Cyanide-free silver plating solution containing auxiliary complexing agent

An auxiliary complexing agent and cyanide-free silver plating technology, which is applied in the field of electrochemical silver plating, can solve the problems of rough and dull plating, interference of electroplating silver, and little research on anode passivation inhibition, so as to achieve bright plating adhesion and good anode Passivation suppression, good coating bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A cyanide-free silver plating solution containing auxiliary complexing agent, which is composed of silver ion source, complexing agent, auxiliary complexing agent, supporting electrolyte, electroplating additive and pH adjuster, etc. The specific material composition and concentration are shown in the table 1 shown. The configuration method is as follows: control the temperature to 50°C, mix the complexing agent, supporting electrolyte and pH adjuster evenly, then slowly add the source of silver ions, stir until the solution is clear, and then add auxiliary complexing agent to make cyanide-free silver plating. electroplating solution, and finally add electroplating additives to it, stir evenly, and let it stand for use. The pH value of the plating solution ranges from 8 to 12. During the plating process, the plating solution is maintained at 50 to 60 °C. Then, the pretreated metal substrate was connected to the circuit and immersed in the electroplating solution with a...

Embodiment 2

[0025] The substances in the cyanide-free silver-plating electroplating solution containing the auxiliary complexing agent are shown in Table 2, and the preparation method is the same as that in Example 1. The current density of the electroplating is 1.0A / dm 2 , the plating time is 2min.

[0026] Table 2 The composition of each substance in the cyanide-free silver plating solution containing auxiliary complexing agent

[0027] component specific substance concentration silver ion source AgCl 40g / L complexing agent Succinimide 170g / L auxiliary complexing agent EDTA 20g / L Supporting Electrolytes K 2 CO 3 15g / L pH adjuster KOH 10g / L Plating Additives Selenite 200mg / L Plating Additives Potassium Antimony Tartrate 50mg / L

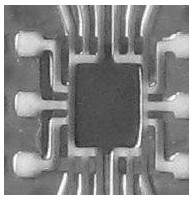

[0028] like figure 2 Shown is a silver-plated sample of copper sheet electroplated with the above bright cyanide-free silver-plating electroplating solution.

Embodiment 3

[0030] The material composition of the cyanide-free silver-plating electroplating solution containing the auxiliary complexing agent is shown in Table 3, and the preparation method and the test method are the same as those in Example 2.

[0031] Table 3 The composition of each substance in the cyanide-free silver plating solution containing auxiliary complexing agent

[0032] component specific substance concentration silver ion source AgNO 3 30g / L complexing agent Hein 140g / L auxiliary complexing agent HEDP 10g / L Supporting Electrolytes K 2 CO 3 20g / L pH adjuster NaOH 15g / L Plating Additives L-Histidine 200mg / L Plating Additives vanillin 300mg / L

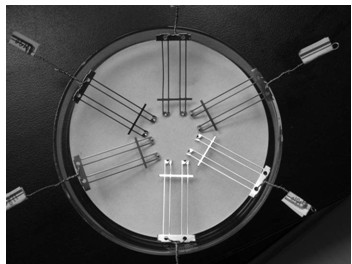

[0033] like image 3 As shown, it is a picture of a prepared LED lead frame electroplated with the above bright cyanide-free silver plating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com