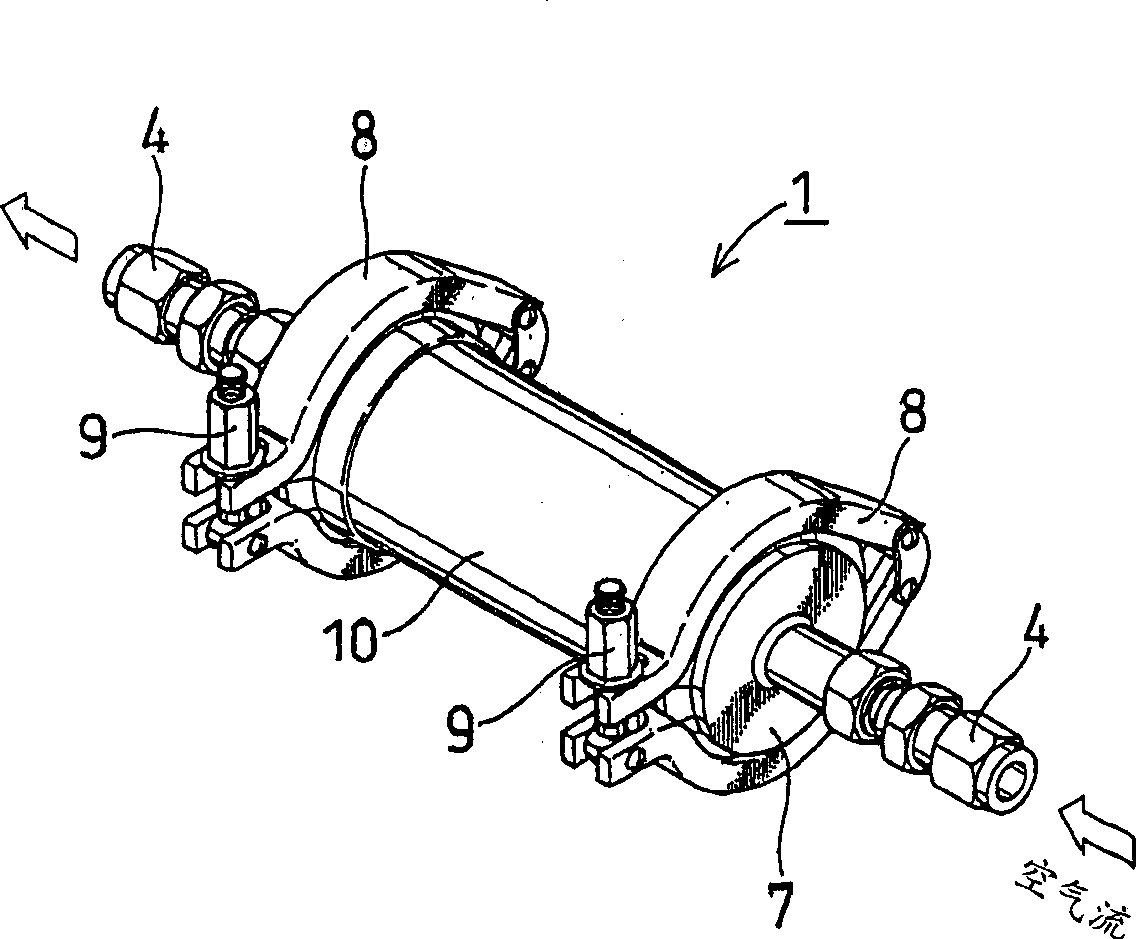

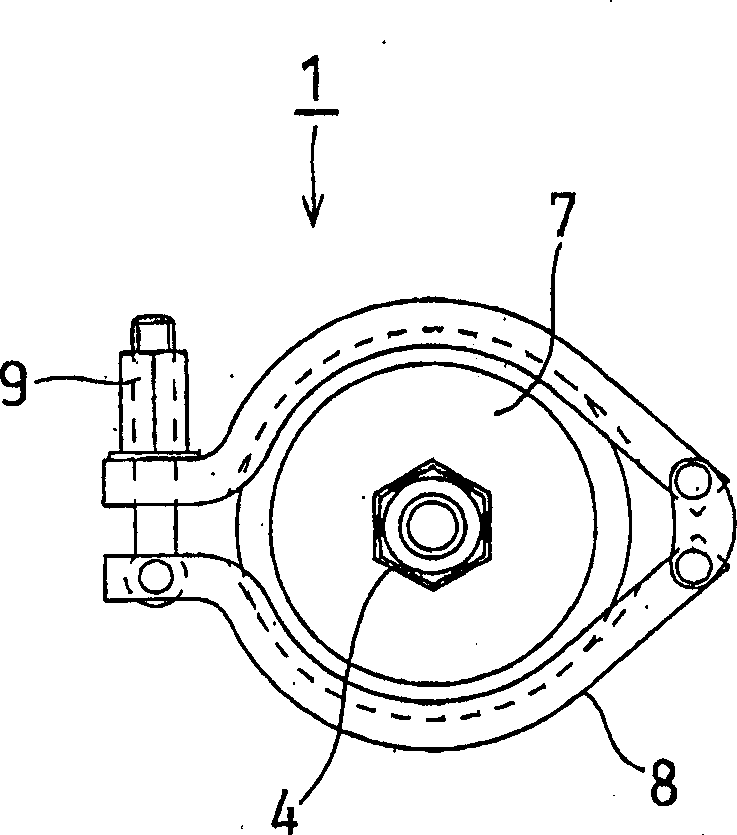

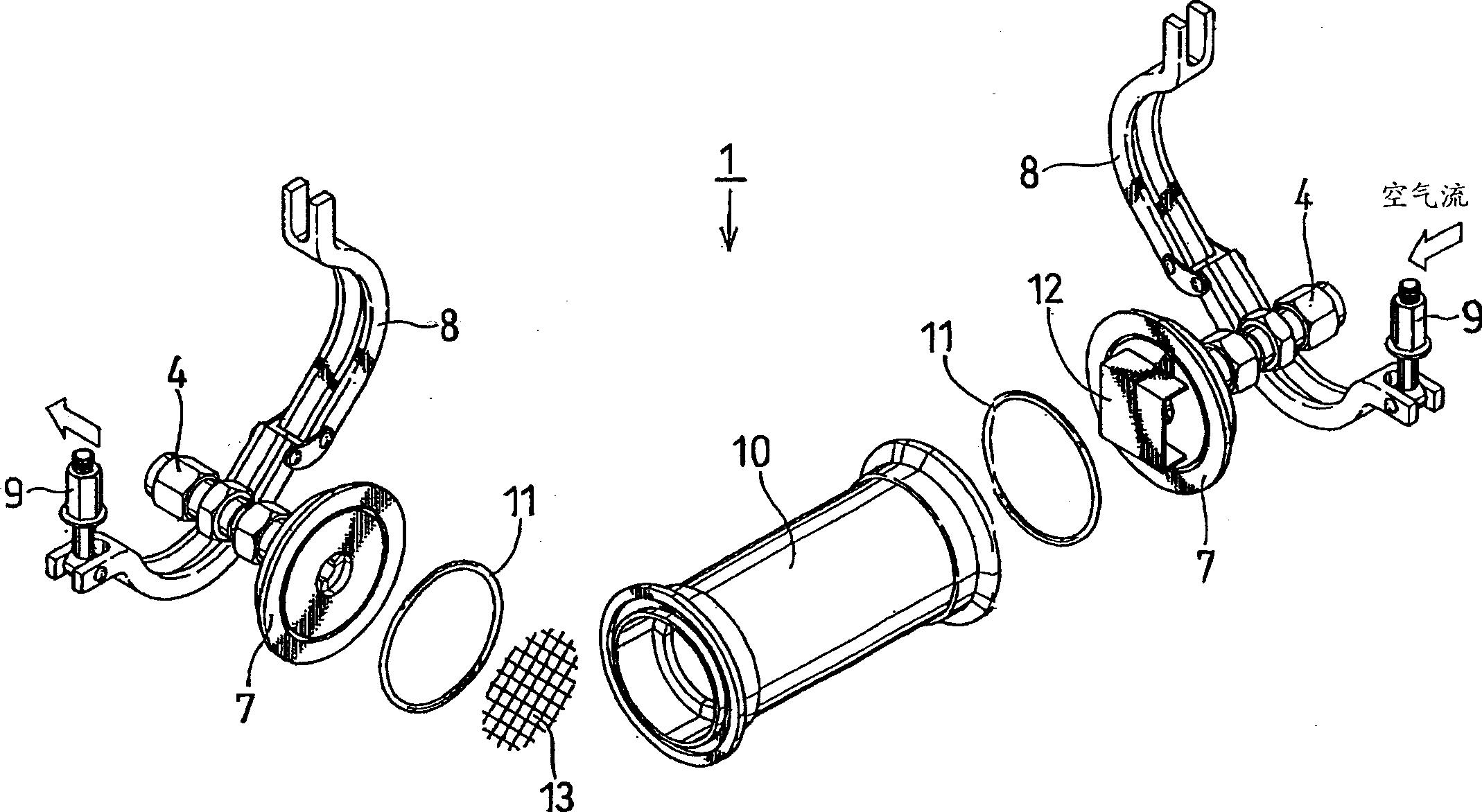

Chemical filter

A technology of chemical filter and unit body, which is applied in the direction of gravity filter, chemical instrument and method, filtration and separation, etc., which can solve the problem that the optical processing of the substrate cannot be carried out smoothly, and achieve the effect of maintaining purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The unit body 10 was treated in the same manner as in Comparative Example 2, except that it was baked at 150° C. instead of 50° C. for 30 minutes.

Embodiment 2

[0048] The unit body 10 was treated in the same manner as in Comparative Example 2, except that it was ultrasonically cleaned with IPA and then demineralized water, and dried at 200° C. for 30 minutes. [B] Air leakage measurement of Comparative Examples 1 and 2 and Examples 1 and 2

[0049] Air leakage was measured as follows.

[0050] Each unit cell was placed in a SUS container and heated in an oven up to 50° C. while supplying 2 to 300 ml / min of pure air. The air was collected with a Tenax collection tube (using a packer for adsorbed gas, Tenax (trade mark) GR).

[0051] The collected air was condensed by a thermal desorption condensation injector (Model CP4020 manufactured by JL Science Inc.) and analyzed by a gas chromatography mass spectroscope GC-MS (Model MD800). From the area of the chromatogram, the area was converted to the amount of toluene and determined. And the determined amount of toluene is divided by the sampled amount to calculate the concentration of air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com