Novel filtration method for refining and chemical industries

a technology for chemical industries and filtration methods, applied in separation processes, magnetic separation, filtration separation, etc., can solve problems such as paramagnetic whole mass of contaminants, and achieve the effects of reducing downtime and hazardous operations, easy scaling, and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

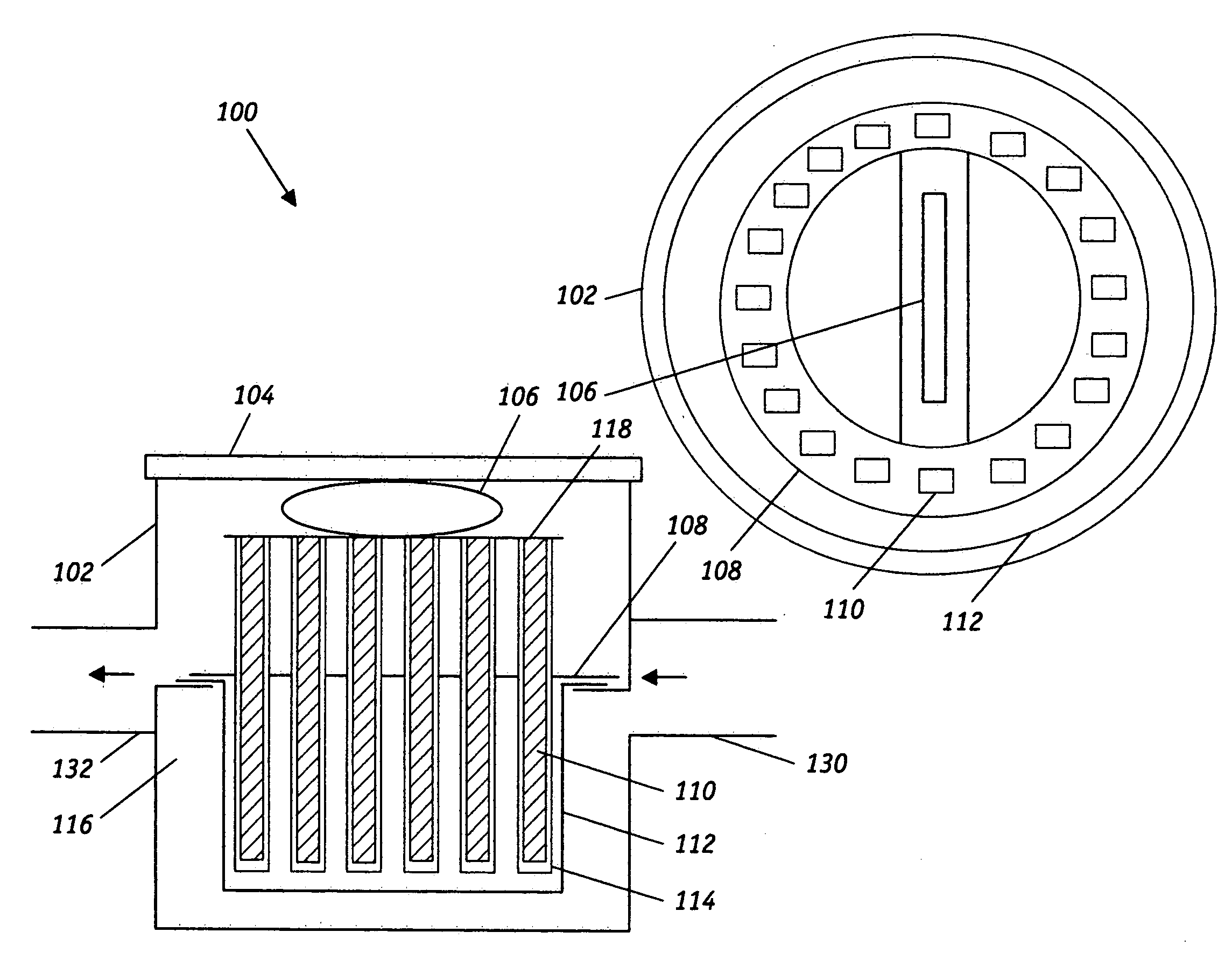

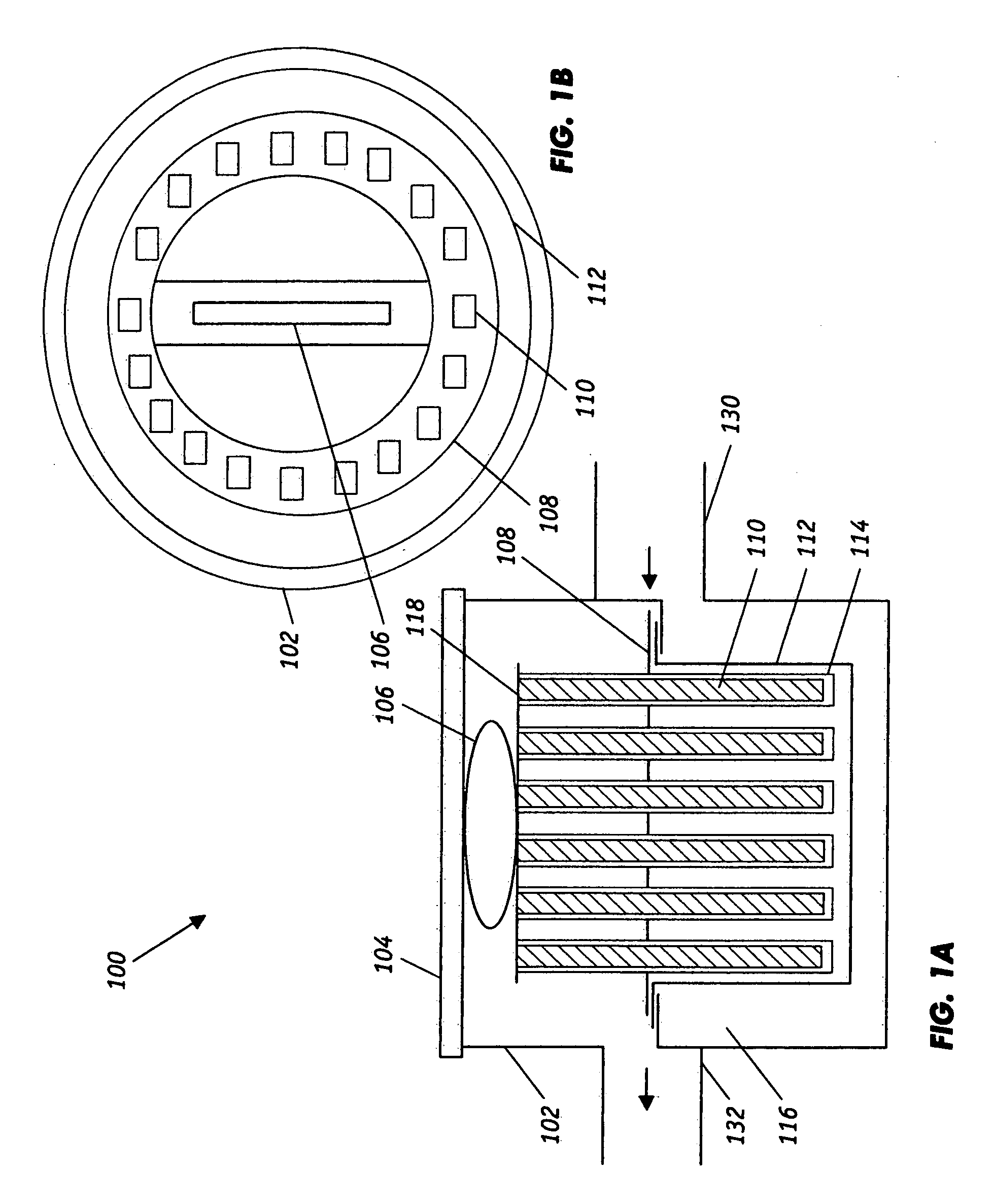

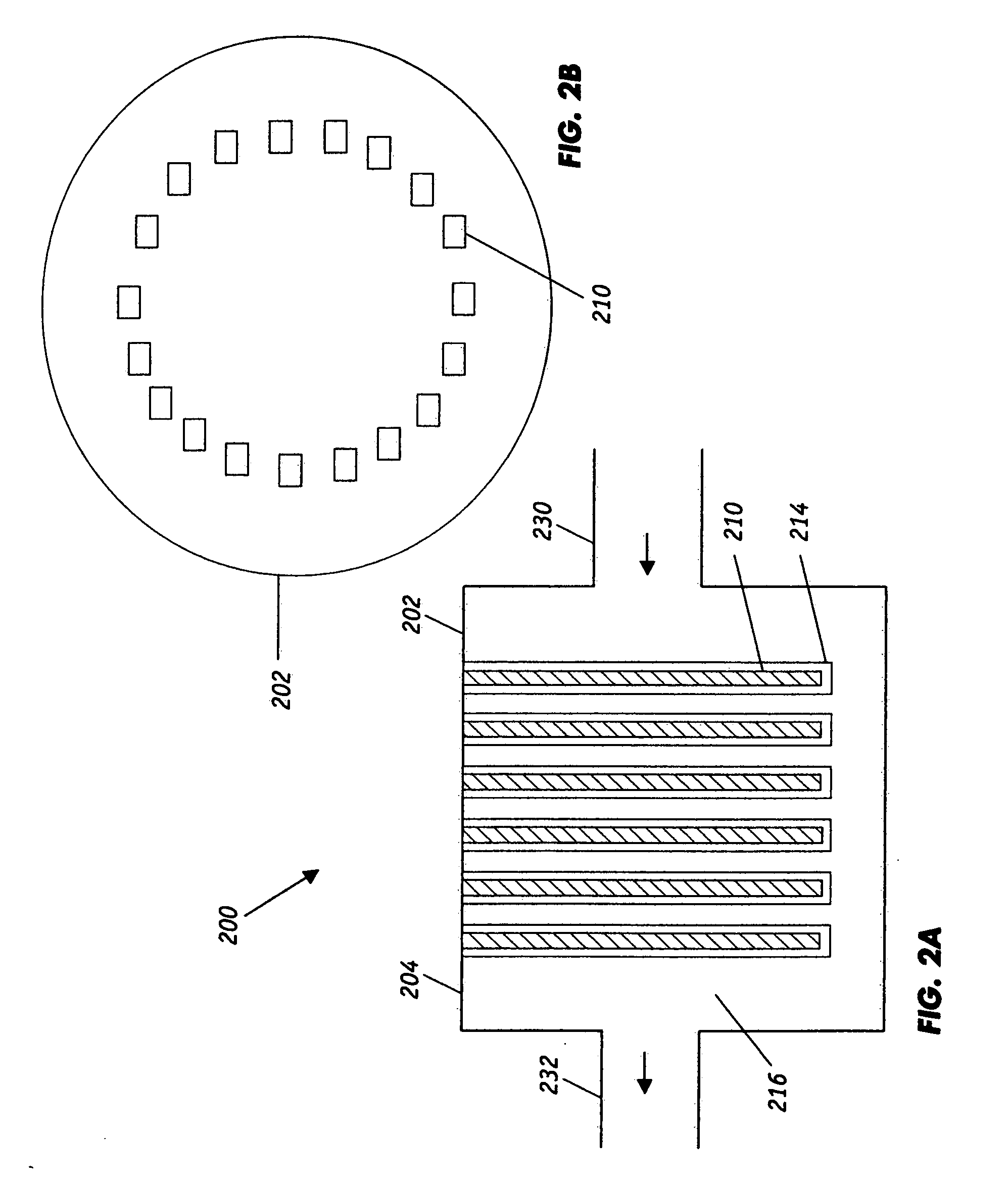

[0015]Filtration devices of the present invention are particularly effective in removing contaminants from process streams. One source of the contaminants is the corrosion of process equipment and another source is the presence of active species in the process streams that ultimately lead to the formation of polar polymeric sludge. It has been demonstrated that these contaminants are paramagnetic in nature and therefore are attracted to magnets. The contaminants generally comprise a mixture of different materials are acidic, low in pH, black and viscous, and tend to deposit throughout the process lines, including filters, heat exchangers, catalyst beds, thereby reducing process capacity and efficiency. Since most process equipment in the refining and chemical industries is made from carbon steel that is susceptible to corrosion by the acidic substances in the process streams, the contaminants are generated by oxidation due to air leakage in the system as well as by the chlorinated a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| operating temperatures | aaaaa | aaaaa |

| operating temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com