Multi-wing centrifugal fan

A centrifugal fan and air inlet ring technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of failure to effectively reduce the flow loss at the impeller inlet, and can not effectively reduce the flow loss at the impeller inlet, so as to reduce the intake Effect of air attack angle, reduction of flow loss, and increase of air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

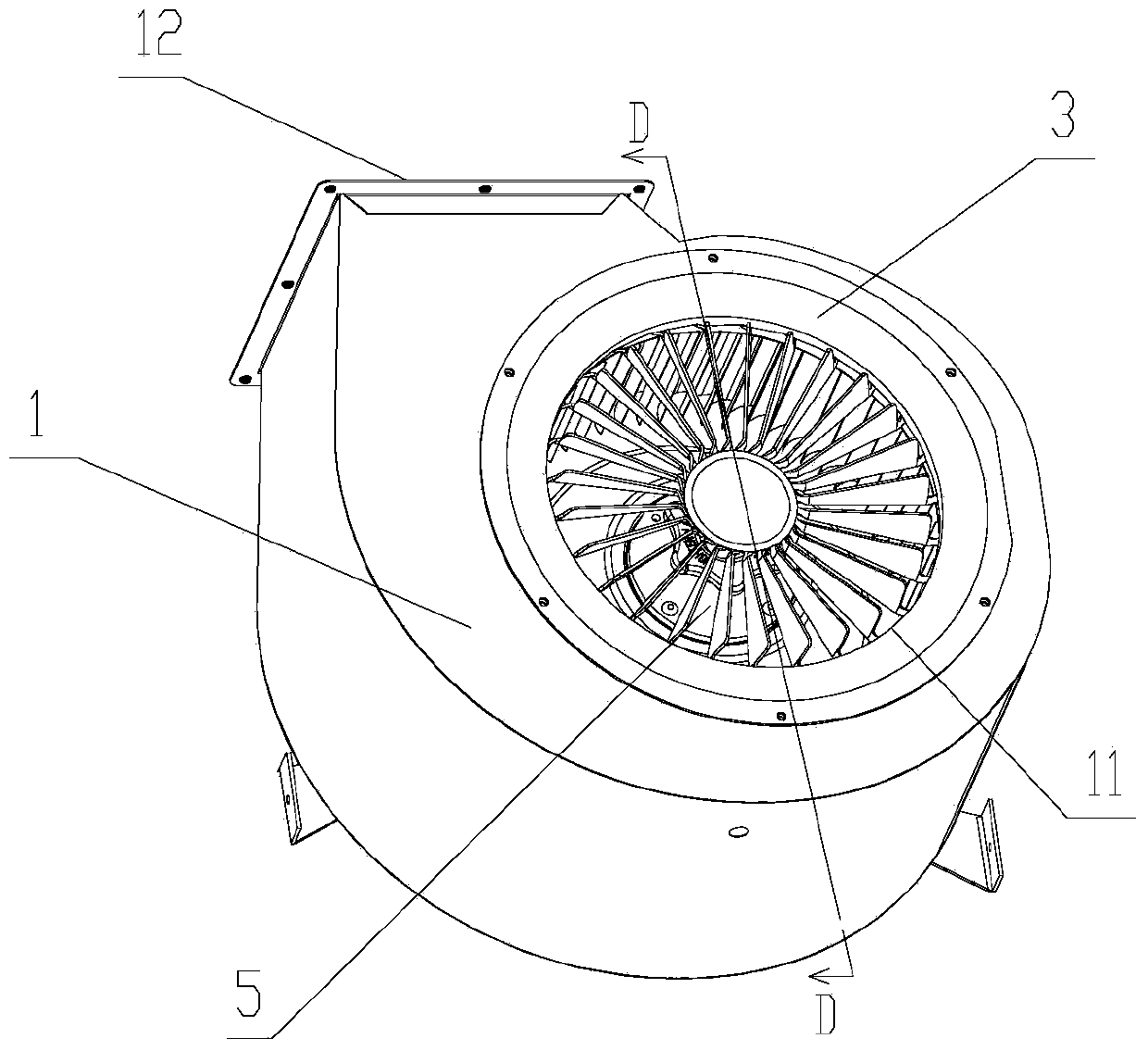

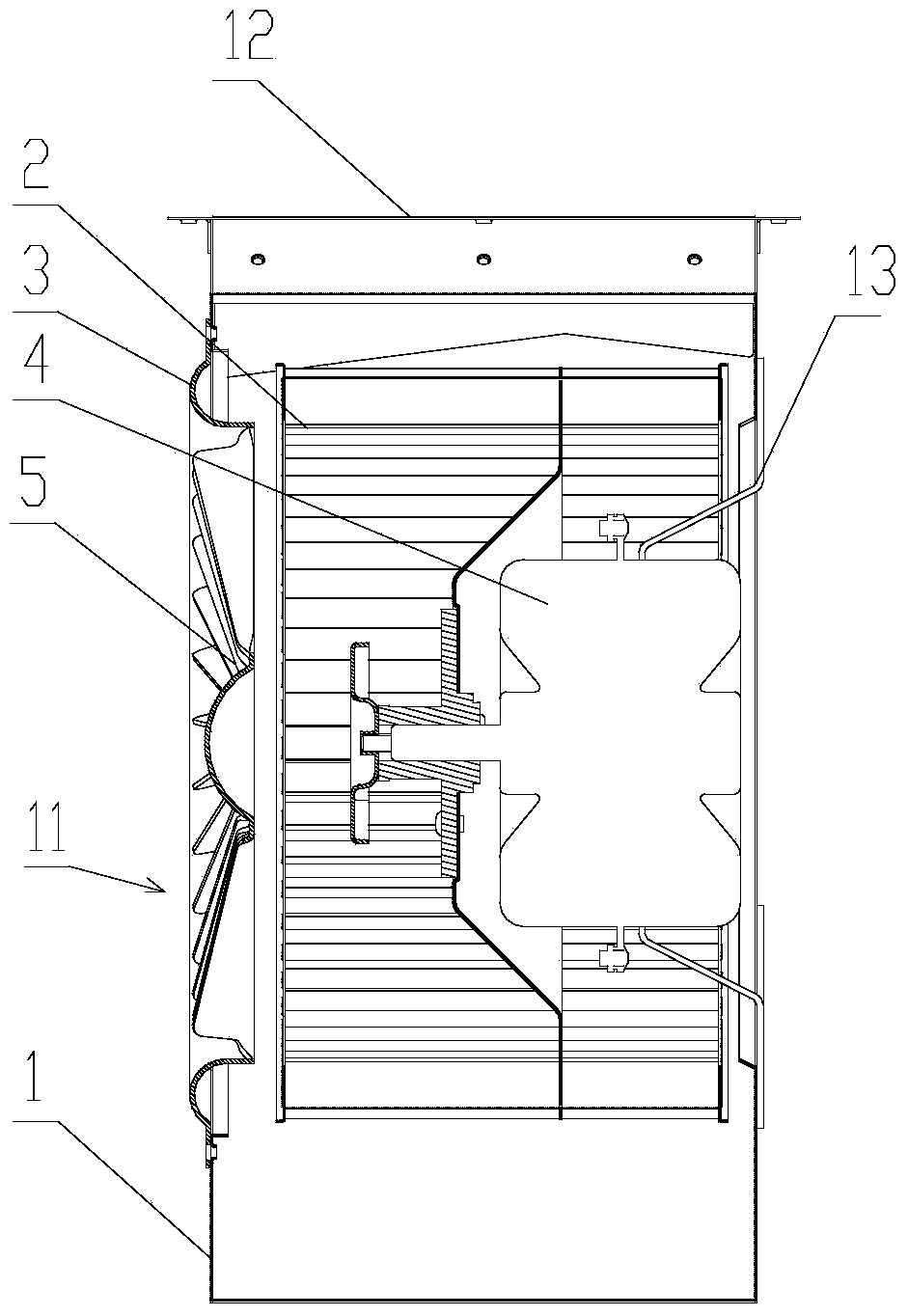

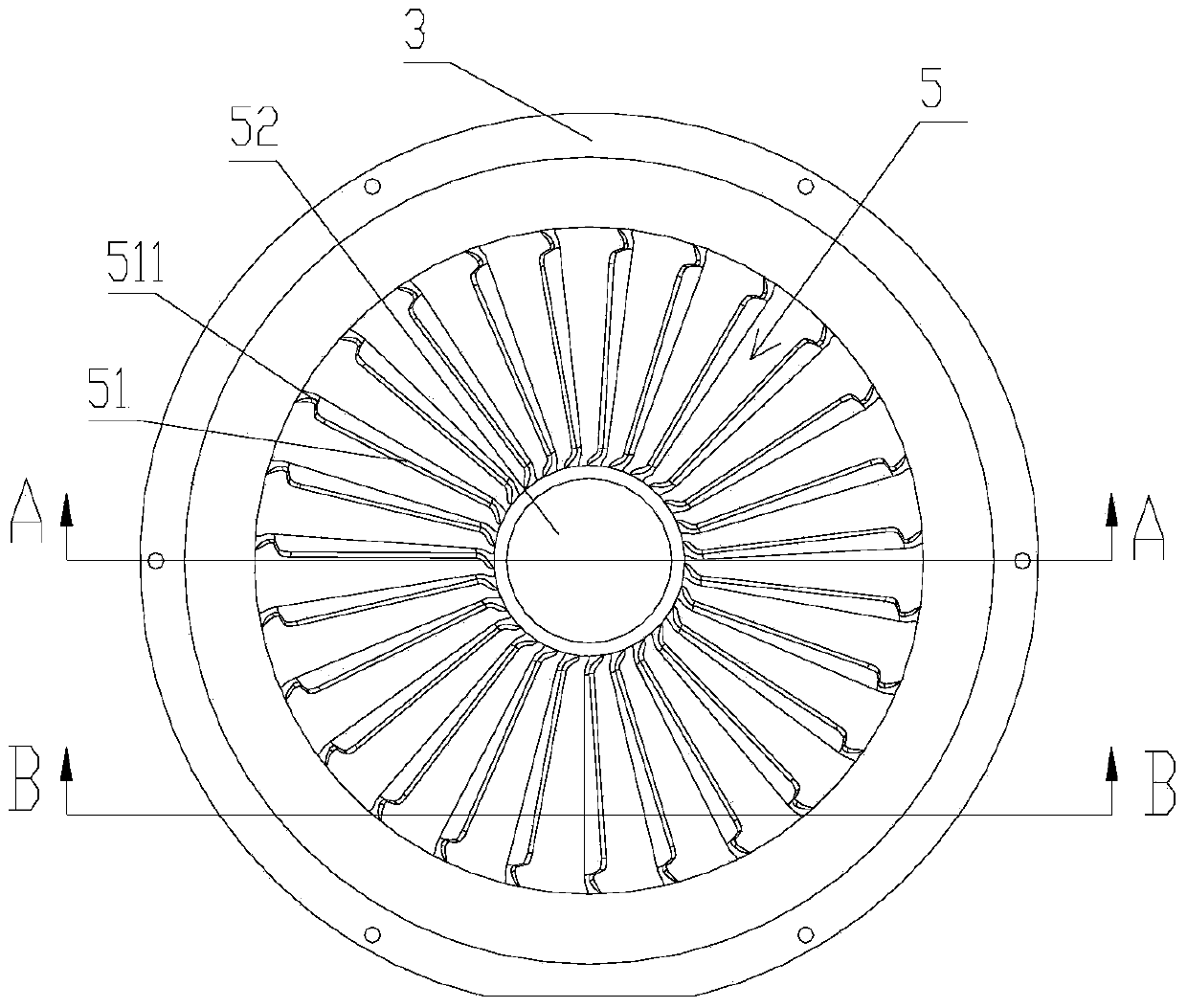

[0028] The multi-blade centrifugal fan of the present invention is as Figures 1 to 5 As shown, it includes a volute 1, an impeller 2, an air inlet ring 3, a motor 4 and a vane guide 5, wherein the impeller 2 is installed on the rotating shaft of the motor 4 and placed in the volute 1, and the motor 4 drives the impeller 2 to rotate. The volute 1 is provided with an air inlet channel 11 and an air outlet channel 12, the air inlet ring 3 is installed at the position of the air inlet channel 11 of the volute 1, the vane guide 5 is placed in the air inlet channel 11, and the air inlet ring 3 is set On the periphery of the vane guide 5, the vane guide 5 includes guide vanes 51 and a hub 52, the guide vanes 51 are evenly distributed on the periphery of the hub 52 in a ring shape, the guide vanes 51 are arranged obliquely, and the inclined direction of the guide vanes 51 rotates with the impeller 2 The direction is the same, one end of the guide vane 51 is connected to the hub 52 th...

Embodiment 2

[0033] The multiblade centrifugal blower of the present embodiment is similar to embodiment 1, and its difference is: as Figures 6 to 9 As shown, the outer surface of the above-mentioned wheel hub 52 is a plane, and the wheel hub 52 is provided with several ventilation holes 521 to reduce the end face of the wheel hub 52 blocking air, and the loss of air flow. The periphery of the vane guide 5 is also provided with a connecting ring 4 , the end of the vane 51 of the vane guide 5 away from the hub 52 is connected to the connecting ring 6 through a curved surface connecting body 511. In this embodiment, the vane guide 5 and the connecting ring 6 are integrally formed injection molded parts or sheet metal parts. When the connecting ring 4 is located outside the air inlet ring 3, the screw passes through the connecting ring 6, and the air inlet ring 3 is connected with the volute 1 to realize the fixed installation of the air inlet ring 3 and the vane guide 5. Of course, it can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com