Preparation method of Ag / Ti3SiC2 electric contact composite material

A composite material, electrical contact technology, applied in the direction of contacts, circuits, electrical switches, etc., can solve the problems of surface temperature rise, difficult material processing and molding, poor wettability, etc., to achieve the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

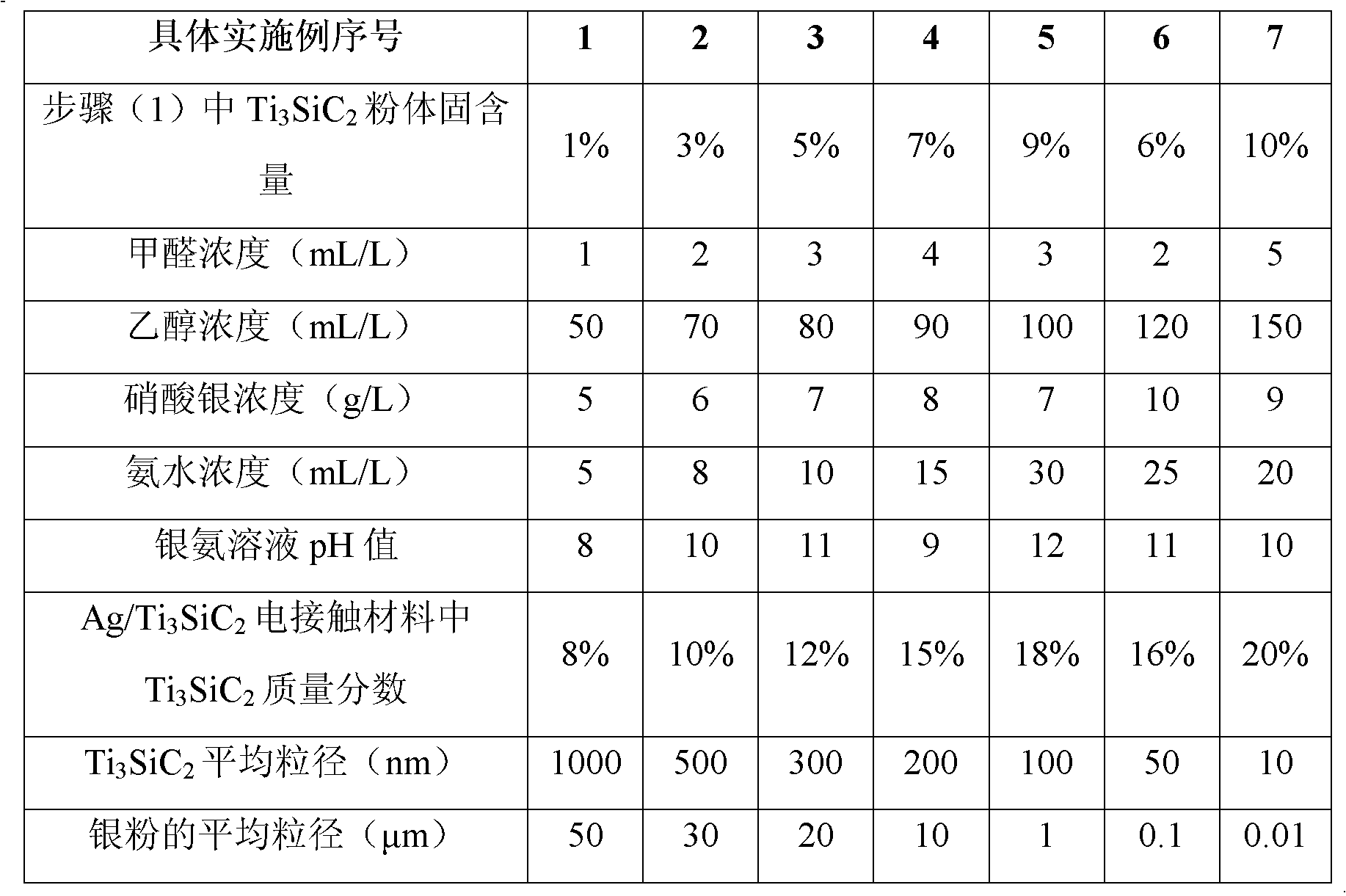

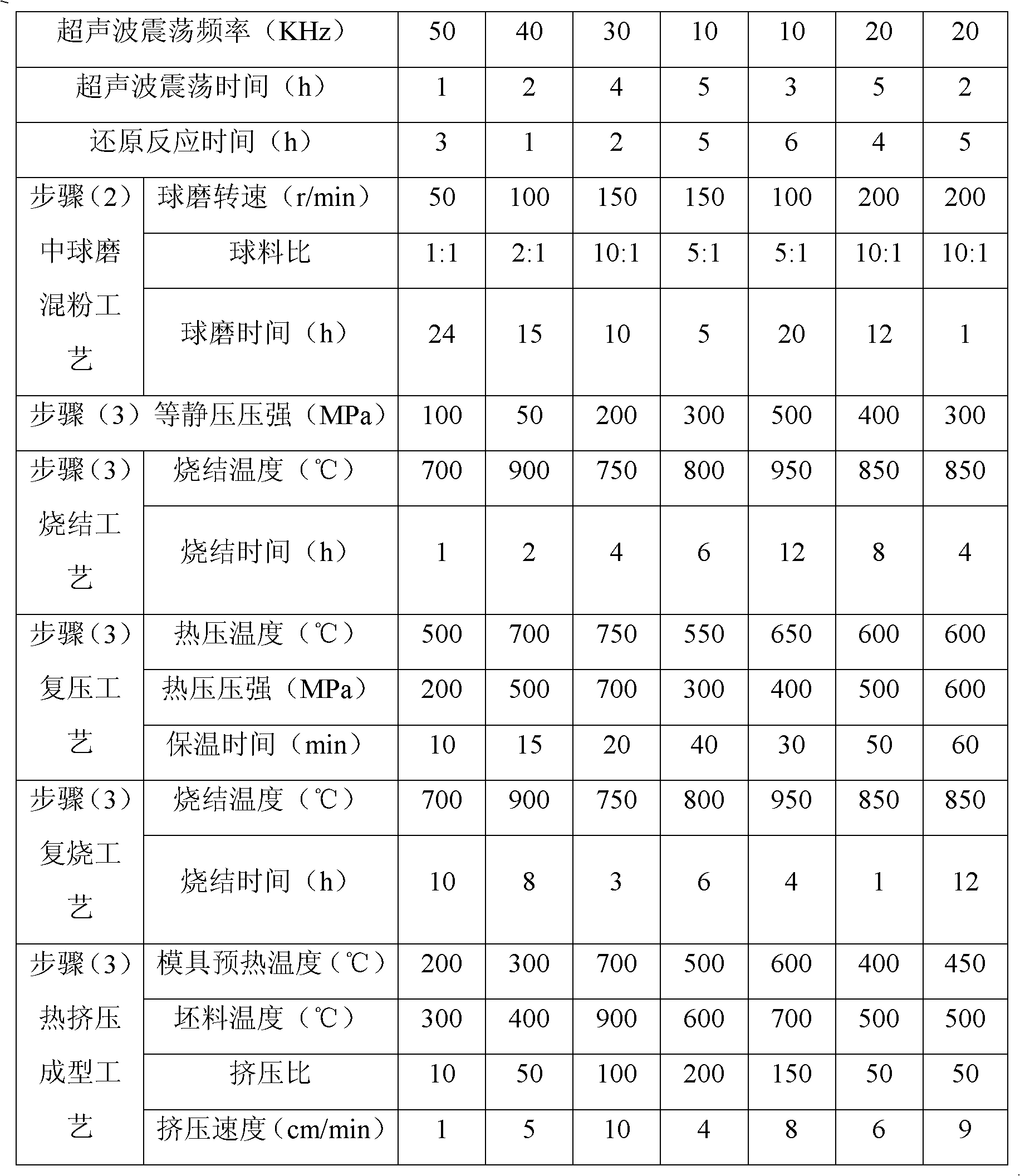

[0021] The present invention is further described by examples below.

[0022] Ag / Ti provided by the invention 3 SiC 2 A method for preparing an electrical contact composite material specifically comprises the following steps:

[0023] (1) Preparation of silver-coated Ti by electroless silver plating with silver ammonia solution 3 SiC 2 powder, and then the powder is washed with distilled water to neutrality, and then dried in a vacuum after washing with alcohol;

[0024] (2) The above-mentioned dried silver-coated Ti 3 SiC 2 The powder and silver powder are ball-milled evenly, and silver-coated Ti 3 SiC 2 The powder accounts for 8% to 20% of the total mass of the mixed powder;

[0025] (3) The uniformly mixed powder is pressed into a green body by isostatic pressing, and then undergoes sintering, re-pressing, and re-firing processes in sequence, and finally hot-extruded to obtain Ag / Ti 3 SiC 2 Electrical contact composites.

[0026] The method of silver-ammonia solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com