Lead brass silver plating process

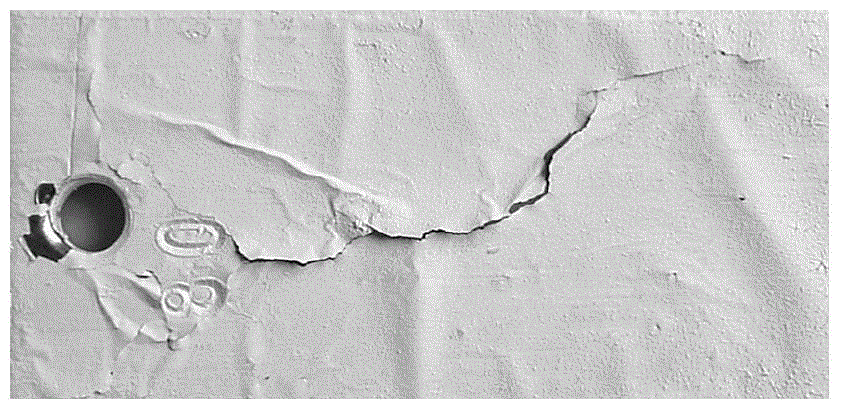

A lead brass and process technology, which is applied in the field of lead brass silver plating process, can solve the problems of poor surface compactness, unqualified adhesion, and hidden quality problems of the silver layer, so as to improve the adhesion of the plating layer, ensure the compactness, Solve the effect that slag and hanging ash are difficult to remove completely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

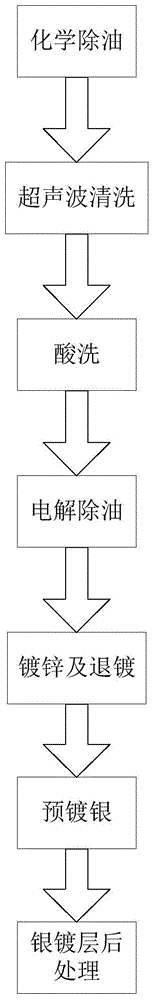

Method used

Image

Examples

Embodiment 1

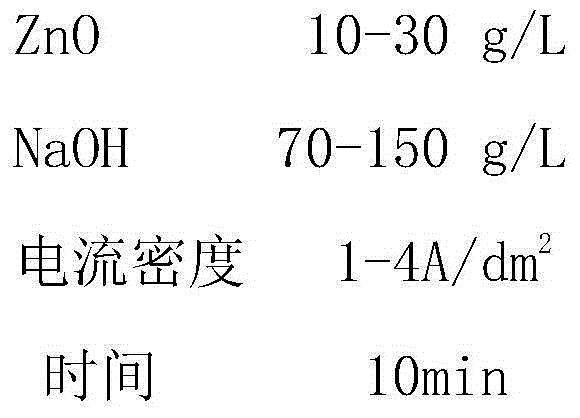

[0048] Embodiment 1: A lead-brass soldering piece adopts a traditional process formula, and the binding force is poor, which fails to meet the requirements. The following process is used for plating, and the reasonable rate reaches 100%.

[0049]

Embodiment 2

[0051] A kind of lead brass gasket adopts the traditional process formula, the binding force is poor, and it cannot meet the requirements. The following process is used for plating, and the reasonable rate reaches 100%.

[0052]

[0053]

Embodiment 3

[0055] A kind of lead brass bracket adopts the traditional process formula, the binding force is poor, and it cannot meet the requirements. The following process is used for plating, and the reasonable rate reaches 100%.

[0056]

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com