Preparation method and application of three-dimensional interpenetrating porous magnesium-based material

A technology of porous magnesium and base materials, applied in prosthetics, medical science, etc., can solve problems such as the inability to guarantee the uniformity of the pore structure, the connectivity of the pore structure, the corrosion of the metal of the magnesium matrix of the pore-forming agent, and achieve the protection of integrity and purity. , uniform distribution of pores, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

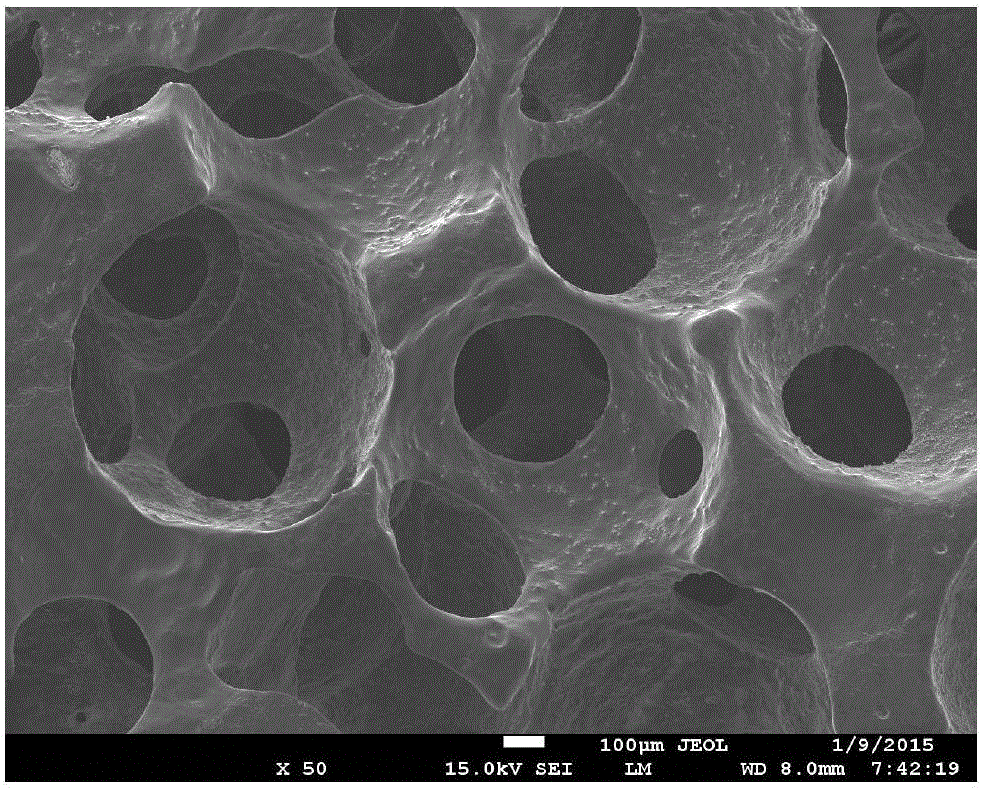

[0030] This embodiment relates to a degradable three-dimensional open-pore porous magnesium alloy used in the field of tissue engineering. The pore type is spherical and the pore diameter is 400-600 μm. It is 150-250 μm, and the porosity is 75%. Its structure is as figure 1 As shown in the physical figure, it can be seen that the spherical hole type and the connected holes evenly distributed on the hole wall.

[0031] This embodiment relates to the aforementioned degradable three-dimensional open-pore porous magnesium and magnesium alloy preparation method for tissue engineering, and the method includes the following steps:

[0032] Step 1, conduct spark plasma sintering of spherical titanium particles with a size of 400-600 μm, the sintering temperature is 800°C, the heating rate is 20°C / min, the pressure is 5MPa, heat preservation and pressure for 3 minutes, and then naturally cool to obtain a porous titanium ball preform ;

[0033] Step 2: Fill the Mg-5wt.%Zn-1wt.%Mn all...

Embodiment 2

[0036] This embodiment relates to a degradable open-pore porous magnesium alloy used for bone tissue engineering scaffolds. The pore type is spherical and the pore diameter is 400-600 μm. It is 250-350 μm, and the porosity is 85%.

[0037] This embodiment relates to the aforementioned degradable open-pore porous magnesium and magnesium alloy preparation method for tissue engineering scaffolds, the method includes the following steps:

[0038]Step 1. Spherical iron particles with a size of 400-600 μm are subjected to spark plasma sintering. The sintering temperature is 900°C, the heating rate is 40°C / min, and the pressure is 10MPa. After holding the heat for 3 minutes, cool naturally to obtain the porous iron ball preform with open pores. ;

[0039] Step 2: Fill the Mg-3wt.%Nd-0.2wt.%Zn-0.5wt.%Zr-0.5wt.%Ca alloy into the gap of the porous iron ball preform by infiltration casting at 720°C and a pressure of 6MPa , and air-cooled to room temperature to obtain a composite block ...

Embodiment 3

[0042] This embodiment relates to a degradable open-pore porous magnesium alloy used for tissue engineering scaffolds. The pore type is spherical and the pore diameter is 800-1000 μm. ~500μm, the porosity is 90%.

[0043] This embodiment relates to the aforementioned degradable three-dimensional open-pore porous pure magnesium preparation method for tissue engineering scaffolds, and the method includes the following steps:

[0044] Step 1, hot isostatic pressing sintering of spherical titanium particles with a size of 600-800 μm, the sintering temperature is 1000°C, the heating rate is 100°C / min, the pressure is 50MPa, heat preservation and pressure holding for 5 minutes, then naturally cool to obtain open porous iron balls Preform;

[0045] Step 2: Fill the pure magnesium melt into the gap of the porous iron ball preform by percolation casting at 720°C and a pressure of 0.1 MPa, and air-cool to room temperature to obtain a composite block of the preform and pure magnesium; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com