Electroplating solution for silver

A technology of electroplating solution and conductive salt, applied in the field of silver electroplating solution, can solve the problems of pre-silver plating or immersion silver, inconvenient operation and management, poor stability of the plating solution, etc., and achieves bright coating adhesion, good corrosion resistance, The effect of mild plating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

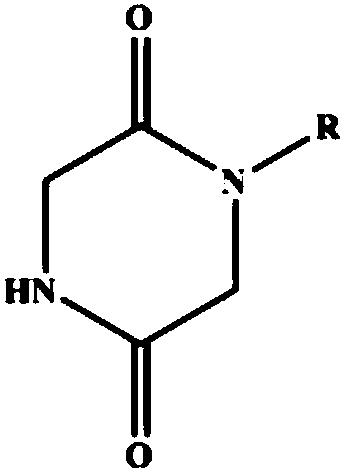

[0017] Thin-walled copper tubes are electroplated in an electroplating tank. The electroplating solution in the electroplating tank includes solvent water, 20g / L silver nitrate, 40g / L potassium sulfate, 4g / L ethylenediamine, 0.2g / L thio Sodium sulfate, the boric acid of 12g / L, the complexing agent of 40g / L, wherein, described complexing agent is following structure,

[0018]

[0019] The pH value of the plating solution in the electroplating tank is 6.5, and the current density is 14A / dm 2 , the temperature was 47°C, and the electroplating time was 7 minutes.

[0020] After the electroplating is completed, the electroplated silver layer has good bright effect, high uniformity, and no pinholes, black spots, etc.; according to the ASTMB571 standard, heat the electroplated silver-plated copper tube to 240-260°C in the furnace, then take it out and put it in After cooling in water at room temperature, the silver coating does not bubble or fall off, indicating that the bonding ...

Embodiment 2

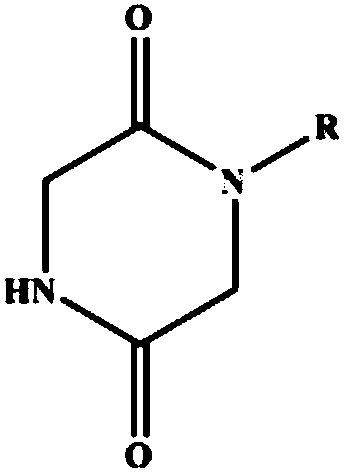

[0022] The rectangular iron sheet is electroplated in the electroplating tank. The electroplating solution in the electroplating tank includes solvent water, 40g / L silver chloride, 60g / L potassium chlorate, 5g / L tetraethylenepentamine, 0.3g / L thio The complexing agent of the citric acid of sodium sulfate, 13g / L, 80g / L, wherein, described complexing agent is following structure,

[0023]

[0024] The pH value of the plating solution in the electroplating tank is 7.5, and the current density is 7A / dm 2 , the temperature is 25°C, and the plating time is 12 minutes.

[0025] After the electroplating is completed, the electroplated silver layer has good brightness, high uniformity, and no pinholes, black spots, etc.; according to the ASTMB571 standard, heat the iron sheet of the electroplated silver coating to 240-260 ° C in the furnace, then take it out and put it in After cooling in water at room temperature, the silver coating does not bubble or fall off, indicating that the...

Embodiment 3

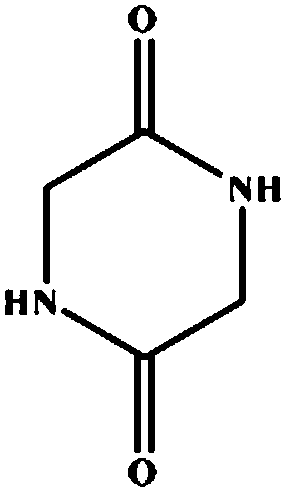

[0027] The iron block with several deep holes and blind holes is electroplated in the electroplating tank. The electroplating solution in the electroplating tank includes solvent water, 60g / L silver chloride, 80g / L ammonium sulfate, 5.5g / L ethylene glycol Aminotetraacetic acid, potassium thiocyanate of 0.4g / L, the tartaric acid of 15g / L, the complexing agent of 120g / L, wherein, the complexing agent is the following structure,

[0028]

[0029] The pH value of the plating solution in the electroplating tank is 7, and the current density is 2A / dm 2 , the temperature is 57°C, and the plating time is 5 minutes.

[0030] After the electroplating is completed, the electroplated silver layer has good bright effect, high uniformity, and no pinholes, black spots, etc.; according to the ASTMB571 standard, heat the iron block of the electroplated silver layer to 240-260°C in the furnace, then take it out and put it in After cooling in water at room temperature, the silver coating doe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com