Method for preparing rodlike ultrafine silver powder by carrying out chemical silvering on surfaces of attapulgite nanofibers

A surface chemical and nanofiber technology, applied in the field of chemical plating, can solve the problems of low added value and achieve the effects of low cost, consumption saving and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

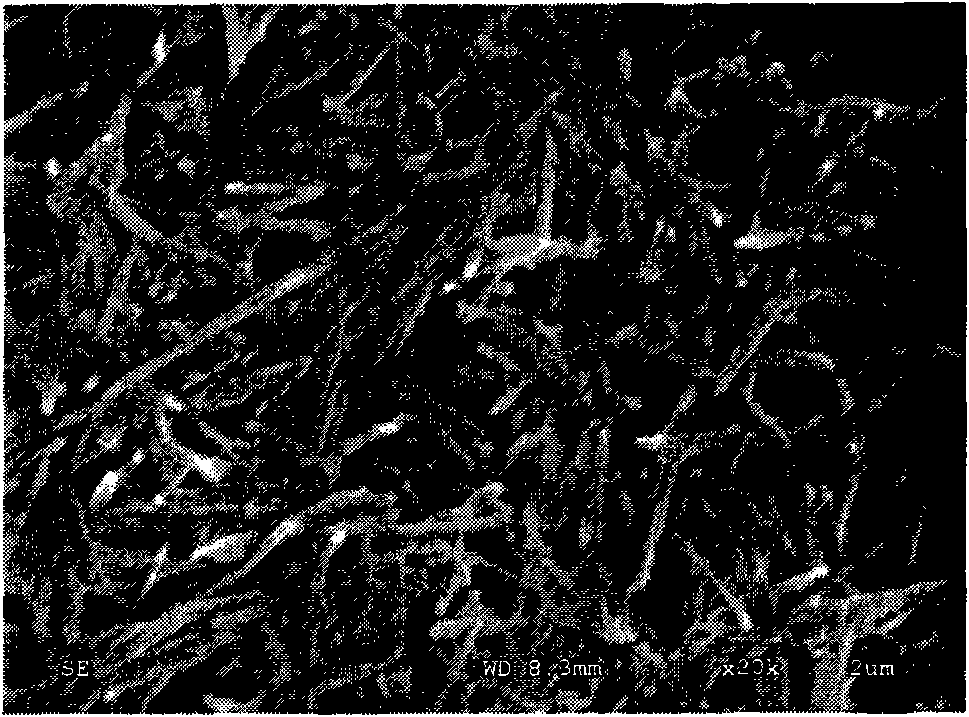

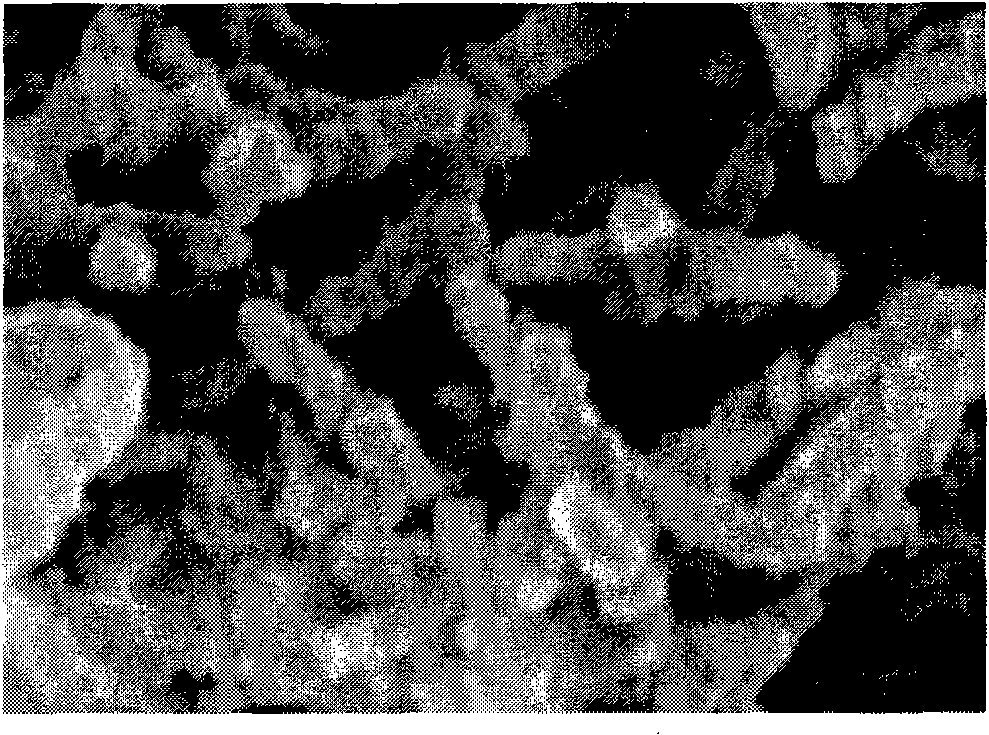

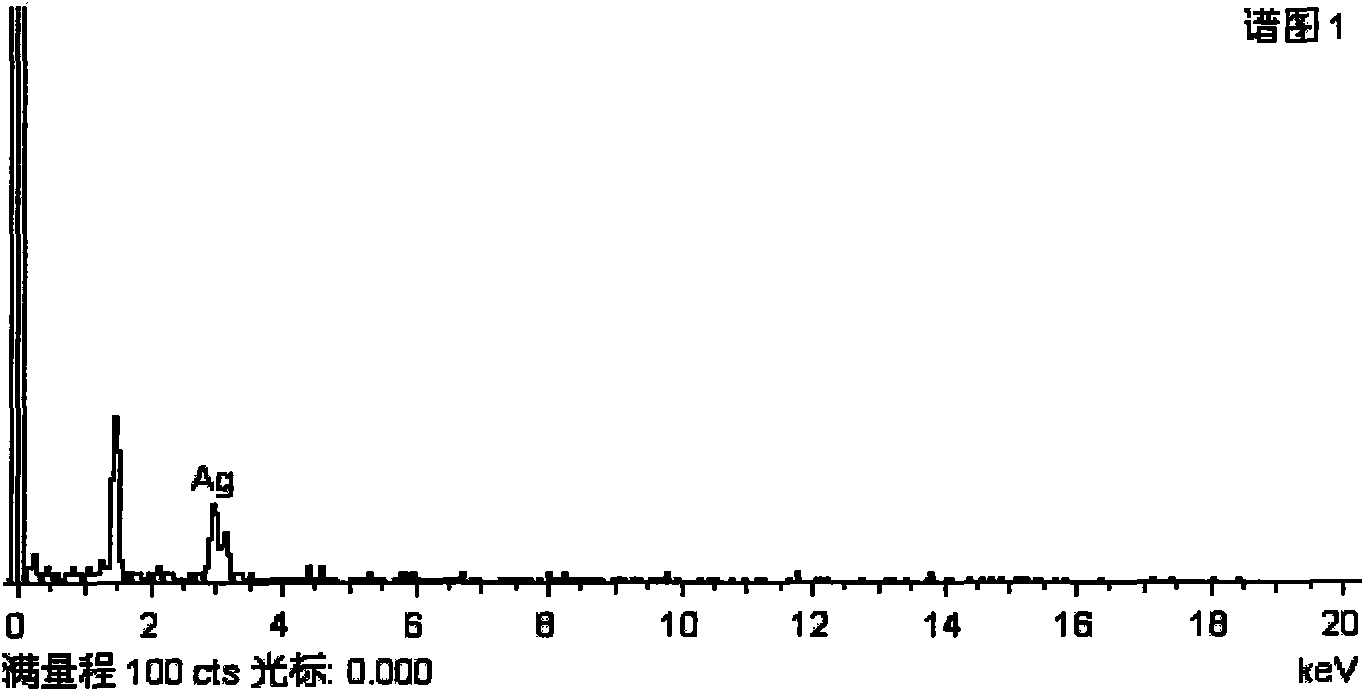

[0019] Embodiment 1: Prepare one-dimensional rod-shaped ultrafine silver powder according to the following steps:

[0020] (1) Add 10 g of attapulgite raw soil to 500 ml of 20% hydrochloric acid for soaking, mechanically stir for 8 hours, centrifuge, wash with deionized water, and set aside;

[0021] (2) Take the attapulgite obtained in step (1) and add 800ml of 1g / L AgNO 3 Soak in the solution for adsorption, mechanically stir for 3 hours at room temperature, centrifuge, wash with deionized water, and set aside;

[0022] (3) Add the attapulgite obtained in step (2) into 800 ml of 10% formaldehyde solution with a mass concentration, adjust the pH value to 10.5 with 1 mol / L NaOH, mechanically stir for 2 hours at room temperature, centrifuge, wash with deionized water, and set aside;

[0023] (4) Take the attapulgite obtained in step (3) and add it to 5000ml of electroless silver plating solution, mechanically stir it in a water bath at 30°C for 40min, after the plating finishe...

Embodiment 2

[0024] Embodiment 2: Prepare one-dimensional rod-shaped ultrafine silver powder according to the following steps:

[0025] (1) Add 5 g of attapulgite raw soil to 250 ml of 15% hydrochloric acid for soaking, mechanically stir for 8 hours, centrifuge, wash with deionized water, and set aside;

[0026] (2) Take the attapulgite obtained in step (1) and add 400ml of 6.5g / L AgNO 3 Soak in the solution for adsorption, mechanically stir for 3 hours at room temperature, centrifuge, wash with deionized water, and set aside;

[0027] (3) Add the attapulgite obtained in step (2) into 400ml of formaldehyde solution with a mass concentration of 12%, adjust the pH value to 10 with 1mol / L NaOH, mechanically stir for 2h at room temperature, centrifuge, wash with deionized water, and set aside;

[0028] (4) Take the attapulgite obtained in step (3) and add it to 2500ml of electroless silver plating solution, mechanically stir it in a water bath at 30°C for 40min, after the plating finishes, ce...

Embodiment 3

[0029] Embodiment 3: Prepare one-dimensional rod-shaped ultrafine silver powder according to the following steps:

[0030] (1) Add 10 g of attapulgite raw soil to 500 ml of 10% hydrochloric acid for soaking, mechanically stir for 8 hours, centrifuge, wash with deionized water, and set aside;

[0031] (2) Take the attapulgite obtained in step (1) and add 800ml of 10g / L AgNO 3 Soak in the solution for adsorption, mechanically stir for 3 hours at room temperature, centrifuge, wash with deionized water, and set aside;

[0032] (3) Add the attapulgite obtained in step (2) into 800 ml of 1% formaldehyde solution with mass concentration, adjust the pH value to 11 with 1mol / L NaOH, mechanically stir for 2 hours at room temperature, centrifuge, wash with deionized water, and set aside;

[0033] (4) Take the attapulgite obtained in step (3) and add it to 5000ml of electroless silver plating solution, mechanically stir it in a water bath at 30°C for 40min, after the plating finishes, ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com