An electronic device casing and a manufacture method thereof

A technology of electronic devices and manufacturing methods, which is applied in lamination devices, chemical instruments and methods, electrical equipment shells/cabinets/drawers, etc., can solve the problem of poor wear resistance and hardness, and the aesthetics of metal shells is not as good as before, Problems such as dullness of the metal shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The electronic device casing and the manufacturing method thereof of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

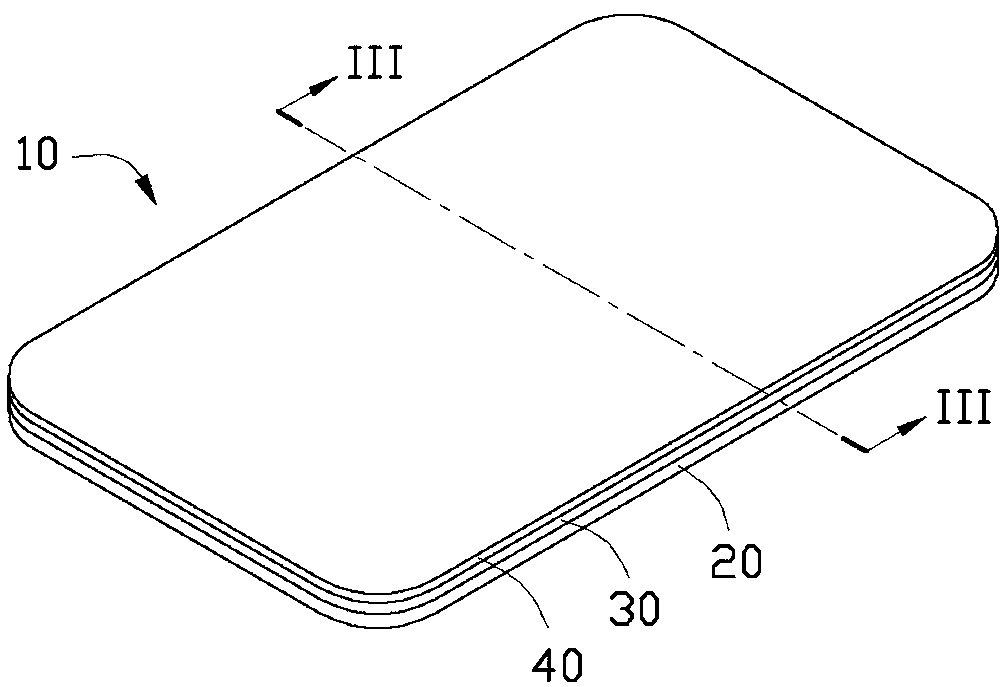

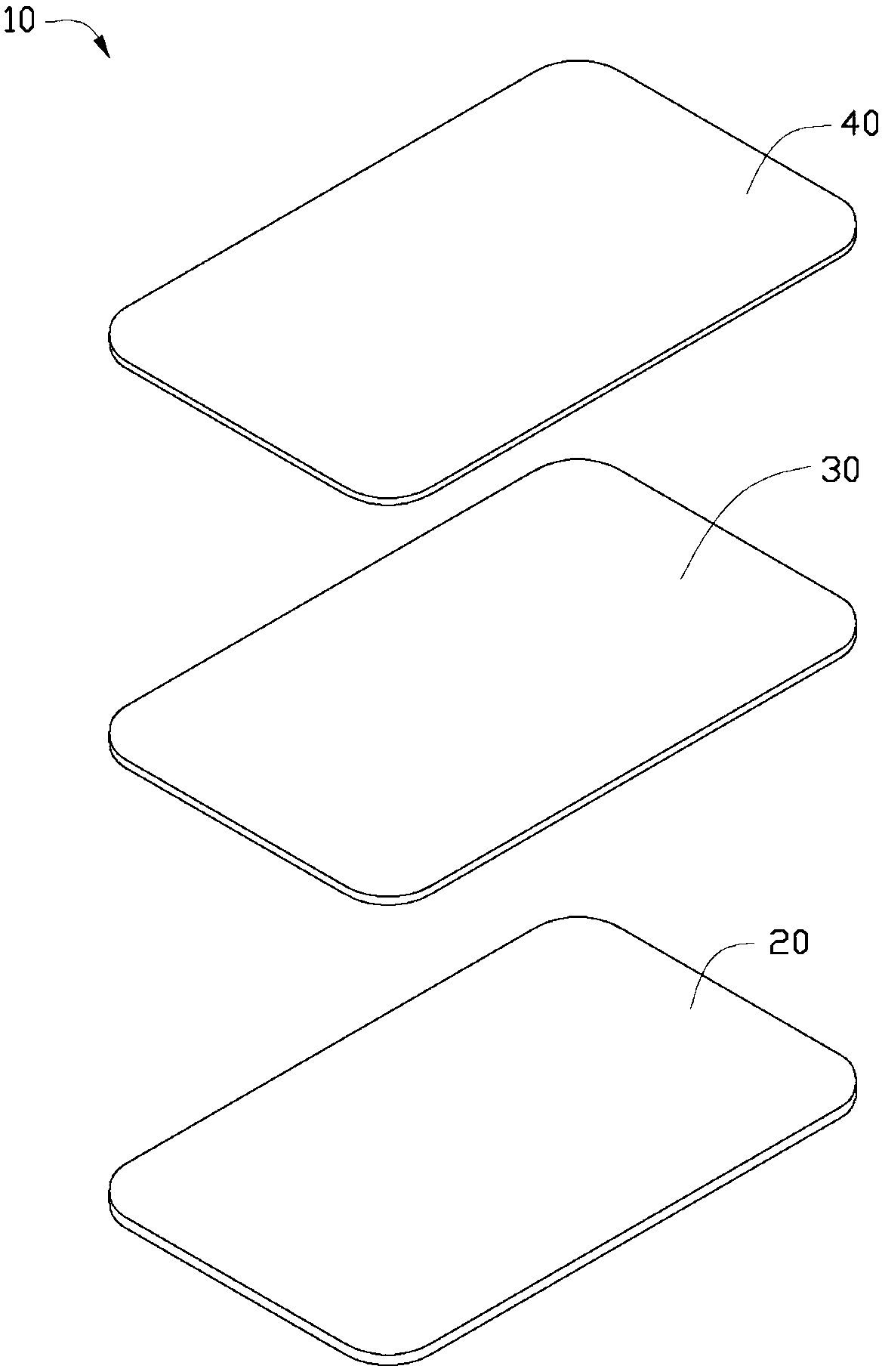

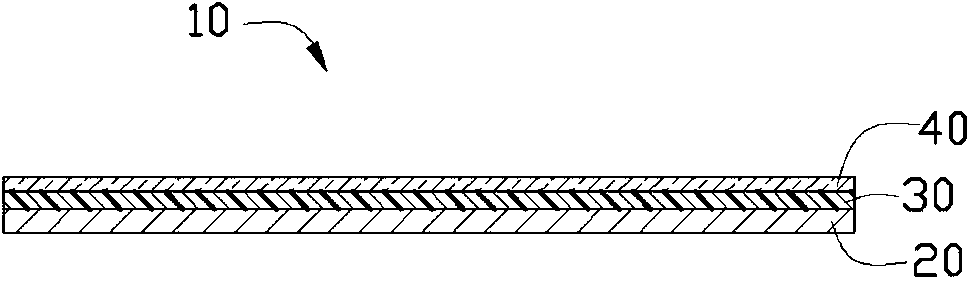

[0018] see figure 1 , the housing 10 of the electronic device according to the embodiment of the present invention includes a base layer 20 , a bonding layer 30 and a protective layer 40 , and the bonding layer 30 is disposed between the base layer 20 and the protective layer 40 . In this embodiment, the electronic device casing 10 is a back cover of a mobile phone.

[0019] see figure 2 and image 3 , the base layer 20 is used to cover the electronic components so as not to be exposed. In this embodiment, the base layer 20 can be made of metal materials such as stainless steel and aluminum alloy, and can be subjected to surface treatments such as polishing, etching, and electroplating. The base layer 20 is provided with a through hole 21 for accommodating the camera module.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com