Environment-friendly nontoxic high-insulation low temperature-resistant polyvinyl chloride cable material and preparation process thereof

A polyvinyl chloride cable and polyvinyl chloride technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as insufficient electrical insulation performance, affecting power supply reliability, and insufficient low temperature resistance, so as to shorten the processing cycle. Good compatibility and stability, the effect of reducing mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

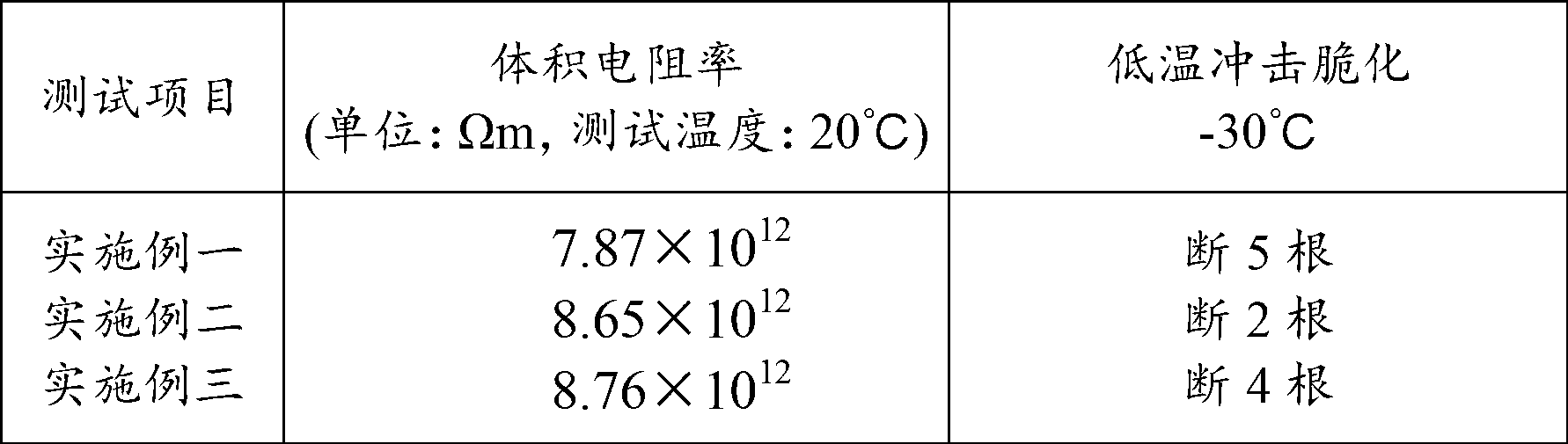

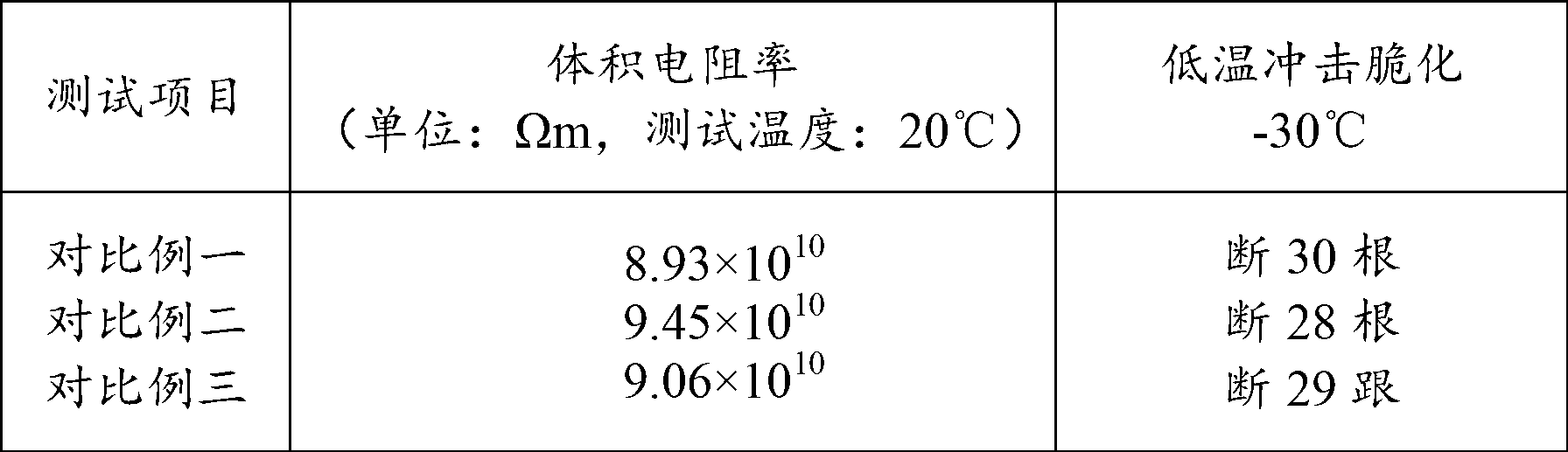

Examples

Embodiment 1

[0050] The environment-friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of the present embodiment and its content are:

[0051] 100 parts of polyvinyl chloride;

[0052] 30 parts of organic modified kaolin;

[0053] 50 parts of plasticizer;

[0054] 5 parts of stabilizer;

[0055] 5 parts of flame retardant;

[0056] Low temperature impact toughening agent 5 parts;

[0057] 1 part lubricant;

[0058] Coloring agent 0.5 part.

[0059] The specific process of the preparation process of the environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of this embodiment is as follows:

[0060] S11: Weigh each component according to the above formula of environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material, and divide the plasticizer into two parts, one of which is 70% of the plasticizer;

[0061] S12: Add ...

Embodiment 2

[0066] The environment-friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of the present embodiment and its content are:

[0067] 100 parts of polyvinyl chloride;

[0068] 40 parts of organically modified kaolin;

[0069] 70 parts of plasticizer;

[0070] 10 parts of stabilizer;

[0071] 10 parts of flame retardant;

[0072] 8 parts of low temperature impact toughening agent;

[0073] 3 parts lubricant;

[0074] Coloring agent 1 part.

[0075] The specific process of the preparation process of the environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of this embodiment is as follows:

[0076] S21: Weigh each component according to the above formula of environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material, and divide the plasticizer into two parts, one of which is 90% of the plasticizer;

[0077] S...

Embodiment 3

[0082] The environment-friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of the present embodiment and its content are:

[0083] 100 parts of polyvinyl chloride;

[0084] 35 parts of organically modified kaolin;

[0085] 60 parts of plasticizer;

[0086] 7 parts of stabilizer;

[0087] 7 parts of flame retardant;

[0088] 6 parts of low temperature impact toughening agent;

[0089] 2 parts lubricant;

[0090] Coloring agent 0.8 parts.

[0091] The specific process of the preparation process of the environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material of this embodiment is as follows:

[0092] S31: Weigh each component according to the formula of the above-mentioned environmentally friendly, non-toxic, high-insulation and low-temperature-resistant polyvinyl chloride cable material, and divide the plasticizer into two parts, one of which is 80% of the plasticiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com