manufacturing method and original board technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as difficulty in increasing the size of insulating rings, inability to meet mass production, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

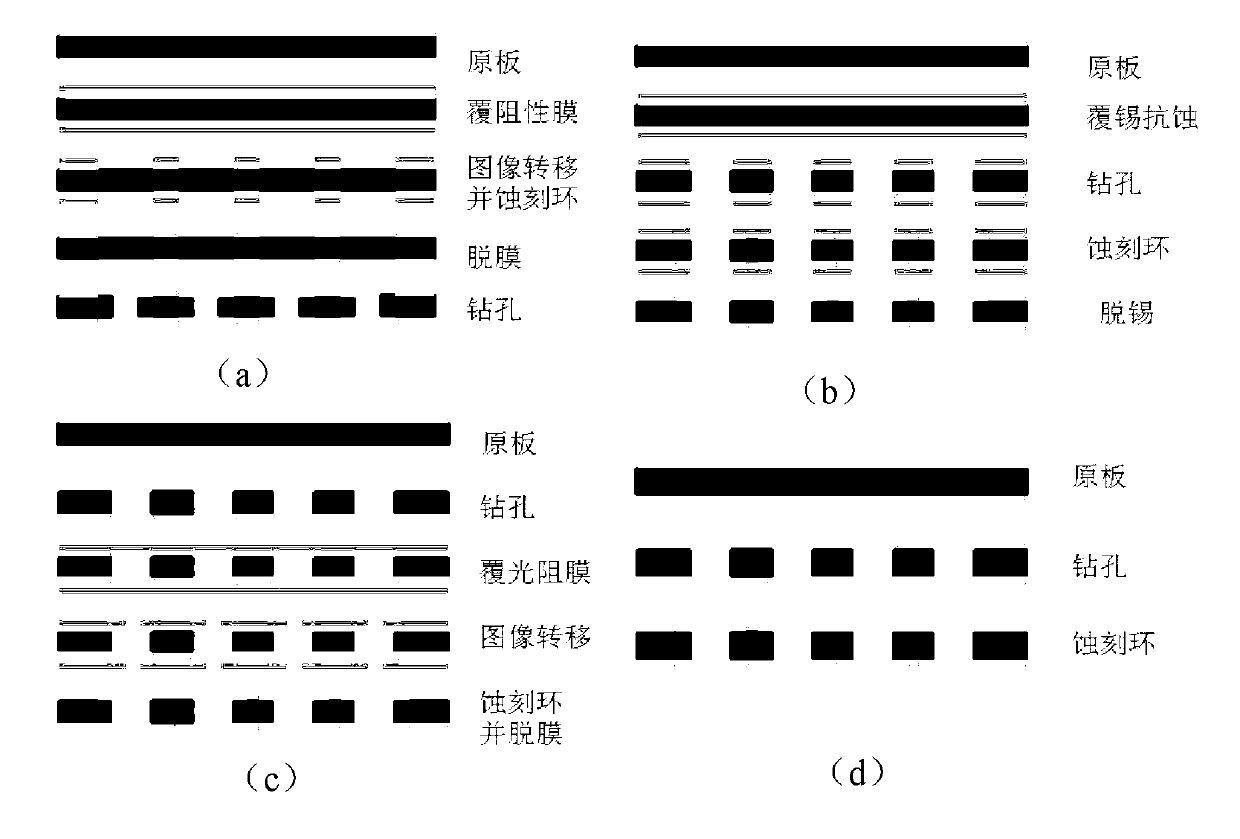

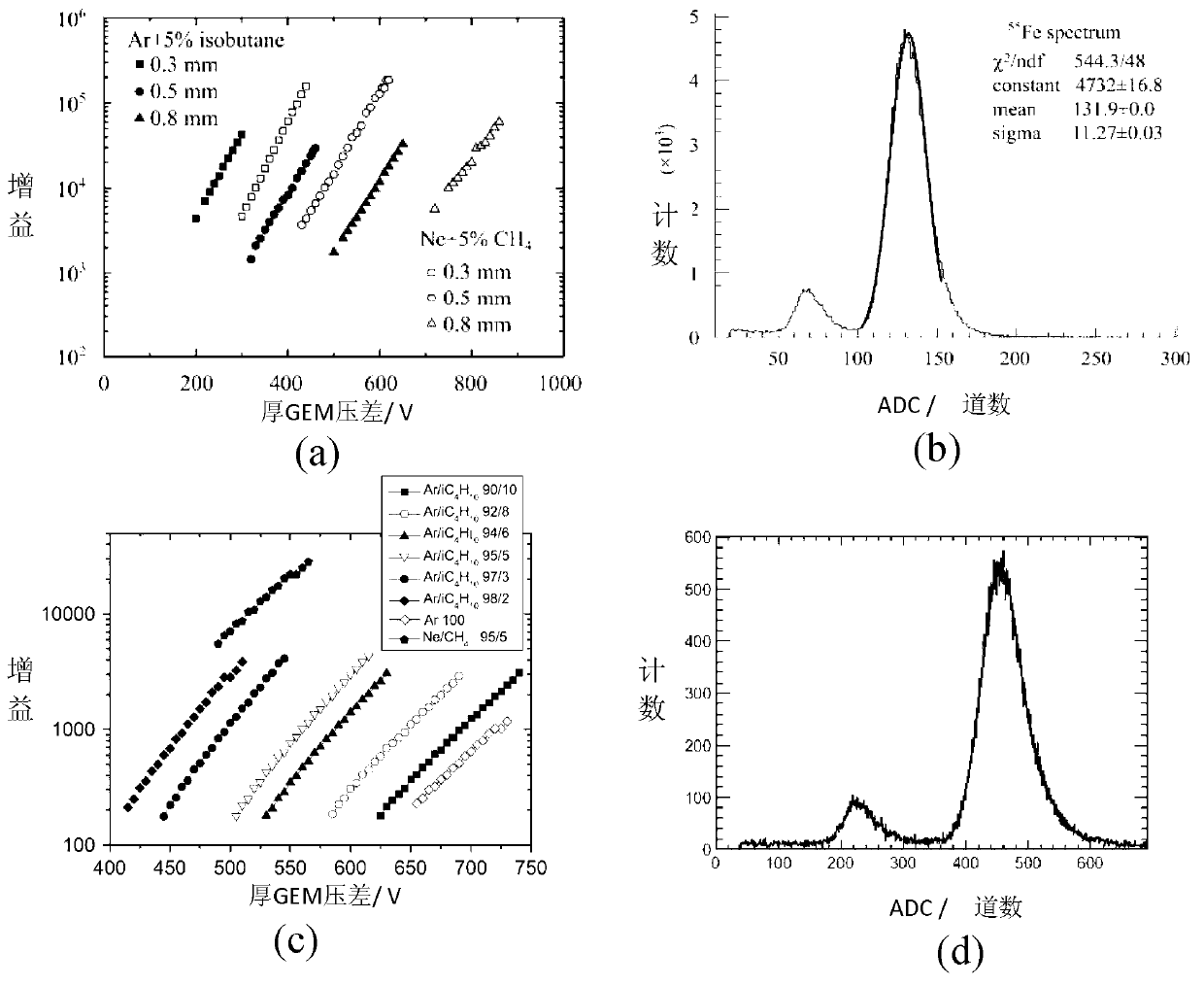

Method used

Image

Examples

Embodiment Construction

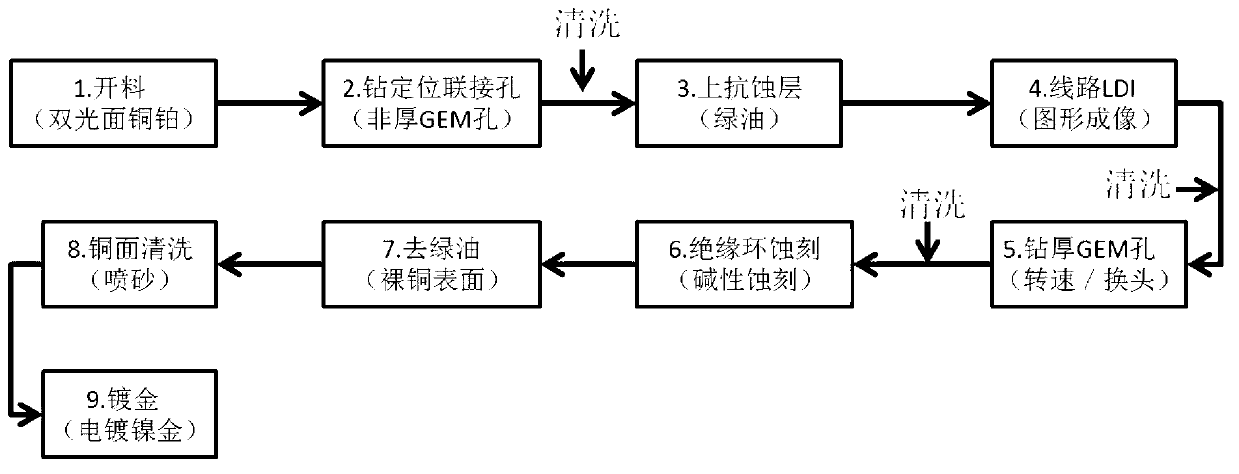

[0058] The general technical process of the present invention is as image 3 Shown, including 9 processes. Among them, it is very important to perform additional cleaning on the plate before and after process 3, and before and after process 5. The main purpose is to remove tiny particles or debris on the plate and the processing platform, which can effectively avoid defects and improve the yield. Generally, ultrasonic cleaning or air blowing can be used. The following is a detailed description of each process link:

[0059] Process 1: cutting

[0060] Whether it is from PCB processing or thick GEM production, I have never paid attention to raw materials before. During our initial process of making thick GEM, we found that thick GEM is very easy to ignite in the mixed gas of argon and carbon dioxide. Basically, it starts to ignite as soon as the signal is issued, and there is no working linear region. There are two reasons for sparking in the mixed gas of argon and carbon d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com