Method for preparing surface silver-plated electric-spinning fiber by using dopamine

A technology of electrospun fiber and dopamine, which is applied in the field of preparing conductive composite materials to achieve the effect of short time consumption, good electrical conductivity, and uniform and dense silver layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Prepare a 70% TEOS hydrolyzate with a mass fraction of 0.15% hydrochloric acid ethanol solution, stir at a stirring rate of 60 rpm for 12 hours, and use a mixture of DMF and DMSO with a mass ratio of 2:1 as a solvent. PVP with a mass fraction of 16% (W M =1.5 million) solution, the two solutions are mixed and stirred evenly at a stirring rate of 60 rpm, and injected into the syringe;

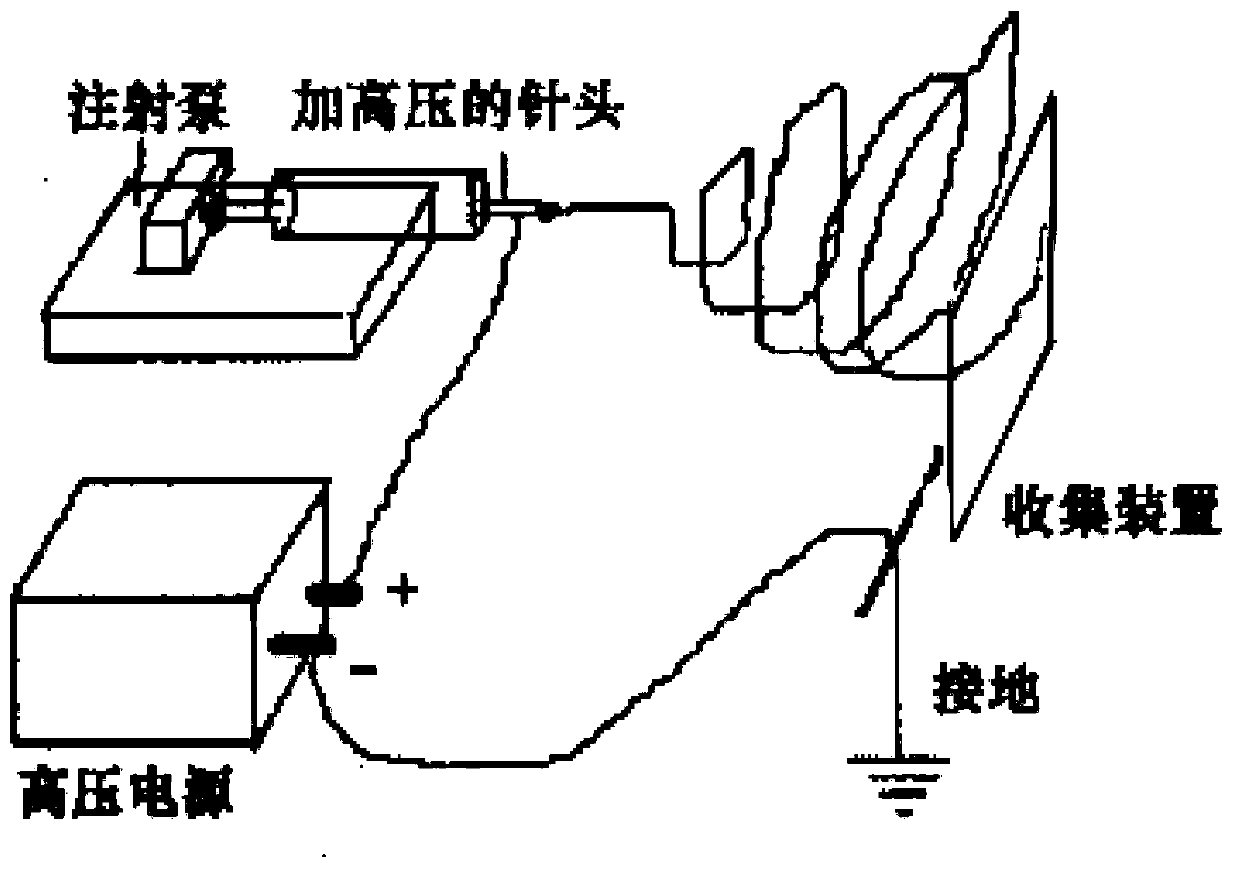

[0035] 2) figure 1 It is a schematic diagram of the high-voltage electrospinning experimental device, the flat receiver is grounded, and the surface is wrapped with a layer of aluminum foil. The syringe is equipped with a 12-gauge stainless steel needle (the inner diameter is 1mm, and the front end is ground flat) connected to the positive electrode of the high-voltage electrostatic power supply. The distance between the needle and the collecting plate is 20cm , spun at a voltage of 15kV, and collected for a period of time, the micro-nano fiber non-woven film can be obtained. The obt...

Embodiment 2

[0044] The process is the same as in Example 1, but the normal temperature reaction time in step 5 is changed to 30 min, 1 h, 3 h and 4 h, and electrospun silica fibers coated with silver particles on the surface can be obtained.

[0045] It is determined that the silicon dioxide / silver core-shell composite fiber can conduct electricity, and the resistivity is between 0.6-0.02mΩ·cm.

Embodiment 3

[0047] The process is the same as in Example 1, except that the concentration of dopamine in step 3 is changed to 0.5g / L, 1g / L and 4g / L to obtain electrospun silica fibers coated with silver particles on the surface.

[0048] It is determined that the silicon dioxide / silver core-shell composite fiber can conduct electricity, and the resistivity is between 0.6-0.02mΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com